Don't wanna be here? Send us removal request.

Text

Top Features Offered by Leading Keyboard Manufacturers in India

Keyboards today go beyond just typing – they enhance user experience with advanced features. Leading keyboard manufacturers in India focus on ergonomic comfort to reduce strain, provide switch options for customized typing experiences, and offer RGB lighting for aesthetics and personalization. Additionally, durability ensures longevity, and wireless operations cater to modern remote working needs.

At Cutek Circuits, we redefine typing experiences with premium, custom keyboards designed for various industries.

To read the full blog, click here: https://cutekcircuits.com/blog/features-of-keyboard-manufacturers-in-india/

0 notes

Text

Tactile Keyboards: A Revolution in Comfort, Performance, and Productivity

Tactile keyboards are redefining the typing experience for professionals, gamers, and enthusiasts worldwide. Known for their mechanical switches that deliver a distinct tactile bump with every keypress, these keyboards provide unmatched feedback and responsiveness. Unlike standard membrane keyboards, tactile keyboards are designed to enhance precision and comfort, making them an excellent choice for anyone who spends significant time typing, coding, or gaming.

The defining feature of a tactile keyboard lies in its mechanical switches. These switches not only register keystrokes more accurately but also provide a tactile sensation that helps users type faster and with fewer errors. This makes tactile keyboards an ideal choice for writers who need to type long documents, programmers who require precision, and gamers who rely on quick and accurate keypresses during intense gameplay. The tactile feedback helps users stay aware of each keystroke without needing to press the keys all the way down, reducing strain and fatigue during long sessions.

Why Choose a Tactile Keyboard?

Comfort and Ergonomics: Tactile keyboards are designed to be more comfortable for extended use. The tactile bump provided by each keypress offers physical feedback, which helps reduce the need for forceful typing. Over time, this ergonomic design can alleviate strain on fingers and wrists, making it a healthier choice for frequent typists and gamers.

Enhanced Durability: Unlike membrane keyboards, which often wear out after a few years, tactile keyboards are built to last. Their mechanical switches are rated for tens of millions of keypresses, ensuring long-term reliability. This durability makes tactile keyboards a wise investment for those seeking quality and longevity.

Customizability: One of the key advantages of tactile keyboards is their customizability. Users can choose from different switch types, such as Cherry MX Brown, Gateron, or Razer tactile switches, depending on their preference for feedback and noise level. Additionally, tactile keyboards often come with customizable keycaps, RGB lighting options, and programmable macros, making them perfect for users who want a personalized experience.

Versatility Across Applications: Tactile keyboards cater to a wide range of users. Gamers love the precise feedback that allows for better control in competitive games, while writers and content creators appreciate the satisfying typing experience that speeds up their workflow. Even casual users can benefit from the superior performance and comfort these keyboards offer.

Aesthetic Appeal: Tactile keyboards are not just functional but also visually appealing. Many models come with sleek designs and RGB backlighting, adding a modern touch to your desk setup. Whether you prefer a minimalist style or a vibrant gaming aesthetic, there’s a tactile keyboard to suit your taste.

How to Choose the Right Tactile Keyboard

When selecting a tactile keyboard, consider factors like size, switch type, and additional features. Full-sized keyboards are ideal for those who need a numeric keypad, while compact models are perfect for users who prioritize portability. Switch types, such as tactile, linear, or clicky, vary in feedback and noise level, so choose one that aligns with your preferences. Features like programmable keys, detachable cables, and wrist rests can further enhance your experience.

Cutek Circuits: Your Go-To Brand for Tactile Keyboards

If you’re looking for a reliable tactile keyboard that combines performance, durability, and style, Cutek Circuits is a name you can trust. Known for their innovative designs and premium quality, Cutek Circuits offers a wide range of tactile keyboards to suit every need. Whether you’re a gamer seeking a high-performance keyboard or a professional looking for a durable and ergonomic option, their keyboards are crafted to deliver an unparalleled typing experience.

With a focus on cutting-edge technology, Cutek Circuits integrates features like advanced mechanical switches, customizable RGB lighting, and robust construction into their products. Their keyboards are built to last, ensuring you get the best value for your investment. Explore the range of tactile keyboards from Cutek Circuits and elevate your typing or gaming setup today.

In conclusion, tactile keyboards offer the perfect combination of comfort, precision, and durability, making them an excellent choice for all kinds of users. Whether you’re upgrading your workspace or seeking an edge in gaming, tactile keyboards are worth the investment. And with trusted brands like Cutek Circuits leading the way, you’re guaranteed a product that meets and exceeds your expectations.

0 notes

Text

Exploring the Excellence of Membrane Keyboard Manufacturers in India

The evolution of technology has significantly influenced how we interact with machines. Among various input devices, keyboards remain indispensable, and within this category, membrane keyboards have carved a niche for themselves. Known for their durability, flexibility, and cost-effectiveness, membrane keyboards are a popular choice across industries. India, as a hub of technological advancement, hosts several prominent membrane keyboard manufacturers that cater to diverse needs, from industrial applications to consumer electronics.

Why Membrane Keyboards?

Membrane keyboards are built with pressure pads that do not rely on separate moving parts like mechanical keyboards. Their compact design offers a plethora of advantages, including:

Enhanced Durability: Membrane keyboards have a sealed structure that makes them resistant to dirt, moisture, and spills.

Cost Efficiency: Their simpler construction translates to affordability without compromising functionality.

Customizability: Industries often demand specialized solutions. Membrane keyboard manufacturers in India excel in delivering tailored products that meet specific requirements.

These features make membrane keyboards a preferred choice for medical equipment, ATMs, industrial machinery, and more.

The Rise of Membrane Keyboard Manufacturing in India

India's manufacturing ecosystem has witnessed remarkable growth, with keyboard manufacturers in India leading the charge. With a strong focus on innovation and quality, these manufacturers have earned a reputation for producing high-performance keyboards that cater to both domestic and international markets.

One of the distinguishing factors is the ability of Indian manufacturers to balance affordability with customization. For instance, a customized membrane keyboard can be designed to include features such as tactile feedback, backlighting, or even waterproofing. This adaptability has positioned Indian manufacturers as reliable partners for global businesses seeking cost-effective yet innovative solutions.

Applications Across Diverse Industries

Membrane keyboards are not confined to consumer electronics; their versatility finds application across various sectors:

Industrial Equipment: In rugged environments, these keyboards stand out due to their resistance to harsh conditions.

Healthcare: The sealed structure of membrane keyboards ensures hygiene, making them suitable for medical devices.

Banking and Retail: ATMs and point-of-sale systems frequently use membrane keypads for their reliability and longevity.

The ability to cater to such varied industries is a testament to the capabilities of membrane keypad manufacturers in India.

Key Features of Indian Manufacturers

Indian membrane keyboard manufacturers stand out for several reasons:

Advanced Technology: Incorporating state-of-the-art machinery ensures precision and quality in every product.

Sustainability: Many manufacturers are adopting eco-friendly practices, reducing their carbon footprint.

Customer-Centric Approach: Whether it's a standard design or a customized membrane keyboard, manufacturers prioritize customer needs, ensuring tailored solutions.

Global Standards Compliance: Products often meet international certifications, making Indian manufacturers competitive on the global stage.

Challenges and Opportunities

While India’s membrane keyboard industry has made significant strides, challenges such as fluctuating raw material prices and competition from global players remain. However, these challenges present opportunities for innovation. For instance, leveraging indigenous resources and developing cost-efficient manufacturing techniques can further strengthen the industry’s position.

The government's "Make in India" initiative also plays a crucial role in encouraging local manufacturing, offering incentives that foster growth and innovation.

Choosing the Right Manufacturer

When selecting a membrane keyboard manufacturer, businesses should consider factors such as:

Experience and Expertise: Look for manufacturers with a proven track record.

Customization Capabilities: Ensure the manufacturer can deliver tailored solutions that align with your specific requirements.

Quality Assurance: Opt for manufacturers that prioritize stringent quality checks and certifications.

After-Sales Support: Reliable customer service ensures a hassle-free experience post-purchase.

Why Cutek Circuits is a Trusted Choice

Among the leading names in the industry, Cutek Circuits has established itself as a reliable partner for businesses seeking high-quality membrane keyboards. With a commitment to innovation, customization, and excellence, the brand caters to diverse needs, including customized membrane keyboards for specialized applications. Whether you’re searching for a keyboard manufacturer in India or a trusted membrane keypad manufacturer in India, Cutek Circuits is a name synonymous with quality and trust. India’s membrane keyboard manufacturers are driving innovation and efficiency, proving that the country is not just a consumer of technology but a creator of world-class solutions. With brands like Cutek Circuits at the forefront, the future of keyboard manufacturing in India looks brighter than ever.

0 notes

Text

Printed Electronics: Revolutionizing Modern Technology

The world of electronics is undergoing a paradigm shift with the advent of printed electronics. Unlike traditional methods of manufacturing electronic circuits, this innovative technology relies on printing techniques to fabricate devices on a variety of surfaces. The result? A cost-effective, versatile, and sustainable way to produce electronic components. As industries continue to explore its potential, printed electronics is proving to be a game-changer, unlocking possibilities that were once deemed impossible.

What Are Printed Electronics?

Printed electronics refer to a set of processes where conductive, dielectric, and semiconducting inks are printed onto substrates such as plastic, glass, paper, or even textiles. Using techniques like screen printing, inkjet printing, gravure, and flexographic printing, electronic circuits are created with precision and efficiency. This process eliminates the need for complex and expensive manufacturing setups traditionally associated with electronics production.

The versatility of printed electronics lies in its ability to accommodate flexible substrates. This has given rise to a new class of electronics that are lightweight, bendable, and even wearable. From smart packaging to flexible displays, the applications of this technology are growing exponentially.

Advantages of Printed Electronics

The shift towards printed electronics is driven by several key advantages:

Cost-Efficiency: Traditional circuit manufacturing involves high costs due to expensive raw materials and labor-intensive processes. Printed electronics, however, utilize less material and faster production methods, leading to significant cost savings.

Design Flexibility: With printed electronics, manufacturers can design circuits on unconventional surfaces, opening new avenues for product innovation.

Scalability: Printing processes are inherently scalable, making it easier to transition from prototyping to mass production without substantial changes in infrastructure.

Sustainability: The use of eco-friendly inks and minimal material wastage aligns printed electronics with sustainable manufacturing practices.

Printed Electronics Applications

The real potential of printed electronics lies in its diverse applications across various industries. Below are some of the most transformative examples:

Healthcare: Printed electronics have made a significant impact on the healthcare sector. Flexible sensors, wearable medical devices, and disposable diagnostic tools are just a few examples where this technology is driving advancements.

Automotive: Modern vehicles integrate printed electronics in the form of sensors, touch controls, and even in-mold electronics to enhance functionality and aesthetics.

Consumer Electronics: Flexible screens, foldable smartphones, and smart clothing are increasingly leveraging printed electronics for their unique properties.

Energy Solutions: Solar cells, printed batteries, and energy-harvesting devices are gaining traction as sustainable energy solutions enabled by printed electronics.

Smart Packaging: Interactive packaging solutions equipped with NFC or RFID tags are transforming the retail and logistics industries.

These applications highlight the versatility of printed electronics, making it a preferred choice for industries looking to innovate and stay competitive.

The Role of Printed Electronics Manufacturers

As the demand for printed electronics continues to surge, the role of a printed electronics manufacturer becomes more pivotal than ever. These manufacturers are at the forefront of innovation, combining expertise in material science, engineering, and design to develop reliable and high-performing printed electronics.

Manufacturers must also stay abreast of the latest developments in conductive inks, substrate materials, and printing techniques. This enables them to create products that meet the growing demand for customization and performance. Additionally, partnerships with research institutions and technology firms help manufacturers push the boundaries of what is possible with printed electronics.

Challenges in Printed Electronics

Despite its promise, the journey of printed electronics is not without challenges. Ensuring the durability and reliability of printed circuits, especially in harsh environments, remains a key concern. Furthermore, the development of advanced inks with higher conductivity and compatibility with various substrates is an area of ongoing research.

Another challenge is the integration of printed electronics into existing manufacturing ecosystems. While the technology is inherently flexible, aligning it with traditional processes requires significant adjustments and investments.

Future of Printed Electronics

The future of printed electronics is incredibly bright. With advancements in nanomaterials, conductive inks, and high-resolution printing techniques, the scope for innovation is immense. Experts predict that printed electronics will play a vital role in the proliferation of the Internet of Things (IoT), smart cities, and next-generation consumer electronics.

Moreover, as industries adopt sustainable practices, the eco-friendly nature of printed electronics will make it a cornerstone of green manufacturing. Its ability to reduce material wastage and enable energy-efficient production processes positions it as a technology for the future.

Cutek Circuits: A Pioneer in Innovation

As industries evolve, embracing innovative technologies like printed electronics becomes imperative. Companies like Cutek Circuits have recognized the immense potential of this technology and are leading the way in delivering cutting-edge solutions. By leveraging expertise in design, manufacturing, and material science, Cutek Circuits is committed to providing high-quality products tailored to meet the unique needs of its clients. Whether it’s exploring printed electronics applications or advancing manufacturing techniques, Cutek Circuits is shaping the future of technology with unwavering dedication. In conclusion, printed electronics represents a groundbreaking shift in how electronic devices are designed and manufactured. Its vast potential across industries ensures that it will remain a critical area of innovation and investment in the years to come.

0 notes

Text

Printed Electronics: Shaping the Future of Modern Technology

In today’s technology-driven world, innovation is paramount. Among the advancements revolutionizing industries, printed electronics has emerged as a game-changing solution. This transformative technology has brought versatility, scalability, and cost-efficiency to electronic manufacturing, enabling endless possibilities across various sectors. With the growing demand for flexible, lightweight, and sustainable electronic devices, the applications of printed electronics are paving the way for a smarter and more connected future.

What Is Printed Electronics?

Printed electronics is a method of creating electronic devices by depositing conductive inks or materials onto flexible substrates such as plastic, paper, or fabric. Unlike traditional methods, which involve complex and resource-intensive processes, printed electronics relies on additive manufacturing techniques. This significantly reduces waste and production costs while maintaining efficiency and functionality.

The technology encompasses a wide range of devices, including printed sensors, displays, batteries, photovoltaic cells, and antennas. By integrating these components into various systems, industries can develop lightweight, energy-efficient solutions tailored to their needs.

The Rise of Printed Electronics Applications

The versatility of printed electronics has enabled its integration into numerous industries. Here are some of the most impactful applications transforming the landscape of modern technology:

Healthcare and Wearable Devices Printed electronics has found extensive use in healthcare, particularly in wearable devices that monitor vital signs like heart rate, body temperature, and oxygen levels. Flexible sensors and circuits are embedded into clothing or wearable patches, providing real-time data to healthcare professionals and patients alike. This innovation not only enhances patient care but also contributes to preventive health solutions.

Smart Packaging The packaging industry has embraced printed electronics to develop smart solutions that enhance consumer experience. Printed RFID tags, NFC chips, and temperature sensors on packages enable functionalities like product authentication, supply chain tracking, and freshness monitoring. For perishable goods, these features ensure better quality control and reduce waste.

Automotive and Transportation Automakers are leveraging printed electronics to design lighter and more efficient vehicles. Applications include touch-sensitive controls, OLED displays, and integrated sensors for autonomous driving systems. This technology also contributes to sustainability by reducing the weight of components, leading to improved fuel efficiency and lower emissions.

Smart Homes and IoT Printed electronics enables the development of IoT devices that are compact, flexible, and cost-effective. From smart thermostats and energy-efficient lighting to security systems and home automation devices, printed electronics ensures seamless integration of these systems into modern living spaces.

Energy Solutions Photovoltaic cells and flexible batteries are among the most notable printed electronics applications in the energy sector. These devices can be used in solar panels, portable energy solutions, and electric vehicles. The reduced manufacturing costs and scalability make renewable energy more accessible to businesses and consumers.

Advantages Driving Adoption

The adoption of printed electronics is skyrocketing due to its numerous benefits, including:

Cost Efficiency: Additive manufacturing techniques significantly reduce material wastage and production costs compared to conventional methods.

Flexibility: Devices produced using printed electronics are lightweight, thin, and bendable, making them suitable for applications requiring compact designs.

Sustainability: By minimizing resource consumption and enabling energy-efficient solutions, printed electronics contributes to a greener future.

Customization: The ability to print circuits directly onto substrates allows for tailored designs to suit specific requirements.

The Growth of Printed Electronics Companies

The surge in demand for flexible and sustainable electronics has led to the rise of numerous printed electronics companies across the globe. These companies are at the forefront of innovation, developing cutting-edge solutions that cater to diverse industries. By investing in advanced materials, scalable manufacturing processes, and research-driven development, they are shaping the future of electronics.

Industries are increasingly collaborating with these companies to incorporate printed electronics into their products. This partnership drives innovation and ensures that organizations stay competitive in an ever-evolving market.

Future Prospects of Printed Electronics

As the technology continues to mature, the future of printed electronics looks exceptionally promising. Advancements in materials, such as conductive polymers and graphene, are expected to enhance device performance and durability. Moreover, the integration of printed electronics with artificial intelligence (AI) and 5G networks will unlock new possibilities in automation and connectivity.

The global market for printed electronics is predicted to grow exponentially in the coming years, driven by increasing demand in healthcare, automotive, consumer electronics, and renewable energy sectors. Governments and private organizations alike are investing in research and infrastructure to support the development of this transformative technology.

Conclusion

Printed electronics is not just a technological trend — it is a cornerstone of the next industrial revolution. By offering cost-effective, sustainable, and versatile solutions, it is addressing the growing demand for smart, connected devices. From healthcare to automotive and IoT to renewable energy, the applications of printed electronics are reshaping industries and creating opportunities for innovation.

As businesses and researchers continue to explore its potential, Cutek Circuits is set to redefine how we interact with technology. The journey has only begun, and the possibilities are limitless. Companies embracing this technology today are undoubtedly positioning themselves as leaders in the world of tomorrow.

0 notes

Text

Printed Electronics: Revolutionizing Modern Technology

Printed electronics is an innovative field that has transformed the way electronic devices are designed, manufactured, and integrated into everyday applications. By leveraging advanced printing techniques, this technology enables the production of lightweight, flexible, and cost-effective electronic circuits and components. As industries increasingly embrace smarter and more efficient solutions, printed electronics have emerged as a cornerstone of modern technological advancements.

Understanding Printed Electronics

At its core, printed electronics involve the use of functional inks containing conductive, semiconductive, or dielectric materials. These inks are deposited onto flexible substrates such as plastic, paper, or textile using printing techniques like screen printing, inkjet printing, or gravure printing. Unlike traditional manufacturing methods that rely on rigid circuit boards, printed electronics offer unmatched versatility in form factor and application.

This shift from conventional fabrication processes has opened doors to countless possibilities, including wearable technology, flexible displays, smart packaging, and energy-harvesting devices. By reducing material usage and simplifying manufacturing steps, printed electronics also promote sustainability, which is a pressing need in today's tech-driven world.

Key Advantages of Printed Electronics

1.Cost Efficiency: Traditional electronics manufacturing involves complex processes, multiple materials, and expensive equipment. Printed electronics, on the other hand, reduce costs significantly by using additive processes, minimizing waste, and eliminating the need for high-temperature treatments.

2. Design Flexibility: With the ability to print circuits on various flexible substrates, manufacturers can create lightweight and adaptable devices. This flexibility is crucial for applications in wearable technology, medical devices, and Internet of Things (IoT) devices.

3. Scalability: Printing techniques are inherently scalable, allowing for the mass production of electronic components with consistent quality. This scalability makes printed electronics an ideal choice for industries requiring high-volume manufacturing.

4.Eco-Friendliness: The additive nature of printed electronics means fewer materials are wasted during production. Additionally, the use of recyclable substrates and energy-efficient processes further enhances their eco-friendly profile.

Applications Transforming Industries

The versatility of printed electronics has made them a game-changer across multiple industries:

Healthcare: Flexible biosensors, wearable devices, and smart patches that monitor vital signs or deliver medication are made possible with printed electronics. Their lightweight and adaptable nature ensures comfort and functionality.

Consumer Electronics: Foldable smartphones, ultra-thin televisions, and transparent displays are just a few examples of how printed electronics have redefined consumer experiences.

Energy Sector: Printed solar panels and energy storage solutions have significantly lowered the cost of renewable energy adoption. These innovations are paving the way for sustainable energy systems.

Automotive Industry: Printed sensors and lighting solutions integrated into car interiors and exteriors enhance safety and aesthetics while reducing weight.

Smart Packaging: The retail and logistics sectors benefit from printed electronic labels and tags that provide real-time tracking, condition monitoring, and interactive consumer engagement.

Challenges in Printed Electronics

Despite its potential, printed electronics face challenges such as:

Material Limitations: While significant progress has been made, finding materials that balance conductivity, flexibility, and cost remains a challenge.

Durability: Flexible electronics must endure bending and stretching without compromising functionality, which requires advanced material development.

Standardization: As a relatively new technology, the lack of standardization across the industry can slow its adoption.

The Future of Printed Electronics

The rapid evolution of printed electronics is reshaping how devices are designed and manufactured. Innovations in materials science, combined with advancements in printing technologies, are expected to address current challenges and unlock new applications. As industries continue to demand smaller, smarter, and more sustainable solutions, printed electronics will play a pivotal role in meeting these needs. Cutek Circuits, a leader in innovative electronic solutions, is at the forefront of this revolution. With a commitment to quality and cutting-edge technology, Cutek Circuits delivers printed electronic solutions that empower industries and drive technological progress. Whether it's smart interfaces, flexible keyboards, or advanced components, Cutek Circuits is dedicated to shaping a sustainable and connected future.

0 notes

Text

Why a Tactile Keyboard is a Game-Changer for Your Typing Experience

In today’s fast-paced digital world, typing speed and accuracy are more important than ever. Whether you're a professional writer, a gamer, or simply someone who spends hours each day in front of a computer, the keyboard you choose can make a significant impact on your productivity and comfort. One type of keyboard that has gained widespread popularity in recent years is the tactile keyboard. But what makes it so special, and why should you consider making the switch?

What is a Tactile Keyboard?

A tactile keyboard features keys that provide a noticeable physical feedback when pressed. This tactile response lets you know when a key has been activated, without the need to bottom out the key completely. This sensation not only enhances typing speed but also improves accuracy, as it reduces the likelihood of accidental key presses. For those who type a lot or engage in activities like programming or gaming, the feel of a tactile switch can make all the difference in terms of both comfort and performance.

Key Benefits of a Tactile Keyboard

1. Enhanced Typing Speed and Accuracy

One of the most significant advantages of a tactile keyboard is the feedback it provides. The tactile bump lets you know that the key has been pressed, so you can quickly move on to the next one. This feedback reduces the need to bottom out the key, allowing for quicker, more precise typing. This is particularly beneficial for professionals who need to type quickly without compromising accuracy. Whether you're drafting emails, writing reports, or coding, the tactile sensation ensures you're always on the right track.

2. Improved Comfort for Long Sessions

Typing for extended periods can lead to discomfort, especially with traditional keyboards that lack feedback or are too noisy. A tactile keyboard offers the perfect balance between comfort and responsiveness. The tactile switches require less force to press than traditional mechanical keys, making them easier on your fingers and reducing fatigue. This makes them ideal for people who spend hours typing each day, whether for work or leisure.

3. Quiet, Yet Satisfying

While tactile keyboards are often quieter than their clicky counterparts, they still provide that satisfying feedback that typists crave. The key benefit here is that you won’t disturb those around you, especially in shared workspaces or quiet environments. Whether you're working in an office, studying at home, or simply typing late at night, the muted sound of a tactile keyboard ensures you can focus without creating distractions.

4. Durability and Longevity

Another key benefit of tactile keyboards is their durability. The switches used in tactile keyboards are often built to last, with many models capable of withstanding tens of millions of key presses. This makes them an excellent long-term investment, especially for professionals who need a reliable keyboard that won’t wear out after years of use.

Choosing the Best Tactile Keyboard for Your Needs

When it comes to choosing a tactile keyboard, there are several factors to consider, including switch type, design, and functionality. Whether you’re looking for a compact model for portability or a full-sized keyboard for maximum comfort, there’s a tactile keyboard out there for you. For the best quality and performance, consider trusted brands like Cutek Circuits, which is known for producing high-quality, reliable tactile keyboards designed to suit the needs of both casual and professional users alike.

Why Choose Cutek Circuits?

If you're looking for a tactile keyboard that offers both exceptional performance and reliability, Cutek Circuits is the go-to brand. They specialize in creating keyboards that feature cutting-edge tactile switches, providing a satisfying typing experience that’s second to none. With an emphasis on durability, comfort, and speed, Cutek Circuits ensures that each keyboard delivers the highest quality experience, whether for work, gaming, or casual use.

Conclusion

A tactile keyboard is more than just a typing tool—it’s a game-changer that can significantly improve your typing experience. With enhanced speed, accuracy, and comfort, it's no wonder why many are making the switch to tactile switches. Whether you're typing for work or play, consider investing in a high-quality tactile keyboard from Cutek Circuits to elevate your productivity and comfort. Don’t settle for anything less than the best when it comes to your typing experience!

0 notes

Text

The Future of Typing: Exploring the World of Capacitive Keyboards

Keyboards are an essential tool for communication, creation, and productivity. Over the years, keyboard technology has evolved significantly, introducing new designs and mechanisms to enhance the user experience. Among the most innovative advancements is the rise of capacitive keyboards. Known for their superior responsiveness, durability, and modern design, capacitive keyboards are quickly becoming the preferred choice for professionals, gamers, and everyday users.

What are Capacitive Keyboards?

Unlike traditional mechanical or membrane keyboards, capacitive keyboards use an electronic sensing mechanism to detect keypresses. When a user touches a key, a change in capacitance (the ability of a system to store an electric charge) occurs, which is detected and interpreted as a keystroke. This eliminates the need for physical contact between parts, resulting in a smooth and highly responsive typing experience.

Key Features of Capacitive Keyboards

Exceptional Responsiveness Capacitive keyboards register keypresses faster than traditional keyboards. The absence of physical contact mechanisms reduces latency, making them ideal for high-speed typing and gaming where every millisecond counts.

Durability With fewer moving parts, capacitive keyboards have a longer lifespan compared to mechanical keyboards. They are resistant to wear and tear, ensuring consistent performance over years of use.

Quiet Operation One of the standout features of capacitive keyboards is their quiet operation. The lack of physical switches means minimal noise, making them perfect for office environments or shared workspaces.

Customizability Modern capacitive keyboards often come with customizable key layouts and backlighting options. This allows users to tailor their keyboards to specific tasks, improving efficiency and comfort.

Smooth and Effortless Typing The light touch required to register a keystroke reduces strain on fingers, making capacitive keyboards ideal for long typing sessions. This ergonomic advantage benefits writers, programmers, and other professionals who spend hours at their desks.

Benefits Across Industries

Capacitive keyboards are versatile and find applications in a variety of settings:

Corporate Workspaces: Their quiet operation and ergonomic design make them perfect for office use. Employees can type efficiently without disturbing colleagues.

Gaming: Gamers appreciate the responsiveness of capacitive keyboards, which provide precise and fast input for competitive gameplay.

Creative Industries: Designers, video editors, and animators benefit from programmable capacitive keyboards that streamline workflows by assigning custom commands to keys.

Healthcare: In environments like hospitals, where durability and hygiene are crucial, capacitive keyboards excel due to their sealed, easy-to-clean surfaces.

Capacitive vs. Mechanical Keyboards

While mechanical keyboards have long been popular for their tactile feedback and durability, capacitive keyboards are emerging as a strong contender. They offer:

Greater Sensitivity: Unlike mechanical keyboards, which require a full press, capacitive keyboards detect even light touches.

Reduced Noise: Mechanical keyboards can be noisy, while capacitive keyboards provide a quieter alternative.

Lower Maintenance: The absence of moving parts means less wear and tear, reducing the need for frequent maintenance.

The Future of Capacitive Keyboards

As technology advances, capacitive keyboards are expected to incorporate features like AI-driven customization, wireless connectivity, and enhanced energy efficiency. These developments will further solidify their position as the keyboard of choice for professionals and tech enthusiasts alike.

Why Choose Capacitive Keyboards from Cutek Circuits?

When it comes to capacitive keyboards, Cutek Circuits is a name you can trust. Combining cutting-edge technology with exceptional craftsmanship, Cutek Circuits delivers keyboards that redefine typing experiences. Their products are designed to cater to diverse needs, from corporate professionals to avid gamers, ensuring unmatched quality and performance.

Upgrade your workspace with a capacitive keyboard from Cutek Circuits, and experience the perfect blend of innovation, durability, and style.

0 notes

Text

Metallic Vandal Proof Keyboards: The Ultimate Solution for Rugged Environments

In a world driven by technology, keyboards are the unsung heroes of human-machine interaction. While traditional keyboards excel in everyday applications, certain environments demand more than just functionality—they require durability, resilience, and security. Enter metallic vandal proof keyboards, the epitome of robust design tailored to withstand extreme conditions and deliberate misuse.

Why Choose Metallic Vandal Proof Keyboards?

Metallic vandal-proof keyboards are not just a choice but a necessity for high-risk environments. They are crafted from high-grade stainless steel or aluminum alloys, ensuring exceptional resistance to physical damage, corrosion, and harsh weather conditions. These keyboards are engineered to thrive where standard keyboards fail, making them indispensable in industries such as public transportation, defense, healthcare, and manufacturing.

Their rugged construction enables them to resist impact, making them ideal for public kiosks, ATMs, and access control systems. The keys are usually designed to withstand heavy use without compromising performance, ensuring a long operational lifespan. Additionally, many of these keyboards are integrated with backlighting options, enhancing usability in low-light conditions—a feature particularly useful in outdoor or poorly lit areas.

Features That Set Them Apart

Unmatched Durability Metallic keyboards are synonymous with resilience. The use of metallic casings and reinforced key mechanisms ensures that they remain intact even under heavy abuse. This durability also makes them resistant to liquid spills, dust, and other contaminants, which is critical for outdoor or industrial settings.

Enhanced Security Security is paramount in applications like payment terminals and public kiosks. Metallic vandal-proof keyboards are designed to deter tampering, with keys firmly affixed to prevent unauthorized removal. This makes them an excellent choice for environments requiring high security.

Customizable Designs Modern metallic keyboards are highly customizable. They can be tailored with specific layouts, branding, or additional features like integrated touchpads or function keys. This level of customization makes them suitable for diverse applications, from military operations to retail setups.

Ease of Maintenance Unlike traditional keyboards, metallic vandal-proof models require minimal maintenance. Their sturdy build reduces the risk of frequent repairs, while their smooth metallic surfaces are easy to clean, ensuring hygiene in settings like hospitals and food processing units.

Applications Across Diverse Industries

Public Infrastructure: Public installations like ticket vending machines and self-service kiosks are prone to heavy usage and vandalism. Metallic keyboards ensure reliable operation while withstanding constant wear and tear.

Healthcare: In sterile environments, cleanliness is critical. The easy-to-clean surfaces of metallic keyboards, coupled with their resistance to liquids, make them ideal for healthcare applications.

Industrial Settings: Factories and manufacturing units often expose equipment to harsh conditions like oil, dust, and vibrations. Metallic vandal proof keyboards provide the ruggedness necessary to operate efficiently in such environments.

Military and Defense: For operations in extreme weather or combat zones, these keyboards are invaluable. Their resistance to extreme temperatures, impact, and tampering ensures reliability in mission-critical applications.

The Future of Rugged Keyboards

The demand for metallic vandal-proof keyboards is growing as more industries recognize their unparalleled benefits. With advancements in technology, manufacturers are incorporating features like capacitive touch sensors, programmable keys, and wireless connectivity, broadening their scope of applications.

One emerging trend is the integration of membrane keypads with bezels, which combine the durability of metallic keyboards with enhanced functionality. These designs are gaining popularity in sectors like aviation and marine industries, where precision and robustness are paramount.

Key Considerations When Choosing a Metallic Keyboard

When selecting a metallic vandal-proof keyboard, several factors come into play:

Material Quality: Stainless steel offers the best combination of strength and corrosion resistance.

Weather Resistance: Look for keyboards with IP ratings for protection against water and dust.

Customization Options: Opt for manufacturers that offer tailored layouts and additional features.

Certification: Ensure compliance with industry standards for durability and safety.

Why Metallic Vandal Proof Keyboards Are a Smart Investment

While these keyboards may have a higher upfront cost compared to conventional models, their longevity and reduced maintenance costs make them a cost-effective solution in the long run. Their reliability in critical applications ensures uninterrupted operations, adding value to businesses that depend on seamless performance.

Conclusion

Metallic vandal-proof keyboards have carved a niche in the market as the ultimate solution for demanding environments. Their combination of durability, security, and adaptability makes them a worthwhile investment for industries seeking robust human-machine interfaces.

At Cutek Circuits, we specialize in crafting high-quality metallic keyboards designed to meet your unique needs. With years of expertise in delivering innovative solutions, we ensure that every product embodies excellence and durability. Contact us today to explore how our metallic vandal-proof keyboards can redefine your operations.

0 notes

Text

The Rise of Metallic Keyboards in Modern Workspaces

In recent years, the metallic keyboard has emerged as a popular choice for both professionals and tech enthusiasts alike. With its durability, premium aesthetic, and reliable functionality, the metallic keyboard has distinguished itself from other keyboard types. This article delves into the reasons behind the growing popularity of metallic keyboards, explores their advantages, and highlights the factors to consider when choosing the perfect model.

1. What Makes Metallic Keyboards Stand Out?

The primary distinction of a metallic keyboard lies in its construction. Unlike traditional plastic keyboards, which may feel lightweight and less durable, a metallic keyboard offers a sturdy feel and robust performance. The metal casing adds weight, making it stable and less prone to slipping during use. Additionally, the metallic finish gives a sleek, professional appearance, making it a preferred choice in high-end workspaces.

For professionals working in fast-paced environments or those who require a resilient keyboard, the metallic keyboard is an ideal solution. Its metal construction not only ensures longevity but also adds a layer of protection, making it resistant to everyday wear and tear. This level of durability is especially beneficial for industries such as manufacturing, healthcare, and finance, where keyboards experience high-frequency use.

2. Enhanced Durability and Longevity

One of the primary reasons people invest in metallic keyboards is their exceptional durability. Unlike plastic keyboards that may crack or wear down over time, a metallic keyboard can withstand significant physical stress. Users do not have to worry about replacing their keyboard frequently, making it a more sustainable and economical choice.

Metallic keyboards also tend to be more spill-resistant than plastic options. The metal construction creates a better seal, protecting the internal components from liquid damage. Given the frequency of accidental spills in office environments, this is a significant advantage, ensuring that the keyboard remains functional and resilient even after exposure to potential hazards.

3. Precision and Tactile Feedback

Beyond durability, a metallic keyboard offers a refined tactile experience. Many metallic keyboard models feature advanced mechanisms that provide precise key travel and responsiveness, which is particularly valuable for professionals who type extensively throughout the day. The firmness and stability of the keys enhance the typing experience, reducing the risk of typing errors and increasing overall productivity.

The tactile feedback of a metallic keyboard is comparable to high-end mechanical keyboards, providing a satisfying “click” with each keystroke. This feedback appeals to typists who prefer the feel of a robust keyboard with definitive responses, making each typing session more engaging and efficient.

4. Sleek Aesthetic Appeal

A metallic keyboard adds a touch of sophistication to any workspace, aligning well with modern and minimalist office setups. The sleek metallic finish complements other tech devices, such as laptops and monitors, creating a cohesive look on a desk. Metallic keyboards often come in a variety of finishes, including brushed aluminum and matte black, allowing users to select a style that best matches their setup.

In markets like backlit keyboard India, where aesthetics and functionality are equally valued, metallic keyboards with backlit keys are gaining popularity. These keyboards feature illuminated keys, adding an extra layer of convenience for late-night work sessions. A backlit metallic keyboard enhances the workspace by providing a refined, professional look.

5. Choosing a Metallic Keyboard Manufacturer

Selecting a reliable metallic keyboard manufacturer is essential for anyone considering this premium keyboard option. Top manufacturers in the industry ensure that their products are not only built to last but also meet stringent quality standards. When choosing a metallic keyboard, it’s crucial to consider factors such as build quality, warranty, and additional features like backlighting or programmable keys. By partnering with a reputable manufacturer, users can be confident that they’re investing in a high-quality product that meets their needs.

6. Versatility Across Various Applications

The versatility of a metallic keyboard makes it suitable for various applications, from gaming to professional use. In the gaming world, metallic keyboards have gained traction due to their responsiveness and durability. Gamers appreciate the stability offered by metallic keyboards, especially during intense gameplay. Professionals in fields like graphic design, coding, and data entry also benefit from the precise key control and ergonomic feel of a metallic keyboard, which can improve productivity over long hours of work.

7. The Future of Metallic Keyboards

As technology advances, we can expect further innovations in metallic keyboards. Features like customizable lighting, wireless connectivity, and enhanced tactile mechanisms are already being integrated into newer models. With the demand for durable, efficient, and aesthetically appealing keyboards on the rise, metallic keyboards are positioned to become a staple in both home and professional settings.

Conclusion

A metallic keyboard offers unparalleled durability, enhanced tactile feedback, and a sleek design, making it a superior choice for professionals, gamers, and tech enthusiasts alike. With benefits such as spill resistance and a premium finish, these keyboards are well-suited for high-performance environments.

By choosing a reputable metallic keyboard manufacturer like Cutek Circuits, users can ensure they’re investing in a product that will serve them reliably for years to come. Whether for daily work or gaming, a metallic keyboard represents a long-lasting and stylish addition to any modern workspace.

0 notes

Text

The Rise of Metallic Vandal Proof Keyboards: Durability Meets Security

In today’s fast-paced, technology-driven world, keyboards are no longer just office essentials or gaming accessories. They have evolved into robust tools used across various industries, from ATMs to public kiosks, requiring enhanced protection from environmental factors and potential damage. This has led to the growing demand for metallic vandal proof keyboards, which combine durability, functionality, and security.

What are Metallic Vandal Proof Keyboards?

As the name suggests, metallic vandal proof keyboards are designed to withstand tough conditions, including vandalism, accidental damage, and harsh environments. Unlike standard keyboards that are more vulnerable to wear and tear, these keyboards are built using high-grade metals like stainless steel or aluminum. The metal casings offer superior protection from external damage, making them ideal for public installations, industrial environments, and even military applications.

These keyboards typically feature reinforced keys that are resistant to prying, hammering, or any form of tampering. The internal mechanisms are protected by robust metal casings, ensuring long-term functionality even under heavy usage. The toughness of the metallic keyboard ensures that they can operate reliably in extreme conditions, from outdoor kiosks exposed to weather elements to industrial control panels in factories.

Key Features of Metallic Vandal Proof Keyboards

1. Durability: Durability is one of the standout features of metallic vandal proof keyboards. Built from materials like stainless steel or aluminum, these keyboards are designed to last, enduring everything from daily heavy usage to attempts at physical damage. The metal construction not only protects the keyboard but also ensures that the keys remain functional over time without wearing out.

2. Water and Dust Resistance: Many metallic vandal proof keyboards are also water and dust resistant, making them ideal for outdoor use or environments with challenging weather conditions. The sealed design prevents water or dust from entering the internal mechanisms, which can damage electronic components. This makes them highly reliable in environments where other keyboards would fail, such as construction sites, outdoor kiosks, and public transportation terminals.

3. Tamper-Resistant Design: One of the core advantages of metallic vandal proof keyboards is their tamper-resistant design. These keyboards are equipped with reinforced keys and mounting systems that prevent unauthorized removal or damage. Whether installed in an ATM or a public kiosk, the design ensures that the keyboards remain securely in place and functional, even in high-traffic areas where they are subjected to repeated usage and potential tampering.

Applications of Metallic Vandal Proof Keyboards

The versatility of metallic vandal proof keyboards allows them to be used in a variety of environments. Below are some of the most common applications:

1. Public Kiosks and ATMs: Publicly accessible machines like ATMs and self-service kiosks often face the threat of vandalism. The sturdy construction of metallic vandal proof keyboards ensures they can withstand attempts at tampering or destruction, providing a reliable interface for users.

2. Industrial Environments: In manufacturing plants, mines, and construction sites, keyboards are subjected to harsh conditions. Dust, dirt, and heavy impacts can easily render regular keyboards unusable. Metallic vandal proof keyboards provide the ruggedness necessary to survive in these environments, ensuring continuous operation.

3. Military and Defense: For defense and military operations, reliability and durability are critical. Metallic vandal proof keyboards can endure extreme environments, ensuring that communication and control systems remain operational even in the most demanding conditions.

4. Transportation Hubs: Airports, bus stations, and train stations often have self-service kiosks and ticketing machines that are used by hundreds, if not thousands, of people daily. These public terminals benefit from metallic vandal proof keyboards because of their resistance to both heavy usage and malicious damage.

Why the Shift Toward Metallic Keyboards?

With the growing demand for reliability and enhanced security, organizations are increasingly choosing metallic keyboards over traditional plastic models. This shift is driven by the need for durable and tamper-resistant solutions in high-risk environments. Additionally, with the advancements in technology, manufacturers can now produce metallic vandal proof keyboards that are not only robust but also aesthetically pleasing, adding value to public and private installations.

The Role of Metallic Keyboard Manufacturers

As the demand for robust input devices grows, the role of a metallic keyboard manufacturer becomes increasingly vital. These manufacturers are tasked with producing keyboards that meet industry standards for durability and security while also catering to the specific needs of different industries. By incorporating cutting-edge materials and technology, they ensure that metallic vandal proof keyboards deliver unmatched performance and longevity.

When choosing a manufacturer, it's essential to look for companies with a proven track record of producing high-quality products. A good metallic keyboard will offer customizable solutions, ensuring that the keyboard is tailored to the specific needs of the client, whether it's for an outdoor kiosk or a factory control panel.

Conclusion

The growing use of metallic vandal proof keyboards is a testament to the increasing need for durable, secure, and reliable input devices in today’s world. Whether it’s for public kiosks, industrial environments, or defense operations, these keyboards offer the perfect combination of strength and functionality. By investing in such high-quality products, businesses can reduce downtime, prevent vandalism-related damage, and ensure long-term operational efficiency.

At Cutek Circuits, we specialize in producing premium-quality metallic vandal proof keyboards that are built to last, ensuring both security and reliability for our customers across various industries.

0 notes

Text

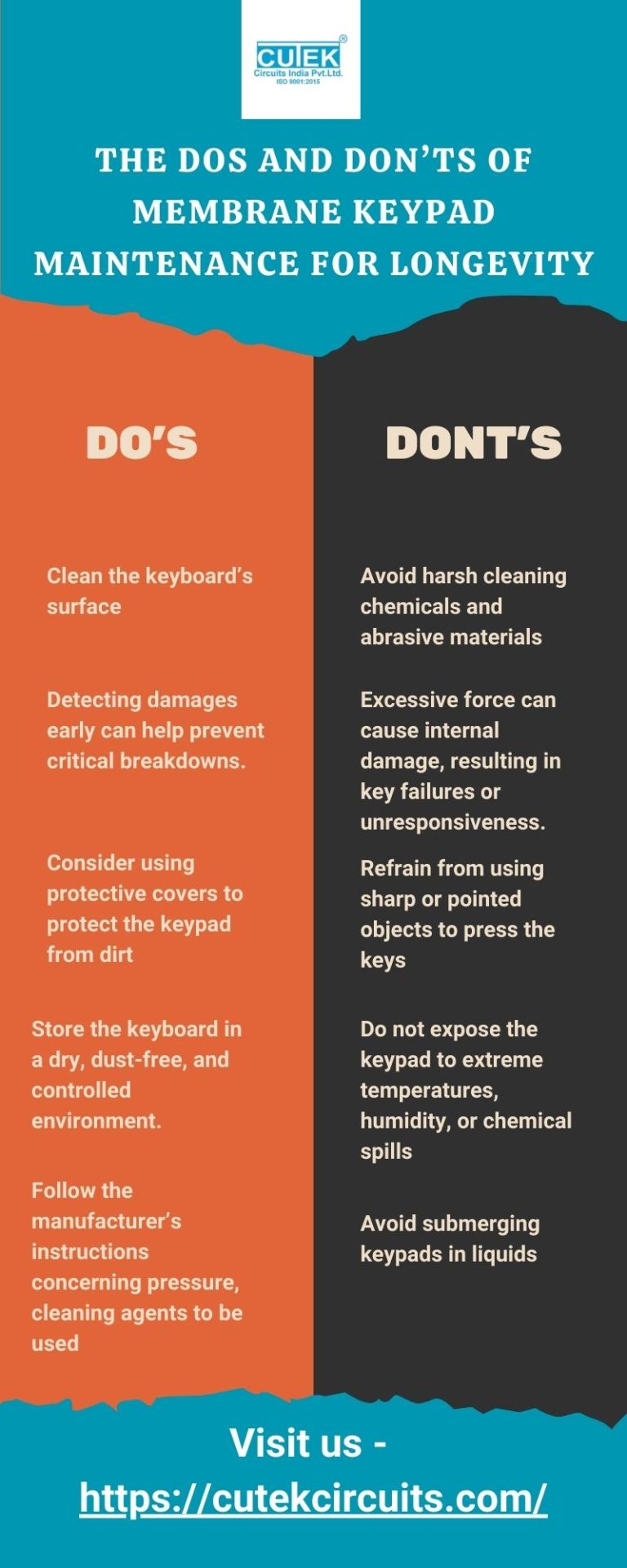

Membrane keyboards are known for their versatility and durability. However, like every other keypad, they demand regular upkeep and adherence to maintenance instructions from membrane keypad manufacturer in india. If you have recently purchased a membrane keyboard for long-term use, this blog is for you. It discusses the various dos and don’ts you must follow to enhance your keyboard’s durability. Read the full blog at - https://cutekcircuits.com/blog/membrane-keypad-maintenance-for-longevity/

0 notes

Text

The Rise of Metal Illuminated Keyboards in the Digital Era

In today’s rapidly advancing technological landscape, the demand for high-performance peripherals has skyrocketed. Among these, keyboards have evolved far beyond their traditional role, offering users enhanced functionality, aesthetic appeal, and long-lasting durability. One of the standout innovations in this field is the metal illuminated keyboard, a fusion of robustness and cutting-edge design. With a growing number of industries requiring durable, versatile, and visually striking keyboards, the importance of a metal illuminated keyboard manufacturer cannot be overstated.

The blend of metal construction with illuminated keys provides several advantages that cater to both personal users and professional industries. Whether it’s gaming, industrial use, or professional typing environments, these keyboards offer features that outperform traditional plastic models. This article delves into the importance of finding a reliable metal illuminated keyboard manufacturer, exploring the advantages of these products and what makes them a top choice for diverse applications.

Why Metal Illuminated Keyboards?

When considering a high-quality keyboard, the material used is critical. Metal keyboards offer a rugged design, making them far more durable than their plastic counterparts. The metallic frame not only withstands heavy daily use but also adds a premium feel to the device. A trusted metal illuminated keyboard manufacturer ensures that the metal used is of the highest quality, offering resistance to wear and tear, spills, and accidental impacts.

The illuminated feature is another game-changer. Whether you're working in low-light environments or simply prefer the aesthetic appeal of backlit keys, illumination helps users navigate the keyboard efficiently. For industries like data entry, gaming, and design, where precision and speed are critical, the clarity provided by a metal illuminated keyboard makes all the difference. Therefore, sourcing products from an established metal illuminated keyboard manufacturer ensures reliability and high performance across various tasks.

Applications Across Industries

The applications for metal illuminated keyboards are vast. In gaming, where response time and precision are crucial, these keyboards provide the durability needed to withstand hours of intense usage. The tactile feedback of illuminated keys enhances the overall gaming experience, offering both functionality and style.

In industrial sectors, where robust equipment is a necessity, a metal mechanical keyboard manufacturer plays a vital role. These keyboards are designed to endure harsh conditions like exposure to dust, water, and extreme temperatures. For manufacturing floors, control rooms, or outdoor applications, these keyboards offer unmatched durability, making them indispensable tools.

Offices and professionals also benefit greatly from metal illuminated keyboards. Long hours of typing can lead to fatigue, but ergonomic designs coupled with well-lit keys can ease the strain on the eyes and hands. A proficient metal illuminated keyboard manufacturer understands these needs, designing products that merge functionality with aesthetics.

The Future of Keyboard Technology

The future of keyboards seems firmly planted in the realm of metal and illumination. With the rise of programmable keys, multi-device compatibility, and customization options, users are seeking out keyboards that offer flexibility without compromising on durability. A metal illuminated keyboard manufacturer must stay ahead of these trends, ensuring that their products incorporate the latest technology while maintaining the trusted durability of metal construction.

Customization is another emerging trend. Industries now require keyboards tailored to their specific needs, whether that’s adding unique layouts, special function keys, or integrating proprietary software. This is where partnering with a reputable metal illuminated keyboard manufacturer becomes essential. The ability to offer custom solutions while maintaining the rugged design and illuminated features makes these manufacturers valuable allies in technological innovation.

Choosing the Right Manufacturer

When it comes to selecting the right metal illuminated keyboard manufacturer, a few factors stand out. First, consider the manufacturer’s experience and expertise in the field. A company with a proven track record in creating durable, high-quality keyboards will be able to meet specific industry needs. Second, examine the range of products offered. A manufacturer with a wide selection of illuminated and metal keyboards is more likely to have the customization options you require. Lastly, look for innovation. The best metal illuminated keyboard manufacturers are those who are not afraid to push the boundaries, incorporating the latest technologies to improve user experience.

Conclusion

In an era where technology and durability converge, metal illuminated keyboards have become a go-to choice for professionals and enthusiasts alike. These keyboards offer a blend of robustness, style, and functionality, setting them apart from conventional plastic models. Whether it's for industrial use, gaming, or professional environments, the demand for such keyboards continues to rise.

For businesses seeking to invest in high-quality keyboard solutions, working with a reputable metal illuminated keyboard manufacturer is crucial. This ensures not only product reliability but also the ability to customize solutions for various industries. As a leading player in this space, Cutek Circuits offers top-tier products, backed by innovation and quality. With years of expertise as a trusted metal illuminated keyboard manufacturer, Cutek Circuits continues to set benchmarks in the keyboard manufacturing industry.

0 notes

Text

Trusted Membrane Keypad Manufacturer in India: Quality and Innovation

As a leading membrane keypad manufacturer in India, Cutek Circuits stands out for its commitment to providing high-quality, durable, and customized keypads tailored to diverse industrial needs. Our expertise in designing innovative membrane keypads ensures superior functionality and long-lasting performance, making us a trusted partner for businesses nationwide.

We specialize in offering customized solutions that cater to various sectors such as electronics, healthcare, automation, and more. Our team works closely with clients to understand specific requirements, ensuring the best design, material, and manufacturing process for each product. The result is a seamless user experience with keypads that are reliable, responsive, and durable.

Our state-of-the-art manufacturing facilities are equipped with advanced technology, ensuring that each product meets stringent quality standards. As a membrane keypad manufacturer in India, we adhere to industry regulations and ensure that our keypads are both functional and aesthetically pleasing.

At Cutek Circuits, we believe in delivering innovative solutions that enhance user interaction and device performance. With years of experience, we have established ourselves as a leading choice for businesses seeking reliable, cost-effective, and customized membrane keypads in India.

0 notes

Text

Understanding Standard Matrix Keyboards: Efficiency and Versatility for Specialized Applications

Keyboards have become an essential part of modern technology, serving as the primary interface between users and machines. While most people are familiar with conventional QWERTY keyboards, there are other specialized designs that cater to different industries and applications. Among these, standard matrix keyboards stand out for their unique structure and functionality. Designed with efficiency and versatility in mind, matrix keyboards offer benefits that make them ideal for various industrial, medical, and technological environments.

What Are Standard Matrix Keyboards?

A standard matrix keyboard differs from traditional keyboards in how its keys are arranged and how signals are sent when a key is pressed. In a matrix keyboard, the keys are organized in a grid of rows and columns. Instead of each key having its own unique circuit, the matrix layout allows multiple keys to share the same connection lines. This creates an efficient system for detecting keypresses with fewer wires, reducing the overall complexity of the keyboard's internal design.

When a key is pressed, it completes the circuit at the intersection of a specific row and column. The keyboard’s controller then interprets this interaction to determine which key was pressed. This grid-based structure is what gives matrix keyboards their name and is the foundation for their key advantages in terms of efficiency and design simplicity.

Key Advantages of Standard Matrix Keyboards

The matrix layout offers several benefits that make these keyboards ideal for a wide range of specialized uses. Let’s explore some of the primary advantages:

Efficient Design and Cost-Effectiveness: One of the most significant advantages of standard matrix keyboards is their efficient wiring system. By reducing the number of wires required to detect keypresses, the matrix structure simplifies the keyboard's internal architecture. This reduction in wiring not only makes the design more cost-effective but also minimizes the space required for circuitry, allowing for more compact designs. For industries that need highly reliable yet affordable keyboards, matrix designs are an attractive option.

Customizability: Matrix keyboards are highly customizable and can be tailored to suit specific industry needs. This versatility allows companies to design keyboards with unique layouts, key arrangements, or even programmable keys for specialized functions. For example, in industrial environments where machinery needs to be controlled with precision, a matrix keyboard can be programmed to execute specific commands when certain key combinations are pressed.

Reliability in Harsh Environments: Standard matrix keyboards are designed to be used in demanding environments. With fewer wires and components, there is less chance of mechanical failure or damage, which is particularly valuable in industrial and medical settings. Their robust construction allows them to withstand extreme temperatures, dust, and other harsh conditions. This durability ensures that matrix keyboards continue to function optimally even after prolonged exposure to challenging environments.

Fast Key Response and Anti-Ghosting: Matrix keyboards typically feature fast key response times, ensuring that every keypress is registered with minimal delay. This speed is essential in applications like gaming, industrial control systems, and medical equipment, where rapid and accurate input can be critical. Additionally, many matrix keyboards include anti-ghosting technology, which prevents errors that occur when multiple keys are pressed simultaneously. This feature ensures that the keyboard accurately registers each keypress, even during complex operations.

Low Power Consumption: Another benefit of matrix keyboards is their energy efficiency. Since they require fewer components and less complex wiring, they tend to consume less power than other types of keyboards. This makes them suitable for battery-powered devices, portable equipment, and environments where minimizing power consumption is essential.

Applications of Standard Matrix Keyboards Across Industries

Standard matrix keyboards are not limited to consumer electronics. They play a crucial role in various industries where specialized input devices are needed. Here are some examples of industries and sectors that benefit from the unique features of matrix keyboards:

Industrial Automation: In factories and production facilities, standard matrix keyboards are used to control machinery and automation systems. Their durability and reliability make them ideal for these environments, where regular keyboards may not withstand the wear and tear of constant use in challenging conditions.

Medical Equipment: Hospitals and laboratories often rely on standard matrix keyboards for their precision and ease of use. In medical settings, equipment needs to be both durable and easy to clean, and matrix keyboards fit the bill. Their compact design and customizable layouts also make them suitable for use in complex medical devices where space is limited.

Aerospace and Defense: The aerospace and defense sectors require highly reliable and efficient control systems. Matrix keyboards, with their simple yet robust design, are used in a variety of military and aerospace applications. Their ability to perform consistently in extreme environments ensures that they meet the high standards required by these industries.

Gaming and Entertainment: Gamers and professionals in the entertainment industry benefit from the fast response times and anti-ghosting features of matrix keyboards. These attributes make matrix keyboards a popular choice for gaming setups and high-performance workstations where rapid and accurate input is crucial.

Custom Control Panels: In specialized control panels, such as those used for security systems, matrix keyboards offer a customizable interface. Businesses can design layouts that fit their specific needs, whether it’s for operating elevators, managing access control, or coordinating security systems.

The Future of Standard Matrix Keyboards

As technology continues to advance, standard matrix keyboards will remain an essential tool in many specialized fields. Innovations in materials, sensor technologies, and key mechanisms will likely enhance the performance and durability of these keyboards, making them even more versatile and adaptable to various applications. For industries that rely on precision, durability, and customization, matrix keyboards will continue to provide an efficient solution for years to come. For businesses and professionals seeking a reliable, cost-effective, and customizable input device, standard matrix keyboards offer the perfect blend of simplicity and performance. Their adaptability across industries ensures that they will remain a staple in applications where high-performance, durability, and efficiency are essential. Check out Cutek Circuits.

0 notes

Text

Metallic keyboards are popular for their durability, customizability, and aesthetics. However, did you know these keyboards are worthwhile in enhancing security across highly sensitive workplaces? Read the full blog at - https://cutekcircuits.com/blog/metal-keyboards-enhance-security/

0 notes

Text

Metal Illuminated Keyboard Manufacturer: A Revolution in Precision and Durability

In today's rapidly advancing technological world, the demand for high-quality, durable, and efficient keyboards has never been higher. Industries ranging from aerospace to military, medical to industrial control systems, require keyboards that not only perform flawlessly but also withstand the rigors of harsh environments. This is where a metal illuminated keyboard manufacturer comes into play, offering an innovative solution that combines the robustness of metal with the practicality of illumination.

The Evolution of Keyboards

Keyboards have evolved significantly from the early days of computing, where the focus was primarily on functionality and less on durability and user experience. Traditional plastic keyboards, while sufficient for standard office work, fall short in more demanding environments. Their susceptibility to wear and tear, coupled with the lack of durability, makes them unsuitable for applications where reliability and longevity are crucial.

This gap in the market led to the rise of the metal illuminated keyboard manufacturer, a niche but essential player in the manufacturing industry. These manufacturers specialize in creating keyboards that are not only sturdy and resistant to external factors such as dust, water, and chemicals but also feature illuminated keys that enhance visibility in low-light conditions.

Why Metal?

The choice of metal as the primary material for these keyboards is driven by its inherent properties. Metal, particularly stainless steel and aluminum, offers unparalleled durability and resistance to environmental factors. Unlike plastic, metal does not crack, warp, or degrade over time, making it ideal for use in environments that demand reliability. Additionally, metal keyboards can be easily cleaned and sanitized, an important feature in industries such as healthcare, where hygiene is paramount.

Moreover, the tactile feel of a metal keyboard is superior to that of plastic, providing users with a more satisfying and precise typing experience. This level of precision is particularly important in applications where accuracy is critical, such as in control rooms or medical devices.

The Role of Illumination

Illumination is another key feature that sets metal illuminated keyboards apart from their traditional counterparts. In many industrial and military applications, keyboards are often used in low-light or no-light conditions. The backlit keys of a metal illuminated keyboard ensure that the user can easily see and use the keyboard, regardless of the lighting conditions.

This feature is not only practical but also enhances safety and efficiency. For instance, in a military setting, a poorly lit keyboard could lead to errors, delays, or even accidents. The illumination provided by a metal illuminated keyboard manufacturer ensures that operations can continue smoothly, even in challenging conditions.

Applications of Metal Illuminated Keyboards

The versatility of metal illuminated keyboards means they are used in a wide range of applications. In the aerospace industry, these keyboards are found in cockpits and control panels, where their durability and visibility are crucial. In the medical field, they are used in operating rooms and diagnostic machines, where cleanliness and reliability are of utmost importance.

In industrial settings, metal illuminated keyboards are commonly used in control systems, machinery, and heavy equipment. Their resistance to dust, moisture, and chemicals makes them ideal for harsh environments. Additionally, the ability to function in low-light conditions ensures that they are suitable for night shifts and underground operations.

The military is another sector that relies heavily on the products of a metal illuminated keyboard manufacturer. From communication devices to control panels, these keyboards play a critical role in ensuring that operations run smoothly, even in the most challenging environments.

Choosing the Right Metal Illuminated Keyboard Manufacturer

When selecting a metal illuminated keyboard manufacturer, it is essential to consider several factors. The first is the quality of the materials used. A reputable manufacturer will use high-grade stainless steel or aluminum, ensuring that the keyboard is both durable and resistant to external factors.

Another consideration is the quality of the illumination. The backlighting should be bright enough to be visible in low-light conditions but not so bright as to cause glare or distraction. Additionally, the lighting should be evenly distributed across the keys to ensure consistent visibility.

Customization options are also important. Depending on the application, you may need a keyboard with specific features, such as programmable keys, special symbols, or a particular layout. A good metal illuminated keyboard manufacturer will offer a range of customization options to meet your specific needs.

Finally, consider the manufacturer’s reputation and customer service. Look for a company with a proven track record of delivering high-quality products and providing excellent customer support. This is particularly important if you are purchasing a large number of keyboards or if you require ongoing maintenance and support.

Conclusion

In conclusion, a metal illuminated keyboard manufacturer plays a vital role in today’s technology-driven world. By providing durable, reliable, and customizable keyboards that can withstand harsh environments and low-light conditions, these manufacturers ensure that industries such as aerospace, military, medical, and industrial control can operate efficiently and safely. When choosing a manufacturer, it is essential to consider factors such as material quality, illumination, customization options, and reputation to ensure that you get a product that meets your specific needs.

0 notes