I like mining equipment, there is no equipment that cannot be repaired!(xgncrusher.com)

Don't wanna be here? Send us removal request.

Text

Uses of Bauxite in Arkansas

🔥Arkansas bauxite - the "white gold" of American industry💎Trillion-level industrial chain dug out!

1. The "blood formula" of the military industry maniac🛡️

✈️ Fighter heart: Each F-35 uses 1.2 tons of aluminum! The ultra-pure alumina extracted from the Arkansas mine allows the temperature resistance of the fighter engine to soar to 800℃+

🚀 Space code: NASA's latest lunar module shell, 70% of the aluminum comes from the nano-alumina coating in the mine area, and the cosmic ray protection performance has increased by 3 times

2. The "invisible battery" of new energy vehicles🔋

⚡ Lithium battery revolution: Tesla's secret formula! Boehmite purified from special alumina in the mining area is applied to the battery separator, which can directly extend the battery life by 150 kilometers.

🌍 Environmental protection killer: water purification gel developed with waste slag, 1 kg can absorb heavy metals in 2 tons of sewage, and the Environmental Protection Bureau is rushing to place orders

3. The "skin care metaphysics" that is crazy about the ladies' circle💄

✨ Beauty black technology: alumina nanoparticles containing rare minerals are made into anti-aging masks, and Hollywood stars' customized models are sold at $500/piece

💎 New species of jewelry: crystallized bauxite raw stones are cut into cyberpunk-style jewelry, and every model at New York Fashion Week has one

4. "Transformers" in the agricultural industry🌱

🚜 Soil modifier: sprinkle modified alumina powder on acidic soil, the pH value becomes neutral in seconds, and the strawberries grown are bigger than eggs

💦 Drought-resistant artifact: porous alumina particles buried in the soil automatically lock in rainwater, and desert farmers have measured water savings of 60%

5. High-profit unpopular gameplay💰

🎮 E-sports peripherals: mouse coating containing bauxite powder, no matter how much sweaty your hands are, it will not slip, and the customized version of the e-sports team is sold out

🏡 Luxury house building materials: self-cleaning exterior wall tiles made of calcined alumina, automatically wash away stains when it rains, and the developer adds $300 per square meter

⚠️ Cold knowledge warning: During World War II, this place supplied 90% of aluminum in the United States. Now you can still dig up vintage military aluminum plates in the slag heap, and collectors offer $2000/piece!

Next time you see a white stone, don't kick it randomly, maybe it's the "aluminum gold mine" that changes your destiny~🗝️

Author: Xingaonai Reprint address: http://xingaonai.cn/mineral-profile/uses-of-bauxite-in-arkansas.html

0 notes

Text

Teach you how to identify gold ore

There are many kinds of ores in nature, and any ore containing gold is called gold ore. Because the chemical properties of gold are very stable and will not react chemically under different environments, it is necessary to identify gold ore by combining the main characteristics of gold ore with professional instruments.

Appearance identification

First, we identify the appearance of the ore. Generally, gold ores are golden yellow, black, copper or reddish brown, with a smooth and bright surface. Among them, gold ore with high gold content are mostly golden yellow in color, and sometimes there are different degrees of oxidation crystals and oxide films on the surface. However, ores with the above characteristics are not necessarily gold ore, and other methods are needed to identify them.

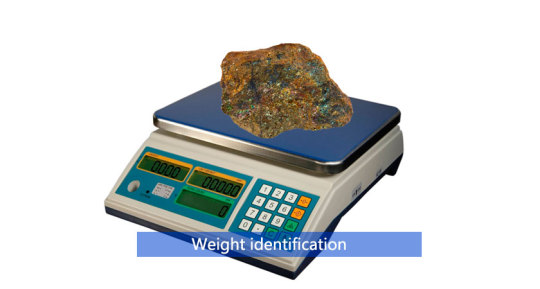

Weight identification

After identification through appearance, we identify the weight of the ore. Everyone knows that gold has a high density and a higher specific gravity than other metals. Generally speaking, real gold ore is heavier, with a specific gravity of about 17 to 19, and most stones have a specific gravity of 12 to 15, so we can use an electronic scale to measure the weight of the ore, first put the ore in a density solution, and then infer the density component of the ore by comparison.

Hardness identification

Then identify by the hardness of the ore. By rubbing two stones against each other, it should be gold ore that is not easy to scratch. Generally, it is tested by scratching or friction, and it can also be tested by a specific hardness instrument.

Fire identification

We can also use fire to identify whether it is gold ore. When the red-burned ore is put into water, it can produce noise and splashes, indicating that the ore is real, otherwise it is fake.

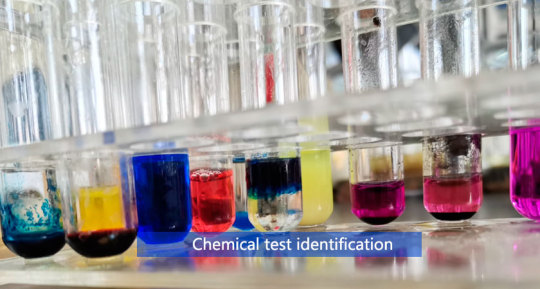

Chemical test identification

Another reliable method is chemical testing, using sodium hydroxide solution to soak the ore. If the ore does not change, it means it is real gold ore, otherwise it is fake.

The above method can preliminarily identify the authenticity of gold ore. It should be noted that with the development of technology, some people use artificial gold ore raw stones to defraud in order to gain higher profits, so it is necessary to carefully identify. If the value is relatively large, it is recommended that professionals identify it.

Article Source:Teach you how to identify gold ore_Industral news_Xingaonai Group

0 notes

Text

How to solve the problem of blocked holes, cracks and perforations in the vibrating screen?

The screen is one of the main components of the vibrating screen.(Stone Crusher) Its main function is to filter materials. Since the screen is in direct contact with the materials during the production process, it is also the main wearing part of the vibrating screen. Breakage and perforation of the screen often occur during the operation. , plugging and other phenomena. If the screen is frequently broken or blocked in a short period of time, it will not only affect the production schedule, but also lead to an increase in investment costs and directly affect the economic benefits of the enterprise. Therefore, understand the causes and solutions of screen cracks, perforations and plugging failures. Measures can effectively save maintenance time, improve work productivity, and ensure orderly and normal production.

Analysis of the causes of screen clogging

The phenomenon of screen damage caused by materials blocking the screen holes often occurs during the production process, especially when the screen mesh is small, this phenomenon is more obvious. Due to the diversity of material particle shapes, various forms of screen hole blockage will occur. The common causes of screen hole blockage are mainly as follows:

1. The particle size of the crushed stone is critical to the mesh size of the screen. During the screening process of the stone, such particles are stuck in the mesh and cannot pass through the screen smoothly, causing blockage. This phenomenon is called critical blockage.

2. There are many materials with shapes that have multiple contact points for the screen holes.(Xingaonai group , Stone crusher)

3. If there are more flaky materials in the stone, the flaky materials themselves cannot pass through the screen smoothly during screening. At the same time, the flaky materials are interwoven into a mesh, which hinders the screening of other materials, which will cause clogging.

4. The diameter of the steel wire used to prepare the screen is too thick.

5. The materials to be screened have high moisture and contain viscous substances such as mud and sand. If the materials to be screened contain a lot of mud, or the materials require water washing, the fine-grained stones will stick to each other and form agglomerates due to the intervention of water. The soil adheres to the screen surface, making it difficult to screen materials and causing clogging.

0 notes

Text

Adjustment of discharging particle size of roller sand making machine and key points of daily maintenance

The double-roller crusher is mainly used for medium-to-fine crushing of brittle and tough medium-hard materials, such as limestone, bluestone, coal gangue, shale, etc. It is widely used in sand and gravel yards and mining.(Stone Crusher)

The double-roller crusher uses rollers to crush materials. It uses two high-strength and wear-resistant alloy rollers to crush materials with high extrusion force generated by relative rotation. After the materials enter the gap between the two rollers, they are affected by the relative rotation of the two rollers. Under the action of extrusion force and shearing force, under the conditions of extrusion, shearing and grinding, the material is broken into the required particle size and then discharged from the discharge port at the bottom of the machine. Since the working distance between the rollers is relatively fixed, it can be The particle size of the crushed products is controlled from being too coarse, and the material is clamped into the extrusion zone between the spokes by pulling force, which can produce a continuous extrusion cycle. It not only has high productivity, but also can handle sticky and wet materials. However, the roller system The feed particle size of the sand machine is relatively small and cannot exceed 40mm.

Since the double-roller crusher relies on double-roller extrusion for crushing, if the gap size between the two rollers is not adjusted appropriately, its crushing efficiency and effect will be affected, thereby affecting the discharge granularity. Below we will briefly explain the factors that affect the discharging granularity and how to adjust it.(Xingaonai group , Stone crusher)

Influencing factors

Speed and ratio of the two rollers: If the two rollers rotate at the same speed, they can only squeeze the material, while the crushing effect on the material mainly depends on the relative movement and the difference in deflection between the two rollers. Therefore, the speed of the two rollers is the same. Fast and slow are better. The ratio of the speed of the fast roller to the slow roller is the ratio. The larger the ratio, the longer the crushing area, the stronger the crushing effect, and the better the particle shape of the finished product. The commonly used ratio is 2.5-1.

0 notes

Text

How to deal with the deviation and breakage of the filter belt of the belt filter press?

As a commonly used solid-liquid separation sludge treatment equipment,(Stone Crusher) the belt filter press consists of two upper and lower tensioned filter belts carrying the sludge layer, passing through a series of regularly arranged roller cylinders in an S-shape. The tension of the filter belt itself forms a squeezing and shearing force on the sludge layer, squeezing out the water in the sludge layer, and obtaining a mud cake with a higher solid content, thereby achieving sludge dehydration. It has a high degree of automation and its operation mode is continuous processing, so it has a huge advantage in processing capacity.

Since the supporting system of the belt filter press is relatively complex, various faults may occur during long-term operation. Among them, the most frequent fault is the deviation of the filter belt from the center line, that is, The direction of the filter belt is deflected, and the degree of deflection of the filter belt is related to the normal and long-term stable operation of the filter press. Once the filter belt is seriously misaligned, it will not only affect the mud removal effect, but even if other supporting equipment systems can operate normally, the filter press will be forced to shut down, thus affecting the normal operation of the (Xingaonai group , Stone crusher)equipment. In serious cases, the filter belt and related equipment may even be damaged. Hydraulic control system. There are many factors that lead to serious deviation of the filter belt (making the equipment unable to operate normally). Among them, issues such as component accuracy and rationality, filter belt quality, and whether the deviation adjustment system is properly set up are issues of the manufacturer.

0 notes

Text

How to solve the problem of material blocking in double rotor sand making machine? What should we pay attention to in daily operation?

The dual-rotor sand making machine mainly consists of two rotors, pendulums, linings and other components to complete the sand-making operation. (Stone crusher)The operating principle is "stone against stone". Driven by the dual motors, the two sets of rotors connected in series rotate at high speed at the same time, and the materials are After being crushed by the upper rotor, the inner cavity of the machine is immediately crushed again by the hammer head of the rapidly rotating lower rotor. Through the combination of the rotor, machine cavity shape and speed, the stones are allowed to collide, impact and crush each other as much as possible, thereby achieving the hammer powder. It is a practical small and medium-sized sand making machine.

Double transfer

Regarding plugging, almost all types of sand making machines will encounter this problem, and the reasons are various. Once blockage occurs in the sand making machine, it will affect the progress of the entire production line and cause losses to the company's benefits. Therefore, understanding the common causes and solutions of blockage in advance is extremely important for the normal production of the company, so that it can be avoided at the source. Or reduce the occurrence of material blockage to ensure smooth and smooth production.(Xingaonai group , Stone crusher)

Effect of blocking material

1. Cause serious wear and tear to the components of the sand making machine: If blockage occurs in the sand making machine, the friction between the material and the crushing parts will increase, causing additional wear and tear on the components within the equipment.

2. Resulting in uneven discharge particle size: Once blockage occurs, the crushing space is reduced, coupled with the wear and tear of the crushing parts, the material will not be completely crushed and the discharge particle size will be uneven.

3. Cause abnormal vibration of the machine body: Material blockage will cause the equipment to overload, especially when the material is unevenly distributed in the crushing chamber, it will cause uneven stress on the machine body, causing excessive vibration of the equipment.

4. Reducing production volume: Material blockage may cause the equipment to become stuffy and forced to shut down, greatly reducing production volume.

0 notes

Text

What to do if the fine sand recycling machine produces unclean sand? How to improve recycling rate?

In the later stage of the sand making production line, (Stone crusher)for sand with a large mud content or a sand-water mixture with a large sand content, only a sand washing machine may not meet the requirements for the final finished sand, so a fine sand recovery machine is required. , it has become the standard equipment in the sand making production line, and its importance is self-evident. When the equipment is used for a long time, some problems will inevitably occur, such as: the sand is not clean. In order to solve the problem of unclean sand produced by the fine sand recovery machine, we must first find out the cause of the problem before we can prescribe the right medicine to solve the problem. Xingao Nai Heavy Industry has summarized the following 5 reasons.(Xingaonai group , Stone crusher)

Reasons and solutions for unclean sand production

1. The discharge port is blocked

If the sand and gravel particles in the slurry in the fine sand recovery machine are too fine, and the single feeding amount suddenly increases, causing material to accumulate at the discharge port, the sand discharge will be unclean.

Solution: Stop feeding immediately, open all discharge openings, rinse with clean water before continuing the operation. When starting the operation again, be sure to feed the material evenly.

2. The pressure of the cyclone is too large

During operation, if the pressure given by the cyclone is too high, it will cause water to spray and splash from the cyclone. Eventually, the sediment cannot be completely separated when the material passes through the vibrating screen. If the pressure is too small, the fine sand cannot be completely separated. Recycling, resulting in low fine sand recovery rate.

Solution: Properly configure the cyclone and provide appropriate pressure.

3. The vacuum high-pressure pump is clogged

If debris enters the mud, causing the vacuum high-pressure pump to become clogged, it will result in unclean sand production.

Solution: During operation, try to prevent debris from entering the mud. You can directly connect the outlet of the dewatering screen to the feed port of the fine sand recovery machine to prevent debris from entering and clogging the high-pressure pump.

4. Sieve plate

When the screen mesh of the screen plate is too large and the particle size of the recovered fine sand is small, there will definitely be no sand. If the mesh size is too small and the particle size of the sand is too large, it will easily cause the dewatering fine sand recovery machine to become clogged. This will also cause it to not produce sand.

Solution: Choose the appropriate screen according to the fine sand particle size in the production line.

5. Vibration motor

If the motor power is too small, the motor will not be able to drive the equipment, resulting in no sand production. If the motor power is too large, electricity will be wasted, making the investment uneconomical.

Solution: Choose the appropriate vibration motor according to your actual situation.

0 notes

Text

Reasons why the amplitudes on both sides of the vibrating screen are inconsistent and how to adjust the amplitude

Amplitude is an important technical parameter of the vibrating screen.(Stone crusher) It affects the screening efficiency and production volume. However, we cannot directly observe the amplitude with our eyes and need to calculate it with a formula.

During the production process, if the amplitudes on the left and right sides of the vibrating screen are inconsistent, it will cause unbalanced force on the equipment, which may also lead to impenetrable sieves and low efficiency. In the long run, it will also cause damage to the screen box(Xingaonai group , Stone crusher).

In order to avoid this phenomenon, amplitude stickers can be attached to the inlet end of the vibrating screen, the bottom of the exciter, and the left and right sides of the discharge end. Pay attention when the vibrating screen is started. When the amplitude difference between the two sides is within 0.5mm, it can still It meets the usage requirements, but if it exceeds 1mm, it will cause changes in the flow direction of the material and induce various failures. At this time, measures should be taken in time to adjust.

New high resistance vibration screen

The first reason for the inconsistent amplitude on both sides of the vibrating screen is: uneven feeding, because when the feeding is unevenly distributed along the width of the vibrating screen, it will cause the vibrating screen to be overweight, which will affect the amplitude, so it should be adjusted A good feeding chute ensures the uniformity of feeding materials.

The second reason is: parts are loose or deformed. When the universal coupling or flexible coupling between the two exciters is loose or deformed, it will also affect the amplitude of the vibrating screen. If it is only loose, tighten it in time. That's it. If it is deformed, you need to replace it with new parts according to the specific situation.

The third reason is: the use of the exciter exceeds the limit. After the vibrator is used continuously for more than 8,000 hours, it will cause wear of the bearings, resulting in inconsistent amplitudes on both sides. Therefore, regular attention must be paid to the vibrator before it reaches its service life. If the vibration exciter is in good condition, replace it with a new one in a timely manner and do not wait until problems arise to solve them.

The fourth reason is: the spring is used beyond the limit. The life of the rubber spring used to support the four corners of the vibrating screen is about 8000h~10000h, and the life of the metal spring is about 3000h~5000h. If damage occurs before the specified time, it may be It is caused by long-term overload use of the spring or its own quality defects. Therefore, in order to avoid causing more serious failures, when the spring has been used for the specified time or is overloaded for a long time, it should be replaced in time. Do not continue to use it opportunistically. If there is a problem with the quality of the spring itself, choose a large manufacturer when purchasing again. Products with guaranteed quality.

0 notes

Text

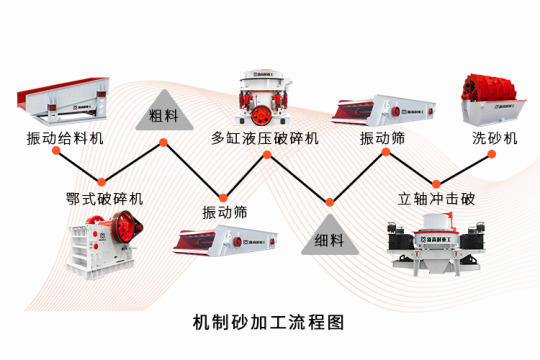

Let’s take a hot example in the sand and gravel industry.(Stone crusher) A machine-made sand production line with an hourly output of 300 tons can run for 10 hours a day and can produce 3,000 tons of machine-made sand per day. If the conservative price of a ton of machine-made sand is about 100 yuan, the daily output is 3,000 tons. This means that the daily operating income can reach 300,000. Although the above examples may seem exaggerated, they are enough to illustrate the popularity of the machine-made sand and gravel market.(xingaonai)

Coupled with the constraints of natural sand mining, the crackdown on illegal sand mining, environmental protection inspections and other major environmental impacts, and artificial sand has more advantages than natural sand in all aspects, the demand for machine-made sand and gravel aggregates has only increased. The development prospects are broad.

The market is hot and has broad prospects. How can it not attract capital investment from all parties? So if you invest in a sand and gravel production line, how to estimate the investment cost and what factors need to be considered?

The investment cost budget of a sand and gravel production line varies greatly due to different raw materials and production scale. The actual cost varies greatly. When estimating the investment cost of a sand and gravel production line, it is mainly affected by raw materials, infrastructure construction, equipment configuration, production capacity, market supply and demand, and manufacturer strength. Later, Influenced by many factors such as operations.

0 notes

Text

Everything is graded, and sand and gravel aggregates are no exception. The content of flat and oblong particles in the finished materials of the sand and gravel production line directly affects the quality of the finished products. Let’s talk about the factors that affect the quality of finished materials.(xingaonai)

Parent rock properties

The quality of finished sand and gravel aggregate is first determined by the quality of the parent rock. The strength, mineral composition, rock structure and chemical composition of the parent rock are different, which has an important impact on the energy consumption of the equipment, the stone powder content and particle shape of the finished product. Another factor is the cleanliness of the parent rock. When choosing sand mines, choose mines with less impurities such as soil and light substances and good rock integrity. During mining, there will be relatively less impurities and sediment mixed in. It is also easier to control the mud content of machine-made sand and gravel to ensure the quality of finished sand and gravel aggregates.

Equipment selection

The control of sand and gravel quality first needs to start from the source. The source is mainly the selection of sand and gravel equipment, which will directly affect the quality indicators of finished product particle size, mud content, finished material grade and taste. Equipment selection can make corresponding equipment configuration and process design plans based on the size of the raw materials and the needs of the production line. In these plans, how to combine the jaw crusher, cone crusher, impact crusher, sand making machine and other equipment depends on the material properties and production capacity. Adapt based on size and finished product granularity.

0 notes

Text

The impact of the performance of the sand making machine on its sand production rate

Due to the increasing intensity of infrastructure construction, the demand for machine-made sand is also increasing day by day. In daily operations, some customers will encounter situations where the production capacity of the sand making machine is too low and the sand production volume is insufficient. The sand production rate of the sand making machine determines the production efficiency. In actual production, the performance of the sand making machine itself has a certain impact on its sand production rate.

PCK Series Sand Making Machine

In terms of sand making machine models, there are single-rotor sand making machines, double-rotor sand making machines, vertical shaft sand making machines, double-roller sand making machines, etc. (xingaonai)These equipments have different working performances, and the sand making machines produced by each manufacturer There are certain differences in the machine models. The sand production volume and energy consumption of different models of equipment during operation are different. In addition, different mining machine manufacturers have different levels of mastery of the production technology of sand making machines, which will also lead to different performance of sand making machine equipment. The following aspects are the factors that affect the sand production rate of the sand making machine:

VSI Series Vertical Shaft Impact Crusher

Impeller speed: For sand making machines, the speed is inversely proportional to the throughput, and has a square relationship to the energy-rich material. The higher the speed, the lower the throughput. For example, if the speed is increased by 50%, in fact, the material The energy content is increased by 2.5 times.

0 notes

Text

Effect of material characteristics on sand production rate of sand making machine

In fact, in actual production, in addition to the performance of the sand making machine itself, there are also some other external factors that affect the sand production rate of the sand making machine, such as: the hardness, viscosity, moisture content, composition, and finished sand of the material.(Stone crusher) Fineness requirements, etc.

New high-resistant single rotor

The following is an analysis of factors affecting sand production rate:(xingaonai)

Hardness: In actual production, the hardness of the ore itself has a great impact on the difficulty of crushing. The higher the hardness of the sand-making material, the greater its density and the more difficult it is to crush. Therefore, the lower the sand formation rate.

Viscosity: The greater the viscosity of the raw material, the easier it is to adhere. It will adhere to the inner wall of the crushing chamber of the sand making machine during the sand making process. If not cleaned in time, it will affect the working efficiency and sand production rate of the sand making machine, and in serious cases, it will damage the sand making machine. machine, reducing the service life of the sand making machine.

Humidity: When the material is crushed in the sand making machine, if the moisture content of the material is high, it will not only easily adhere to the inner wall of the crushing cavity of the sand making machine, but also be easily blocked during the unloading and transportation process, resulting in a reduction in the output of the sand making machine. Reduce the sand production rate of the sand making machine.

Composition: The fine powder content of the material will affect the efficiency and sand production rate of the sand making machine, because the fine powder is adhesive and will affect the transportation, thereby affecting the sand production rate.

Finished sand fineness requirements: The higher the fineness requirements of the sand making machine, that is, the finer the finished material is required, the smaller the sand making capacity will be, so the lower the sand formation rate will be.

To sum up, different raw materials of machine-made sand will have certain differences in hardness, viscosity, humidity, composition, etc., and the sand production volume will also vary according to the different crushed materials.

0 notes

Text

How to improve the sand production rate of sand making machine?

The first two articles describe(sand crusher) the factors that affect the sand production rate of the sand making machine from the perspective of the performance of the sand making machine and the characteristics of the raw materials for machine-made sand. (Stone crusher)Today we will talk about how to improve the sand production rate of the sand making machine. You can start from the following aspects:

0 notes

Text

Causes of unbalanced sand making machine rotor and how to adjust it

Sand making machine is a commonly used key equipment in the machine-made sand process. (sand crusher) It is usually used in the fine crushing and shaping stages of materials. The rotor is its core component.(Stone crusher) Generally, before leaving the factory, manufacturers will use an online dynamic balancer to add a counterweight to the rotor. To ensure the balanced operation of the sand making machine rotor. For example: According to industry standards, the impeller rotor balance grade of an impact sand making machine is G16.

0 notes

Text

Can manufactured sand replace natural sand? What sand making machine is best to use?

Sand is an important material required for modern buildings and highway construction.(stone crusher) Natural sand refers to original rock particles with a particle size of less than 5mm formed by natural conditions. Depending on their origin, it is mainly divided into river sand. (sand crusher) Sea sand and mountain sand.

After all, natural sand is limited. With the over-exploitation of natural sand and the shortage of supply, machine-made sand has emerged. It refers to rock particles with a particle size less than 4.75mm after mechanical crushing. It is mainly divided into granite sand and pebble sand. , limestone sand making, construction waste sand making, etc.

Driven by my country's huge infrastructure construction volume, policy and environmental protection awareness, and the gradual depletion of natural sand in the market environment, my country's market demand for machine-made sand and gravel aggregates is extremely considerable. At present, many concrete and mortar companies have begun to Manufactured sand is used instead of natural sand in production, and good economic benefits have been achieved.

0 notes

Text

Mobile crushers are obviously so expensive, why are they said to be more economical?

Mobile crusher, also known as mobile crushing station, is equivalent to a complete crushing production line and can even serve as a small crushing production workshop. Its emergence has greatly expanded the conceptual field of crushing operations and made up for the shortcomings of fixed crushing equipment. Board, strong environmental adaptability + flexible maneuverability, (sand crusher) eliminating a series of problems caused by site and environmental requirements.

The mobile crusher has been on the market for a short time. In addition, it is a large-scale equipment with high manufacturing costs. Therefore, if you only look at the quotation of a single machine, its investment price is naturally more expensive than that of a single fixed crushing machine. However, it must be considered in terms of comprehensive investment. If you look at it, mobile crushers are actually more economical. Here’s how to save money:

0 notes

Text

Crushing ratio, crushing sections and crushing process of the crusher

The ratio of the particle size of the raw material to the particle size of the crushed finished product(sand crusher) is referred to as the crushing ratio, which directly affects the energy consumption and processing capacity of the crusher and is a key factor in measuring the crushing effect of the crusher. (stone crusher)There are three commonly used crushing ratio calculation methods, and different crushing ratio calculation methods have different applicable objects.

0 notes