Materials Handling and Storage Equipment Since 1924 https://clarkecasters.com/BLOG ARCHIVEPhone:1-800-325-27531700 Roseneath Rd.Richmond, VA 23230Mon-Fri 8:30am-4:00pm [email protected]

Don't wanna be here? Send us removal request.

Text

Pallet Jack Safety - Toe Guards

Pallet jacks, also known as pallet trucks, are one of the most important tools in nearly every type of industry. Even if your particular line of work does not have a direct use for them, the truck drivers, dock workers, and warehouse workers who are responsible for components of your business are most certainly using pallet jacks at some point along the way. The paper you use in your printers and copiers, the bottles of water on your cooler, and the cubicle panels that fill your office are all very likely to have spent some time on a pallet jack. So with pallet jacks being used so widely across industries throughout the world, it is highly important to ensure the safety of their operators and those nearby.

We are excited to now offer a pallet jack safety feature that can decrease the risk of injury and can be installed on your current pallet jack: PALLET JACK TOE GUARDS.

What is a toe guard?

A toe guard is pretty much exactly what it sounds like. In this case, it is a field-installable "box" that mounts around the steer wheels of your pallet jack and prevents the steer wheels from rolling over the toes of the operator or anyone else in the vicinity. Quite simply, the box will bump into your toes instead of the wheels rolling over them.

Toe guards are also available on a wide range of casters that we carry, and have been around in the caster world for quite some time, so we can attest to their effectiveness based on decades of use.

We are now offering a range of pallet jack toe guards that can be retrofitted to your pallet jack. They are easy to install - simply remove your steer wheels and steer wheel axle, then replace the axle with the one that comes with the toe guard kit. Next, just reinstall your wheels and install the toe guard.

Click HERE to see the models we offer online. In the images shown, match your hydraulic pump to the one shown in the second image to ensure fit. As always, if you don't see what you need, give us a call at 1-800-325-2753 or EMAIL US and we can help!

#warehousesafety#safetyfirst#warehouse equipment#dock equipment#pallet jacks#safety equipment#clarkecasters#rva#scottsaddition#cepalletjack#cepallettruck#wheels#familybusiness#100yearsinbusiness

0 notes

Text

Move Safely with Cup Dolly Inserts

When it comes to moving heavy equipment, furniture, or fixtures, there are many ways to get the job done. The best way to move these items will depend on the unique needs of each application. Some things to consider when preparing to moving large, heavy items are weight, overall dimensions, leg configuration, and floor surface. There may also be special considerations such as vibration, impact, and even static electricity.

For today's topic, we are focusing on large, heavy items with legs such as desks, wire shelving, and any type of large machinery or conveyor.

One of the most versatile products available for moving large items - with or without legs - are 3-wheel dollies, also known as cup dollies.

What is a Cup Dolly?

A cup dolly is a triangular-shaped platform made from steel or aluminum with three wheels and a recessed cup in the center.

Cup dollies are available in a range of sizes and weight capacities (VIEW OUR OPTIONS) to help you tackle everything from desks and cabinets, to machine presses and safes. However, when the items you are moving has smaller diameter legs, sometimes even the smallest cup dolly will have a cup that is too large to safely transport your cargo. Our friends at Bond Caster and Wheel have come up with a great solution for this with their polyurethane cup dolly inserts:

These inserts are made from solid polyurethane, and they rest perfectly in any of the Bond 2127-series dollies available from our website. Simply place the polyurethane cup dolly insert in your 2127 dolly, and you have a much smaller diameter cup for safely transporting your cargo.

In addition to added safety for transporting equipment with legs, these inserts also provide a larger, flat dolly base for moving equipment that may not have legs. The polyurethane is durable, and just grippy enough to keep things from sliding on the dolly surface.

For more information on these products or any other materials handling solutions that we offer, please CONTACT US or stop by our Richmond, VA showroom in the Scott's Addition neighborhood. We look forward to helping you!

#cupdollies#cup dollies#bond dollies#floor dollies#moving equipment#casters#clarkecasters#warehouse equipment#safety#mobility#3 wheel dollies#tri dollies#movers dollies#richmond va#rva#scottsaddition

0 notes

Text

Hand Truck Repair - Installing B&P Stairclimbers on The Competitor’s Hand Truck

We have stocked B&P aluminum hand trucks and parts in our Richmond, VA warehouse for decades. It has always been the only brand that we have carried because B&P simply makes the absolute best aluminum hand trucks and parts. That is not just our opinion, as our customers regularly tell us how much better B&P hand trucks perform, and how much longer they last compared to the competition. Since this has always been our house brand, we have run into countless instances of having to fit B&P parts to the competitors’ brand when making repairs on hand trucks made by those competitors. In most cases, the parts are universal and easy to replace, but sometimes we have to make some adaptations to make the repair. Of those adaptations, one of the most common occurs when replacing stairclimbers.

What are stairclimbers?

Stairclimbers are optional attachments for hand trucks that make going up and down stairs or curbs smoother and easier. This is accomplished by making a tapered transition from the outermost edge of the hand truck wheel to the back of the hand truck frame. Imagine moving heavy cargo up a staircase with a hand truck without stairclimbers: as the hand truck wheels transition from the horizontal surface of each step to the vertical surface of the next step, the load becomes more difficult to move because you now have to essentially pull it straight up against the vertical surface. Stairclimbers allow the user to slide the hand truck up the step on more of an angle, taking a little bit of gravity out of the equation. So now instead of lifting a few hundred pounds vertically, you are leaning the load into the apex of the step and sliding it on an angle.

The following photos show a broken stairclimber and a broken wheel bracket on a hand truck we recently repaired in our Richmond, VA shop.

So how do we retrofit B&P stairclimbers to the competitor’s brand?

First, let’s look at how the competitor’s stairclimbers attach to the hand truck. Each stairclimber is attached at two points: at the base of the frame, and below that at the wheel axle. They clamp onto the frame and are secured with a thru-bolt, and the wheel axle runs through a hole in the bottom of the stairclimber.

The competitor’s hand truck (flipped to make the repair) and how the stairclimber attaches to the wheel bracket:

Now, let’s look at how the B&P stairclimbers attach. They still attach at two points: at the base of the frame using a clamp with a bolt and lock nut, and at the back of the wheel bracket using a thru-bolt. Since the lower attachment is configured differently than that of the competitor’s hand truck, that is where the adaptation has to occur. The B&P wheel bracket has an extra tab with a hole for the stairclimber to bolt onto, where the competitor’s brand does not because of the thru-axle design. We simply replace the wheel brackets on the competitor’s hand truck with B&P wheel brackets, and now we have a place to bolt the B&P stairclimbers onto.

The B&P Stairclimber and wheel bracket (flipped to make the repair):

There are two main benefits to making the repair like this:

1. You replace the stairclimbers themselves to make navigating curbs and steps much easier than it would be without stairclimbers.

2. You end up with a superior stairclimber design that is more ergonomic, stronger, and much easier to replace down the road as needed.

3. You get a longer, replaceable nylon wear strip that protects stairs and smooths out the process of going up and down them.

As you can see by the first photo, we also replaced the wheels and nose plate on this hand truck to get it working as if it were brand new.

Curious about a hand truck repair? Need our help? Just give us a call at 1-80-325-2753, email us by clicking HERE, or just bring your hand truck by our showroom in the Scott’s Addition neighborhood in Richmond, VA. We’re right off of I-95 near the I-64 interchange and also right off of Powhite Parkway at the Broad St. exit.

#hand truck#handtruckrepair#rva#deliverydriver#beerdistributors#foodservice#food delivery#richmondva#scottsaddition#wheels#routedriver#drinklocal#breweries#clarkecasters

1 note

·

View note

Text

Hand Truck Highlight: Plumber’s Little Helper

For plumbers handling bulky water heaters and other large equipment, the featured hand truck has provided an optimal solution. Typically, those in the plumbing or HVAC fields tend to use either large steel appliance dollies, or budget-friendly hardware store hand trucks. Each of these options has their pros and cons, and the featured aluminum hand truck manages to pull the pros from each while eliminating the cons.

APPLIANCE DOLLY PROS:

1. RATCHET STRAP: Appliance dollies all have some type of strap assembly built in to secure equipment to the dolly itself. The majority have an automatically recoiling ratchet strap assembly that make securing loads easy. From a safety and ease-of-use standpoint, the ratchet strap is an absolute must when moving bulky cargo.

2. WEIGHT CAPACITY: Appliance dollies usually have a higher weight capacity than the typical hardware store hand truck, with starting weight capacities of 800 lbs. for a steel appliance dolly compared to 500 lbs. for a hand truck

3. DURABLE CONSTRUCTION: The more popular appliance dollies are constructed of welded, heavy-gauge tubular steel, making them virtually indestructable

APPLIANCE DOLLY CONS:

1. WEIGHT: As mentioned above, the most popular appliance dollies are constructed of welded tubular steel. While this makes them very durable, it also makes them very heavy, sometimes weighing nearly double that of a standard hand truck. When loading in and out of trucks, and moving up and down stairs, this additional weight makes a huge difference, leading to earlier user fatigue.

2. PRICE: High-quality appliance dolly prices generally start in the $500 range.

3. MAINTENANCE: Welded steel is strong, durable, and also hard to repair. Even the most durable steel appliance truck doesn’t stand a chance when you forget to load it back into the truck and you back over it (believe us - we’ve seen the results of this scenario MANY times). Accidents happen, and if the steel frame cracks, bends, or breaks, unless you are an experienced welder, the appliance dolly will be worthless at that point.

Now let’s take a look at the other end of the spectrum... hardware store hand trucks (inexpensive steel hand trucks)

HARDWARE STORE HAND TRUCK PROS:

1. PRICE: We have seen these hand trucks selling for as low as $50.00. As far as price goes, that is tough to beat, but as the saying goes, “you get what you pay for.” (more on that in the CONS list)

2. WEIGHT: Very light - because they use thin steel and not much else.

3. THEY WORK IN A PINCH: We have to admit, it was challenging to come up with another PRO for this list, but when you simply need a hand truck to move something, you will probably get the job done with one of these.

HARDWARE STORE HAND TRUCK CONS:

1. DURABILITY: As mentioned before, these hand trucks are inexpensive, and as we all know, there is usually a good reason for that. Hardware store hand trucks do the bare minimum to be called hand trucks. The steel frames use the thinnest possible tubing, the wheels are usually the narrowest, lightest duty, tubelsss pneumatic wheels.

2. CAPACITY: Usually 500 lbs. at best, but in our experience, if you put 500 lbs. on one of them, you are going to run into problems like bent plates, frames, or broken wheels

3. NO LOAD-SECURING FEATURE: Bulky loads need to be secured to the hand truck before transport. That is why the ratchet strap feature is available on appliance dollies. Safety for the user and the load are significantly decreased without one.

4. MAINTENANCE: Just like with appliance dollies, if the steel bends or breaks, then throwing the hand truck away and buying a new one is the only option.

Now for the featured hand truck: THE PLUMBER’S LITTLE HELPER.

1. RATCHET STRAP - this is an add-on feature to any of our aluminum hand trucks. It can be retro-fitted to your existing aluminum hand truck as well and installs easily with 4 bolts.

2. CAPACITY: 600 lbs. with solid Super CareFree wheels... and that’s a TRUE 600 lb. capacity - bet on it!

3. DURABILITY: Constructed with high grade channel aluminum frames and solid nose plates, these have a proven track record of holding up to the most abusive environments

4. WEIGHT: Significantly lighter than an appliance dolly, and usually only a few pounds heavier than a hardware store hand truck.

5. PRICE: As mentioned before, they start at about half of the price of an appliance dolly.

6. MAINTENANCE: In our opinions, this is the best feature of these hand trucks. They are assembled by components that bolt together. That means when one component (handle, frame, plate, wheels, accessories) breaks, you can replace that one component and not the entire hand truck.

7. CUSTOMIZATION: As with all of our B&P aluminum hand trucks, we can customize them to your specific needs. Various handles, wheels, plates, and many additional options are available.

So, as you can see, the featured aluminum hand truck offers the best of both worlds for plumbers, HVAC workers, and more. Let us know how we can customize one for you!

#hvaclife#plumbing#plumber#handtrucks#appliance trucks#clarkecasters#rva#scottsaddition#b&p#aluminum hand trucks#delivery drivers

2 notes

·

View notes

Text

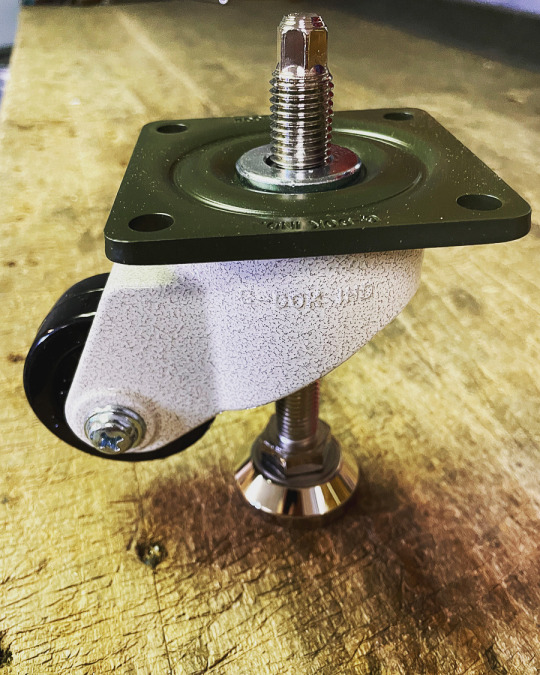

Using Casters to Level Equipment - Leveling Casters

“Can I use threaded stem casters to level my equipment on an uneven floor surface?”

While you should not use the stem of a threaded stem caster to level equipment, there are other options such as leveling casters.

First though, why shouldn’t you use threaded stem casters to level equipment?

Threaded stem casters have a threaded stem or post that extends from the top of the swivel raceway. This stem can either be screwed into equipment that is also threaded to match, or it can be inserted through the attachment point and secured with a hex nut. The reason that threaded stem casters should not be used to level equipment is because of how the caster itself is designed to hold a certain amount of weight (weight capacity). Nearly all swivel casters will have a swivel raceway - which is a circular row or rows of ball bearings that allow the caster to rotate. Beyond that, the swivel raceway is also the part of the caster designed to hold the weight of the application. That is, the equipment on which the caster is installed should rest directly on the swivel raceway. If you were to use the threaded stem of a caster to level equipment, you would be transferring the weight of the equipment from the raceway to the stem itself. Since the stem of a threaded stem caster is not intended to hold the weight of the application, there is an extremely high risk of failure - the stem bending or breaking.

Enter the leveling caster:

There are many styles of leveling casters, but the concept is typically the same: a leveling foot or pad located adjacent to the wheel of the caster. The height of the foot is adjustable either by turning a knob, a hex nut, and in some cases a built in ratchet. Simply roll the equipment into place, and adjust the foot accordingly. When you need to move the equipment again, retract the foot and repeat the process.

Using leveling casters to adjust equipment height is ideal because it allows the weight of the equipment to be transferred to a mechanism specifically designed for that purpose. The caster shown in the above image is rated to hole 1,100 lbs. and has a height range of 4″ to 6″ overall. This allows for significant variance in floor surface without sacrificing performance.

Leveling casters come in a variety of styles and sizes, as well as with different mounting configurations such as 4-hole plates (pictured), threaded stems, and hollow kingpins.

For more information on how you can use leveling casters for your application, please email us by clicking HERE, or call us at 1-800-325-2753.

2 notes

·

View notes

Text

Are ball casters right for my chair?

What is a ball caster?

A ball caster is a type of caster where the wheel is spherical or ball-shaped. These casters are usually found on furniture such as office chairs or dining room chairs, as well as on store fixtures such as clothing racks in a department store. Some ball casters actually have a ball or sphere that is the wheel. The ball has a hole drilled through it on which it spins. Other ball casters are ball-shaped, but only one half of the ball acts as the wheel, while the opposite half acts as the frame.

Which ball casters can I use on my floor?

If you have hardwood, tile, or vinyl floors, a caster with a softer tread is best because it will offer greater protection to your floor as the caster rolls across it. Ball casters with rubber treads are available in various sizes, styles, and configurations that can be viewed by clicking HERE and HERE. These will work well for any hard floors.

If you have carpeted floors, ball casters with metal treads are great options, but softer treads will also work well. Metal-tread ball casters will not pick up dirt, dust, or carpet fibers like softer treads, which is why many choose these for carpeted floors. These casters can be viewed by clicking HERE.

How do I install ball casters?

Installation of ball casters depends on the application. Chairs with wooden bases usually use casters with grip neck stems and accompanying sockets, but may also use casters with 4-hole mounting plates.

Grip ring stem casters are the common choice for office chairs with metal or plastic legs. These chair legs are usually pre-fabricated to use a 7/16″ grip ring stem caster, making replacement easy.

Ball casters with threaded stems are another option. If the application has pre-threaded inserts or holes, matching the proper thread size is all that is needed to select the right caster. Installation is very easy, as you just screw casters in or out. Threaded stems are also a good option for applications where the stem can pass all the way through the leg to have a hex-nut inserted on the other end.

(Pictured above: Ball casters with antique brass finish)

(Pictured above: Ball casters with bright chrome finish)

(Pictured above: Ball casters with bright brass finish)

1 note

·

View note

Text

Socket To Me! Adapting Casters To Fit Furniture and Fixtures

When you need furniture or fixtures to roll, it is not always a simple as just buying some stem casters and popping them into a chair leg or fixture base. First, you need a plan for how to install your casters. Most likely, part of that plan will include adapting your caster stems to fit your furniture or fixture. While there are a few common caster stems available including grip ring stems, grip neck stems, and threaded stems, there are countless ways a piece of furniture or a fixture can be made. Rather than making a caster to fit every type of furniture leg or fixture pedestal, a large range of socket adapters are available instead to make the task of installing casters easy. The image below shows just a few styles of sockets, along with the two most common caster stems to go with them:

By identifying a few key elements and measurements, you can select the right caster and socket for your project to make installation a breeze.

First, identify the material of the leg or pedestal where the casters will be installed. If it is wood, that usually narrows it down right away to a metal socket that will either be attached with bolts, or with a serrated flange built into the socket. If plastic, metal, or other, that usually indicates a tubular style leg that might be round or square. In this case, a plastic socket is ideal.

Second, measure the area where the socket and caster will be installed. If wood, you want to make sure there is enough surface area to drill into for a socket and/or bolt holes without splitting the wood. If metal or other, measure the inside diameter of the tubing where the socket will be installed.

Third, select the appropriately sized socket and caster/stem that goes with it. Plastic sockets come in either round or square shapes, and in sizes ranging from 7/16″ outside diameter to 1-1/8″ outside diameter, usually in 1/16″ increments. They are also available with either a 7/16″ inside diameter for common grip ring stems, or with a 5/16″ diameter for grip neck stems. Generally, if you can use the larger diameter stem, that is what you will want to do for added durability, but that options may not always exist.

Once you have the above information, selecting casters and sockets is easy, and installation will be as well. As always, we are here to help if you have any questions. Just call us at 1-800-325-2753, or email us at [email protected].

0 notes

Text

Tow Away Zone - Albion 310 Series Kingpinless Casters

For mobility applications where carts or equipment must be towed through a manufacturing plant or warehouse, special considerations must be made for the casters being used. Albion Casters, the leaders in heavy duty casters and wheels, has focused several of their caster series on addressing these special towing considerations. Today, we are discussing the advantages of the Albion 310 Series caster line, which includes heavy duty kingpinless casters that hold up to 4,100 lbs. each.

The main concerns when using casters in a towing application come from the abuse that swivel casters can sustain. The increased distance traveled in many towing applications leads to more debris and obstacles that the casters can come in contact with. In addition to those issues, basic wear and tear is increased just by the increased volume of caster usage from increased distances traveled. All of these issues combined lead to the need for a stronger, more durable swivel raceway. The swivel raceway is the section of the caster between the mounting plate and fork where ball bearings are aligned in a circular row or rows, which allow the 360-degree swivel motion. This area of a caster is particularly vulnerable to failure in many casters because and bumps, jolts, or impact to the caster get transferred to the raceway. Since swivel casters have an offset to allow easy changes in direction, more stress is put on the raceway because it is not centered over the wheel itself. And since a swivel offset is necessary and cannot realistically be eliminated, the solution must come from a stronger raceway, which is where the Albion 310 Series comes into play.

The 310 Series has a kingpinless swivel raceway that is precision machined. All that really means is that instead of using a kingpin (either a hex bolt or rivet) to hold the mounting plate to the fork and swivel raceway, these casters have a raceway that is formed and integrated into the the fork and mounting plate. By eliminating the kingpin, which can stretch and break due to impact and fatigue, Albion eliminates the potential for raceway failure.

So what makes the 310 Series better for towing besides the raceway? Well, the 310 Series has an industry standard 4.5″ x 6.25″ mounting plate, which is common to casters with 2″ wide wheels, as well as 2.5″ and 3″ wide wheels, which are what the 310 Series uses. This allows easy adaptation of any equipment to accept the heavy duty 310 Series. With capacities up to 4,100 lbs. per caster and a range of ergonomic and non-marring heavy duty wheel options, the 310 Series is just simply more rugged and higher capacity than the comparable kingpin-style casters.

Additional features and options include special towable swivel leads which are slightly increased from the standard leads, making direction changes easier; toe guards, which protect workers by shielding the wheels from rolling over toes and other larger obstacles; and several brake, bearing, and mounting plate options.

Albion 310 Series casters are made in the USA in Michigan, resulting in 70% shorter lead times. They have 3/8″ thick legs welded to inside and out for longer life and strength and carry a 3-year warranty from Albion Casters.

For popular available casters in the 310 Series, click HERE to view these products on our website. You can shop online, but if you do not see exactly what you need, just contact us either by clicking HERE, or calling 1-800-325-2753. Many options are available that have not been added to our online store.

#casters#towing#cart#dolly#dollies#towtrucks#bakeryrack#production#manufacturing#wheels#albion#albioncasters#clarkecasters#materialshandling#materialshandlingequipment

0 notes

Text

Hand Truck Highlight - The Lightweight Champion

B&P hand trucks are, hands down, the strongest aluminum hand trucks available. As we have showcased before, there are many, many options and features that B&P hand trucks offer. And while we wholeheartedly endorse any of the available options, the truth is that they can add weight to the hand truck. And for many deliver drivers, warehouse workers, and truckers who have to lift their hand trucks in and out of trucks or up and down docks all day, hand truck weight is critical. The heavier they are, the sooner worker fatigue sets in, which can lead to accidents and injuries. And that’s where today’s highlighted hand truck comes in. We give you: THE LIGHTWEIGHT CHAMPION!!!

This hand truck uses all standard B&P components the ensure the highest levels of quality and durability, but they have been carefully selected to minimize hand truck weight. These hand trucks clock in at under 19 lbs!!

They come equipped with soft rubber on aluminum wheels for a cushioned ride and low maintenance, as well as a cast aluminum nose plate with cutouts to reduce weight, and a standard B&P loop handle. And of course, as with all B&P hand trucks, they are MADE IN THE USA!

The cherry on top is that these hand trucks are priced to compete with “hardware store hand trucks”, while delivering the quality of a true delivery driver’s hand truck, so call us at 1-800-325-2753 or EMAIL US for more information.

When it comes to value, these lightweight contenders just can’t be beat!

#handtruck#aluminum#delivery#lightweight#materialhandling#food service#beverage packaging#rva#richmond#dollies

0 notes

Text

Hand Truck Highlight - The Snappy Delivery

Convertible hand trucks are the undisputed champs when it comes to bulk package delivery. With the press of a lever, drivers can convert their hand truck to a 4-wheel platform truck that they can load with up to 1,200 lbs. cargo. This makes transporting a large number of boxes, crates, or other packages much more timely and efficient. And while this feature is great for medium to large size packages, it may not be ideal for small items. This is because most hand truck frames are built similar to a ladder with rungs. As you can see in the image below, small packages don’t stand a chance with the gaps between frame pieces.

So what is the solution for the delivery or transport of small packages? A solid deck surface like the one shown below.

The great thing about this deck surface is that it is modular - meaning it can be installed and removed with ease. It comes equipped with spring-clips and brackets that hold it securely to the hand truck frame as shown below. Just snap it into place, and slide it down to secure the brackets over the frame cross members. When you need to remove it, just slide it up and snap it out.

These snap-on aluminum hand truck decks are available for Sr. and Jr. sized convertible hand trucks, as well as for standard 2-wheel hand trucks. If you think these might work for you, just let us know and let’s make it happen!

#handtruck#b&p#delivery#foodservice#foodserviceequipment#beverage#delivery driver#clarkecasters#ceclarke#scottsaddition#rva#material handling

0 notes

Text

Ergonomic Casters - Mobility, Durability, and Safety

Work smarter, not harder, as the old adage goes. And if your warehouse, production facility, or office is anything like ours, then “work smarter” means having anything and everything on casters or wheels to increase mobility. If that is the case, then you are off to a great start, but we are here to help you take “work smarter” to the next level with ergonomic casters and wheels.

Ergonomics, simply put, is the science of designing things that humans use with the goal of maximizing safety and efficiency. If we apply this concept to casters and wheels, it means casters that start rolling and swiveling easily, change direction easily, and keep rolling easily. When a caster can achieve all of these things, the safety and efficiency of workers and equipment operators is increased. No more struggling to start moving a heavy cart or machine because the wheels do not roll easily means less injury and worker fatigue.

There are a few characteristics of a caster that increases ergonomics:

1. Precision Wheel Bearings - precision ball bearings are the easiest-rolling, and smoothest bearings available for caster wheels. They offer very low resistance, are pre-lubricated and sealed, and are generally very quiet. Low resistance in a wheel bearing translates to a wheel that rolls with minimal push/pull force.

2. Crowned or Rounded Wheel Tread - most common caster wheels have flat treads, meaning that the surface of the wheel that comes into contact with the floor (the wheel tread), is completely flat from one side to the other. Crowned tread wheels round the tread from side to side creating a sort of “donut” look to the wheel. By rounding the tread, the surface area of the wheel that comes into contact with the floor is reduced, which in turn reduces friction between the wheel and the floor. This allows the caster to swivel or turn with less resistance, making it easier to change the direction of equipment as it is moved.

3. Precision Swivel Raceways - swivel casters rotate on a series of ball bearing raceways between the mounting plate or stem and the caster fork. Most common casters use a basic setup of two rows of somewhat exposed ball bearings. By improving the swivel raceway from this standard setup to a precision machined and/or sealed ball bearing raceway, the swiveling resistance is lowered, making it that much easier for a caster to change direction.

You may have noticed that a big part of caster ergonomics is precision ball bearings. While the use of precision bearings in both the caster wheel and swivel raceway dramatically increases ergonomics, it also offers a couple additional benefits: noise reduction and reduced maintenance. Since the precision sealed bearings used in casters are pre-lubricated and sealed, the need to regularly inject grease into the bearing is eliminated. This directly decreases maintenance time, and also extends the life of the bearing. On top of that, precision bearings are very quiet compared to roller bearings and other bearing types.

We offer a full line of ergonomic casters for various applications in a couple different caster series:

Albion 18-Series Ergonomic Precision Casters:

These casters are hands down the most ergonomic option for medium heavy duty applications. They are rated for up to 1,250 lbs. each, and use sealed precision ball bearings in the swivel raceway. The casters pictured above have the 18-Series precision yoke, and Albion’s crowned tread X-tra Soft gray rubber wheels for the ultimate in quiet and floor protection.

Albion 110-Series Kingpinless Casters:

These casters are very similar to the 18-series, but instead of a precision sealed ball bearing raceway, they have a single row of ball bearings mounted in a heat-treated precision machined raceway. What this means is that the swivel section is not completely sealed. While that could be considered a downside, it allows these casters to withstand much greater impact, increasing durability and lifespan. The casters in the above image have Albion’s 110-Series kingpinless swivel yoke and their Trionix high impact polymer wheel for maximum durability, and a capacity of 2,000 lbs. each.

To summarize, the Albion 18-Series is the pinnacle of mobility in ergonomic casters, and the Albion 110-Series is the pinnacle of durability in ergonomic casters. If you are not sure which is best for your application, just EMAIL US or give us a call at 1-800-325-2753. With five generations worth of caster knowledge, our expert staff can point you in the right direction and get things rolling!

#casters#ergonomics#safety#albion#wheels#maintenance#worksmarternotharder#worksmarter#ceclarke#clarkecasters#scottsaddition#rva#material handling

0 notes

Text

Catering Cart Casters

If you work for a catering company, chances are good you rely on some type of cart or dolly to transport food and equipment for the events you are working. And with any event, there is no room for mishaps. With many carts used for catering, a light weight cart is usually ideal because of having to transport the cart itself from one location to the next. The downside to a lightweight cart though, is that they usually come equipped with lightweight casters that are very susceptible to failure.

Imagine working a wedding and using your cart to transport the wedding cake, when suddenly one of your wheels breaks, or the bearings on your caster give out causing the cart, and the cake, to go toppling to the ground. Luckily, this situation is avoidable with the right casters.

We recently helped a catering company upgrade their cart casters from lightweight casters that were only rated for about 125 lbs. each, to much stronger casters rated for 190 lbs. each with a wider wheel and larger swivel raceway. The image below shows the type of grip ring stem casters we replaced (bottom), as well as the heavy duty replacements (top).

Both have 4″ diameter non-marring gray rubber wheels and 7/16″ diameter grip ring stems that simply “pop” into the cart for easy installation. The casters on the top though have 1-1/4″ wide wheels compared to 15/16″ wide on the bottom. They also have precision ball bearings and a sturdy poly hub, where as the lightweight casters have a plain bore (no bearing), and a very thin plastic hub that can easily crack.

And as is the case with many upgrades, it’s the little things that really make the difference. The replacement casters have total lock brake systems that lock the wheel and swivel at the same time with the push of one pedal. This allows any cart to be rendered completely stationary with ease.

The brake pushes a stopper onto the tread of the wheel from the top to stop the wheel from rolling, and simultaneously engages an arm into the raceway slots underneath the caster to keep it from swiveling (image below).

We understand the appeal of lightweight carts for catering, as well as the appeal of lightweight casters, especially when cost is a concern. But when your event is relying on your cart to get the job done, this upgrade will prove to be some of the best money you could spend. For more information on upgrading your casters, whatever the application, give us a call at 1-800-325-2753, or EMAIL US HERE.

#casters#catering#cateringequipment#foodserviceequipment#carts#wheels#maintenance#restaurantequipment#replacementwheels#rva#scottsaddition#richmondva#clarkecasters

0 notes

Text

Hand Truck Highlight - Senior Citizens

These hand trucks may be called, “Sr. Convertibles” but don’t let the name fool you - they can hang with any hand truck out there.

Rated for 600 lbs. each in the 2-wheel position, or 1,200 lbs. each in the 4-wheel position, these Senior Convertible hand trucks boast true old-man strength.

You may notice a few differences between the two hand trucks in the photos. The one on the right is the full scale version with a vinyl grip handle and a solid nose plate. The one on the left is slightly scaled down to save some weight, and some money for the end user. The scaled down “SSR” truck on the left has a cast nose with cutouts, and does not have the frame crossmembers above and below the logo crossmember like it’s counterpart does. These slight differences amount to substantial cost savings, making this truck a great option for those seeking durability and dependability on a budget.

Both trucks use all the same mechanical components, and we offer full repair service on them if you are in the Richmond, VA area. Just like with all of the aluminum hand trucks we carry, these are fully customizable. We can switch handles, nose plates and wheels to whatever you need, and we can add accessories like snap-on solid frame decks, folding nose extensions, even additional handles.

Stop making deliveries on a less than ideal hand truck or cart, and let these Senior Convertible hand trucks from B&P Manufacturing show you how it’s done. Call us at 1-800-325-2753, email us at [email protected], or shop online at clarkecasters.com.

0 notes

Text

Pallet Jack Repair - Show Us Your Pump!

Pallet jacks break down - it’s just part of the deal. While they are made to handle 5,500 lbs. or more, over time, pieces and parts become worn, bent, broken, rusty, or deteriorated. As we have mentioned before, we offer repair service on pallet jacks if you are in the Richmond, VA area, but we also carry a full line of replacement parts that we can ship anywhere you need. Pallet jacks are not terribly complicated pieces of equipment, and most repairs can be made with a few basic tools. So now you just need to make sure you get the right parts for your pallet jack.

While many pallet jacks display a make and model number (usually on a decal on the back of the frame) that make getting the correct parts easy, many do not display this information. So how can you identify the parts you need if you don’t even know the make and model? That’s where we can help. We can identify the type of pallet jack you have just by looking at the hydraulic pump unit that the handle is attached to.

“But I need the wheels at the ends of the forks. How is a picture of the pump going to help?”

If you send us a picture of the pump like these from actual customers....

...we can match them up with one of the many drawings we have like these....

... and VOILA!... we know what kind of pallet jack you have, and have a full breakdown of any parts you might need.

So don’t waste anymore time trying to figure out what parts you need for your pallet jack, and let us help. Show us your pump, and we will give you all the information you need to keep your pallet jack running smoothly.

Just email your photos to [email protected] and we will get back to you with your options.

0 notes

Text

Specialty Stem Casters

The majority of casters available to the market today can be used across a variety of applications. A light duty caster could be used on a chair, or a store display. An institutional caster could be used on a stock cart, but could also be used on a medical table. A heavy duty caster might be found on a dolly, or it might be found on a million-dollar piece of automation machinery. This list could go on and on, but the point is that many caster applications might have the same caster solution. This is great because it makes it easy to find a caster that will do the job. Sometimes, however, a caster solution is extremely specific to an application, and there is really only one caster that does the job. A couple examples are scaffolding casters and cart-specific casters.

Scaffolding casters like the one shown below have the very important job of allowing scaffolding used for painting, construction, and more to be mobile when needed, and securely “locked down” when needed. Since scaffolding allows users to work, at times, multiple stories off the ground, having a secure mobility system is a without question of the utmost importance to maintain safety. Scaffolding casters use heavy duty frames and swivel raceways that can hold several hundred pounds each, a large (1″ to 1-3/8″) diameter stem that will not bend or fail easily, and a total lock brake, which locks the wheel and swivel at the same time. With all of these special features combined, there really is no substitute for a scaffolding caster.

Another example of an application-specific caster is the square stem caster shown in the picture below. This one is made for a Lakeside cart, and it uses a small diameter square stem with a couple cross-drilled holes in it to allow it to be fastened to a one-of-a-kind food service cart. You may find other square stem casters, but not with this very specific stem size. This particular caster has a stainless steel frame and wheel hardware to prevent rust and corrosion. Standard zinc-plated options are also available for this caster.

So when you are searching for a specific caster for your application, save time and energy and work with a caster expert like the sales staff at C.E. Clarke & Son, Inc. Call us at 1-800-325-2753, email us by clicking HERE, shop online HERE, or come by our Richmond, VA showroom. There a plenty of companies who can sell you casters, why not go to one who will sell you the RIGHT caster?

0 notes

Text

Shock Absorbing Casters and Wheels

Your car has all sorts of components to absorb the shock and vibration of the road. Why should your casters and industrial wheels be any different? When you are transporting delicate or sensitive cargo on your carts or dollies, you need to reduce the vibration and shock from rolling across rough surfaces to protect that equipment. Depending on the size and nature of your application, there are a few ways to do this.

1. Soft / Cushioned Wheels

Your wheels are the first line of defense against rough terrain, because they are in direct contact with that terrain. There is a wide range of sizes and options to get more forgiving wheels. There are various forms of rubber, neoprene, and air-filled (pneumatic) wheels that can greatly reduce vibration by absorbing shock before it is transferred to your cart and equipment. One of our favorites here is the flat-free wheel, which performs (and appears) very similarly to a pneumatic wheel, but without the maintenance of having to be filled with air regularly. These 8″ x 2″ flat free wheels are super soft, while still maintaining durability:

2. Spring-Loaded Casters

There is a fairly large selection of spring-loaded casters to help absorb shock from both the floor/ground as well as from anything being dropped or placed on top of the cart or dolly. Most spring-loaded casters have additional “floating” legs that can pivot on the caster’s primary legs. These floating legs are attached to springs at one of their ends, and the caster wheel at the opposite end, with the pivot point located in between the two. Typically, this style of spring-loaded caster is geared more towards heavy duty applications such as shock sensitive carts, aircraft jacks, medical and computer equipment, and heavy duty toolboxes. The caster below has an 8″ x 2″ neoprene on aluminum wheel and is rated for 500 lbs.

3. Impact Resistant Casters

These casters are designed more to handle impact from the picking up and putting down of a cart itself, or for impact from dropping heavy equipment onto the top of a dolly or cart. They use a heavy duty kingpinless swivel frame that can handle more impact and abuse than a standard swivel caster frame. They also have a high-impact nylon wheel with oversized precision ball bearings to add to the impact-resistance of the caster, as well as increase overall weight capacity to 2,000 lbs in a 4″ x 2″ caster (shown below).

So as you can see, carefully selecting the right casters for your application can have a huge impact (pun intended) on performance and longevity of your equipment and your casters themselves. As always, we are here to help you make that selection, so give us a call at 1-800-325-2753, EMAIL US HERE, or stop by our Richmond, VA showroom.

0 notes

Text

Antimicrobial Casters and Wheels

With casters being used in all types of medical, food processing, and pharmaceutical applications, the need for them to stay clean and free of bacteria led to the development of Prevenz antimicrobial wheels.

Prevenz wheels are available in polyurethane, soft gray rubber, and nylon (pictured above). They are made with an antimicrobial compound that suppresses the growth of microbes including bacteria, molds, mildew, and fungi for the life of the wheel.

Prevenz is an integral part of each wheel, so it cannot be chipped off, or scratched off. It is an additive used in standard wheels. The image below shows a standard glass-filled nylon wheel (black) next to the Prevenz version of the same wheel (gray/blue).

While Prevenz wheels to fight the growth of microbes, they do not eliminate the need for cleaning of casters or wheels. Typically, these wheels are used with stainless steel caster components, but it all depends on the application and the user. The casters shown in the image at the beginning of this post are not stainless, but they do have an optional poly cam brake.

Prevenz is EPA registered and FDA compliant. The active ingredient has been used in hospitals for more than 30 years in a variety of products like soap and toothpaste.

If you think Prevenz wheels are the solution for your caster needs, give us a call at 1-800-325-2753 or EMAIL US to discuss available sizes, options, and specifications.

0 notes