#lowvoltage

Explore tagged Tumblr posts

Text

Low Voltage Switchgears Supplier in UAE and GCC.

Civaux is a leading supplier of low Voltage switchgears in UAE and GCC. We offer cost-effective and efficient cooling and filtration solutions for all industrial and commercial applications. Our products incorporate a range of features to maximize both performance and energy efficiency while also improving reliability. This ensures a much longer service life. We are committed to providing ventilation and filtration solutions that are designed to your specific needs, where necessary.

7 notes

·

View notes

Text

A quick guide every electrical engineer should read.📘

5 notes

·

View notes

Photo

Dacă nesiguranța prețului energiei îngrijorează afacerea ta, soluția de stocare de la PanouriCluj SRL poate oferi independență. Distribuitorii de energie nu vor mai avea ultimul cuvânt! 💡🌍 Containere de stocare de la 200kW la 2MW, celule LIFEPO4 cu garanție de 10 ani și soluții atât pentru low voltage, cât și high voltage. ⚡️🔋 Site-ul nostru: www.panouricluj.ro #IndependentaEnergetica #PanouriCluj #StocareEnergie #SoluțiiEnergetice #ContainereStocare #LIFEPO4 #10AniGaranție #LowVoltage #HighVoltage #EnergieSustenabila #SigurantaEnergetica #AfaceriVerzi #InovatieEnergetica #EnergieCurata #panouricluj ⚡️💡🌍

#IndependentaEnergetica#PanouriCluj#StocareEnergie#SoluțiiEnergetice#ContainereStocare#LIFEPO4#10AniGaranție#LowVoltage#HighVoltage#EnergieSustenabila#SigurantaEnergetica#AfaceriVerzi#InovatieEnergetica#EnergieCurata#panouricluj

1 note

·

View note

Text

#cablelabels #wiremarkers #engineering #wiresolutions #cableinstallation #ElectricalEngineers #Electricians #structuredcabling #datacabling #madeinamerica #InfoComm #audio #video #cablemanagementmatters

www.cablelabelsusa.com

0 notes

Text

Low Voltage vs. High Voltage Conduit: Do You Know the Critical Difference?

Using the wrong conduit isn't a minor mix-up - it's a recipe for code violations, equipment failure, and serious safety hazards. The standards for low and high voltage systems are worlds apart.

Are you 100% confident you're making the right choice on every project?

Our new guide breaks down everything you MUST know:

⚡️ Definitions: What really separates low from high voltage applications.

🏗️ Materials: Choosing the right conduit for the job (and the code).

📜 Code Requirements: Key differences you can't afford to ignore.

❌ Costly Mistakes: Common pitfalls that lead to project failure.

👉 Get the essential guide to choosing the right conduit, every time. Click here to read more!

#ElectricalSafety#Conduit#HighVoltage#LowVoltage#ElectricalContractor#ElectricalEngineering#Construction#NEC#CodeCompliant#Ledes

0 notes

Text

Core Highlight: Factory-Preinstalled Fuses for Plug-and-Play Safety This series of 4-pole isolator switches (32–125A AC-23A 690VAC) is engineered for harsh industrial applications. Pre-equipped with fuses for immediate installation—no additional procurement needed. Key advantages:

✅ Integrated Fuses: Factory-preinstalled fuses ensure complete overload/short-circuit protection. ✅ Enhanced Safety: ・IP65-rated metal enclosure (RAL7035) ・Door-interlocked operating handle ・Padlocking in OFF position ・Finger-safe terminals (IP20) ✅ Flexible Expansion: Top/bottom removable cable glands for multi-directional wiring. ✅ Full Compliance: Meets IEC/EN 60947-3, with UKCA & CE dual certification. ✅ Safety Assurance: Includes door grounding wire for operational security.

#FusedDisconnect#IndustrialSwitchgear#HVIsolator#ElectricalSafety#PanelBuilders#IEC60947#UKCA_CE#MotorProtection#ShortCircuitProtection#IndustrialAutomation#LowVoltage#PowerDistribution

0 notes

Text

Improve Switchgear Safety with the Right Panel Components

In the heart of any robust electrical distribution system lies the switchgear. It’s the central control and protection hub, responsible for safely directing and interrupting electrical currents. However, the overall safety and reliability of a switchgear assembly are not solely dependent on its primary switching devices. The often-overlooked panel components and accessories play a crucial role in enhancing operational safety, preventing accidents, and ensuring the longevity of the entire system. This article delves into the critical switchgear panel components that directly contribute to improved safety, emphasizing their functions and the importance of selecting the right ones.

Understanding the Importance of Switchgear Panel Components for Safety:

While the main circuit breakers and disconnectors handle the primary switching functions, a network of supporting switchgear accessories works in concert to create a safer operating environment. These components provide essential functionalities like indication, control, interlocking, and protection against various hazards. Neglecting the quality or proper selection of these seemingly minor parts can compromise the entire switchgear system’s safety integrity, leading to potential equipment damage, operational disruptions, and, most importantly, personnel injury.

Key Switchgear Panel Components and Their Role in Safety:

Let’s explore some essential switchgear panel components and how they contribute to a safer electrical installation:

· Indicating Lamps and Pilot Devices: These visual indicators provide immediate feedback on the status of the switchgear (e.g., open/closed, tripped, power on/off). Clear and reliable indication helps operators understand the system’s state at a glance, preventing accidental switching or access to live parts. Using high-quality, clearly labeled indicating lamps is crucial for safe operation and troubleshooting.

· Control Switches and Pushbuttons: These devices allow for the safe and controlled operation of the switchgear. Properly designed and installed control switches with clear labeling and ergonomic considerations minimize the risk of accidental actuation. Emergency stop pushbuttons, often brightly colored and prominently placed, are vital safety features that allow for immediate power interruption in critical situations.

· Interlocking Systems (Mechanical and Electrical): Interlocks are crucial safety mechanisms that prevent hazardous operations by ensuring that certain actions can only occur under specific conditions. For example, a mechanical interlock might prevent access to a live compartment when the corresponding circuit breaker is closed. Electrical interlocks, using auxiliary contacts and control circuits, can prevent the simultaneous operation of incompatible devices, significantly reducing the risk of short circuits or equipment damage. Implementing robust and well-designed interlocking schemes is paramount for switchgear safety.

· Protective Relays and Current Transformers (CTs) / Voltage Transformers (VTs): While often considered primary protection devices, the correct selection and integration of protective relays, along with their associated CTs and VTs housed within the switchgear panel, are fundamental to safety. These components continuously monitor the electrical system and initiate tripping of circuit breakers in case of faults like overcurrents, short circuits, or earth faults. Properly calibrated and tested protection systems are essential for preventing equipment damage and ensuring personnel safety during fault conditions.

· Terminal Blocks and Wiring Accessories: Secure and well-organized wiring within the switchgear panel is crucial for preventing loose connections, short circuits, and potential fire hazards. High-quality terminal blocks, cable markers, and proper wiring practices contribute significantly to the overall safety and reliability of the switchgear. Clear labeling and organized wiring also simplify maintenance and troubleshooting, reducing the risk of errors.

· Earthing (Grounding) Components: A properly designed and implemented earthing system is non-negotiable for switchgear safety. Earthing components, including earth bars, grounding conductors, and earth terminals within the switchgear panel, provide a low-impedance path for fault currents to flow to the ground, ensuring the rapid operation of protective devices and minimizing the risk of electric shock. Regular inspection and maintenance of the earthing system are vital.

Selecting the Right Panel Components for Enhanced Safety:

Choosing the appropriate switchgear panel components is not merely about meeting basic specifications; it’s about prioritizing safety and long-term reliability. Consider the following factors during selection:

· Compliance with Standards: Ensure all components comply with relevant national and international safety standards (e.g., IEC, IEEE).

· Quality and Reliability: Opt for reputable manufacturers known for producing high-quality and reliable components.

· Application Requirements: Select components that are appropriately rated for the specific voltage, current, and environmental conditions of the switchgear installation.

· Ergonomics and Ease of Use: Choose components that are easy to operate, clearly labeled, and contribute to a user-friendly interface.

· Compatibility: Ensure that all selected components are compatible with the existing switchgear and other system elements.

Conclusion:

Improving switchgear safety is a multifaceted endeavor that goes beyond the selection of primary switching devices. The careful consideration and selection of the right panel components and accessories are equally critical. By investing in high-quality indicating lamps, control devices, robust interlocking systems, reliable protection components, and a well-designed earthing system, you can significantly enhance the safety, reliability, and longevity of your switchgear installation, ultimately protecting personnel and equipment from potential hazards. Remember that a safe switchgear system is a well-equipped one, where every component plays a vital role in ensuring operational integrity and preventing accidents.

#Switchgear#ElectricalSafety#PowerSystems#ElectricalEngineering#IndustrialSafety#ElectricalComponents#SwitchgearSafety#SwitchgearAccessories#PanelComponents#ElectricalPanel#SafetyComponents#Interlocking#ProtectiveRelays#Earthing#Grounding#ElectricalMaintenance#IndustrialAutomation#MediumVoltage#LowVoltage#ImproveSafety#RightComponents#SafetyFirst#ElectricalProtection#ComponentSelection#electrical#engineering#medium voltage

0 notes

Text

The Holidays Are Here—Let’s Celebrate in Style! Dear Valued Clients, Cue the festivities of the holiday season! Excitement is in the air as we prepare to pause, recharge, and celebrate. Before we dash off, here’s a quick update on our holiday schedule: December 24th and 25th: Closed for Christmas December 31th and January 1st: Closed for New Year's Our team will be back, refreshed, and ready to roll on Tuesday, January 2nd, 2025. We are ready to step into the New Year with big plans and even bigger enthusiasm!

We don’t want to end up on your naughty list! While VACT will be closed, our support department will be on hand for any emergencies that may come up. We’re here to ensure your holiday season is a joyous one.

Thank you for letting us be part of your story this year. Your trust and support mean everything to us, and we can’t wait to make 2025 another incredible year together.

From all of us at VACT Inc., we wish you joy, laughter, and just the right amount of delightful surprises.

Warm wishes,

The VACT Inc. Team

0 notes

Text

Low-voltage switchgear

https://sirussystems.in/low-voltage-switchgears/ Low-voltage switchgear provides short-circuit and overload protection via low-voltage power circuit breakers (LV-PCB) with integral trip units. These low-voltage circuit breakers are typically through-the-door, draw-out devices.

0 notes

Text

What are low-voltage tools?

Low voltage tools are specialized tools designed for working with electrical systems that operate at voltages below a certain threshold, typically 50 volts AC or 120 volts DC. These tools are commonly used by electricians, technicians, and other professionals who work on low voltage electrical systems.

Wire strippers: Used to strip insulation from electrical wires without damaging the conductors.

Cable cutters: Designed to cleanly and efficiently cut various types of cables and wires.

Crimping tools: Used to crimp connectors onto the ends of wires and create reliable electrical connections.

Multimeters: Used to crimp connectors onto the ends of wires and create reliable electrical connections.

Voltage detectors: Used to quickly and safely determine whether a conductor is energized.

Fish tapes and rods: Used for routing and pulling wires through conduits and other confined spaces.

Nut drivers and screwdrivers: Used to tighten and loosen nuts and bolts on electrical components.

These tools are designed to meet the specific needs and safety requirements of working with low voltage tools, providing reliable performance and protection for both the user and the equipment being worked on.

0 notes

Text

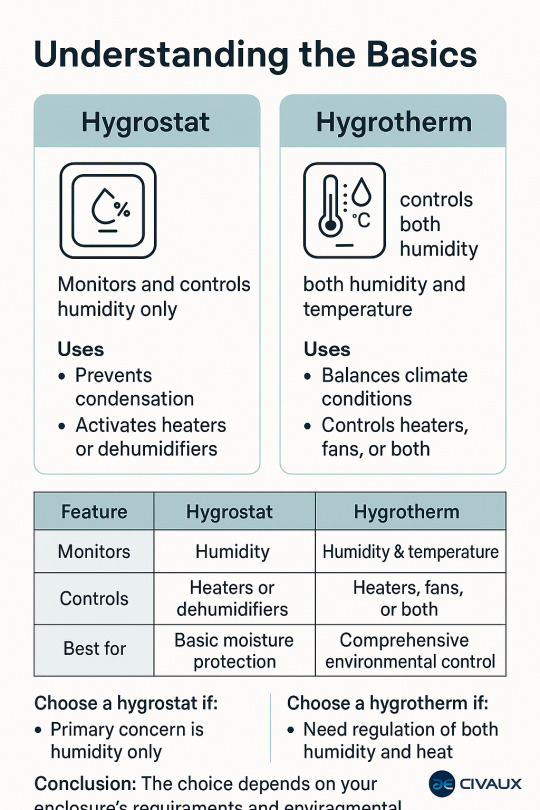

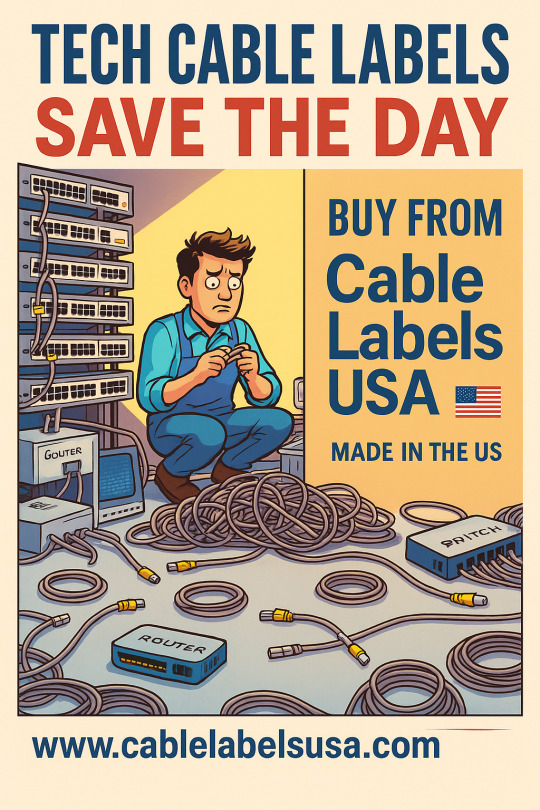

Hygrostat vs. Hygrotherm: Which Offers Better Moisture Management?

Moisture is one of the most damaging yet often overlooked threats to electrical enclosures and control panels. In high-humidity regions like the GCC, effective moisture management is critical to ensuring equipment longevity, operational safety, and uninterrupted performance. Two of the most widely used solutions in this space are hygrostats and hygrotherms. But which one is better for your application?

In this article, we compare hygrostats vs. hygrotherms in terms of functionality, performance, and suitability for different environments — helping you make the right choice for your electrical enclosure needs.

What is a Hygrostat?

A hygrostat is a humidity-regulating device that monitors the relative humidity inside an enclosure and activates connected equipment (like a heater or fan) when a preset humidity threshold is exceeded. It’s a single-function device focused purely on moisture control.

Key Functions:

· Monitors internal humidity

· Activates heaters or dehumidifiers to prevent condensation

· Simple and cost-effective solution for moisture problems

What is a Hygrotherm?

A hygrotherm is a dual-function device that combines the capabilities of a thermostat (for temperature) and a hygrostat (for humidity). It can monitor and control both parameters, ensuring balanced temperature and humidity regulation within the enclosure.

Key Functions:

· Simultaneous monitoring of temperature and humidity

· Activates heaters, fans, or filters based on combined conditions

Why Moisture Control Matters

In regions with high temperature fluctuations — like warehouses, factories, and outdoor panels in the Middle East — condensation can form inside enclosures. This can lead to:

· Corrosion of components

· Electrical short circuits

· Reduced equipment lifespan

· Safety risks for operators

Choosing the right controller ensures stable environmental conditions, reduces downtime, and cuts maintenance costs.

When to Use a Hygrostat

Choose a hygrostat if:

· Your enclosure operates in a relatively stable temperature range

· Your primary concern is humidity only

· You need a low-cost, targeted solution

· You’re upgrading older enclosures with basic needs

When to Use a Hygrotherm

Choose a hygrotherm if:

· Your environment experiences extreme heat and humidity (e.g., GCC summer months)

· You’re running sensitive electronics or automation panels

· You need proactive climate control for both heat and moisture

· You want to consolidate devices into a single, efficient unit

Conclusion: Which is Better?

Both hygrostats and hygrotherms are effective tools for enclosure climate control — but the better choice depends on your environmental conditions and system complexity.

· For basic, budget-friendly moisture protection: ✅ Go with a hygrostat.

· For comprehensive, long-term protection in critical systems: ✅ Invest in a hygrotherm.

Civaux Electric, we offer both hygrostats and hygrotherms with wide voltage range, compact design, and reliable performance — built to handle the GCC’s demanding climates.

#Hygrostat#Hygrotherm#Moisture management#Humidity control devices#Temperature and humidity regulator#Industrial climate control#electrical equipment#switchgears#electrical#panel#lowvoltage#dubai#united arab emirates

2 notes

·

View notes

Text

Mytek Pros offers a holistic solution for businesses of all scales, serving as your one-stop destination for a wide array of services. Our extensive offerings encompass hardware and software solutions, as well as comprehensive expertise in cybersecurity and cloud services. We're here to handle all aspects of your project, from low-voltage, computer networks, surveillance, to access control solutions, enabling you to enhance efficiency and cost management.

#mytekpros#Surveillancesystem#computernetworks#ITservices#lowvoltage#securitysystems#ubiquiti#ManagedIT#ManagedITservices#EVcharging#ITadministration#ITautomation#VPN#computerInfrastructure#networkinfrastructure#multifamily#smb#enterprisesolutions#itsolutionsprovider#businessautomation#automationsystems#businesstechnology#businesssolutions

1 note

·

View note

Text

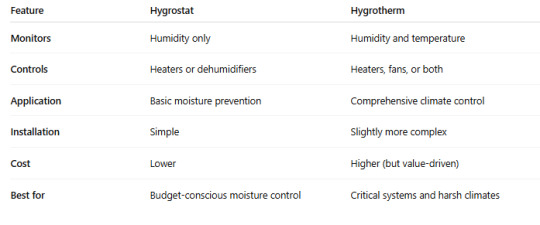

How to Choose the Right Cable for Outdoor Lighting

When it comes to outdoor lighting, choosing the right cable is crucial. The cable you select can make a significant difference in the performance and safety of your outdoor lighting system.

In this comprehensive guide, we will walk you through the essential steps of selecting the perfect cable for your outdoor lighting project. We will cover everything from voltage and gauge to cable types and length. Let's shed some light on the intricacies of outdoor lighting cables.

Understanding Your Lighting System

Before diving into the world of cables, it's vital to have a clear understanding of your outdoor lighting system. Consider factors such as the number of fixtures, the distance between them, and the total wattage your system will consume.

Voltage Matters

Voltage: The starting point of your cable selection process is determining the voltage rating for your outdoor lighting system. In most cases, low-voltage lighting systems (12-24V) are the preferred choice for outdoor applications. They are safer and more straightforward to install compared to high-voltage systems.

Cable Gauge and Current Capacity

Gauge: The cable gauge plays a critical role in ensuring the efficient operation of your outdoor lighting system. The gauge determines the cable's current-carrying capacity. Be sure to choose a cable with a gauge that can handle the wattage of your lighting fixtures. For example, a 12-gauge cable can carry up to 20 amps, making it suitable for approximately 20 LED lights.

Types of Outdoor Lighting Cable

Types: There are two primary types of cable used for outdoor lighting: direct burial and non-direct burial.

Direct Burial Cable

Direct burial cable is designed to be buried underground, making it ideal for installations where the cable needs to be hidden. This type of cable is rugged and durable, with protection against moisture, soil, and physical damage.

Non-Direct Burial Cable

Non-direct burial cable is suitable for aboveground installations. It should not be buried in the ground and is typically used in scenarios where the cable is exposed.

Consider Cable Length

Length: Select a cable that is just the right length for your outdoor lighting project. It's essential to avoid using excessively long cables, as this can lead to voltage drops. The longer the cable, the more significant the voltage drop, which can result in dimmer lights and potential operational issues.

Weather Resistance

When choosing your outdoor lighting cable, consider the climate and weather conditions in your area. It's crucial to pick a cable that can withstand exposure to the elements, especially if it will be installed aboveground.

Outdoor Cable Protection

Make sure your outdoor lighting cable comes with adequate protection, such as UV resistance, moisture resistance, and durability against physical wear and tear.

Installation Guidelines

Adhering to the manufacturer's installation guidelines is essential. Follow the recommended installation practices to ensure the cable's longevity and safety.

For complex outdoor lighting projects, it's often a wise choice to hire professional electrical contractors. Experienced electricians can ensure that the cable selection and installation are done correctly, guaranteeing the longevity and safety of your outdoor lighting system.

Regular Maintenance

Remember that outdoor lighting systems require periodic maintenance. Inspect the cables, fixtures, and connections regularly to ensure everything remains in working order.

Conclusion

Choosing the right cable for your outdoor lighting project is crucial for ensuring safety, efficiency, and the overall effectiveness of your lighting system. Pay close attention to voltage, gauge, cable type, and length to guarantee a seamless and well-illuminated outdoor space. By following these guidelines, you can create an outdoor lighting system that not only enhances your property's appearance but also provides a secure and inviting environment.

#OutdoorLighting#LightingDesign#CableSelection#GardenIllumination#DIYLighting#SafetyFirst#VoltageMatters#GaugeSelection#IlluminateOutdoors#TotalPowerEnergy#CableGuide#GardenLights#LowVoltage#LightingSolutions#OutdoorDecor#EnergyEfficiency#HomeImprovement#LandscapeLighting#LightingTips#TotalPowerEnergyServices

0 notes

Text

#cablelabels #wiremarkers #engineering #wiresolutions #cableinstallation #ElectricalEngineers #Electricians #structuredcabling #datacabling #madeinamerica #InfoComm #audio #video #cablemanagementmatters

0 notes

Text

#fiberoptic#cat#fiber#network#telecom#wifi#internet#fiberoptics#cabling#ftth#telecommunications#networking#structuredcabling#cable#datacenter#data#lowvoltage#indihome#wifimurah#internetcepat#cisco#myrepublic#tvkabel#xlhome#fttx#promoxlhome#hargaxlhome#hargapromoxlhome#internetxlhome#xlhomebekasi

0 notes

Text

Why Do Many Customers Choose ONCCY's 1000V DC Fuses?

In a market filled with various brands, why should you choose ONCCY's DC fuses? Let me explain. Here are the advantages of our DC fuses:

The EDFH series fuses are made with fire-resistant materials that comply with IEC 60269-6 standards, ensuring safety and reliability. This series has a maximum rated voltage of 1000 volts and a maximum current of 30 amps, serving as protection against short circuits and overcurrents. They are widely used in high and low voltage distribution systems, control systems, distribution boxes, inverters, and other electrical equipment.

Product Advantages:

1.DIN35 Rail Mounting: Facilitates quick installation, saving time.

2.Adjustable Terminal Connectors: Ensures secure connections, enhancing safety.

3.Flame-retardant Housing: High-temperature resistant design increases durability.

4.Flexible Installation: Easy to replace, adapting to various application needs.

By choosing ONCCY, you will receive high-quality DC fuses with reliable protection features. Feel free to contact us for more information!www.onccy.com [email protected]

#ONCCY#DCFuses#ElectricalSafety#IEC60269-6#FireResistance#PowerDistribution#Inverters#HighVoltage#LowVoltage#ElectricalComponents#FuseProtection#ElectricalInstallation#DINRail#AdjustableTerminals#Durability#ReliableProtection#nccy

0 notes