Don't wanna be here? Send us removal request.

Text

The Role of Heat and Humidity in Concrete Curing: A SmartSet Approach

Concrete curing is a crucial process that directly affects the strength, durability and overall quality of concrete products. The key factors influencing curing are heat and humidity, which regulate the hydration of cement. Inadequate curing conditions can lead to weaker concrete, cracks and long-term performance issues.

The SmartSet Curing Systems offer an advanced approach to optimizing heat and humidity for concrete curing. By maintaining controlled curing environments, SmartSet Curing Systemensure consistent hydration, efficient energy use and superior product quality. This article explores the role of heat and humidity in concrete curing and how SmartSet Curing Systems revolutionize the process with precision and automation.

Role of Heat in Concrete Curing with SmartSet Approach

Importance of Heat in Cement Hydration

Cement hydration is a chemical reaction that binds particles together to form a strong and durable structure. Heat accelerates this process, but excessive or uncontrolled temperatures can weaken the final product.

Optimal Temperature Range: Concrete requires a controlled temperature range to cure properly. Typically, curing temperatures between 10°C and 29.4°C (50°F and 85°F) allow proper hydration without causing thermal cracking.

Acceleration of Strength Gain: Higher temperatures speed up the hydration reaction, allowing concrete to gain strength faster.

Risk of Thermal Cracking: If heat levels fluctuate or exceed recommended limits, internal stresses can develop, leading to cracks.

Heat Management in SmartSet Curing Systems

SmartSet Curing Systems use direct-fired steam generators to provide a consistent and controlled heat environment.

Automated temperature adjustments ensure that concrete receives optimal heat without manual intervention.

Dynamic firing rate control maintains uniform heat distribution, preventing localized overheating or under-curing.

Kiln control systems enhance precision, keeping the temperature stable throughout the curing process.

By leveraging these technologies, SmartSet Curing Systems provide an efficient and reliable way to manage heat during concrete curing.

The Role of Humidity in Concrete Curing : A SmartSet Approach

Why Humidity Matters in Concrete Strength Development?

Humidity is another crucial factor in curing. Without sufficient moisture, cement hydration slows down, leading to weaker concrete.

Prevention of Moisture Loss: Evaporation can cause drying shrinkage, leading to surface cracks and poor bonding.

Uniform Hydration: A high-humidity environment allows cement particles to react fully with water, ensuring consistent strength development.

Reduction in Internal Stresses: Maintaining the correct humidity levels prevents uneven expansion and contraction, which can weaken the structure.

Humidity Control in SmartSet Curing Systems

The SmartSet Curing Systems incorporate advanced humidity control mechanisms to prevent rapid moisture loss and maintain optimal curing conditions.

Automated misting systems ensure a constant supply of moisture to prevent early drying.

Precise steam injection regulates humidity, allowing concrete to cure without cracking or shrinkage.

Advanced kiln control systems maintain the perfect balance between temperature and humidity, ensuring ideal curing conditions.

By integrating these features, SmartSet Curing Systems provide a controlled curing environment that enhances the structural integrity and durability of concrete products.

SmartSet Automated Approach to Concrete Curing

Advanced Combustion and Water Control Technology

One of the standout features of the SmartSet Curing Systems is their ability to automatically adjust to environmental and production changes.

Combustion-engineered burners maintain a stable heat supply, ensuring efficient curing.

Precise water control mechanisms adjust steam temperature and humidity levels in real time.

Prevention of carbon monoxide formation by separating water introduction from the combustion chamber.

These innovations make the SmartSet Curing Systems an ideal choice for maintaining consistent and efficient curing conditions.

Automated Curing System for Energy Efficiency

Unlike traditional curing methods, SmartSet automated curing system optimizes energy use and resource management.

Self-regulating controls adjust firing rates based on the curing load.

Automated compensation for water pressure fluctuations ensures stability.

Reduced manual intervention lowers labour costs and enhances precision.

By combining automation, energy efficiency and intelligent curing control, the Smart Concrete Curing System significantly improves concrete quality and production efficiency.

The Key to Precision Concrete Curing: SmartSet’s Kiln Control Systems

The SmartSet Curing Systems are designed to provide precision in concrete curing, ensuring that every batch meets high-quality standards.

Kiln control systems actively monitor temperature and humidity levels, making micro-adjustments as needed.

Exhaust and circulation systems manage airflow to maintain uniform curing conditions.

Customizable curing programs allow manufacturers to adapt curing conditions to different concrete products.

With these advanced technologies, SmartSet Curing Systems deliver superior strength, durability and reliability in concrete production.

Why Choose SmartSet for Concrete Curing?

The SmartSet Curing Systems offer a state-of-the-art solution for managing heat and humidity in concrete curing. Here’s why they stand out:

Automated Control - The automated curing system minimizes manual intervention while ensuring precision.

Energy Efficiency - SmartSet concrete curing system optimizes fuel and water use, reducing waste.

Consistent Quality - Uniform curing conditions result in stronger, more durable concrete products.

Advanced Technology - Featuring dynamic firing rates, misting systems and kiln controls for superior performance.

Customizable Solutions - SmartSet Curing Systems can be tailored to specific curing requirements.

Conclusion

The role of heat and humidity in concrete curing is critical for achieving maximum strength, durability and quality. By maintaining controlled curing environments, SmartSet Curing Systems ensure that concrete products cure efficiently, uniformly and without defects.

With features such as advanced kiln control systems, automated curing technology and energy-efficient combustion systems, the SmartSet Curing Systems provide a cutting-edge approach to precision concrete curing.

For manufacturers looking to improve product quality and optimize curing efficiency, investing in a SmartSet Curing System is a game-changer.

FAQs

Why is temperature control important in concrete curing? Temperature affects the hydration process of cement. If it's too low, curing slows down and if it's too high, thermal cracks may form. SmartSet Curing Systems ensure optimal temperature control.

How does humidity impact concrete strength? Humidity prevents premature moisture loss, reducing shrinkage and cracking. Smart Concrete Curing System maintains ideal humidity levels for uniform curing.

Can SmartSet adjust curing conditions automatically? Yes, the automated curing system dynamically adjusts temperature and humidity based on real-time conditions, ensuring consistency.

What are the benefits of using SmartSet’s kiln control systems? They provide precise temperature and humidity regulation, reducing manual intervention while ensuring uniform curing.

How does SmartSet improve energy efficiency in concrete curing? The advanced curing system optimizes fuel consumption, reduces waste and adjusts steam flow automatically, leading to cost savings.

youtube

1 note

·

View note

Text

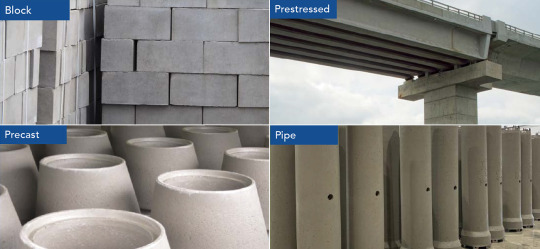

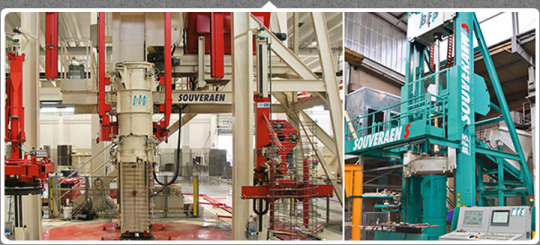

How CAP Series Machines Create High-Quality Concrete Products

Discover how CAP Series Machines from Apollo Hawkeye Pedershaab deliver superior concrete product manufacturing with cutting-edge technology. These machines are designed for versatile production, including reinforced and non-reinforced pipes, box culverts, U-drains, and manhole risers.

Key Features:

✅ Advanced Compaction & Vibration Technology – Ensures optimal concrete compaction and strength. ✅ Efficient Concrete Feeding & Molding – Features a radial horizontal feeder for uniform material distribution. ✅ Flexible Production with Single & Twin Stations – Enhances efficiency with dual production capabilities. ✅ Smart Control & Customization – PLC system operation, digital display, and safety features for enhanced productivity.

Designed for precision, durability, and efficiency, CAP Series Machines set the standard for high-quality concrete products.

🔗 Learn more: https://www.ahct.in/

0 notes

Text

How CAP Series Machines Create High-Quality Concrete Products

Discover how CAP Series Concrete Pipe Making Machines from Apollo HawkeyePedershaab Concrete Technologies (AHCT) are revolutionizing the concrete industry. These cutting-edge machines are designed to produce high-quality concrete pipes with precision, durability, and efficiency.

🔹 Key Features of CAP Series Machines: ✅ High-speed production with superior compaction ✅ Advanced vibration & pressing technology for uniform strength ✅ Automated operation for consistent quality ✅ Suitable for reinforced and non-reinforced concrete pipes

📌 Applications: ✔️ Drainage & Sewer Systems ✔️ Culverts & Irrigation Projects ✔️ Industrial & Municipal Infrastructure

Watch this video to see how CAP Series Machines deliver top-notch concrete solutions for modern infrastructure projects.

📞 Learn More: https://www.ahct.in/products/category/concrete-pipe-making-machines

#ConcretePipeMachines #CAPSeries #ConcreteTechnology #AHCT #InfrastructureDevelopment #PipeMaking

0 notes

Text

The Impact of Advanced Safety and Automation Features in Concrete Pipe Making Machines

Concrete pipe manufacturing has evolved significantly with the integration of advanced safety and automation features. These enhancements have not only improved worker safety but also increased production efficiency, precision and overall cost-effectiveness.

This article explores the impact of safety and automation features in modern concrete pipe making machines and how they contribute to improving quality, efficiency and operational safety.

The Benefits of Safety Measures in Concrete Pipe Manufacturing

Higher Productivity and Cost Efficiency

With automation-driven production lines, pipe making machine manufacturers can significantly boost productivity.

Optimized material handling reduces waste and ensures precise compaction.

Automated curing systems accelerate pipe hardening without affecting strength.

Continuous operation minimizes machine idle time, increasing overall output.

These advancements lead to reduced operational costs, making concrete pipe making plants more profitable.

Better Pipe Quality and Durability

The latest Circular Pipe Making Machines feature enhanced automation to ensure consistent quality across all pipe batches.

Automated mould handling reduces surface imperfections.

Smart vibration control systems enhance compaction density.

Automated demoulding processes minimize structural weaknesses.

With these features, RCC Pipe Making Machines can produce stronger, more durable pipes with minimal defects.

Lower Maintenance and Repair Costs

Modern pipe making machinery incorporates self-monitoring technology, reducing maintenance costs and downtime.

Predictive maintenance alerts inform operators of potential issues.

Lubrication automation prevents component wear and tear.

Smart tracking systems notify manufacturers when parts need replacement.

These features extend the lifespan of the core pipe making machine in India, ensuring long-term cost savings.

Advanced Safety Features in Concrete Pipe Making Machines

Reduction in Workplace Accidents

Modern concrete pipe making machines come with several safety enhancements that reduce human involvement in hazardous processes:

Automated Core Vibration Systems:

Reduces the need for manual adjustments.

Minimizes exposure to high-intensity vibrations that may cause long-term health issues.

Mechanical Elevation Systems:

Automatically adjusts to accommodate different pipe lengths.

Reduces manual lifting, lowering the risk of worker injuries.

Emergency Stop Mechanisms

To prevent accidents, concrete pipe making plants now include:

Automated Emergency Stop Buttons: Immediate shutdown in case of system failure.

Motion Sensors & Safety Barriers: Ensures operators do not come in direct contact with moving parts.

Enclosed Work Areas

Advanced large concrete pipe making machines now feature:

Protective Shields & Enclosures: Prevents direct exposure to machinery in motion.

Operator-Friendly Control Panels: Allows remote operation, reducing the need for physical contact.

These innovations significantly reduce injuries and improve workplace safety.

Automation Features Transforming Concrete Pipe Production

Improved Precision and Consistency

Automation ensures uniformity and accuracy in pipe making machinery, leading to:

High-Quality Concrete Pipes:

Vertical Vibrated Casting Technology improves concrete compaction.

Laser fine-filling controls allow precise concrete distribution.

Consistent Pipe Diameter & Structure:

Frequency-controlled vibrator speeds optimize material placement.

Automated quality checks detect structural inconsistencies.

Increased Production Efficiency

Modern pipe making machines have dual-station capabilities, which means:

Simultaneous production of different sizes of pipes.

Reduction in production time by 40-50% compared to traditional methods.

For example:

CAP 150 and CAP 200 - Designed for pipes up to 2000 mm in diameter.

CAP 250 and CAP 360 - Handles pipes up to 3600 mm in diameter with higher capacity and enhanced automation.

Energy Optimization

Many pipe making machine suppliers have incorporated smart energy management systems, which:

Automatically adjust power consumption based on production load.

Reduce energy waste by optimizing pneumatic systems in lined pipe casting.

This ensures cost savings and efficient resource utilization.

The need for Advanced Safety and Automation in Concrete Pipe Making

Traditional concrete pipe making machines required substantial manual intervention, which posed numerous risks, including:

Workplace Accidents: Manual handling of heavy machinery increased the risk of injuries.

Inconsistent Product Quality: Variations in manual operations led to inconsistencies in pipe structure.

High Labour Costs: Extensive workforce requirements increased operational expenses.

Production Inefficiencies: Manual processes limited output and increased downtime.

With the introduction of automation and enhanced safety mechanisms, these challenges have been significantly mitigated.

Concrete Pipe Making Machine Prices

Factors Affecting Price

The concrete pipe making machine price depends on various factors, including:

Level of automation - Fully automated machines are costlier but offer long-term savings.

Production capacity - Larger machines with high-output capabilities are priced higher.

Customization and additional safety features - Advanced safety mechanisms and automation levels affect pricing.

Comparing Pipe Making Machine Prices in India

For manufacturers seeking the best value, comparing pipe making machine prices in India is essential.

Pipe making machine suppliers offer a range of options with varying automation levels.

Pipe making machine welding manufacturers provide customized solutions for reinforced pipe production.

RCC pipe making machines are available at different price points, catering to various production needs.

By carefully selecting the right pipe making machine, manufacturers can achieve cost-effective, high-quality production.

Conclusion

The adoption of advanced safety and automation features in concrete pipe making machines has transformed the industry by the integration of advanced safety and automation features in concrete pipe making machines has transformed the industry by improving safety, efficiency and cost-effectiveness. With innovations such as automated quality checks, smart sensors, emergency stop mechanisms and energy-efficient designs, modern pipe making machines are redefining concrete pipe production.

Manufacturers investing in these advanced systems not only ensure better safety for their workers but also enhance the overall quality and precision of their products. As technology continues to evolve, the future of concrete pipe making plants will witness even more innovative solutions, making production smarter and safer.

FAQs

How do automation features improve efficiency in concrete pipe making machines?

Automation ensures precise control over the production process, reducing errors and increasing speed. Features like laser fine filling controls and dual-station capabilities enhance productivity.

What safety mechanisms are included in modern concrete pipe making machines?

Most machines include emergency stop buttons, enclosed operational areas, motion sensors and synchronized vibration systems to reduce workplace accidents.

How does predictive maintenance benefit concrete pipe manufacturers?

Predictive maintenance uses smart sensors to detect potential failures before they occur, reducing machine downtime and repair costs.

Can automation reduce production costs?

Yes, automated pipe making machines require fewer workers, optimize energy use and minimize errors, leading to cost savings.

youtube

0 notes

Text

Concrete Pipe Making Machine Demand and Supply for Indian Cities

India’s rapid urbanization and infrastructure development have significantly increased the demand for efficient and durable construction materials. Concrete pipes are indispensable for infrastructure projects, including sewage systems, drainage networks, and water supply pipelines. This surge in construction activities has fueled the demand for concrete pipe making machines in cities across India. These machines are pivotal in producing high-quality concrete pipes that meet the needs of urban development projects.

This article explores the demand for concrete pipe making machines in different Indian cities, highlighting key trends, challenges, and opportunities in the supply chain.

Why Concrete Pipes Are Vital for Indian Cities

Concrete pipes are essential for building reliable infrastructure in urban and rural areas. Their durability, resistance to environmental factors, and cost-effectiveness make them a preferred choice for:

Sewage systems.

Storm water management.

Irrigation channels.

Industrial wastewater disposal.

The demand for concrete pipes is directly tied to urban development, necessitating an efficient and scalable production process enabled by concrete pipe making machines.

Demand for Concrete Pipe Making Machines in Indian Cities

Metropolitan Cities

Cities like Mumbai, Delhi, Bangalore, and Chennai are witnessing exponential growth in infrastructure projects.

Drivers of Demand:

Expansion of metro rail networks.

Upgrading sewage and drainage systems to meet population growth.

Smart city projects requiring modern infrastructure solutions.

Preferred Solutions: Large-scale concrete pipe making machine capable of high-volume production to meet the fast-paced demands.

Tier-2 Cities

Cities like Pune, Ahmedabad, Jaipur, and Lucknow are experiencing rapid industrialization and urbanization.

Drivers of Demand:

Construction of industrial zones and residential complexes.

Implementation of drainage and water supply projects under government schemes.

Preferred Solutions: Medium-capacity concrete pipe making machines tailored for diverse project requirements.

Coastal Cities

Cities like Kochi, Visakhapatnam, and Mangalore require specialized concrete pipes to handle storm water and seawater exposure.

Drivers of Demand:

Coastal protection projects.

Improved drainage systems to combat flooding during monsoons.

Preferred Solutions: Machines designed to produce corrosion-resistant concrete pipes.

Northern Plains and Agricultural Regions

Cities like Chandigarh, Ludhiana, and Kanpur rely heavily on concrete pipes for irrigation and rural water supply systems.

Drivers of Demand:

Development of large-scale irrigation projects.

Upgrading rural water distribution networks.

Preferred Solutions: Affordable concrete pipe making machines for producing pipes in varying sizes to suit agricultural needs.

Industrial Hubs

Cities like Surat, Vadodara, and Jamshedpur have a high demand for industrial-grade concrete pipes.

Drivers of Demand:

Efficient waste disposal systems for factories and industrial plants.

Expansion of industrial parks requiring durable underground utilities.

Preferred Solutions: High-capacity machines capable of producing reinforced concrete pipes for industrial use.

The Role of Concrete Pipe Making Machine Manufacturers

Indian concrete pipe making machine manufacturers play a critical role in meeting the demand for these machines by offering:

Custom Solutions: Machines designed to produce pipes of varying sizes and specifications to suit different projects.

Advanced Technology: Incorporation of automation and IoT for precision and efficiency in pipe production.

Cost-Effectiveness: Competitive pricing to cater to both large-scale urban projects and small-scale rural needs.

After-Sales Support: Comprehensive support, including installation, training, and maintenance, ensuring optimal machine performance.

Supply Challenges for Concrete Pipe Making Machines

Despite the growing demand, several challenges affect the supply chain of concrete pipe making machines in India:

High Initial Investment

The cost of large-scale concrete pipe making machines can be prohibitive for small contractors, limiting adoption in certain regions.

Logistics

Transporting heavy machinery to remote or inaccessible areas can be challenging, particularly in hilly or coastal regions.

Skilled Workforce

Operating advanced machinery requires trained personnel, which can be scarce in smaller towns and rural areas.

Customization Needs

Different cities have unique requirements based on their geographical and infrastructural challenges, necessitating highly customized solutions.

Opportunities for Manufacturers and Suppliers

Government Initiatives

Programs like Smart Cities Mission, AMRUT, and Jal Jeevan Mission are driving infrastructure development, creating opportunities for manufacturers to meet the demand for concrete pipe making machines.

Expanding to Tier-2 and Tier-3 Cities

Manufacturers can tap into the growing demand in smaller cities by offering affordable and portable concrete pipe making plants.

Technological Advancements

Developing machines with energy-efficient and automated features can attract cost-conscious buyers while enhancing production capabilities.

Export Potential

Indian manufacturers can explore export opportunities in developing countries with similar infrastructural needs.

Benefits of Using Concrete Pipe Making Machines

Precision and Consistency

Modern concrete pipe making machines ensure uniformity in size, shape, and quality, meeting stringent project specifications.

High Efficiency

These machines enable mass production of concrete pipes, reducing time and labor costs.

Versatility

From small drainage pipes to large industrial-grade pipes, machines can produce a wide range of sizes and designs.

Cost Savings

Efficient use of materials and reduced wastage contribute to lower production costs over time.

Sustainability

Machines designed to minimize energy consumption and material wastage align with environmentally conscious construction practices.

FAQs

What is a concrete pipe making machine used for? A concrete pipe making machine is used to produce concrete pipes for various infrastructure projects, including drainage, sewage, and water supply systems.

Why is there a growing demand for concrete pipe making machines in India? The rapid urbanization, industrialization, and implementation of government infrastructure projects have significantly increased the need for durable and high-quality concrete pipes, driving demand for these machines.

What are the advantages of using advanced concrete pipe making machines? Advanced machines ensure precision, reduce production time, lower material wastage, and enable the production of customized pipe designs.

How do manufacturers cater to the diverse needs of different Indian cities? Manufacturers offer customized machines designed for specific requirements, such as corrosion-resistant pipes for coastal areas or large pipes for industrial use.

Are there affordable options for smaller projects? Yes, many manufacturers provide medium- and small-capacity machines that are cost-effective and suitable for smaller projects in Tier-2 and Tier-3 cities.

youtube

Conclusion

The demand for concrete pipe making machines in India reflects the country’s growing focus on infrastructure development. From metropolitan cities to rural agricultural regions, these machines are vital for producing durable and efficient concrete pipes. By addressing supply challenges and leveraging technological advancements, manufacturers can meet the diverse needs of Indian cities, contributing to sustainable and robust infrastructure.

0 notes

Text

Understanding the Importance of Box Pallet and U-Drain Pallets in Modern Construction Projects

In the ever-evolving construction industry, precision and efficiency are paramount. Components like box pallets and U-drain pallets play a crucial role in shaping modern infrastructure projects. These tools streamline the production of concrete structures, ensuring high-quality results while optimizing time and resources. In this article, we will explore the significance of box pallets, U-drain pallets, and associated equipment in construction, shedding light on their applications, benefits, and frequently asked questions.

What Are Box Pallets and U-Drain Pallets?

Box Pallets

Box pallets are specialized moulding tools used in the production of rectangular concrete components like box culverts, chambers, and other structural units. They provide a base, ensuring precise shaping and consistent quality of the concrete elements.

U-Drain Pallets

U-drain pallets are used to create U-shaped drainage channels that are essential for effective water management in urban and industrial settings. These pallets support the moulding and curing of U-drains, ensuring durability and dimensional accuracy.

Applications in Construction Projects

Storm water Management

U-drains produced using U-drain pallets are essential for channeling rainwater, preventing flooding, and ensuring proper drainage in urban areas.

Sewer Systems

Box culverts and U-drains are widely used in sewage networks, providing reliable conduits for wastewater management.

Transportation Infrastructure

Box pallets are crucial for manufacturing box culverts used in underpasses, bridges, and road drainage systems.

Industrial Projects

In industrial settings, U-drains facilitate the safe disposal of liquid waste and prevent water logging.

Agricultural Irrigation

Both box pallets and U-drain pallets are used to create systems for efficient water distribution in agricultural fields.

Advantages of Using Box Pallets and U-Drain Pallets

Enhanced Precision

The use of box pallet equipment ensures consistent dimensions and smooth finishes, reducing errors in the production process.

Durability

Structures created using high-quality pallets are robust, capable of withstanding heavy loads and environmental stresses.

Efficiency

Modern pallet equipment automates key production stages, significantly reducing time and labor requirements.

Cost-Effectiveness

By optimizing material usage and minimizing waste, pallets contribute to cost savings in large-scale construction projects.

Customization

Pallets can be tailored to meet specific project requirements, ensuring compatibility with diverse construction needs.

The Role of Box Pallets in Construction Projects

Box pallet revolutionizes the production of box culverts by:

Automating the compaction process for uniform strength.

Reducing manual intervention, enhancing productivity.

Allowing for quick mould changes to adapt to different project needs.

Key Features of U-Drain Pallets

Structural Support U-drain pallets provide a stable base during moulding and curing, ensuring the integrity of the final product.

Dimensional Accuracy They help maintain precise dimensions, critical for seamless integration in drainage systems.

Material Versatility U-drain pallets can be used with various concrete mixes, enhancing their applicability across different projects.

FAQs

What is a box pallet used for in construction? A box pallet is used to create rectangular concrete structures like box culverts and chambers, ensuring precision and durability.

How do U-drain pallets contribute to drainage systems? U-drain pallets are used to mould U-shaped channels that facilitate efficient water management in urban and industrial settings.

What are the advantages of using box pallet and header equipment? Box pallet and header equipment are used for forming tongue and groove joints.

Can pallets be customized for specific projects? Yes, pallets can be tailored to meet the dimensions and design requirements of specific construction projects.

How do modern pallets support sustainable construction? By optimizing material usage, reducing waste, and incorporating eco-friendly materials, modern pallets promote sustainability in the construction industry.

Conclusion

Box pallets and U-drain pallets are game-changers in the construction industry, offering unmatched precision, efficiency, and versatility. By leveraging advanced Box pallet and U-Drain pallet equipment, construction professionals can achieve superior results while reducing costs and environmental impact. As the industry continues to innovate, the role of these tools in shaping modern infrastructure will only grow stronger.

youtube

0 notes

Text

Pipe Pallet: A Game-Changer in Concrete Pipe Production Processes

The concrete pipe industry has seen significant advancements in recent years, with innovations aimed at improving efficiency, precision, and durability. Among these breakthroughs, pipe pallets have emerged as a revolutionary component in the production process. These indispensable tools, used in conjunction with modern machinery, enhance the quality and consistency of concrete pipes. This article explores the role of pipe pallet, their applications, benefits, and the technology behind their integration into concrete pipe production.

What Is a Pipe Pallet?

A pipe pallet is a specially designed platform used in the manufacturing of concrete pipes. It serves as a base to support the concrete during the forming process, ensuring stability and accurate shaping. Pipe pallets are typically made from high-strength materials like steel or cast iron to withstand the rigors of industrial production.

Role of Pipe Pallets in Concrete Pipe Production

Pipe pallets are integral to the operation of concrete pipe machines, facilitating efficient and accurate pipe formation.

Provide a sturdy base during the moulding process and a mediator for transferring vibration.

Support the weight of the concrete to maintain joint shape and dimensions.

Ensure consistency in the production of pipes of various sizes.

Minimize deformation during curing and handling.

Materials Used in Pipe Pallet Manufacturing

Steel

Offers high durability and strength.

Resistant to wear and tear.

Cast Iron

Combines strength with lightweight properties.

Suitable for high-volume production lines.

Applications of Pipe Pallets

Pipe pallets are used across a wide range of applications in the concrete pipe industry:

Storm water Management Systems Support the production of pipes used in drainage systems for managing rainwater and preventing flooding.

Sewage Systems Ensure precision in pipes designed to transport wastewater in municipal and industrial projects.

Irrigation Systems Facilitate the production of durable pipes for agricultural water distribution.

Industrial Applications Used in producing pipes for transporting chemicals and waste materials.

Benefits of Using Pipe Pallets

Enhanced Pipe Quality

The rigid and stable structure of pallets for concrete pipe machines ensures uniform dimensions and surface finish, enhancing the overall quality of the final product.

Increased Efficiency

By streamlining the moulding and curing processes, pipe pallets reduce production time and increase throughput.

Cost-Effectiveness

Durable pipe pallets minimize the need for frequent replacements, lowering operational costs over time.

Versatility

Pipe pallets can accommodate different sizes and types of concrete pipes, offering flexibility in production.

Environmental Sustainability

By improving production efficiency and reducing material wastage, pipe pallets contribute to more sustainable manufacturing practices.

Pipe Pallet Equipment and Technology

Modern pipe pallet equipment integrates advanced technology to improve the production process:

Automated Handling Systems Facilitate the movement of pallets within the production line, reducing manual labor and speeding up operations.

Robust Materials High-strength steel or composite materials ensure durability and resistance to wear and tear.

Precision Engineering State-of-the-art machining ensures that pallets meet exact specifications, contributing to consistent pipe quality.

Customizable Designs Equipment allows for the production of pallets tailored to different pipe sizes and shapes.

Integration of Pipe Pallets in Modern Concrete Pipe Process

Pallets for concrete pipe machines are seamlessly integrated into automated production lines, enhancing efficiency and reducing errors.

Production Process Overview:

Preparation Pipe pallets are positioned within the moulding machine, ready to receive the concrete mix.

Moulding Concrete is poured and compacted over the pallet, with the mould ensuring precise shaping.

Curing The pallet provides structural support as the pipe cures, maintaining its shape and integrity.

Demoulding and Handling Once cured, the pipe is removed along with the pallet for further processing or transport.

Factors to Consider When Choosing Pipe Pallets

Material Quality Opt for pallets made from high-grade materials to withstand repeated use and heavy loads.

Compatibility Ensure the pallet design matches the specifications of your pipe making machine.

Durability Select pallets type that resist wear, corrosion, and deformation.

Customization Work with manufacturers to develop pallets tailored to unique production requirements.

FAQs

What is a pipe pallet used for? A pipe pallet serves as a base in concrete pipe production, supporting the concrete during moulding, curing, and socket joint forming to ensure consistent quality.

What materials are pipe pallets made from? Pipe pallets are typically made from high-strength materials like steel and cast iron for durability and long-term use.

How do pipe pallets improve concrete pipe production? Pipe pallets provide stability and precision, ensuring uniform dimensions and reducing production errors. They also streamline the moulding and curing processes, enhancing efficiency.

Can pipe pallets be customized? Yes, manufacturers offer customizable designs to meet specific project requirements, including unique pipe sizes and shapes.

Are pipe pallets compatible with all concrete pipe machines? Not all pipe pallets are universally compatible. It’s essential to select pallets that match the specifications of your pipe-making equipment.

Conclusion

Pipe pallets have transformed concrete pipe production by enhancing efficiency, precision, and sustainability. As technology continues to advance, these tools will play an even greater role in meeting the growing demands of the construction industry. By investing in high-quality pipe pallet equipment and working with reputable suppliers, manufacturers can achieve superior results while optimizing their operations.

youtube

0 notes

Text

Applications of Manhole Moulds in the Construction and Utility Sectors

Manhole systems are indispensable in urban infrastructure, providing access points for maintenance, inspection, and repairs of underground utilities. The production of these systems heavily relies on manhole moulds and advanced machinery, such as manhole producing machines and manhole making machines. These tools enable the creation of high-quality, durable manholes that meet the diverse needs of the construction and utility sectors. This article explores the wide-ranging applications of moulds for manhole systems and their critical role in modern infrastructure.

Understanding Manhole Systems

Manhole systems consist of vertical shafts and covers that provide entry to underground networks like sewage, storm water, and utility lines. They are designed to:

Facilitate access for inspections and repairs.

Safeguard underground systems from external elements.

Ensure safe and efficient utility management.

The design and durability of manholes depend significantly on the precision and quality of the manhole moulds and equipment used during production.

Role of Manhole Moulds in Construction Sectors

Defining Shapes and Sizes

Manhole moulds serve as frameworks for shaping concrete into precise dimensions, ensuring uniformity across all components.

Ensuring Structural Integrity

By maintaining consistency in the production process, moulds enhance the structural integrity of manhole systems, enabling them to withstand heavy loads and environmental stresses.

Facilitating Large-Scale Production

Modern manhole mould equipment enables the efficient production of large volumes, catering to the growing demands of infrastructure projects.

Applications in the Construction Sector

The construction industry relies heavily on manhole systems for various projects. Key applications include:

Urban Drainage Systems

Manholes are vital components of storm water drainage systems, allowing access to underground pipelines and ensuring proper water flow in urban areas.

Sewage Infrastructure

Manhole systems form an integral part of sewage networks, enabling maintenance and preventing blockages in wastewater pipelines.

Road and Highway Projects

Manholes are installed along roads and highways to manage drainage and provide access to underground utilities, ensuring road safety and longevity.

Industrial Complexes

Industrial facilities use manholes for access to utility lines, ensuring seamless operations and easy maintenance of critical systems.

Applications in the Utility Sector

The utility sector benefits immensely from the versatility of manhole systems. Key applications include:

Telecommunications

Manholes provide access points for fiber optic cables and other telecommunication infrastructure, ensuring efficient maintenance and upgrades.

Electricity Networks

Manhole systems house electrical lines, offering safe and secure access for repair and inspection without disrupting surface activities.

Gas Pipelines

Gas distribution networks utilize manholes for monitoring and maintenance, ensuring safety and efficiency in the supply chain.

Advanced Equipment in Manhole Production

Manhole Producing Machines

These machines automate the production process, ensuring consistency, precision, and efficiency in creating manhole components.

Features:

Automated concrete mixing and pouring.

Adjustable moulds for different sizes.

High-speed production capabilities.

Manhole Making Machines

Modern manhole making machines integrate multiple processes, from moulding and curing to finishing, streamlining production workflows.

Advantages:

Reduces manual labor.

Enhances production accuracy.

Supports customization for specific project needs.

Moulds for Manhole Systems

High-quality moulds form the backbone of the production process. They are designed to ensure durability, dimensional accuracy, and surface finish.

Types:

Steel moulds for heavy-duty applications.

Modular moulds for flexibility and scalability.

Benefits of Using Advanced Manhole Mould Equipment

Enhanced Efficiency

Modern equipment accelerates production timelines while maintaining high-quality standards.

Customization

Advanced moulds allow for the production of customized manholes tailored to specific infrastructure projects.

Sustainability

Energy-efficient machines and recyclable materials reduce the environmental footprint of the production process.

Cost-Effectiveness

Automated equipment minimizes labor costs and reduces material wastage, leading to significant savings.

Challenges for Manhole Production in Utility Sector

Despite technological advancements, manhole production faces several challenges:

Ensuring Durability

Manhole systems must withstand heavy loads, chemical exposure, and temperature variations. This requires precision in the manufacturing process.

Meeting Diverse Requirements

Projects often demand customized designs, which can complicate production without advanced mould equipment.

Adhering to Regulations

Compliance with local and international standards for safety, quality, and environmental impact is critical.

Solutions to Overcome Challenges in Utility Sector

Investing in Advanced Equipment

Using modern manhole mould equipment ensures precision, efficiency, and adherence to quality standards.

Training and Support

Providing operators with training on using equipment and adhering to regulations can improve production outcomes.

Collaboration with Reputable Suppliers

Partnering with reliable manufacturers and suppliers ensures access to high-quality moulds and machines.

Innovations in Manhole Moulds at Construction Areas

IoT Integration

Smart machines equipped with IoT technology enable real-time monitoring, predictive maintenance, and enhanced efficiency.

Modular Designs

Modular moulds offer flexibility, allowing manufacturers to adapt to different project requirements quickly.

Sustainable Materials

The use of eco-friendly and durable materials in moulds and machines supports sustainable infrastructure development.

Selecting the Right Equipment for Manhole Production

Assessing Project Requirements

Determine the size, volume, and specifications of the manholes needed for the project.

Evaluating Equipment Features

Look for machines and moulds with features that match production goals, such as automation, modularity, and durability.

Considering Manufacturer Reputation

Choose equipment from trusted manufacturers with a proven track record in the industry.

Prioritizing After-Sales Support

Ensure suppliers provide comprehensive after-sales support, including maintenance and training.

The Future of Manhole Moulds in Construction and Utility Sectors

The demand for efficient, durable, and customizable manhole systems is expected to grow as urbanization continues. Key trends shaping the future of manhole production include:

Automation: Increased reliance on AI-driven machines for precision and efficiency.

Sustainability: Emphasis on eco-friendly materials and processes.

Customization: Greater demand for project-specific solutions.

Global Standards: Adoption of universal safety and quality standards to meet international infrastructure needs.

Conclusion

Manhole systems are indispensable in the construction and utility sectors, ensuring the efficient operation of underground infrastructure. Advanced manhole moulds, manhole producing machines, and related equipment have revolutionized their production, offering unmatched precision, efficiency, and customization. By embracing innovation and investing in quality equipment, the industry can meet the growing demands of modern infrastructure development.

youtube

0 notes

Text

A Step-by-Step Guide for Using Pipe Moulds in Construction Projects

Pipe moulds are essential tools in the construction industry, playing a crucial role in the production of concrete pipes used in infrastructure development. From drainage systems to irrigation projects, concrete pipe moulds ensure the creation of durable and precise components. This step-by-step guide provides a comprehensive overview of using pipe moulds in construction projects, highlighting their significance, applications, and tips for efficient operation.

Understanding Pipe Moulds

Pipe moulds are frameworks designed to shape concrete into cylindrical pipes. These moulds are precision-engineered to meet specific project requirements, ensuring that the final product is durable, uniform, and functional.

Role in Construction Projects

Facilitate the production of pipes for drainage, sewage, and irrigation systems.

Ensure dimensional accuracy and structural integrity.

Allow customization to meet unique project specifications.

Applications of Concrete Pipe Moulds

Concrete pipes produced usingpipe moulds serve various purposes in construction:

Urban Drainage Systems

Concrete pipes manage storm water in urban settings, preventing flooding and ensuring proper water flow.

Sewage Networks

Durable and leak-proof pipes are critical for transporting wastewater, making concrete pipe moulds essential in sewage projects.

Irrigation Systems

In agriculture, concrete pipes distribute water efficiently to crops, helping optimize irrigation processes.

Industrial Applications

Industrial facilities use concrete pipes for transporting wastewater, chemicals, and other materials.

Tools and Equipment for Using Pipe Moulds

The use of pipe mould equipment streamlines the production process, ensuring precision and efficiency.

Essential Tools

Mixing Machines: For preparing concrete with the right consistency.

Compaction Equipment: Ensures even distribution of concrete in the mould.

Curing Systems: Maintains optimal temperature and humidity for concrete curing.

Demoulding Tools: Facilitates easy removal of pipes from the moulds.

Modern Advancements

Automated Pipe Mould Equipment: Integrates multiple processes, from pouring to curing.

IoT-Enabled Machines: Allow real-time monitoring and predictive maintenance.

Step-by-Step Process for Using Pipe Moulds

Step 1: Preparing the Mould

Cleaning: Remove any residues from previous uses to ensure a smooth surface.

Step 2: Preparing the Concrete Mix

Mix Design: Use the appropriate dry mix of cement, aggregates, water and reinforcing materials for pipes.

Testing: Conduct slump tests to ensure the mix achieves the desired consistency.

Step 3: Pouring the Concrete

Even Distribution: Pour the concrete into the mould, ensuring it fills all sections evenly.

Compaction: Use Core vibrator to eliminate air pockets and ensure uniform density.

Step 4: Curing the Pipe

Initial Setting: Allow the concrete to set by covering polythene in a factory shed area

Controlled Curing: Transfer the pipe to a curing yard with water spay to achieve maximum strength.

Step 5: Demoulding

Timing: Immediate demoulding by overhead crane.

Step 6: Quality Inspection

Dimensional Checks: Verify that the pipe meets the required dimensions and tolerances.

Structural Testing: Conduct load and water tests to ensure the pipe’s qality.

Tips for Efficient Operation

Regular Maintenance of Moulds

Clean and inspect pipe moulds after each use to prevent wear and ensure longevity.

Optimize Concrete Mix

Adjust the mix design based on project requirements to enhance pipe strength and durability.

Invest in High-Quality Equipment

Using advanced pipe mould equipment improves efficiency and reduces production errors.

Train Operators

Ensure that operators are well-trained in handling moulds and equipment for optimal results.

Advantages of Using Pipe Moulds

Precision and Uniformity

Concrete pipe moulds ensure consistent dimensions and shapes, meeting project specifications accurately.

Cost-Effectiveness

Efficient moulds reduce material wastage and production time, lowering overall costs.

Versatility

Pipe moulds can produce a variety of pipe sizes and designs, catering to diverse construction needs.

Choosing the Right Pipe Moulds and Equipment

Assess Project Requirements

Determine the size, type, and volume of pipes needed for your project to select suitable moulds.

Evaluate Manufacturer Reputation

Collaborate with trusted pipe mould manufacturers that offer high-quality products and after-sales support.

Consider Material Durability

Opt for moulds made from robust materials to withstand frequent use and heavy-duty applications.

Prioritize Technological Features

Invest in equipment with advanced features.

Conclusion

Pipe moulds are indispensable in construction projects, enabling the production of reliable and durable concrete pipes for various applications. By following a systematic approach and leveraging advanced pipe mould manufacturer, contractors can achieve efficiency, precision, and cost-effectiveness. With innovations in mould design and technology, the potential of concrete pipe production continues to grow, supporting the development of sustainable and robust infrastructure.

youtube

0 notes

Text

The Importance of Pipe Moulds and Applications in the Concrete Industry

The concrete industry is at the heart of modern infrastructure, producing critical components for construction, water management, and transportation. Among these components, concrete pipes are indispensable, serving as conduits for drainage, sewage, and utility lines. At the core of concrete pipe production are pipe moulds, which play a pivotal role in shaping these structures. This article explores the significance of pipe moulds, their applications, and the innovations brought by pipe mould manufacturers in advancing the concrete industry.

What Are Pipe Moulds?

Pipe moulds are specialized tools used to shape concrete into the desired dimensions for pipes. They provide the framework necessary to produce durable, precise, and consistent concrete pipes. The design and quality of the moulds directly impact the strength, functionality, and longevity of the finished pipes.

The Role of Pipe Moulds in the Concrete Industry

Ensuring Consistency

Pipe moulds ensure uniformity in size, shape, and strength across all produced pipes, which is critical for maintaining system integrity in construction and utility applications.

Improving Efficiency

Using advanced pipe mould equipment accelerates the production process, reducing manual labor and operational costs.

Enhancing Durability

High-quality concrete pipe moulds produce pipes capable of withstanding environmental stresses, heavy loads, and chemical exposure.

Supporting Large-Scale Production

With innovations introduced by pipe mould manufacturers, it is now possible to produce large quantities of concrete pipes quickly and efficiently, meeting the demands of modern infrastructure projects.

Applications of Pipe Moulds in the Concrete Industry

Drainage Systems

Concrete pipes produced using moulds are widely used in storm water drainage systems to prevent water logging and manage rainwater effectively.

Sewage Networks

In sewage systems, durable and leak-proof pipes are essential for transporting wastewater safely. High-precision concrete pipe moulds ensure the structural integrity of these pipes.

Water Supply Infrastructure

Concrete pipes are crucial for water distribution systems, delivering water to urban and rural areas. Pipe moulds facilitate the production of pipes that meet health and safety standards.

Industrial Applications

Industries use concrete pipes for handling waste water and transporting materials, benefiting from the robustness of mould-produced pipes.

Agricultural Irrigation

In agricultural settings, concrete pipes are used for irrigation systems, helping distribute water efficiently to crops.

Innovations in Pipe Mould Manufacturing

The advancements in pipe mould manufacturing have significantly enhanced the efficiency and versatility of concrete pipe production.

Precision Engineering

Modern concrete pipe moulds are designed using machines, ensuring precise dimensions and tolerances.

Modular Designs

Many moulds are now modular, allowing manufacturers to adapt to different pipe sizes and shapes with minimal adjustments.

Durable Materials

The use of high-grade steel and alloy materials extends the lifespan of pipe moulds, making them more cost-effective over time.

Automation Integration

Pipe mould equipment integrated with automation and robotics ensures consistent quality and reduces human error during production.

The Role of Pipe Mould Equipments in Concrete Industry

Streamlining Production

Modern pipe mould equipment automates critical processes, from concrete pouring to curing, ensuring high productivity.

Enhancing Quality Control

Automated equipment monitors every stage of production, ensuring the pipes meet industry standards for strength, durability, and dimensional accuracy.

Sustainability

Innovative equipment incorporates energy-efficient technologies and reduces waste, supporting sustainable practices in the concrete industry.

Choosing the Right Pipe Moulds and Equipment

Assessing Project Requirements

Select moulds based on the size, shape, and type of pipes needed for your project. Customized solutions from pipe mould manufacturers can meet unique specifications.

Material Quality

Opt for moulds made from high-quality materials like stainless steel or reinforced alloys to ensure durability and precision.

Manufacturer Reputation

Collaborate with reputable pipe mould manufacturers that offer advanced equipment, after-sales support, and a proven track record.

Technological Features

Look for equipment with automation, IoT integration, and energy-efficient systems for optimized production.

Challenges in Concrete Pipe Industry

Maintaining Precision

Achieving consistent dimensions and strength across all pipes requires high-quality moulds and equipment.

Scaling Production

Meeting large-scale production demands without compromising quality can be challenging without advanced machinery.

Adhering to Standards

Concrete pipes must comply with strict industry standards for safety, durability, and environmental impact.

Overcoming Challenges with Advanced Mould Equipment

High-Tech Solutions

Modern pipe mould equipment integrates precision engineering and automation to address production challenges effectively.

Customization Options

Customized moulds ensure that pipes meet specific project and regulatory requirements.

Continuous Innovation

Manufacturers are continuously innovating to enhance mould designs, materials, and equipment capabilities, ensuring the industry keeps pace with infrastructure demands.

Future Trends in Pipe Moulds and Equipment

Sustainable Practices

Eco-friendly materials and processes are being incorporated into pipe mould manufacturing, reducing the environmental footprint of the industry.

Smart Manufacturing

The integration of IoT and AI enables real-time monitoring and predictive maintenance of pipe mould equipment, improving efficiency.

Lightweight Moulds

The development of lightweight yet durable moulds is making production and transportation more efficient.

Conclusion

Pipe moulds are a cornerstone of the concrete industry, enabling the production of high-quality, durable pipes that serve diverse applications. From advanced pipe mould equipment to innovative manufacturing techniques, the industry continues to evolve, meeting the demands of modern infrastructure projects. By investing in reliable pipe mould manufacturers and cutting-edge equipment, the concrete industry can ensure efficient, sustainable, and cost-effective production processes.

youtube

0 notes

Text

The Role of Precast Manhole Systems in Modern Infrastructure Development

Manhole systems play a crucial role in urban and rural infrastructure, providing access points for maintenance, inspection, and servicing of underground utilities. The efficiency and durability of these systems largely depend on the quality of the manhole moulds used in their production. As modern cities expand, the demand for advanced manhole mould equipment and manhole systems producing machines has grown significantly. This article explores the importance of manhole moulds in infrastructure development, their manufacturing process, and the technological advancements driving their evolution.

Understanding Manhole Systems

Manhole systems are integral to modern infrastructure, offering access to underground utilities like sewer lines and electrical issues. Their design must balance functionality, durability, and safety to withstand environmental stresses and facilitate maintenance operations.

The construction of these systems involves key components:

Manhole covers.

Connecting pipelines.

These components are often created using high-quality manhole moulds and specialized equipment, ensuring consistent performance and durability.

What Are Manhole Moulds?

Manhole moulds are precision-engineered tools used in the production of concrete manhole components. These moulds provide the framework for shaping concrete into the desired dimensions and specifications.

The Manufacturing Process

The production of manholes involves several key steps, heavily reliant on manhole mould equipment:

Preparing the Mould

The mould is thoroughly cleaned and treated with release agents to prevent concrete from sticking.

Pouring the Concrete

High-strength concrete is poured into the moulds using manhole systems producing machines, ensuring uniform distribution and compaction.

Curing the Concrete

Curing is a vital step that allows the concrete to gain its full strength. Controlled temperature and humidity conditions ensure optimal results.

Demoulding

Once cured, the manhole components are carefully removed from the moulds to prevent damage.

Quality Control

Each component undergoes rigorous testing to meet structural and dimensional standards.

Importance of Manhole Moulds in Infrastructure Development

Ensuring Consistency

High-quality moulds ensure uniformity in size, shape, and strength, which is critical for maintaining system integrity.

Reducing Construction Time

Efficient moulding processes facilitated by advanced manhole making machines accelerate production timelines, enabling faster project completion.

Enhancing Durability

Precision-engineered moulds ensure that the final products can withstand heavy loads, environmental factors, and wear and tear over time.

Customization Capabilities

Modern moulds for manhole systems can be tailored to meet specific project requirements, offering flexibility in design and application.

Role of Manhole casting machines in Infrastructure Development

Automation

Manhole systems producing machines automate key steps in the production process, reducing manual labor and ensuring consistent results.

Scalability

These machines are designed to handle large-scale production, meeting the growing demands of urban development.

Integration

Advanced machines integrate various production stages, from mixing and pouring to curing and demoulding, into a seamless workflow.

Sustainability

Modern machines incorporate energy-efficient technologies and waste reduction features, aligning with sustainable construction practices.

Advances in Manhole mould Equipment

Precision Engineering

Modern manhole mould equipment leverages CNC machining and laser cutting to achieve precise dimensions and tolerances.

Modular Designs

Moulds now feature modular designs, allowing for easy assembly, maintenance, and adaptation to different projects.

High-Performance Materials

The use of advanced materials like stainless steel and reinforced alloys enhances mould durability and longevity.

IoT Integration

Smart mould equipment integrates IoT technology for real-time monitoring, predictive maintenance, and operational efficiency.

Applications of Manhole Systems in Infrastructure Development

Manhole systems are vital in various infrastructure projects:

Urban Drainage Systems

Facilitating the management of wastewater in cities.

Utility Access

Providing entry points for the maintenance of electrical, telecommunication, and gas lines.

Sewage Networks

Ensuring the efficient operation of sewage systems in residential and industrial areas.

Road and Highway Projects

Integrating with drainage systems to prevent water logging and maintain road safety.

Challenges in Manhole Moulds

Quality Control

Ensuring consistent quality in large-scale production can be challenging without advanced equipment.

Durability in Difficult Conditions

Manhole systems must withstand exposure to chemicals, moisture, and extreme temperatures, requiring robust materials and designs.

Customization Needs

Meeting diverse project requirements necessitates flexible mould designs and adaptable machinery.

Choosing the Right Manhole Mould and Equipment

Manufacturer Reputation

Opt for reliable manufacturers with a proven track record in producing high-quality manhole making machines and moulds.

Material Quality

Ensure the moulds are made from durable materials like high-grade steel or reinforced alloys.

Production Capacity

Select equipment that meets your project’s production demands, whether small-scale or large-scale.

After-Sales Support

Choose suppliers offering comprehensive support, including maintenance, training, and spare parts availability.

Future Trends in Manhole Production

Sustainable Materials

Eco-friendly materials, such as recycled aggregates and low-carbon concrete, are becoming more popular in manhole production.

Advanced Manufacturing Techniques

3D printing and robotic automation are revolutionizing the way manholes are designed and produced.

Smart Systems

Integration of IoT and AI is enabling real-time monitoring of manhole systems for maintenance and operational efficiency.

Lightweight Designs

Innovations in material science are leading to lighter, more durable manhole components, reducing installation challenges.

Conclusion

Manhole moulds and associated equipment play a pivotal role in the development of modern infrastructure. From ensuring consistent quality to accelerating production timelines, they form the backbone of efficient manhole system production. As urbanization continues to grow, the demand for advanced manhole systems producing machines and high-quality moulds will rise. By embracing innovation and sustainability, the industry can meet these challenges while contributing to safer, more resilient infrastructure.

youtube

0 notes

Text

The Science behind Reinforced and Non-Reinforced Concrete Pipes

Concrete pipes have been a cornerstone of modern infrastructure for decades, playing a critical role in drainage, sewage, and water management systems. The choice between reinforced and non-reinforced concrete pipes depends on the project's structural and environmental demands. This article delves into the science behind these two types of concrete pipes, the technology used in their manufacturing, and the importance of advanced equipment like the concrete pipe making machine in India and beyond.

Introduction to Concrete Pipes

Concrete pipes are cylindrical structures made from a mixture of cement, aggregates, and water. They are used in a variety of applications, including:

Storm water drainage.

Sewer systems.

Culverts and irrigation channels.

Two primary categories of concrete pipes exist: reinforced and non-reinforced. The distinction lies in their structural design and the presence or absence of reinforcement materials.

Non-Reinforced Concrete Pipes

Non-reinforced concrete pipes rely solely on the inherent strength of concrete to bear loads. These pipes are typically used in low-load conditions, such as small drainage systems or areas with minimal traffic.

Characteristics:

Made without steel reinforcement.

Depend on the compressive strength of concrete.

Cost-effective for light-duty applications.

Applications:

Agricultural drainage.

Low-pressure sewer systems.

Advantages:

Simple manufacturing process.

Lower cost compared to reinforced pipes.

Easy to install in areas with minimal load requirements.

Limitations:

Limited structural strength.

Not suitable for high-traffic or high-pressure applications.

Reinforced Concrete Pipes

Reinforced concrete pipes incorporate steel reinforcement, enhancing their ability to bear heavy loads and withstand extreme conditions. These pipes are the go-to choice for most large-scale infrastructure projects.

Characteristics:

Include steel cages or mesh for added tensile strength.

Designed to handle high loads and pressure.

Manufactured using advanced concrete pipe making machinery.

Applications:

Urban drainage systems.

High-pressure sewage pipelines.

Bridges, culverts, and tunnels.

Advantages:

Superior load-bearing capacity.

Longer lifespan.

Resistance to cracking and deformation.

Limitations:

Higher production costs.

More complex installation process.

Manufacturing Process: Reinforced vs. Non-Reinforced Pipes

The manufacturing process for both types of pipes differs due to the inclusion of reinforcement in RCPs.

Non-Reinforced Pipe Manufacturing:

Mixing: A combination of cement, water, and aggregates is mixed to achieve the desired consistency.

Molding: The mixture is poured into cylindrical molds.

Curing: Pipes are cured to enhance their strength and durability.

Remolding: Once cured, the pipes are removed from molds and finished.

Reinforced Pipe Manufacturing:

Reinforcement Setup: Steel cages or mesh are prepared and positioned in molds.

Concrete Pouring: Concrete is poured around the reinforcement.

Compaction: Machines compact the mix to eliminate air gaps and ensure uniformity.

Curing: Curing enhances both the concrete and reinforcement bond.

Finishing: Final finishing ensures smooth surfaces and accurate dimensions.

Role of Concrete Pipe Making Machines

The advent of advanced concrete pipe making machines has revolutionized the manufacturing process. These machines ensure precision, efficiency, and scalability, meeting the demands of modern infrastructure projects.

Features of Modern Concrete Pipe Machines:

Automation: Reduces human error and increases production speed.

Flexibility: Handles the production of both reinforced and non-reinforced pipes.

Durability: Built to withstand the demands of continuous operation.

Customization: Configurable for different pipe sizes and specifications.

Concrete Pipe Making Machine in India

India is a growing hub for infrastructure development, and the demand for efficient pipe-making equipment is rising. Indian manufacturers are producing state-of-the-art machinery to cater to both domestic and international markets.

Advantages of Using Concrete Pipe Making Machinery

Precision: Ensures accurate pipe dimensions and consistent quality.

Efficiency: Reduces production time and operational costs.

Versatility: Supports the manufacturing of a wide range of pipe types.

Sustainability: Machines are designed to minimize waste and energy consumption.

Choosing the Right Concrete Pipe Type

Selecting between reinforced and non-reinforced pipes depends on several factors:

Load Requirements

Use non-reinforced pipes for low-load conditions like agricultural drains.

Opt for reinforced pipes in high-load applications.

Project Scale

Small-scale projects can benefit from the cost savings of non-reinforced pipes.

Large-scale infrastructure requires the durability of reinforced pipes.

Budget Considerations

Non-reinforced pipes are more affordable.

Reinforced pipes justify their higher cost with superior performance and longevity.

Innovations in Concrete Pipe Technology

Sustainability: Eco-friendly materials and energy-efficient manufacturing processes are gaining traction.

Smart Reinforcement: Advanced reinforcement designs reduce material usage without compromising strength.

3D Printing: Emerging technology is enabling the production of custom concrete pipes with intricate designs.

IoT Integration: Machines equipped with IoT capabilities for real-time monitoring and predictive maintenance.

Role of Manufacturers in Advancing Concrete Pipe Technology

Leading Innovations

Concrete pipe making machine manufacturers continuously innovate to meet the evolving needs of infrastructure projects, developing equipment that enhances productivity and reduces costs.

Providing Expertise

Manufacturers guide clients in selecting the right machinery and pipe types based on project requirements.

After-Sales Support

Comprehensive support services, including maintenance and training, ensure optimal performance of pipe-making machines.

The Future of Concrete Pipes

The demand for efficient, durable, and cost-effective concrete pipes will continue to grow. Manufacturers and engineers are focusing on:

Enhanced Durability: Developing pipes with longer lifespan and greater resistance to environmental factors.

Automation: Increasing reliance on fully automated machinery for precision and efficiency.

Customization: Designing pipes tailored for specific applications, such as earthquake-resistant or corrosion-resistant variants.

Conclusion

Concrete pipes, whether reinforced or non-reinforced, are indispensable for modern infrastructure. Understanding the science behind these pipes and leveraging advanced manufacturing technologies like concrete pipe making machines ensures that projects meet both technical and economic requirements. As technology evolves, the capabilities of concrete pipes and their manufacturing processes will continue to advance, supporting the infrastructure needs of tomorrow.

0 notes

Text

Applications of Automated Curing Systems in the Construction Industry

The construction industry is evolving rapidly, with automation playing a pivotal role in enhancing efficiency and precision. Among the many technological advancements, automated curing systems have emerged as a game-changer, especially in the realm of concrete production. These systems ensure optimal curing conditions, significantly improving the strength, durability, and quality of concrete products.

In this article, we’ll explore the diverse applications of automated curing systems in the construction industry, the benefits they offer, and how it is leading the way with cutting-edge solutions.

What is an Automated Curing System?

An automated curing system is an advanced technology designed to control and optimize the curing process of concrete products. Curing system uses precise temperature, humidity, and timing controls to create ideal curing conditions. By automating the process, it eliminates inconsistencies and human errors, ensuring superior results.

Importance of Curing in Construction

Curing is a vital process in concrete production. It involves maintaining appropriate moisture, temperature, and time conditions to allow the concrete to gain strength and durability. Poor curing can lead to cracks, reduced strength, and compromised structural integrity. Automated curing system address these challenges by offering consistent and efficient curing, regardless of external factors.

Key Applications of Automated Curing Systems

Automated curing systems are versatile and can be applied across various segments of the construction industry.

Concrete Pipe Manufacturing

For concrete pipes used in drainage and sewage systems, uniform curing is crucial to withstand high pressure. Automated curing systems ensure consistent results, enhancing the durability and reliability of the pipes.

Architectural Concrete Products

Products like decorative panels and cladding require not just strength but also aesthetic perfection. Automated systems create ideal curing conditions to minimize defects and ensure uniform finishes.

Infrastructure Projects

Large-scale infrastructure projects like bridges, tunnels, and highways rely on high-performance concrete. Automated curing systems optimize the curing process, resulting in concrete that can withstand heavy loads and extreme environmental conditions.

Masonry Products

Automated curing is increasingly being used for blocks and bricks. It improves their strength and reduces the time needed for production, meeting high demand without compromising quality.

Benefits of Automated Curing Systems

Enhanced Concrete Quality

Automated curing systems provide precise control over curing conditions, ensuring uniformity and reducing defects. The result is stronger, more durable concrete.

Increased Efficiency

Automation significantly reduces the time and labor required for curing, enabling faster production cycles and meeting tight deadlines.

Energy Efficiency

Modern systems, such as SmartSet Curing Systems, are designed to optimize energy use, reducing operational costs while maintaining high performance.

Reduced Human Error

Automation eliminates the variability associated with manual processes, ensuring consistency in every batch.

Sustainability

Efficient curing reduces material wastage and energy consumption, aligning with green building practices.

Key Features of Automated Curing Systems

Precise Control: Advanced sensors and software ensure optimal temperature and humidity levels.

Energy Optimization: Smart systems minimize energy consumption without compromising performance.

Customizable Solutions: Designed to cater to specific project requirements, whether for precast elements or large-scale infrastructure.

Durability and Longevity: Built with high-quality materials to withstand continuous use.

Industries Benefiting from Automated Curing Systems

Residential Construction

Housing projects benefit from faster production of masonry units and precast components, enabling timely project completion.

Commercial Construction

From office buildings to shopping malls, automated curing systems help deliver high-quality concrete products for diverse applications.

Industrial Construction

Factories, warehouses, and industrial facilities require durable concrete structures, which automated systems help achieve with precision.

Infrastructure Development

Bridges, flyovers, and drainage systems rely heavily on consistent and durable concrete, made possible by automated curing systems.

How Automated Curing Systems Support Large-Scale Projects

Large-scale projects face unique challenges such as tight timelines, quality control, and environmental considerations. Automated curing systems address these challenges by:

Improving Production Speed: Faster curing cycles mean quicker project completion.

Ensuring Quality Control: Automation provides uniform results, crucial for large structures.

Reducing Costs: Energy-efficient systems and reduced labor costs result in significant savings.

Meeting Environmental Goals: Optimized energy use aligns with sustainability initiatives.

Tips for Choosing the Right Automated Curing System

Assess Your Needs

Determine the scale of your project and the specific curing requirements.

Look for Energy Efficiency

Choose systems that offer energy-saving features to reduce operational costs.

Opt for Customizable Solutions

Ensure the system can be tailored to your project’s needs, whether for precast elements or other applications.