Don't wanna be here? Send us removal request.

Text

The Importance of Reliable Indication Lamps in Electrical Safety

In the intricate world of electrical systems, safety is paramount. While primary protective devices like circuit breakers and fuses often take center stage, the seemingly humble indication lamp plays a vital, yet often underestimated, role in ensuring operational safety and preventing potential hazards. Reliable indication lamps act as the eyes of the electrical system, providing immediate visual feedback on the status of circuits, equipment, and power availability. In critical applications across industries in Sharjah, UAE, and beyond, the dependability of these small components can have significant implications for personnel safety, equipment integrity, and overall operational efficiency. This article delves into the crucial importance of reliable indication lamps in maintaining a safe electrical environment.

The Silent Guardians of Electrical Systems:

Indication lamps, also known as pilot lights or indicator lights, are visual signaling devices that communicate the operational state of an electrical circuit or piece of equipment. They provide instant, at-a-glance information, allowing operators and maintenance personnel to quickly assess whether a system is powered on or off, if a fault has occurred, or if a specific process is active. Their simplicity belies their significance in preventing human error and ensuring safe interaction with electrical installations.

Why Reliability Matters in Indication Lamps for Electrical Safety:

The effectiveness of indication lamps as safety tools hinges entirely on their reliability. A faulty or malfunctioning indicator can lead to misinterpretations, potentially resulting in dangerous actions. Consider the following scenarios where unreliable indication lamps can compromise electrical safety:

· False Off Indication: If a machine or circuit is actually live but the indication lamp shows it as “off,” maintenance personnel could unknowingly come into contact with energized parts, leading to severe electric shock.

· False On Indication: Conversely, if an indication lamp remains illuminated even after a circuit has been de-energized, it could mislead someone into believing the system is still live, causing unnecessary delays or incorrect procedures.

· Intermittent or Unclear Indication: Flickering or dimly lit indication lamps can lead to ambiguity and uncertainty about the true status of the system, potentially leading to rushed or incorrect decisions.

· Complete Failure: A completely failed indication lamp provides no information at all, leaving operators blind to the actual state of the electrical system.

Key Contributions of Reliable Indication Lamps to Electrical Safety:

When indication lamps function reliably, they significantly contribute to electrical safety in numerous ways:

· Visual Confirmation of System Status: They provide immediate and unambiguous visual confirmation of whether equipment is energized or de-energized, allowing personnel to safely interact with electrical systems during operation, maintenance, and troubleshooting.

· Prevention of Accidental Energization/De-energization: Clear “on” and “off” indicators help prevent the accidental activation or deactivation of equipment during critical processes or maintenance procedures, safeguarding both personnel and machinery.

· Rapid Fault Identification: In the event of a fault or abnormal condition, dedicated indication lamps (often with specific colors like red or amber) can provide immediate visual cues, allowing for quicker identification of the problem area and faster response times, minimizing potential damage and safety risks.

· Enhanced Lockout/Tagout (LOTO) Procedures: Reliable indication lamps can complement LOTO procedures by providing a visual confirmation that the energy source has indeed been isolated before maintenance or repair work begins.

· Improved Communication and Awareness: In complex electrical panels and control systems, clearly labeled and functioning indication lamps enhance communication between operators and maintenance teams, ensuring everyone has a clear understanding of the system’s state.

· User-Friendly Interface: Well-placed and reliable indication lamps contribute to a more intuitive and user-friendly interface for electrical equipment, reducing the likelihood of human error.

Choosing Reliable Indication Lamps for Enhanced Safety:

Selecting high-quality and reliable indication lamps is crucial for ensuring electrical safety. Consider the following factors:

· Quality of Components: Opt for lamps from reputable manufacturers known for using durable and long-lasting components.

· Clear and Consistent Illumination: Choose lamps that provide bright, consistent, and easily visible light output.

· Appropriate IP Rating: Select lamps with an ingress protection (IP) rating suitable for the environmental conditions of their application (e.g., dust and moisture resistance in industrial settings in Sharjah).

· Correct Voltage and Current Ratings: Ensure the lamps are compatible with the voltage and current of the circuits they are indicating.

· Vibration and Shock Resistance: In industrial environments with potential vibrations or impacts, choose robust lamps designed to withstand these conditions.

· Compliance with Safety Standards: Ensure the indication lamps meet relevant national and international safety standards.

· Clear Labeling: Ensure the purpose of each indication lamp is clearly and durably labeled on the electrical panel.

Conclusion:

In the realm of electrical safety, even the smallest components can play a critical role. Reliable indication lamps, often overlooked, serve as essential visual indicators that provide immediate feedback on the status of electrical systems. Their dependable operation is crucial for preventing accidents, facilitating safe maintenance procedures, and ensuring the overall integrity of electrical installations across various industries in UAE, Gcc and globally. By recognizing the importance of reliable indication lamps and making informed choices during selection and maintenance, we can significantly enhance electrical safety and create a safer working environment for everyone interacting with electrical systems.

#ElectricalSafety#SafetyFirst#ElectricalEngineering#IndustrialSafety#PowerSystems#ElectricalComponents#IndicationLamps#PilotLights#IndicatorLights#PanelLights#LEDIndicators#VisualSignaling#ReliableIndicators#SafetyCritical#PreventAccidents#OperationalSafety#MaintenanceSafety#DowntimePrevention#UAE#Sharjah#UAEElectricians#ElectricalContractorsUAE#IndustrialUAE#MEPContracting#ELVSystems#FacilityManagement#IndustrialAutomation#CommercialElectrical#LockoutTagout#LOTO

0 notes

Text

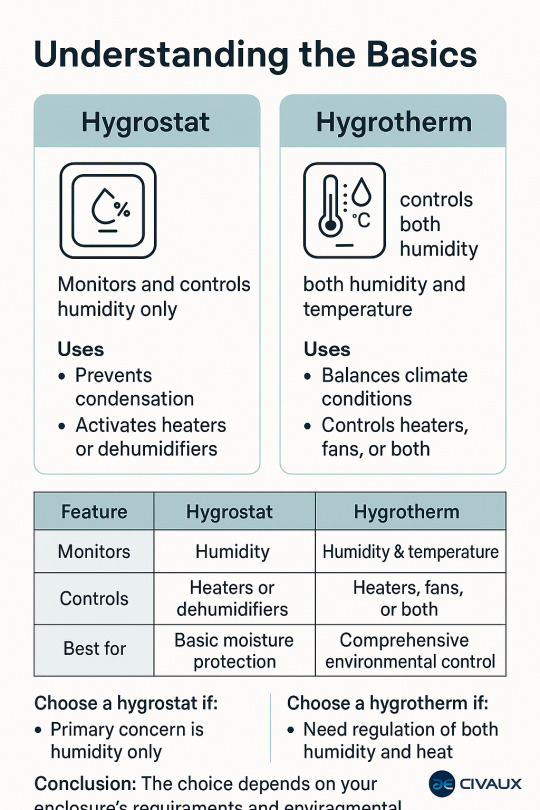

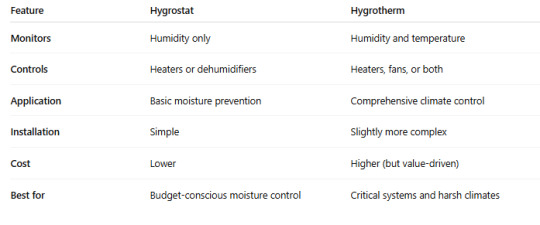

Hygrostat vs. Hygrotherm: Which Offers Better Moisture Management?

Moisture is one of the most damaging yet often overlooked threats to electrical enclosures and control panels. In high-humidity regions like the GCC, effective moisture management is critical to ensuring equipment longevity, operational safety, and uninterrupted performance. Two of the most widely used solutions in this space are hygrostats and hygrotherms. But which one is better for your application?

In this article, we compare hygrostats vs. hygrotherms in terms of functionality, performance, and suitability for different environments — helping you make the right choice for your electrical enclosure needs.

What is a Hygrostat?

A hygrostat is a humidity-regulating device that monitors the relative humidity inside an enclosure and activates connected equipment (like a heater or fan) when a preset humidity threshold is exceeded. It’s a single-function device focused purely on moisture control.

Key Functions:

· Monitors internal humidity

· Activates heaters or dehumidifiers to prevent condensation

· Simple and cost-effective solution for moisture problems

What is a Hygrotherm?

A hygrotherm is a dual-function device that combines the capabilities of a thermostat (for temperature) and a hygrostat (for humidity). It can monitor and control both parameters, ensuring balanced temperature and humidity regulation within the enclosure.

Key Functions:

· Simultaneous monitoring of temperature and humidity

· Activates heaters, fans, or filters based on combined conditions

Why Moisture Control Matters

In regions with high temperature fluctuations — like warehouses, factories, and outdoor panels in the Middle East — condensation can form inside enclosures. This can lead to:

· Corrosion of components

· Electrical short circuits

· Reduced equipment lifespan

· Safety risks for operators

Choosing the right controller ensures stable environmental conditions, reduces downtime, and cuts maintenance costs.

When to Use a Hygrostat

Choose a hygrostat if:

· Your enclosure operates in a relatively stable temperature range

· Your primary concern is humidity only

· You need a low-cost, targeted solution

· You’re upgrading older enclosures with basic needs

When to Use a Hygrotherm

Choose a hygrotherm if:

· Your environment experiences extreme heat and humidity (e.g., GCC summer months)

· You’re running sensitive electronics or automation panels

· You need proactive climate control for both heat and moisture

· You want to consolidate devices into a single, efficient unit

Conclusion: Which is Better?

Both hygrostats and hygrotherms are effective tools for enclosure climate control — but the better choice depends on your environmental conditions and system complexity.

· For basic, budget-friendly moisture protection: ✅ Go with a hygrostat.

· For comprehensive, long-term protection in critical systems: ✅ Invest in a hygrotherm.

Civaux Electric, we offer both hygrostats and hygrotherms with wide voltage range, compact design, and reliable performance — built to handle the GCC’s demanding climates.

#Hygrostat#Hygrotherm#Moisture management#Humidity control devices#Temperature and humidity regulator#Industrial climate control#electrical equipment#switchgears#electrical#panel#lowvoltage#dubai#united arab emirates

2 notes

·

View notes

Text

How Wide Voltage Range LED Lamps Improve Electrical Panel Efficiency

In today’s fast-paced industrial environments, electrical control panels must be efficient, safe, and easy to maintain. One often overlooked yet critical component that contributes to this is cabinet LED lighting — specifically, those with a wide voltage range. These small but powerful devices not only illuminate confined electrical enclosures but also enhance overall panel efficiency and reliability.

In this article, we’ll explore how wide voltage range LED lamps optimize electrical panel performance, minimize energy losses, and simplify installation in varied power environments.

What Are Wide Voltage Range LED Lamps?

A wide voltage range LED lamp can operate across a broader input voltage — commonly AC/DC 24V to 265V — unlike standard lamps limited to fixed inputs like 110V or 230V. This feature makes them adaptable to diverse applications without requiring voltage conversion or multiple product variants.

Key Benefits for Electrical Panel Applications

1. Universal Compatibility Across Power Sources

One of the primary advantages of wide voltage range LED lamps is their ability to function with both AC and DC voltages. Whether your panel uses:

· AC 110V/230V power lines

· DC 24V control systems

· Or fluctuating industrial voltages

… these lamps auto-regulate input, ensuring safe and stable lighting operation.

2. Reduced Downtime from Voltage Fluctuations

In regions like the GCC, where voltage instability or surges are common in industrial zones, wide voltage LED lamps maintain consistent brightness and functionality. This reduces the risk of burnout, component failure, or flickering — contributing to greater system uptime.

3. Simplified Inventory & Installation

For panel builders and system integrators, wide voltage range lamps:

· Eliminate the need for multiple SKUs for different voltages

· Simplify installation logistics

· Reduce wiring complexity

· Lower procurement and stocking costs

Whether you’re working on a control panel in Dubai or a process automation system in Jeddah, a single lamp model can serve multiple voltage standards.

Technical Features That Enhance Efficiency

LED Technology with Long Lifespan

LEDs consume significantly less energy than traditional incandescent or fluorescent bulbs, generating less heat and demanding less cooling within the enclosure.

Integrated Power Units

Many high-quality cabinet lamps (like those from Civaux) include integrated power supply units, meaning no external driver is needed. This:

· Saves space

· Minimizes energy loss

· Improves electrical efficiency

Flexible Mounting Options

Options like magnet or screw mounting allow for easy placement, even in compact or pre-wired enclosures, without reconfiguring the panel layout.

Where Wide Voltage LED Lamps Make a Difference

Industrial Automation Panels

Continuous operation and vibration-resistant design make them ideal for high-duty manufacturing systems.

Switchgear Cabinets in Harsh Climates

Wide voltage range lamps paired with IP20+ protection and anti-condensation design enhance reliability even in dusty or humid environments like those in the GCC.

Maintenance and Inspection Tasks

Consistent internal lighting improves operator safety, troubleshooting speed, and maintenance accuracy.

Efficiency Gains in the Bigger Picture

By integrating wide voltage LED lamps into your electrical panels, you achieve:

· Energy savings due to high luminous efficiency

· Improved operational safety through consistent visibility

· Reduced maintenance costs and fewer replacements

· Streamlined project planning with universal voltage support

This aligns with modern goals of sustainable infrastructure and lean electrical design.

Conclusion

Wide voltage range LED lamps are more than just lights — they’re an essential part of a modern, efficient, and reliable electrical panel system. By adapting to varied input voltages, enhancing energy efficiency, and reducing failure risks, they play a quiet yet critical role in industrial and commercial electrical environments.

At Civaux Electric, we provide high-performance cabinet LED lighting solutions engineered for versatility and durability — perfect for your switchgear and control panel needs across the GCC.

Need help selecting the right LED lighting for your enclosure? Get in touch with Civaux for expert consultation and product support.

1 note

·

View note

Text

Why Panel Heaters Are Essential in GCC’s Harsh Climate Conditions

When we think of the Gulf region — countries like the UAE, Saudi Arabia, Qatar, and Oman — the first thing that comes to mind is extreme heat. So, it might seem surprising that panel heaters are needed at all. But in reality, panel heaters play a critical role in protecting electrical enclosures and switchgear systems, even in such hot climates.

In this article, we’ll explore why panel heaters are essential in the GCC, how they work, and the benefits they offer for industrial and commercial electrical systems.

The Problem: Temperature Fluctuations & Humidity

While daytime temperatures can be very high in the GCC, nights can be much cooler — especially during winter months or in air-conditioned facilities. This creates temperature fluctuations inside electrical enclosures. When the air inside a panel cools, moisture can condense, especially if the enclosure is in a humid environment or near the coast.

Condensation = danger. Moisture buildup inside electrical enclosures can cause:

· Short circuits

· Corrosion of terminals

· Component failure

· Unplanned downtime

What Is a Panel Heater?

A panel heater is a small heating device installed inside electrical enclosures or switchgear panels. Its purpose is to maintain a stable internal temperature and prevent moisture buildup by eliminating condensation.

Many modern panel heaters use PTC (Positive Temperature Coefficient) heating elements, which self-regulate and provide safe, even heating. They are often mounted on DIN rails and come in various power ratings depending on the size of the enclosure and climate conditions.

Why Panel Heaters Are Important in the GCC

Even in hot climates like the GCC, panel heaters are needed for several key reasons:

1. Night time Cooling

Desert regions cool quickly after sunset. If electrical panels are placed outdoors or in poorly insulated buildings, the temperature drop can cause internal condensation. Panel heaters prevent this drop from reaching dangerous levels.

2. Humidity & Coastal Conditions

Many Gulf countries have high humidity, especially near the sea. Moisture in the air can enter panels — even sealed ones. A heater helps keep the internal temperature above dew point, reducing the chance of water droplets forming.

3. Air-Conditioned Environments

Indoor industrial spaces are often cooled to protect people and equipment. Ironically, this cool air can lead to condensation inside panels. Panel heaters work in sync with thermostats to ensure a dry and safe internal environment.

4. Condensation After Rain or Washing

Enclosures exposed to the elements or cleaned with water may trap moisture inside. Heaters dry out internal air and protect circuits after these events.

Key Features of a Good Panel Heater

When choosing a panel heater, especially for the GCC, consider:

· PTC Technology: Safe and self-regulating

· Aluminum Profile Body: For even heat distribution

· DIN Rail Mounting: For easy installation

· IP Rating: At least IP20 or higher for electrical safety

· Thermostat Compatibility: For automatic on/off control

Where Are Panel Heaters Used?

Panel heaters are used in:

· Electrical switchgear panels

· Control cabinets

· Automation enclosures

· Outdoor telecom cabinets

· Renewable energy systems (solar, wind)

· Industrial machinery panels

Benefits of Using Panel Heaters in the GCC

🌫 Eliminates condensation

⚡ Prevents corrosion and short circuits

🧰 Improves lifespan of electrical components

🕒 Reduces maintenance and repair costs

🔒 Enhances overall safety and reliability

Conclusion: Don’t Ignore Panel Heaters in Hot Climates

Even in the hot and dry environments of the GCC, panel heaters are a small investment with a big return. They protect your electrical systems from hidden threats like moisture, condensation, and corrosion, especially during temperature swings or in humid, indoor, or coastal environments.

At Civaux, we offer high-quality panel heaters designed for industrial performance, quick installation, and safe operation across the Gulf region. Our solutions ensure your equipment stays dry, efficient, and reliable — no matter the climate.

1 note

·

View note

Text

Panel Fans vs. Air Conditioners: Which Cooling System Is Right for Your Enclosure?

When it comes to protecting sensitive electrical equipment inside enclosures, temperature control is not just a convenience — it’s a necessity. Without proper cooling, heat buildup can shorten equipment lifespan, reduce operational efficiency, and even pose safety risks. Two of the most commonly used cooling solutions for enclosures are panel fans and air conditioners. But which one is right for your application?

In this article, we’ll break down the key differences, pros and cons, and the factors to consider when deciding between panel fans and enclosure air conditioners.

Why Do Electrical Enclosures Need Cooling?

Electrical components such as contactors, PLCs, drives, and transformers generate heat during operation. If this heat isn’t removed, internal temperatures can exceed safe operating limits, leading to:

· Component failure

· Downtime and costly repairs

· Decreased efficiency

· Potential fire hazards

Effective cooling is critical for maintaining stable operating conditions — especially in regions like the GCC, where ambient temperatures are high.

Panel Fans: Efficient Ventilation for Mild Heat Loads

What Are Panel Fans?

Panel fans are compact, electrically powered fans mounted on the enclosure wall. They draw cooler ambient air into the cabinet while exhausting hot air out — creating airflow that removes excess heat.

Advantages of Panel Fans

· Cost-effective solution for basic cooling needs

· Easy to install and maintain

· Low energy consumption

· Ideal for environments with moderate ambient temperatures

· Often paired with filters to block dust and debris

Limitations of Panel Fans

· Cannot cool below ambient temperature

· Not effective in hot or humid climates (like much of the GCC)

· Can allow contaminants if not sealed with proper filters

Best Use Cases:

· Light-duty applications

· Indoor enclosures in temperature-controlled facilities

· Panels with minimal heat load

Air Conditioners: Active Cooling for Demanding Applications

What Are Enclosure Air Conditioners?

These are closed-loop cooling systems that remove internal heat without exchanging air with the external environment. They use refrigerant-based or thermoelectric systems to reduce internal temperatures below ambient levels.

Advantages of Air Conditioners

· Effective in high ambient temperature conditions

· Ideal for outdoor enclosures or heat-sensitive equipment

· Prevents moisture, dust, and contaminants from entering the cabinet

· Maintains a stable internal temperature regardless of external environment

Limitations of Air Conditioners

· Higher upfront cost and energy consumption

· Requires regular maintenance (filters, condensate removal)

· Needs space and power capacity for installation

Best Use Cases:

· Enclosures located outdoors or in hot industrial settings

· High-power electrical systems generating significant heat

· Situations requiring precise temperature control

Factors to Consider When Choosing Between the Two

1. Ambient Temperature

If your enclosure is in a hot climate (like UAE, Saudi Arabia, Qatar), a panel fan won’t lower the temperature below ambient, making air conditioners the better choice.

2. Heat Load

High-density equipment or continuous operation = more internal heat. Use a thermal calculation to assess the cooling demand before selecting the system.

3. Location & Air Quality

Dusty or humid environments call for closed-loop cooling systems (like ACs). In clean, air-conditioned indoor areas, panel fans with filters may be enough.

4. Budget and Energy Efficiency

For cost-conscious setups with low to moderate cooling needs, panel fans offer great value. But if reliability and performance are critical, investing in an air conditioner pays off long-term.

Conclusion: Which Cooling System Should You Choose?

The decision between panel fans and air conditioners depends on your application’s specific demands.

· Choose panel fans for simple, cost-effective cooling in clean, mild environments.

· Opt for air conditioners when precision, protection, and performance in hot or dirty environments are essential.

At Civaux, we help businesses across the GCC select the most efficient and reliable cooling solutions for their electrical enclosures. Whether you’re designing a new panel or upgrading your existing system, we can recommend the right products to meet your thermal management goals.

1 note

·

View note

Text

Selecting the Right Enclosure Cooling System for Your Control Panels

In the world of industrial automation and electrical infrastructure, control panels serve as the nerve center of operations. Yet, one often overlooked aspect is how thermal management can make or break the performance and lifespan of these panels. Selecting the right enclosure cooling system is critical — not just for performance, but also for safety, efficiency, and equipment longevity.

Why Is Enclosure Cooling So Important?

Electrical components like contactors, PLCs, VFDs, and relays generate heat during operation. When this heat builds up inside an enclosure, it can lead to:

· Overheating and component failure

· Increased downtime and repair costs

· Reduced equipment life

· Safety hazards due to overheating

Proper cooling ensures your control panel operates within the recommended temperature range, protecting sensitive electronics and avoiding costly disruptions.

Factors to Consider When Choosing a Cooling System

1. Ambient Temperature

Start by evaluating the environment. Is the control panel located indoors or outdoors? In a high-temperature region like the GCC, ambient heat plays a major role in cooling system selection. Outdoor panels often require NEMA-rated enclosures and active cooling systems like air conditioners or heat exchangers.

2. Heat Load Calculation

Calculate the total heat load inside the enclosure. This includes:

· Internal heat generated by components

· External ambient heat

· Solar load (if the panel is exposed to sunlight)

Tools like thermal calculators or consulting with a cooling specialist can help with accurate estimation.

3. Enclosure Size and Material

Larger enclosures and metal types (like steel or aluminum) dissipate heat differently. Size and insulation matter when choosing between passive and active cooling methods.

4. Ventilation Options

Sometimes, natural ventilation or forced air cooling with panel fans is sufficient. Fans with filters are ideal for dusty environments, preventing debris from entering the enclosure.

5. Power Availability and Efficiency

Check the power rating of the cooling system. Energy-efficient cooling solutions like EC (electronically commutated) fans can save energy and reduce operational costs over time.

Types of Enclosure Cooling Systems

Cooling in GCC Climate Conditions

In regions like the Gulf Cooperation Council (GCC) — where ambient temperatures can soar past 50°C — choosing the right cooling method is especially critical. Filtered fan systems with thermal controls or industrial-grade AC units are highly recommended for outdoor and high-load panels.

Also, using UV-resistant enclosures, sunshades, or thermal barriers can help reduce heat load from solar radiation.

Final Tips for Optimal Cooling

· Install temperature sensors inside the panel for real-time monitoring.

· Keep filters clean and replace them periodically.

· Consider smart cooling systems that adapt to environmental conditions.

· Seal the enclosure properly to avoid unwanted air infiltration.

Conclusion

Investing in the right enclosure cooling system is not just about temperature control — it’s about ensuring reliability, safety, and performance for your electrical control panels. Whether you’re operating in a controlled indoor setting or facing the harsh heat of the GCC, there’s a solution that fits your needs.

At Civaux, we specialize in providing high-performance panel fans, filters, and cooling solutions tailored to your application. Reach out to us today for expert advice on choosing the best system for your setup.

#electrical equipment#switchgears#electrical#panel#lowvoltage#coolingsolutions#heating and cooling services#coolingtechnology#coolingmattress#coolingexperts#uae

1 note

·

View note

Text

The 7 Most Important Low-Voltage Switchgear Standards That Every Engineer Must Follow

It becomes highly important to have the right understanding and usage of the standards while dealing with low-voltage switchgear.

In this article, we point out the seven most significant standards that every engineer must follow to when working with low-voltage switchgear.

The main content in this article covers the seven most essential standards that engineers must consider when dealing with low-voltage switchgear.

1. IEC 61439 — Low-Voltage Switchgear Assemblies

This is the primary global standard for low-voltage switchgear and control gear assemblies. It addresses design, construction, performance, and testing.

It replaced the earlier IEC 60439 and contained rules on temperature rise, short-circuit performance, and degrees of protection (IP ratings).

IEC 61439 has to be applied by engineers to verify switchgear panels comply with safety and performance criteria.

2. IEC 60947 — Individual Switchgear Components

IEC 60947 provides standards related to low-voltage switchgear appliances like circuit breakers, contactors, and isolators.

Such appliances have to work properly under certain atmospheric conditions and also under electric stress.

This is of utmost importance from component selection and testing point of view.

3. National Electrical Code (USA)-NFPA 70

NFPA 70 an American standard applies to primary electrical installation in the US and for international projects designed using American codes.

This standard covers safe electrical design encompassing wiring methods, groundings, and overcurrent protection.

NEC compliance guarantees that the system will be safe to use and will pass legal building codes.

4. IEC 60529 — IP Ratings (Ingress Protection)

It explains the amount of protection offered by electrical enclosures against dust and water.

For low-voltage switchgear, the relevant IP rating means that the enclosure is suited to the environment, which is either a dusty outdoors or an internal control room.

5. IEC 60068 — Environmental Testing

Low-voltage switchgear is used generally under severe industrial conditions.

IEC 60068 describes the testing of equipment for resistance to vibrations, humidity, temperature, and corrosion.

This standard ensures compatibility that guarantees stability through a prolonged period in harsh conditions.

6. IEEE C37 Standards (North America)

These standards concentrate on power switchgear systems, which are applied primarily in industrial and utility installations.

These cover switchgear ratings, testing, and maintenance. More prevalent in medium-voltage systems, many of the guidelines are also applicable to high-end low-voltage switchgear.

7. ATEX / IECEx — Hazardous Area Certifications

For low-voltage switchgear used in the oil, gas, and chemical industries, ATEX (EU) and IECEx (global) standards are most important.

These ensure that the equipment is explosion-proof for explosive atmosphere potential. Compliance is mandatory for projects in these industries.

Final Thoughts

Understanding these seven standards enables project engineers to choose the appropriate low-voltage switchgear, achieve compliance, and minimize risk.

These standards are not merely forms in triplicate — these standards help build safer, more efficient systems.

If you’re uncertain what standards are relevant to your next project, talk to your designer partner or supplier.

The fitting of certified low-voltage switchgear and accessories will allow you to comply with all these standards without compromise.

Whether you’re sourcing IP-rated fans or reliable cabinet heaters, Civaux’s products are built to support compliant, high-performance LV systems.

Explore our range designed with industry standards in mind.

Connect us at: [email protected]

1 note

·

View note

Text

How Low Voltage Systems Can Improve Safety and Minimize Downtime

Today’s highly complex industrial and commercial environments have the aims of protecting personnel and optimizing operations. One of the most effective ways to improve security, reduce downtime, and maximize output is by Utilizing low-voltage systems. These systems do more than just prevent electrical hazards but also ensure seamless operations. Low-voltage solutions contribute significantly to modern plant environments through the attainment of a safer workplace, reduced disruption in operations, and increased efficiency in resource utilization. From avoiding serious incidents to ensuring operational uptime, architectures are critical to their reliability and productivity in the present day. While safety concerns link it to a premium priority, sustained performance comes close to it. Consequently, a blended development in such technologies leads companies not just to survive the increasingly stringent global competition but also to thrive within.

Comprehending Low Voltage Systems

When referring to “low-voltage systems,” this is generally defined to operate at a maximum of 1,000 V for alternating current (AC) and 1,500 V for direct current (DC). It can be handled much more safely than high-voltage systems and thus has wide applications in industries such as industrial facilities (machinery control and automation), commercial buildings (lighting, security systems, HVAC), healthcare facilities (medical equipment and emergency systems), and data centers (power backup and communication networks). Low-voltage solutions improve employment efficiency, reduce risks, and allow a safe environment at workplaces.

How Low Voltage Systems Improve Safety

Reducing Electrical Dangers

The low-voltage system has a built-in protection mechanism against electric shock as well as short circuits. This low voltage ensures that the equipment is less likely to cause serious harm through a possible electric fault. In maintaining safe working environments, low-voltage systems are essential for the safety of personnel and operational efficiency.

Prevention of Electrical Fires:

High voltage electricity systems can infer to so much heating that electrical fires might occur. Low voltage systems generate heat on the low side with considerably less strain on electrical components, hence decreasing the risk of potential fires in both the workplace and home. A minor problem in high voltage systems can result in Serious breakdown. Low voltage systems minimize the possibility of electrical fires, providing a safer environment and comfort for business and homeowners alike.

Improved Equipment Lifespan

Low voltage systems are protective because excessive voltage can damage delicate electrical parts. Proper voltage regulation will enable the company personnel to use the equipment for more extended periods before replacement becomes necessary, thus preventing losses.

Risk-Free Repairs

Specialists are required for the maintenance of high-voltage systems since the associated risks are significantly higher. Most low-voltage systems can be installed by local personnel trained in simple electrical safety practices so that maintenance is more accessible and less expensive.

How Low Voltage Systems Minimize Downtime

Faster Fault Detection & Repairs

The low voltage systems come with advanced monitoring and diagnostic tools by which any faults can be located early by the business. Hence, the repair is done very quickly with minimal disruption to the operations.

Reliable Power Supply

A stable low voltage distribution system ensures a consistent power supply reducing unexpected breakdowns in the environments.

✅ Manufacturing equipment ✅ Security and surveillance systems ✅ IT infrastructure and data centers

Smart Automation for Efficiency

Most of the new low voltage systems are equipped to work together with IoT-based automation. Certain features such as remote monitoring and predictive maintenance provide businesses with a means to avoid severe failure before it actually happens.

Reduced Equipment Downtime

The reduced number of breakdowns of the equipment allows a company to avoid losses which it incurs from prolonged downtime for maintenance and production stoppage, because it places less stress on electrical components.

Conclusion

A low-voltage system can bring changes in safety and an increase in the operational availability time of all industries. Safety from electric shock, reduced fire hazards, and improved operational efficiency are just some of the features offered by low-voltage systems-an excellent investment in any business.

0 notes

Text

The Role of Low Voltage Switchgear in Data Center Power Management

Data centers form the foundation of our digital world. They make sure businesses, cloud services, and vital IT infrastructure keep running without breaks. To stay up and running and avoid expensive shutdowns, these centers need a steady and productive power management system. Low voltage switchgear plays a key part in making sure power gets where it needs to go. This article will look at why low voltage switchgear matters in data center power management, what good it does, and how it helps make everything work better and more.

What is Low Voltage Switchgear?

Low voltage switchgear is a central system that controls electricity. It manages, protects, and separates electrical equipment that works with voltages up to 1,000V. This system has circuit breakers, busbars, fuses, disconnect switches, and protection relays. All these parts work together to control and handle power distribution in a smart way.

The Role of Low Voltage Switchgear in Data Centers

Data centers need a constant power supply to keep running. If the power goes out, it can cause data to disappear, services to stop, and big money losses. Low voltage switchgear has a key part to play:

Ensuring Reliable Power Distribution:

Prevents power fluctuations and overloads that could damage critical IT equipment.

Controls power flow between systems ensuring smooth operations.

2. Improving Power System Protection:

Isolates faulty circuits to stop widespread blackouts.

Employs protective relays and circuit breakers to spot and address electrical problems.

3. Reducing Downtime and Boosting Efficiency:

Smart low voltage switchgear includes remote monitoring and automation cutting down on manual work.

Helps optimize energy consumption, leading to lower operational costs.

4. Growth and Future-Readiness:

Modular low voltage switchgear allows data centers to grow their power capacity when needed.

Supports the transition to renewable energy sources and sustainable power solutions.

Benefits of Low Voltage Switchgear in Data Centers

Better Safety — Cuts down risks linked to electrical issues short circuits, and arc flashes.

Energy Savings — Cuts power waste and makes overall energy handling better.

Remote Monitoring & Control — Allows users to track power use and system health as it happens.

Longer Equipment Lifespan — Shields key IT gear from sudden voltage spikes and breakdowns.

Compliance with Industry Standards — Follows worldwide safety and efficiency rules making sure data centers stay reliable.

Choosing the Right Low Voltage Switchgear for Data Centers

When choosing low voltage switchgear for a data center, think about:

Power Capacity & Growth — Make sure it meets today’s and tomorrow’s electricity needs.

Smart Tech & Automation — Go for switchgear with IOT-connected tracking.

Dependability & Backup — Pick top-notch parts to stop power outages.

Following Rules — Stick to IEC, ANSI, and UL guidelines.

Conclusion

Low voltage switchgear plays a key role in managing power for data centers. It keeps things safe, efficient, and running. New switchgear tech with remote checks and energy-saving features helps data centers stay on longer, spend less, and run in an eco-friendly way. Putting money into the right low voltage switchgear matters a lot for any data center to do well and grow over time.

By putting cutting-edge low voltage switchgear solutions into action, companies can prepare their data centers for what’s ahead lower risks, and keep power management running in a digital scene that’s always changing.

0 notes

Text

The Future of Switchgear Panels: Innovations and Trends

Switchgear panels are the heart of any electrical distribution system because they ensure reliability, safety, and efficiency. With the continued growth of industries and infrastructure projects, there is an ever-growing demand for more advanced and intelligent switchgear solutions. Technology has grown rapidly, and without a doubt, switchgear panels of the future will be more efficient, smarter, and greener. This blog will outline the most important innovations and trends in future switchgear panels.

Smart and Digital Switchgear Panels:

The biggest change in switchgear technology is the innovation towards digital and smart switchgear. These all possess sensors, systems for real-time monitoring, and automation, thus enabling maximum efficiency and safety.

Real-time Monitoring & Diagnostics- Smart switchgear panels provide real feedback related to voltage levels, load conditions, and fault detections, giving the maintenance team prior warnings.

IoT-Enabled Switchgear- This integration of Internet of Things (IoT) enables the monitoring of switchgear systems to be managed remotely, thus reducing the hours of manual inspection.

Predictive Maintenance — AI-driven prediction analytics predicts possible failures before they happen, reducing downtime and maintenance costs.

Eco-Friendly and SF6-Free Switchgear:

The rising environmental concerns have been a major impetus for innovation in green switchgear technology. SF6, or sulfur hexafluoride, which has long been used in switchgear as an insulating gas, is a potent greenhouse gas, the industry is now looking toward alternative insulating gases. Air-Insulated and Vacuum Switchgear- Manufacturers are developing air-insulated and vacuum-insulated switchgear to eliminate the use of SF6 gas. Sustainable Materials- There is an increased usage of recyclable and biodegradable materials to lessen the carbon footprint in the production of switchgear.

0 notes

Text

Switchgear Secrets: How It Ensures Power Safety & Efficiency

Switchgear is a crucial but often overlooked aspect of modern electrical systems. Covering circuit protection, power flow control, and overall system reliability. Residential, commercial, or industrial power; switchgear is the unsung hero behind the scenes of every device.

In this article, we‘ll unveil switchgear secrets and take a closer look at how it helps deliver safe and efficient power. So why is switchgear so vital for electrical systems from fault protection to power distribution?

What is Switchgear?

Switchgear is an aggregate of electrical devices, such as circuit breakers, fuses, relays, switches, and disconnectors, used to manage electrical power systems. It acts as a guarding as well as controlling device for electrical circuits, providing safe empirical and lowering the risks.

How Does Switchgear Help in Safe Power?

The first need for any electrical system is safety. It’s impossible to overstate the importance of switchgear in protecting both equipment and people from electrical hazards. Here’s how it ensures safety:

Fault Detection & Isolation

Short circuits, overloads, & misconfigurations damaging to appliances causing shock or fires. The switchgear’s main role is to detect such faults and cut off the impinged segment to avoid any extended damage.

For example, when too large of a current flows through, a circuit breaker will trip and break the supply to that section. This speeds up the isolation process, ensuring that the rest of the system is safe and operational.

Overload Protection

Indexes the electrical load and provides overload protection. If the current exceeds the limit, a protective device such as a fuse or circuit breaker will remove the load, preventing overheating or damage to the system.

Automated Control for Smart Grids:

Switchgear encloses key components and is critical for automation in the smart grid era. With the capabilities of fault detection, individual component diagnosis, automatic reconfiguration, and power restoration, smart switchgear systems reduce downtime and elevate system efficiency.

Smart switchgear can reap real-time data monitoring and prediction with the use of IoT technology, thus guaranteeing that energy continues to flow on as efficiently and cost-effectively as possible.

Low-Voltage Switchgear (LV)

It is common to use LV switchgear at the premises of residential and commercial buildings to safeguard the circuits being affected through faults. It covers fuses, circuit breakers, and switches. The same can be said for LV (low voltage) switchgear — even though it deals with lower currents, it still helps to protect equipment and reduce the risk of power outage.

Medium-Voltage Switchgear (MV)

MV Switchgear, which is commonly used in industrial applications and power distribution, typically ranges from 1kV to 36kV. These are better in terms of the control of energy flow through a power system, voltage regulation, and the ability to isolate faulted sections of the system. Vacuum circuit breakers and load break switches are also used in MV switchgear.

High-Voltage Switchgear (HV)

Switchgear at extra-high voltage (EHV) (≥ 230 kV): Used in the power transmission systems and large substations at EHV (≥ 230 kV)Up to 36kV, MV switchgear is used. Common types of HV switchgear include: Gas Insulated Switchgear (GIS) and Air Insulated Switchgear (AIS). Their extremely high fault protection, reliability, and efficiency are essential for the stability of national power grids.

Why Switchgear is Essential in Modern Power Systems?

Today, switchgear is more than just a protective device — it is the cornerstone of a modern electrical infrastructure. Why switchgear is important for safety and efficiency of power?

Dependable Safety — Protects electrical systems from fault-caused damage, minimizes repair expenses.

Improved Efficiency — It corrects the energy flow and power usage, enabling reduction of losses.

Cost Savings — Stability and reliability translates to cost savings as an effective IT helps prevent unnecessary downtime and repairs.

Environmental Protection — Lowers the chance of fire and other environmental threats linked to electrical flaws.

0 notes

Text

Panel Fan and Filters

Electrical panel rooms can be found within almost every building and organization and are designed to contain the essential electrical components needed to power a facility, and maintaining the proper ventilation for these rooms ensures proper functioning and keeps the equipment from overheating.

Need for Panel Fans in Electrical Panel Rooms

Because of constant operation, electrical panels emit a lot of heat, especially in manufacturing and commercial settings. When there is excess heat in any electrical system, it can cause equipment malfunctions or overheating, adversely affecting efficiency, and even causing safety hazards or short circuiting or electrical fire hazards.

Advantages of Panel Fans:

Effective preventing electrical components from overheating, ensuring the stability of circuits.

Prevents heated hotspots and allows for continuous airflow around the interior of the panel enclosure.

Reduce wear and tear of sensitive electronic components due to overheat conditions.

Enables localized cooling, thereby reducing dependence on costly air conditioning systems.

When combined with filters, the panel fan stops dust from settling down and damaging the circuits.

How Do Panel Fans Work?

Panel fans work by drawing cooler air from outside and exhausting warmer air from inside your electrical panel. The venting process exchanges air and keeps the internal temperatures within acceptable operating limits.

Active Cooling: These fans push warm air out and brings in cooler air from the environment.

Ventilation Shell Control: Integrates with these exhausts vents or air filters to ensure the appropriate amount of airflow.

Weather Control: It can be connected with thermostats for fan control based on temperature.

0 notes

Text

What is Low Voltage Switchgear?

Lower voltage (LV) switch equipment refers to the electrical equipment used to control, protect and separate the low voltage circuit (usually up to 1000V AC or 1,500V DC). These products ensure safe power distribution, safety against errors and effective energy management in commercial, industrial and residential applications.

0 notes

Text

Low Voltage Switchgears Supplier in UAE and GCC.

Civaux is a leading supplier of low Voltage switchgears in UAE and GCC. We offer cost-effective and efficient cooling and filtration solutions for all industrial and commercial applications. Our products incorporate a range of features to maximize both performance and energy efficiency while also improving reliability. This ensures a much longer service life. We are committed to providing ventilation and filtration solutions that are designed to your specific needs, where necessary.

7 notes

·

View notes