Easteel Hard Ware Co., Ltd. is a professional Metal & Plastic fittings manufactuer in Hangzhou, Zhejiang, China.

Don't wanna be here? Send us removal request.

Text

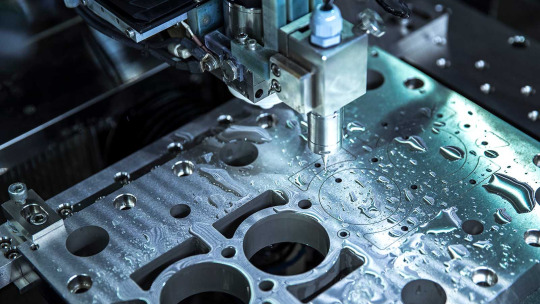

Aluminum Die Casting: Precision Manufacturing for Durable Parts

Aluminum die casting is a versatile manufacturing process used to create intricate and durable metal parts with high precision. This method is widely favored in various industries, including automotive, aerospace, electronics, and consumer goods, for its ability to produce complex shapes with excellent dimensional accuracy and surface finish.

Process Overview

The Aluminum Die casting process involves several key steps:

Tooling Design: The process begins with designing molds, also known as dies, that are typically made from hardened steel. These molds are customized to the specific geometry and features of the part to be produced.

Melting and Injection: Aluminum alloys, such as ADC12 or A380, are melted in a furnace at high temperatures. The molten metal is then injected into the die cavity at high pressure using a hydraulic or mechanical press. This pressure ensures that the metal fills the entire cavity and solidifies quickly.

Cooling and Ejection: Once the metal solidifies, the die is opened, and the casting is ejected. The rapid cooling process within the die helps to achieve precise dimensional control and minimizes internal defects.

Trimming and Finishing: Excess material, such as flash or gate remnants, is removed from the casting through trimming. Additional finishing processes, such as machining, polishing, or surface treatments like powder coating or anodizing, may be applied to achieve the desired final surface quality and appearance.

Advantages of Aluminum Die Casting

Complex Geometry: Die casting allows for the production of parts with intricate shapes and thin walls that are difficult or impossible to achieve with other manufacturing methods.

High Precision: Offers tight tolerances and excellent dimensional stability, ensuring consistency in part dimensions and specifications.

Strength and Durability: Aluminum die castings exhibit high mechanical properties, including strength and stiffness, making them suitable for applications requiring structural integrity and reliability.

Cost Efficiency: The ability to produce large quantities of parts quickly and efficiently reduces per-unit costs compared to machining or fabrication processes.

Applications

Aluminum die casting finds extensive applications across industries:

Automotive: Engine components, transmission housings, and structural parts.

Electronics: Enclosures, heatsinks, and components for electronic devices.

Consumer Goods: Household appliances, power tools, and decorative hardware.

Conclusion

Aluminum die casting China is a versatile and efficient manufacturing process that meets the stringent requirements of modern industrial applications. By leveraging its capabilities to produce complex parts with high precision and durability, manufacturers can achieve cost-effective solutions for a wide range of products. Understanding the advantages and applications of aluminum die casting underscores its importance in the production of reliable and high-performance components across diverse industries.

1 note

·

View note

Text

The Importance of Choosing the Right Plastic Fittings Manufacturer

Choosing a reliable plastic fittings manufacturer is crucial for ensuring the quality, performance, and reliability of plastic fittings used in various industries. Plastic fittings play a critical role in plumbing, HVAC systems, automotive applications, and more, providing essential connections and sealing solutions. Here are key considerations when selecting a plastic fittings manufacturer:

Quality and Standards

A reputable manufacturer adheres to stringent quality control measures and industry standards. Look for certifications such as ISO 9001, which ensure that manufacturing processes meet international quality management standards. High-quality plastic fittings are durable, resistant to corrosion and chemicals, and maintain tight seals over extended periods.

Material Selection

Different applications require specific materials with suitable properties such as temperature resistance, chemical compatibility, and mechanical strength. A reliable manufacturer offers a variety of materials like PVC, CPVC, polypropylene, and PEX, ensuring compatibility with diverse operational environments and fluid types.

Customization Capabilities

The ability to customize plastic fittings to meet unique specifications is essential for many industries. Whether it's specific dimensions, thread types, or color coding, a manufacturer capable of accommodating custom orders ensures fittings integrate seamlessly into existing systems and meet project requirements effectively.

Technical Expertise and Support

Choose a plastic fittings manufacturer China with a knowledgeable technical support team that can guide material selection, design considerations, and installation techniques. Reliable customer support ensures the smooth integration of plastic fittings into your applications and resolves any issues promptly.

Cost and Value

While cost is a factor, prioritize value over price alone. Consider factors such as product quality, customization options, technical support, and overall reliability when evaluating the total cost of ownership. Investing in high-quality plastic fittings reduces maintenance costs, downtime, and potential risks associated with substandard components.

Industry Experience and Reputation

An established manufacturer with years of experience in producing plastic fittings for diverse industries demonstrates reliability and expertise. Research customer reviews, case studies, and industry certifications to gauge the manufacturer's reputation and track record in delivering quality products and excellent service.

Environmental Considerations

Ensure the manufacturer adheres to environmental regulations and practices sustainable manufacturing processes. Choosing eco-friendly materials and production methods reflects a commitment to environmental stewardship and reduces the environmental impact of your operations.

Conclusion

Selecting the right plastic fittings China is essential for ensuring the functionality, reliability, and longevity of plumbing, HVAC, and other systems that rely on plastic fittings. By considering factors such as quality standards, material selection, customization capabilities, technical support, and overall reputation, you can make an informed decision that meets your specific project requirements and contributes to the success of your operations. Partnering with a trusted manufacturer ensures that your plastic fittings perform optimally in diverse applications, enhancing efficiency and minimizing risks associated with inferior components.

1 note

·

View note

Text

Exploring Blow Molding: A Key Process in Plastic Manufacturing

Blow molding manufacturer process used to produce hollow plastic parts and containers. It is widely utilized in various industries, including packaging, automotive, aerospace, and consumer goods. This process allows for the efficient and cost-effective production of plastic products with intricate shapes and designs. Process Overview Blow molding typically involves three main steps: Extrusion:…

#Blow Molding Manufacturer#Blow Molding Manufacturer China#Blow Molding Supplier#Plastic Blow Moulding#Plastic Blow Moulding China

0 notes

Text

The Plastic Injection Molding Basics

The plastic injection molding process begins with generating the product design, followed by tooling a mold to fit the product design, melting the plastic resin pellets, and injecting the molten pellets into the mold using pressure.

Steps

Designing the Product

Designers build a part using fundamental design rules related to the injection molding method.

Create a Tooling Mold to Fit the Product Design

Highly trained machinists and toolmakers use the product design to create a tooling mold for the injection molding machine. A tooling mold, also known as a tool, is the heart and soul of an injection molding machine. They are meticulously built to house the negative cavity for the product design as well as extra features including sprues, runners, gates, vents, ejector systems, cooling channels, and moving components. Tooling molds are constructed from steel and aluminum grades that can survive tens of thousands of heating and cooling cycles. Mold manufacturing can take up to 20 weeks to complete, including fabrication and approval, making it the most time-consuming phase of injection molding. It is also the most expensive component of Plastic Injection Process, and once created, a tooling mold cannot be significantly altered without incurring additional expenditures.

Melt the plastic resin pellets

After obtaining the final mold, operators place it into the injection molding machine, which shuts and begins the injection molding cycle. Plastic pellets are put into both the hopper and the barrel. The reciprocating screw is dragged back, allowing materials to pass through the area between the screw and the barrel. The screw then plunges forward, pushing the material deeper down the barrel and closer to the heater bands, where it melts into molten plastic. The melting temperature is maintained at the material requirements so that no deterioration happens in the barrel or the mold itself.

Using pressure to feed the molten pellets into the mould

The reciprocating screw pushes the molten plastic through the nozzle, which is in a depression in the mold called a mold sprue bushing. The moving platen pressure compresses the mold and nozzle firmly, preventing any plastic from escaping. This Plastic Injection technique pressurizes the melted plastic, allowing it to enter all sections of the mold cavity while displacing cavity air through the mold vents.

#Plastic Injection Molding#Plastic Injection Process#Plastic Injection Process China#Plastic Injection

1 note

·

View note

Text

Know About The Sheet Metal Stamping

This is a brief and straightforward primer for novices to the world of sheet metal stamping. Discover how the process works, what services are included, and how manufacturers conduct it to provide a fully tailored solution. Sheet metal stamping is the process of transforming flat metal sheets into particular forms. Stamping sheet metal is a procedure that uses permanent deformation by cold…

View On WordPress

1 note

·

View note

Text

Here are some general steps to help you find a Vacuum Forming

Vacuum forming is a manufacturing process where a heated sheet of plastic is stretched onto a mold and then vacuumed tightly around it to form a specific shape. Here’s a step-by-step overview: Sheet Heating: A flat sheet of thermoplastic material, typically made of materials like ABS, polystyrene, or acrylic, is clamped into a frame or holder. The sheet is then heated until it becomes soft and…

View On WordPress

#Vacuum Forming#vacuum forming manufacturer#vacuum forming manufacturer China#Vacuum Forming Process

1 note

·

View note

Text

When Is The Investment Casting Employed?

A wax pattern is used in the industrial process of Investment casting China, sometimes referred to as precision casting or lost-wax casting, to create a disposable ceramic mold. The exact shape of the object to be cast is captured in a wax pattern. A ceramic substance that is refractory is applied to this design. After the ceramic material solidifies, it is heated and flipped upside down until the wax melts and runs out. The ceramic shell hardens into a disposable investment mold. The mold is filled with molten metal, which is then allowed to cool. After that, the metal casting is broken out of the used mold.

When to employ investment casting

Investment casting is a rather expensive technique because of its labor needs and intricacy, but the advantages frequently exceed the drawbacks. Almost any metal may be cast for an investment.

Excellent as-cast surface finishes may be achieved in complicated items produced by investment casting. Since the ceramic shells of investment castings break away from the part when it cools, a taper does not need to be incorporated to extract the components from their molds. With the use of this manufacturing feature, castings with 90-degree angles may be created without any shrinkage allowance and without the need for further machining to achieve such angles.

Parts made using the investment casting technique by Investment casting Supplier have excellent dimensional precision, are readily net-shaped, and are frequently produced without the need for further machining. To create wax patterns, a new die is needed for every distinct casting run.

The time and effort saved by reducing or eliminating secondary machining more than offsets the expense of new tools for high-volume orders. Lesser casting runs will probably not pay for itself.

A new wax pattern to a finished casting typically takes seven days, most of which is spent making and curing the ceramic shell mold. To make castings more rapid, certain foundries can quick-dry. Cost is not the only factor affected by investment casting's time- and labor-intensive process. Longer lead times for the investment casting process are typical at foundries because of their restricted production capacity and equipment.

More Information: Mastering the Art of Investment Casting: A Deep Dive into the Process

#Investment casting Supplier#Investment casting manufacturer China#Investment casting manufacturer#Investment casting China

2 notes

·

View notes

Text

Know About The CNC Machining In Details

Computer numerical control, or CNC, machines are becoming essential components of the manufacturing and production sectors, found in anything from small workshops to massive industrial complexes. The term numerical control was all that was used to describe CNC machining back then. This was an earlier system without computers that could be programmed. CNC, which stands for “computer numerical…

View On WordPress

1 note

·

View note

Text

Know About the Working of Die Casting

Melting metal and then pumping it into a mold is a technique called die casting that makes metal pieces. Everything you need to know about the advantages of die-casting is covered in this article.Die Casting China is a standard metal casting process that produces robust, long-lasting parts for a variety of applications. If your organization is looking for a manufacturing process that can produce…

View On WordPress

1 note

·

View note

Text

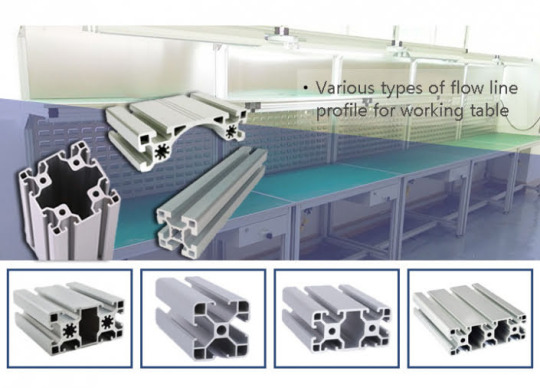

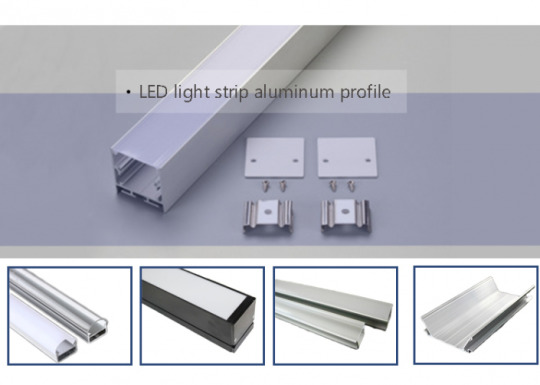

Discovering the Aluminum Profiles Versatility

Aluminum billets are heated and forced through a die's curved aperture to create an Aluminum profile, often referred to as aluminum extrusions, which have consistent cross-sectional geometries. It is possible to create complex designs with exact proportions using this approach. These profiles are appropriate for a variety of applications as they may be made in an extensive array of sizes, forms, and finishes.

Utilization of Aluminum Profiles

Building: A lot of aluminum profiles are utilized in buildings for curtain walls, windows, doors, frame systems, and structural elements. They are perfect for architectural projects because of their lightweight design, resistance to corrosion, and tolerance to extreme weather conditions.

Automobile: Aluminum profiles are used in engine components, heat exchangers, body frames, and chassis constructions in the automobile sector. Their excellent strength-to-weight ratio contributes to improved performance, increased fuel economy, and weight reduction of the vehicle.

Electronics: Aluminum profile China dissipates heat produced by electronic components by acting as heat sinks in electronic equipment. Because of its superior thermal conductivity, heat is dissipated effectively, minimizing overheating and prolonging the life of electronic equipment.

Aluminum profiles are used in aerospace applications for fuselage panels, interior parts, and aircraft structures. Aluminum is a desirable material in aircraft manufacture because of its lightweight characteristics, which also allow for increased cargo capacity and fuel savings.

Industrial Machinery: Conveyor systems, assembly lines, robotic equipment, and other pieces of machinery are made using aluminum profiles. Their adaptability enables machine frames and structural supports to be tailored to individual needs.

Aluminum Profile Benefits

Lightweight: Compared to steel or other metals, aluminum profiles are lighter due to their excellent strength-to-weight ratio. This feature lowers total costs by streamlining the handling, installation, and shipping procedures.

Corrosion Resistance: Due to its inherent corrosion resistance, aluminum can endure exposure to air, moisture, and chemicals. This characteristic guarantees resilience and endurance in many settings.

Formability: Aluminum profiles are easily extruded into intricate combinations and forms, enabling accurate measurements and bespoke designs. This formability makes applications across several sectors more versatile.

Aesthetic Appeal: Anodizing, powder coating, painting, and other surface treatments by Aluminum profile Manufacturer can be applied to aluminum profiles to improve their look and offer more resistance to wear and corrosion.

#Aluminum profile Manufacturer#Aluminum profile Company China#Aluminum profile Company#Aluminum profile Process#Aluminum profile China#Aluminum profile

2 notes

·

View notes

Text

Lost Wax Casting: A Timeless Craft in Modern Context

Within the realm of handicrafts, some methods have withstood the test of time, maintaining their significance and elegance for decades. Among these, Lost wax casting is a technique that is highly valued for its complexity and adaptability and has a long history. This age-old method, which dates back thousands of years, still fascinates artists and fans by providing a window into the harmonious union of science and art.

The Method

Fundamentally, lost wax casting is an exacting procedure that starts with the construction of an intricate wax model, which can be created by hand or with the use of contemporary equipment like 3D printers. This wax model, which is covered in a heat-resistant substance like ceramic or plaster, functions as the prototype for the finished product.

After the mold is ready, it is carefully heated to remove the wax and leave behind a chamber that closely resembles the shape of the original model. The hollow left by the wax is subsequently filled with molten metal, usually silver or bronze but occasionally gold or other alloys. The Lost wax casting and Zamak die casting are in demand.

Talent and Adaptability

The art of lost wax casting is praised for its unmatched accuracy in capturing minute details. The method gives designers and artists the flexibility to realize their ideas in three dimensions, whether they are for intricate jewelry or massive sculptures.

Lost wax casting is a technique used in sculpting and art that allows artists to create physical representations of their ideas while conserving the subtleties of their work for future generations. From the first shaping to the last polishing, every stage of the process calls for dexterity, patience, and a thorough grasp of the materials.

Modern Applications and Innovations

Although lost wax casting has its roots in history, it is still evolving thanks to cutting-edge methods and modern technology. Technological developments in materials, including 3D-printed wax models, have simplified the procedure and increased its potential.

Lost wax casting is essential to the creation of intricate parts and prostheses in sectors like aerospace and dentistry where accuracy and dependability are critical. It's a favored process for producing high-quality, bespoke parts in Metal Assembly since it can build complex forms with little material waste.

3 notes

·

View notes

Text

Selecting the Right Material among Metal vs. Plastic Fittings for Your Needs

The selection between plastic and metal fittings from Metal fittings manufacturer is vital in the fields of manufacturing, plumbing, and building. Both materials have special benefits and drawbacks, so knowing how they differ from one another is crucial to choosing wisely. Fittings Made of Metal: Power and Sturdiness Strength: Because of its well-known strength, metal fittings are appropriate…

View On WordPress

#Metal fittings manufacturer China#Metal Manufacturer China#Plastic Fittings China#Professional Metal Manufacturer

1 note

·

View note

Text

Know About The Potential of Plastic Extrusion Process

A manufacturing technique called plastic extrusion is used to make products with a predetermined cross-sectional profile. To form molten plastic into a continuous profile that can be cut to specified lengths, it is pushed through a die. Numerous items may be produced with this technique, ranging from straightforward pipes and tubes to intricate profiles utilized in packaging, automotive, construction, and other industries.

Flexibility in Utilization

Building: Plastic extrusion plays a key role in the building sector by creating pipes, profiles, and other parts that go into drainage systems, windows, doors, roofing, and plumbing. For example, extrusion is frequently used in the manufacturing of PVC and HDPE pipes because of its robustness and resistance to corrosion.

Consumer Products: The production of toys, furniture, and home appliances has benefited from the usage of the Plastic Extrusion Process. Custom profiles and complex designs may be produced with this technology, meeting the practical and aesthetic needs of many items.

Medical: Tubing, catheters, and other medical equipment are produced in the medical industry via plastic extrusion. The capacity to produce accurate, sterile parts guarantees adherence to strict legal requirements while satisfying the needs of medical practitioners and patients.

Benefits of Plastic Extrusion:

Cost-Effectiveness: Plastic extrusion provides affordable options for producing a variety of goods. Compared to alternative approaches, the process lowers material waste and needs less expensive tooling, making it a financially feasible option for large-scale manufacturing.

Design Flexibility: Manufacturers may design unique profiles and forms using plastic extrusion to satisfy certain specifications. In markets with intense competition, this flexibility promotes innovation and product differentiation.

Efficiency: The production of consistent profiles in continuous lengths with little downtime is possible through the very efficient process of plastic extrusion. This efficacy adds to overall operational effectiveness by translating into increased production and quicker turnaround times.

Material Versatility: PVC, HDPE, LDPE, PP, and ABS are just a few of the thermoplastic materials that may be used with plastic extrusion. Because of its adaptability, plastic extrusion manufacturer may choose the material that best suits their needs by weighing characteristics like strength, flexibility, and chemical resistance.

2 notes

·

View notes

Text

Plastic Injection: A Fascinating Innovation In Manufacturing

Few methods have transformed the complex world of manufacturing as drastically as plastic injection molding. Plastic injection molding influences everything from the biggest automobile parts to the smallest technological components in ways we might not even be aware of. Come along on an engrossing journey into the depths of this intriguing process as we reveal its uses, applications, and effects…

View On WordPress

#Custom Plastic Injection Molding#Plastic Injection#Plastic Injection Molding#Plastic Injection Process#Plastic Injection Process China

2 notes

·

View notes

Text

The Science and Art of Metal Component Stamping

Fundamentally, metal component stamping is the process of utilizing specialized equipment and tools to shape and mold flat metal sheets into a variety of forms. Usually, the process starts with a design that is converted into a tool or dies. The metal is then forced into the appropriate shape using these dies in stamping presses. Methods and Procedures Metal stamping is a broad term that…

View On WordPress

2 notes

·

View notes

Text

Using the Potential of CNC Machining

In the constantly changing field of product development, efficiency, accuracy, and innovation are always sought after. CNC Prototype Machining is the core of this endeavor; this revolutionary technology has completely changed the way prototypes are imagined, created, and executed.

Redefining Precision: The Advantage of CNC

The unmatched accuracy of CNC prototype machining is its foundation. CNC machines are outfitted with the newest technology and are directed by exact CAD/CAM instructions to do jobs with minuscule accuracy. With CNC machining, every detail is painstakingly and precisely carved, whether it be for drilling precise holes or sculpting complex designs.

Innovation Acceleration: Accelerating the Development Cycle

Speed is crucial in the fast-paced environment we live in today. The days of protracted production schedules and never-ending revisions are over thanks to CNC prototype machining. CNC machines help engineers and designers to iterate quickly and bring things to market more quickly than ever before by optimizing the prototype process. This shortened development cycle encourages innovation and experimentation while simultaneously shortening time-to-market.

Unleashing Versatility: From Idea to Actuality

The adaptability of prototype CNC Machining China is among its most impressive features. CNC machines can easily mold a wide range of materials into working prototypes, whether they are made of metal, plastic, wood, or composite materials. The options are endless, ranging from sophisticated consumer electronics to delicate aircraft components.

Filling the Void: From Concept to Manufacturing

In addition to prototypes, CNC machining is essential for bridging the gap between production and design. CNC machines facilitate the process of moving from concept to mass manufacture by producing parts that are ready for production and of superior quality. Prototypes are guaranteed to be workable solutions prepared for practical implementation, not only functional mock-ups thanks to this smooth connection.

Promoting Innovation in All Sectors

Prototype CNC Machining has a significant influence that goes much beyond the boundaries of a particular sector. CNC machines are pushing innovation across a wide variety of sectors, from consumer products and medical devices to aerospace and automobiles. The future of manufacturing is being shaped by CNC prototype machining, which is at the forefront of innovations such as supply chain revolutions, improved product performance, and the ability to enable new design patterns.

#CNC Machining#CNC Machining process#CNC Machining process China#CNC Machining Techniques#CNC Prototype Machining#CNC Prototype Machining China#CNC Machining China

2 notes

·

View notes

Text

Exploring the Aluminum Profile Processing Intricacies

Aluminum profile is unique among components used in modern production because of their versatility and necessary nature. Applications for these extruded forms may be found in a wide range of sectors, including consumer products, electronics, automotive, and construction. A thorough grasp of material qualities, technical innovation, and precise engineering are all required in the exciting process of creating aluminum profiles.

Aluminum Profiles Significance

Because of their many benefits, aluminum profiles are the material of choice for a wide range of applications:

Lightweight

Power and Sturdiness

The corrosion free

Flexibility

The Procedure for Processing Aluminum Profiles

Design and Development of Die: Engineers develop the ideal profile form and proportions during the process's first design step. A unique die, or mold, is made after the design is complete in order to extrude the metal into the required shape.

Heating the billet: To prepare it for extrusion, aluminum billets, which are usually formed from primary or recycled aluminum, are heated to a particular temperature. In order to guarantee consistency and malleability, this preheating phase is critical.

Extrusion: Using mechanical or hydraulic pressure, the heated aluminum billet is pushed through a specifically made die. The metal takes on the shape of the profile as it goes through the die and emerges as a continuous length of extruded aluminum.

Quenching and Cooling: To maintain its shape and characteristics, the extruded aluminum profile is quickly cooled with either water or air. In order to achieve the appropriate mechanical characteristics and avoid distortion, this quenching procedure is essential.

Cutting and Finishing: Using precision saws or shears, the extruded aluminum profile is trimmed to the necessary lengths once it has cooled. The profile may also be modified by using additional machining techniques like punching, drilling, or milling to add holes or features. Lastly, surface treatments like powder coating or anodizing can be used to improve corrosion resistance and appearance.

Quality Control: Strict quality control procedures are followed during the whole Aluminum profile Process to guarantee that the final aluminum profiles have the required mechanical qualities, surface polish, and tolerances. To find any flaws or irregularities, this may entail visual inspections, mechanical testing, and dimensional inspections.

#Aluminum profile#Aluminum profile China#Aluminum profile Process#Aluminum profile Company#Aluminum profile Company China#Aluminum profile Manufacturer#Aluminum profile supplier

2 notes

·

View notes