#materialhandling

Explore tagged Tumblr posts

Text

Chain Sling - Lifting Chains | Kito - Lifting Equipment

The Grade 100 chain sling was developed by Kito Chain Italia's long experience and accumulated technology. A range of solutions for lifting with chains.

2 notes

·

View notes

Text

ACE F150 4WD NextGen Pick and Carry Crane,- the perfect machine for all your lifting needs! With a maximum capacity of 15 tons and a range of features, you can trust this machine to get the job done quickly, efficiently, and safely.

#ACE#ACECranesIndia#acef150#f150crane#f15#mobilecranes#crane#hydracrane#4wd#nextgenpickncarrycrane#acecranes#cranes#lifting#machines#faranacrane#farana#newgenerationcrane#15toncrane#heavylifting#materialhandling#pickandcarry#construction

2 notes

·

View notes

Text

Discover top-notch Forklifts from reliable manufacturers and suppliers in UAE at TradersFind. Whether you need to lift, move, or store, our verified companies offer the best solutions tailored to your needs. 📦✨

Connect with us on WhatsApp at +971 56 977 3623 to discuss your Forklift requirements.

Visit TradersFind today and connect with the right manufacturers and suppliers to elevate your operations. https://www.tradersfind.com/category/forklift

Forklifts In UAE

#forklift#forklifttrucks#materialhandling#warehouseequipment#uaebusiness#tradersfind#logistics#supplychain#heavymachinery#industrialequipment#businessgrowth#forkliftrental#forkliftsales#warehousesolutions#b2bmarketplace#equipmentsuppliers#businessnetworking#liftandmove#uaelogistics#connectandgrow

2 notes

·

View notes

Text

Onshore Toyo

Elevate your lifting game and experience pure power in your hands with Toyo's game-changing Wire Rope Winches.

Designed with YOU in mind, these winches redefine convenience, control, and confidence in every lift.

🔗 Your Power, Your Control: With Toyo Wire Rope Winches, you're in charge. Feel the thrill of controlling heavy loads with precision, making lifting tasks a breeze.

⚙️ Effortless Mastery: Wave goodbye to manual labor. Toyo Wire Rope Winches bring ease to every lifting operation, letting you conquer challenges with efficiency.

🔄 Versatile Performance: From construction to logistics, Toyo's winches adapt to your needs, ensuring every lift is a success story waiting to happen.

🚀 Elevate Your Potential: Boost your lifting potential with Toyo Wire Rope Winches. Minimize effort, maximize productivity, and see your goals reach new heights. Ready to embark on a lifting journey like never before? Experience the power and control of Toyo Wire Rope Winches.

Get in touch today: 👉 WhatsApp: wa. me/966544580607

📞 Call: +966 54 458 0607

📧 Email: [email protected]

💻 Website: lifting.onshoretechnical.com

👉 Like 👍 | Share 🔁 | Comment 💬 | Tag your lifting partners! 🏆🔧

#ToyoLifting#WireRopeWinch#CustomerCentric#ElevateYourLift#EfficiencyBoost#PrecisionControl#IndustrialInnovation#LiftingSolutions#WorkplaceProductivity#ReliableTools#Toyo#Wirerope#IndustrialEquipment#MaterialHandling#Lifting#Winching#HeavyDuty#Manufacturing#Efficiency#Productivity#WorkplaceSafety#Reliability#Durability#Quality#Engineering#Logistics

4 notes

·

View notes

Text

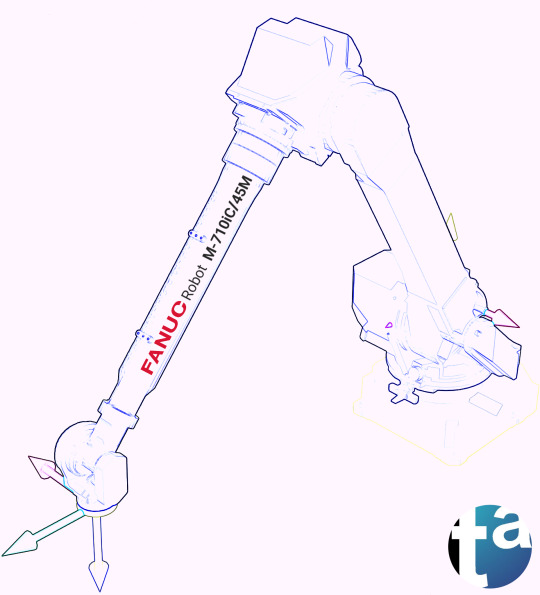

🦾 A007 - Palletizing Robot FANUC M-710iC/45M FanucAmerica Vision Reading QRCodes Automation Manipulator MaterialHandling Robotics ▸ TAEVision Engineering on Pinterest

Data A007 - Jul 17, 2023

#automation#robot#robotics#palletizing#FANUC#FanucAmerica#M-710iC/45M#FANUC M-710iC/45M#Vision Reading QRCodes#manipulator#MaterialHandling

5 notes

·

View notes

Text

Buy High-Quality Material Handling Equipments in Delhi | JOST JOST Delhi provides high-quality material handling equipment known for durability, efficiency, and performance—ideal for warehouses, factories, logistics, and industrial use. For More Info Contact Us: ☎️ 9910895454 ✉️ [email protected] 🌐 https://jostdelhi.com

0 notes

Text

Discover JK Industries’ robust Double Flange Vibratory Motors, engineered with dual flanges for maximum stability, enhanced torque, and minimized wear. Ideal for high-demand industrial uses such as screening, conveying, compaction, and vibratory feeding systems. These motors offer precise vibration control, energy efficiency, and low maintenance, making them a top choice across mining, construction, agriculture, food processing, pharmaceuticals, cement, and recycling industries. Built to international standards and customizable to your specific needs, JK Industries delivers reliable performance and global support. Boost your material-handling systems with our trusted double-flange solutions.

#DoubleFlangeVibratoryMotor#VibratoryMotorIndia#IndustrialVibrators#MaterialHandling#ScreeningEquipment#ConveyingSolutions#EnergyEfficientMotors#LowMaintenance#MiningMachinery#ConstructionEquipment#FoodProcessingMachinery#PharmaEquipment#MadeInIndia#JKIndustries

0 notes

Text

Composite Roller Market Trends Highlight Sustainability Needs in Material Handling and Conveyor Applications

The composite roller market has emerged as a dynamic and rapidly expanding segment within the broader industrial components industry. As global manufacturing, mining, and logistics sectors strive for higher efficiency, safety, and sustainability, composite rollers have gained significant traction due to their lightweight construction, corrosion resistance, and enhanced durability compared to traditional steel or aluminum rollers.

Composite rollers are primarily used in conveyor systems across various industries such as mining, pulp & paper, food processing, packaging, logistics, and automotive. Their composition typically includes reinforced materials like fiberglass or carbon fiber embedded in a resin matrix, offering exceptional strength-to-weight ratios and longer service life under harsh working conditions.

Market Drivers and Opportunities

Several key factors are driving the growth of the composite roller market:

Industrial Automation and Efficiency Demands: The global push toward smart manufacturing and automation has increased the demand for conveyor systems that offer reduced downtime and improved energy efficiency. Composite rollers, being lighter, reduce power consumption and minimize strain on conveyor systems.

Rise in Mining and Bulk Material Handling: In mining, durability and resistance to extreme conditions are crucial. Composite rollers are ideal for dusty, corrosive, and high-load environments, making them an attractive choice for mining operations worldwide.

Environmental and Regulatory Pressures: Many industries are under pressure to adopt eco-friendly and sustainable materials. Composite rollers, due to their corrosion resistance and minimal maintenance requirements, support green manufacturing initiatives by reducing replacement frequency and waste generation.

Growth in E-commerce and Logistics: The exponential rise in e-commerce has fueled the development of large-scale distribution centers that rely heavily on high-speed conveyor systems. Composite rollers help maintain smooth operations while reducing maintenance costs and energy consumption.

Technological Advancements: Innovations in composite material science have resulted in rollers that are more impact-resistant, quieter in operation, and capable of withstanding higher loads. The integration of sensors and IoT capabilities for real-time condition monitoring is also emerging as a trend in smart conveyor systems.

Regional Insights

North America holds a significant share due to established mining and manufacturing infrastructure, coupled with strong demand for advanced automation.

Europe emphasizes sustainability and efficient logistics, driving adoption in industries like packaging, food & beverage, and warehousing.

Asia-Pacific, led by China, India, and Southeast Asian countries, is witnessing the fastest growth. Expanding industrial bases, rising investments in infrastructure, and increasing mining activities contribute to this surge.

Middle East and Africa are also seeing growth due to ongoing mining projects and improvements in industrial logistics.

Competitive Landscape

The composite roller market is moderately fragmented, with key players focusing on technological innovations and strategic partnerships to gain a competitive edge. Companies such as Lorbrand Composites, Sandvik AB, NEPEAN Conveyors, and CPS Conveyors are leading manufacturers offering specialized solutions tailored to various industrial needs.

Product differentiation is mainly based on factors like load capacity, lifespan, weight, noise reduction, and resistance to environmental stress. Additionally, manufacturers are investing in R&D to develop smart rollers integrated with sensors for predictive maintenance and performance monitoring.

Challenges in the Market

Despite its many advantages, the composite roller market faces certain challenges:

High Initial Cost: Composite rollers can be more expensive than traditional metal rollers, which may discourage smaller enterprises from adopting them, despite long-term cost savings.

Limited Awareness and Availability: In some regions, lack of awareness about the benefits and limited supplier presence pose obstacles to market penetration.

Customization Needs: Different industries require specific designs and load-bearing capacities, which may increase production complexity and lead times.

Future Outlook

The composite roller market is expected to continue its upward trajectory in the coming years. As industries worldwide focus more on sustainability, operational efficiency, and automation, the demand for high-performance conveyor components like composite rollers will only grow stronger.

With continued advancements in materials engineering, the development of more cost-effective manufacturing techniques, and the rising adoption of Industry 4.0 practices, the composite roller market is well-positioned for substantial global expansion. Companies that can offer innovative, durable, and intelligent roller solutions will be the key drivers of this transformation.

0 notes

Text

💧➡️ Moving Forward: The Rise of Dewatering Conveyors in Industry

Efficiency meets flow in the evolving world of dewatering conveyors—critical machinery that powers cleaner, faster, and more sustainable material handling across industries.

📊 Market Snapshot

2024: USD 0.33 billion

2025: USD 0.34 billion

2033 (Projected): USD 0.38 billion

CAGR (2025–2033): 📉 1.6% steady, smart growth

⚙️ By Type:

Automatic: Fully integrated systems for continuous, high-volume dewatering

Semi-Automatic: Flexible options for controlled, semi-manual operations

🏭 By Application:

Mining: For separation of solids and liquids in mineral processing

Food Industry: Hygienic, efficient moisture removal from produce or packaged goods

Industrial: Vital in wastewater treatment, sludge handling, and by-product recovery

Others: Custom-fit for chemical, pharma, and agriculture operations

🌍 Key Players Driving Innovation:

Jwala Engineering (India)

Cox and Plant Ltd. (U.K)

Accelor Food Tech Pvt Ltd (India)

Brain Industries (Australia)

Driver Southall, Syspal, CABE Engineering (U.K)

FoodeQ Engineering, Sormac (Netherlands)

Fenner Conveyors (India)

🔧 Why It Matters: In a world focused on cleaner production and resource optimization, dewatering conveyors offer: ✅ Reduced waste volume ✅ Enhanced product quality ✅ Streamlined processing

This tech isn’t just part of the system—it is the system driving sustainability and throughput in industrial workflows.

🔗 Dive deeper into the market: Full Report Here

#IndustrialMachinery#FoodProcessingTech#MiningEquipment#DewateringSolutions#EngineeringInnovation#CleanTech#MaterialHandling#SmartManufacturing#ConveyorSystems#IndustrialDesign#TumblrIndustry#Automation#SustainableEngineering#DewateringConveyorMarket

1 note

·

View note

Text

Move Bulk Materials with EXAIR’s Line Vac Conveyors

EXAIR’s Line Vac Air Operated Conveyors provide in-line material handling using compressed air—ideal for transporting large volumes over long distances. With no moving parts or electricity required, Line Vac is a durable solution for industrial conveying. Available in a variety of sizes and materials to suit different applications.

0 notes

Text

Effortlessly streamline your material handling with our Big Bag Unloading System! Fast, safe, and dust-free unloading for improved efficiency in your operations. Upgrade today for smoother workflow!

For more details, visit - https://www.acmeairequipments.com/product/big-bag-unloading-system/

#acmeairequipments#BigBagUnloading#MaterialHandling#BulkMaterial#IndustrialSolutions#Efficiency#Automation

0 notes

Text

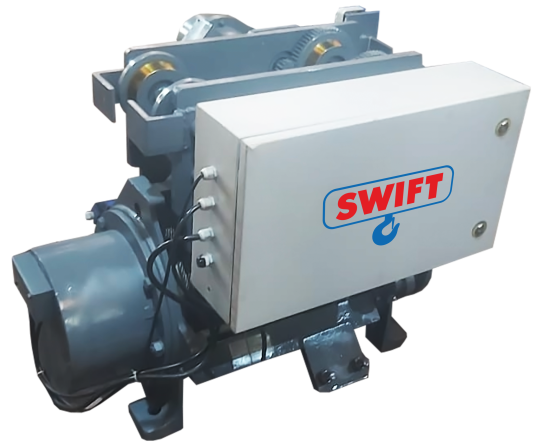

Wire Rope Hoist – Consolidated Swift Industries Limited

Consolidated Swift Industries Limited offers reliable wire rope hoists with capacities ranging from 0.25 to 40 tons and lift heights up to 75 meters. Designed for diverse industrial needs, these hoists feature compact designs, high-torque induction motors, and advanced control panels with overload protection, ensuring efficient and safe material handling.

#wireropehoist#heavylifting#safehoisting#factoryequipment#workshopequipment#constructionsitehoist#materialhandling#industrialhoist#durablehoist#liftingequipment

0 notes

Text

We're thrilled to report that our 8-ton fixed dock leveler will be delivered on schedule to our client in the Philippines. Our team works tirelessly to ensure everything is in place, and the customer’s expectations are fully met. Thank you for trusting us with your project!

Email: [email protected] WhatsApp: 186 1563 3168

#dockleveler#loadingdock#industrialequipment#warehouseequipment#hydraulicdockleveler#docksolutions#logistics#materialhandling#warehouselogistics#loadingandunloading#heavyloadhandling#docklevellers#FixedDockLeveler#8TonDockLeveler#CustomizedSolutions#LoadingUnloading#lglift

0 notes

Text

🚨 Tired of Belt Failures Slowing You Down? 🚨

Upgrade to Premium Conveyor Belt Solutions that deliver unmatched durability, performance, and reliability!

🔧 Our Top-Quality Products:

✅ Bucket Elevator Belts

✅ Heavy Duty Conveyor Belts

✅ Rubber Conveyor Belts

✅ EP Conveyor Belts

✅ Heat Resistant Conveyor Belts

Whether you're in mining, manufacturing, or logistics — we’ve got the perfect belt for your toughest demands! 💪

📩 DM us now or call to get a free consultation!

#ConveyorBelt#IndustrialSolutions#BucketElevatorBelt#RubberConveyorBelt#HeavyDutyBelt#HeatResistantBelt#MaterialHandling#EngineeringSolutions#ManufacturingSupport#MiningEquipment

0 notes

Text

Reliable Chain Pulley Blocks for Efficient Lifting Operations

Chain Pulley Blocks are manual lifting devices designed for heavy-duty applications. With capacities up to 100 tons, they feature multiple sheaves for smooth operation and are equipped with overload protection for safety. Ideal for construction, warehousing, and automotive industries, these pulley blocks offer portability and ease of use, ensuring reliable performance in various lifting tasks.

#ChainPulleyBlock#LiftingEquipment#HeavyDutyLifting#MaterialHandling#RiggingSupplies#WarehouseSolutions#IndustrialEquipment#ConstructionTools#PulleySystem#SafetyFirst#LoadHandling#WorkSmart#Efficiency#LiftRight#ConstructionLife#Hoisting#Mechanics#ToolTips#EquipmentReview#WorkplaceSafety

0 notes

Text

TAEVision 3D Mechanical Design MaterialHandling ForkLift Trucks ATLAS TOYOTA Toyota-Lift of Minnesota @ToyotaEquipment Toyota ▸ TAEVision Engineering on Pinterest ▸ TAEVision Engineering on Google Photos

Data 037 - Jul 16, 2023

#TAEVision#engineering#3d#mechanicaldesign#MaterialHandling#forklift#trucks#ATLAS TOYOTA#TOYOTA#Toyota-Lift of Minnesota#ToyotaEquipment

2 notes

·

View notes