Don't wanna be here? Send us removal request.

Text

What is Water Separator and Why do you Need it for Marine Systems?

A fuel water separator is a filtering device used to remove water from the diesel before it reaches the sensitive parts of the engine. If your system has a compressed air dryer, you might need a water separator to reduce damage from hazardous substances and increase its longevity.

Water and contaminants can have an adverse impact on the service life and performance of diesel engines. It displaces fuel’s lubricative coating on high-precision injector components, causing tolerance erosion, fuel pressure loss, surface pitting, and poor performance. It is ideal to use a water separator to remove excess water from petrol, diesel, kerosene, and bio-diesel to eliminate contamination.

As fuel water separator is a crucial element for any marine system, read on to know more about them.

What does a fuel water separator do?

Fuel water separator plays a significant role in preventing water from entering the fuel system and damaging vital components. It stops contaminated fuel, debris, and water from reaching your engine. As soon as fuel enters the filter, dirt particles or other contaminants are filtered and blocked.

The separator works by trapping water droplets in the filter element and allowing fuel to pass through. However, if the filter element is clogged or dirty, it can’t do the job properly. That’s why it is necessary to inspect, clean, or replace the filter element. Keep your separator in a good condition to ensure your engine always has clean fuel.

When do you need a fuel water separator?

Fuel water separators are used to remove water from diesel fuel. They are designed to remove solid contaminants and separate water from fuel at refineries, product delivery terminals, and fuel storage sites. Supplying clean and dry diesel is crucial to conserve the life of engines and for optimal combustion.

Diesel water separators bring the water content down to 15 ppm which is the optimum level for applications. It is used in marine applications, fuel transportation, and fuel terminals to ensure a high degree of water separation from diesel fuel and biodiesel.

Separating impurities and water from the fuel, lets your engine run smoothly and efficiently. It can also help prolong the life of your engine by preventing corrosion and other damage caused by debris and water.

Applications:

•Removal of water from petrol, diesel, and bio-diesel

•Fuel purification for diesel-based generator application

•Fuel loading and unloading into tankers to eradicate water contamination

•Fuel loading/unloading at refinery terminals

How to Choose the Right Fuel Water Separator?

Fuel water separators and particle filters need to be replaced often to prevent machine failure. So, here are some components you should consider when buying:

•The Filter Element – Marine and industrial systems need to block 10-30 micron particles between the fuel tank and the engine. For sensitive systems, a secondary two-micron filter should be installed for additional protection.

•Inspection Bowl – The fuel water separator uses a pleated filter media. It catches water particles and turns them into bigger droplets. These droplets later fall into a collection bowl at the bottom of the filter. Draining the water from these bowls from time to time is necessary.

•Fuel Flow Rate – Flow is what has to move through the system. Many engines have a system that sends back fuel to the tank. Make sure the separator you pick has the correct flow specification.

•Engine Size – Bigger engines need bigger separators. The same goes for smaller engines, they need small separators. So, when replacing, make sure to check the comparative size of the separator.

Conclusion:

Water build-up and saturated fuel filters can cause a lot of damage to your internal engine components. The dirty and waterlogged fuel filter can affect your engine’s performance. The simple fix is using a highly efficient fuel water separator to remove water and impurities from petrol, diesel, kerosene, and bio-diesel.

A moisture separator for compressor is another crucial device to eliminate moisture from a compressed air/gas stream. This can eliminate the cost of replacement or repair of equipment and reduce downtime.

0 notes

Photo

Delta Filters is one of the India's leading Manufacturer and Supplier of Compressed Air Filters. We supply highly effective filters used in compressed airlines to prevent solid and liquid contaminants from going downstream. Contact now: Email: [email protected] Phone no. +91 9930073977 +91 22-27752357

0 notes

Photo

We are the leading Supplier and Manufacturer of Fuel Gas Coalescers in India. We offer various types of high-efficiency coalescing filter for solving complex filtration problems. Please contact us for details.

Contact us for more details: Email: [email protected] Phone no. +91 9930073977 +91 22-27752357

0 notes

Photo

Get the Best Deal in Diesel Water Separators from Delta Filters A fuel water separator is a tiny device that keeps water out of diesel fuel before it gets to the engine's delicate components. Diesel fuel contains more substantial amounts of water because it is less refined than other fuels. This procedure explains how the diesel water separator cleans the fuel of impurities such as water. Visit our profile for more details - https://deltafilters.com/fuel-water-separators/

0 notes

Audio

What is a Filter Separator and Why is it Used? Solids and liquids are separated from natural gas by producers using a filter separator. To be more precise, a filter separator cleans the natural gas of contaminants such as pipe scale, water, iron sulfide, liquid hydrocarbons, compressor lubricating oil, and sulfur compounds.

For hydrocarbon (oil)-water separation by settling, a retention period of three to five minutes is necessary. The filter separator manufacturers or engineering firm’s calculations and design determine the size of each section of the filter separator. Read more: https://www.atoallinks.com/2022/what-is-a-filter-separator-and-why-is-it-used/

0 notes

Link

Best Sintered Filters Manufacturer and Supplier in India

Delta Filters manufactures and supplies the best quality Sintered filters. We supply high-quality sintered filters for your application. Our sintered metal filter elements are tested & offer many advantages compared to conventional filter elements. Delta Filters & Separators also provides sintered Mesh type filter elements which offers much higher strength.

Visit for more details - https://app.luminpdf.com/viewer/63721322a2b81e058de2e01b

0 notes

Video

tumblr

Check out the wide range of high-quality natural gas filters offered by Deltafilters, and remove dust, rust, condensates and other types of liquid from the gas. Our filters are designed under the ASME code to serve pressure to 300bar.

Delta Filters & Separators Pvt. Ltd. is a reliable demister pad manufacturers in India and supplier of natural gas filters, innovative filters, separators, and strainers for a wide array of industries, such as oil and natural gas, nuclear power, pharmaceutical, steel, fertilizer production and others with an aim to solve complex filtration and separation problems.

0 notes

Photo

Are you looking to buy a reliable and high-quality basket type strainer that can provide a much higher filtration area as compared to Y-type Strainers and Tee-type Strainers? Then visit Delta Filters, as we are one of the leading Manufacturers and Suppliers of Basket Type Strainers in India. Contact now: Email: [email protected] Phone no. +91 9930073977 +91 22-27752357 Website: https://deltafilters.com/basket-type-strainers/

0 notes

Photo

Are you looking to the best manufacturer and supplier of high quality & reliable compressed air filters? Then visit our website as we are the most trustable and quality air filters supplier in India. Our compressed air filters use Pleated Borosilicate Glass fibber-based filter elements which makes it great for eliminating dust, oil & rust from compressed air. Visit for more information: https://deltafilters.com/compressed-air-filters/

CONTACT US Address: Corporate Office B-101 Sanpada Station Complex, Sanpada Navi Mumbai, 400705, INDIA

Manufacturing Facility: 12 Aditya Industrial Estate, Kumbhivali, Savroli Kharpada Road Khalapur, Dist: Raigad. Maharashtra, 410 202, INDIA

PHONE: Corporate Office +91-22-2775 2357 +91-9930073977

Manufacturing Facility: +91-9930643977 Email: [email protected] Website: https://deltafilters.com/

0 notes

Photo

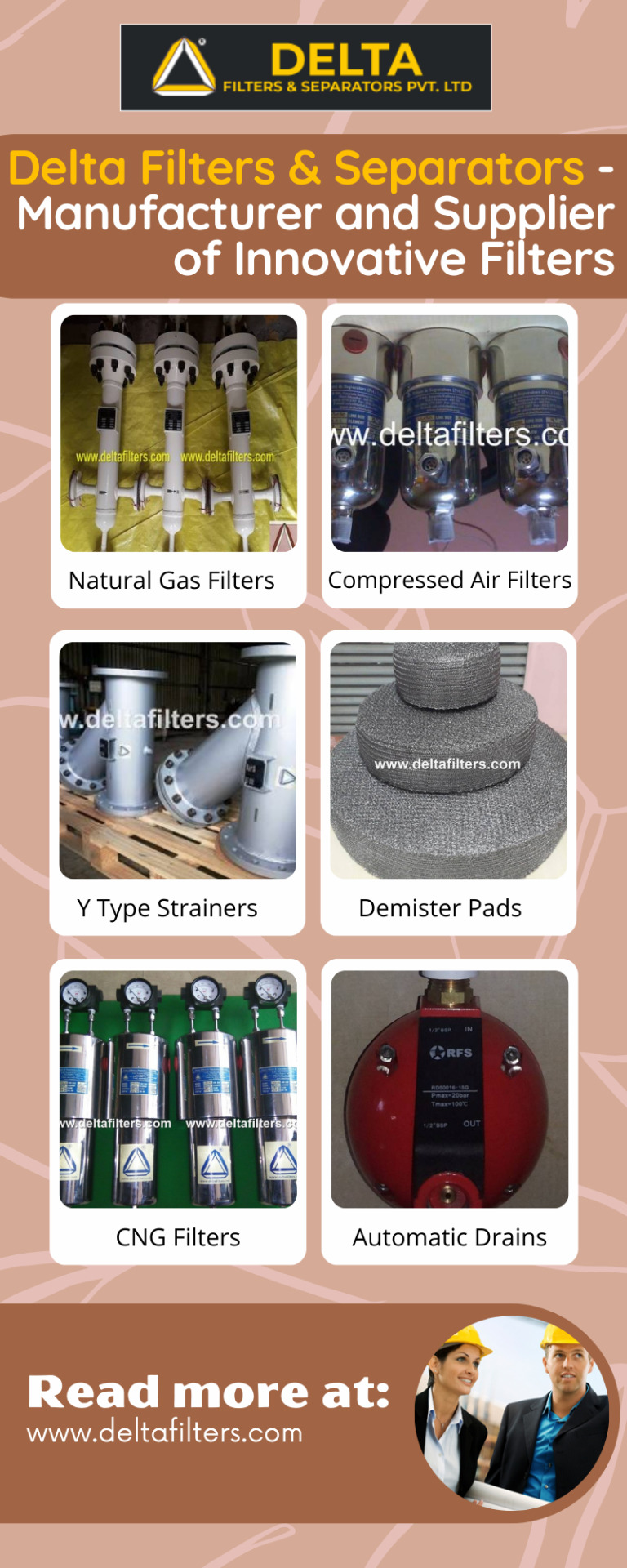

High Quality Natural Gas Filters | Compressed Air Filters - Deltafilters

Natural gas filters are great filters for filtering rust, dust, condensates and other liquids from the natural gas streams. If you are looking to buy high quality natural gas filters that should be reliable, and comes under budget so you better visit Delta Filters as we manufacture wide range of natural gas filters and export them worldwide.

CONTACT US Address: Corporate Office B-101 Sanpada Station Complex, Sanpada Navi Mumbai, 400705, INDIA Manufacturing Facility: 12 Aditya Industrial Estate, Kumbhivali, Savroli Kharpada Road Khalapur, Dist: Raigad. Maharashtra, 410 202, INDIA PHONE: Corporate Office +91-22-2775 2357 +91-9930073977 Manufacturing Facility: +91-9930643977 Email: [email protected] Website: https://deltafilters.com/

#Compressed Air Filters#Natural Gas Filters#demister pads#fuel gas filter coalescer#moisture separator for air compressor

0 notes

Video

tumblr

Buy Reliable & High-Quality Compressed Air Filters | Deltafilters

Compressed air filters are used in compressed air lines to prevent liquid & solid contaminants from going downstream. If you are looking for reliable compressed air filters, then you can visit to Delta Filters & Separators, as we manufacture and supply a range of high-quality air filters offer the best combination of performance and operating cost.

Contact now.

https://deltafilters.com/compressed-air-filters/

0 notes

Photo

Filters, Separators and Strainers - Manufacturer and Supplier in India

Delta Filters & Separators Pvt. Ltd. is a reliable demister pad manufacturers in India and supplier of natural gas filters, innovative filters, separators, and strainers for a wide array of industries, such as oil and natural gas, nuclear power, pharmaceutical, steel, fertilizer production and others with an aim to solve complex filtration and separation problems.

CONTACT US Address: Corporate Office B-101 Sanpada Station Complex, Sanpada Navi Mumbai, 400705, INDIA Manufacturing Facility: 12 Aditya Industrial Estate, Kumbhivali, Savroli Kharpada Road Khalapur, Dist: Raigad. Maharashtra, 410 202, INDIA PHONE: Corporate Office +91-22-2775 2357 +91-9930073977 Manufacturing Facility: +91-9930643977 Email: [email protected] Website: https://deltafilters.com/

0 notes

Video

tumblr

If you are looking for the best fuel water separator then go nowhere just contact Deltafilters. Our fuel water separator was used to remove water from diesel fuel, and our filters were inspected by the American Bureau of shipping and the Indian Register of Shipping.ve your business a new fly. Visit to know more - https://deltafilters.com/fuel-water-separators/

0 notes

Photo

Protect expensive equipment from downtime and damage by using the best basket type strainer which is more effective than Y type strainers & Tee- type strainers. Delta filters is responsible for manufacturing high-quality demister pads that can be used as the separation of liquid and gas.

0 notes

Link

Moisture is a contamination for compressed air and is best removed using a DELTA Moisture Separator. The moving of moisture is imperative to the successful functioning of compressed/gas/steam systems. Moisture source corrosion of pneumatic tools, instruments and machinery resulting in implements malfunctioning. For applications like dynamite and painting, it is imperative that compressed air is moisture-free. Delta Moisture Separators are extensively used in Blasting and Painting applications as well. The cost of replacement and/or restore of equipment, coupled with the corresponding downtime can be remove by using Delta Moisture Separators.

Visit for more Info.: https://www.powershow.com/view0/946369-YWI1Z/Moisture_Separator_For_Air_Compressor_Delta_Filters_Contact_Us_powerpoint_ppt_presentation

0 notes

Link

Having water in fuel gas will directly impact its combustion and delivery of the amount of energy needed. The fuel gas coalescers remove solid and liquid contaminated elements from the gas fuel that is used to power engines, burners, turbines, and compressors. This can further help provide quality fuel gas for the optimal protection of injectors and other related elements from potential damages. Visit for more Info.: https://deltafilters.com/fuel-gas-coalescers/

0 notes

Link

Air compressors produce a substantial amount of condensate in the compressor life-cycle. The condensate that is formed is contaminated with the oil that is used to grease the compressor. Before the condensate can be inclined, the oil must be parted from the water.

They will efficiently optimize compressed air systems through sustaining compliance with ecological industrial waste disposal guidelines. It is ideal to find a certified separator supplier for buying premium quality moisture separators for air compressors. Below, I’m going to share some important things about the moisture separators that you should know.

Visit for more Info.: https://updatedmiami.com/what-important-things-you-should-know-about-moisture-separators/

0 notes