Don't wanna be here? Send us removal request.

Photo

Standard Engineering Plasatic Pickup Tools Flat Tip Design are available from Oricus Semicon Solutions.

Engineering Plastics Flat Tips are a versatile design that are suitable for a wide range of applications. Flat Tip designs feature a single vacuum hole and a flat contact surface controlled to stringent flatness tolerances.

To Know More: Visit here

#dieattach#semicon#semiconductors#semiconductorindustry#semiconductor#oricus#manufacturing#pickuptools#engineeringplastictools#flattipdesign

0 notes

Photo

What is the Bond Test Process? | Oricus Semicon Solutions for more information.

The Bond Test Process from Oricus Semicon Solutions specifies a cutting-edge technology process and a series of processes for determining the precise conditions under which a semiconductor chip must be positioned within a die if it is to work as intended by the original design.

Introduction:-

A Bond Test Process is performed to determine the strength of an adhesive to hold together two materials while being stressed. After the bond has been applied, it is tested the strength of the bond by exerting force on the adhesive in an attempt to detach it from the material.

Purpose of Bond Test Process:-

The overall bonding of a material may be thought of as its bond strength, which is determined by the sort of stress applied to the bond and the temperature at which the test is conducted. The direction of the force applied to the bond will also affect its strength.

There are various types of Bond Testing in the semiconductor industry which are following:-

1) Wire Pull Test

2) Die Share Test

3) Ball Shear Test

4) Wedge Shear Test

5) Wedge Bond Wire Pull Test

The Bond Test equipment such as Nordson Dage 4600 Bond Tester, Stellar 4000 Bond Tester, Dage PC 2400 Bond Tester, and Hook-pull Test gauge.

To Know More: Visit here

#dieattach#oricussemicon#semiconductor#semiconductormanufacturing#semiconductorindustry#manufacturing#oeicus#bondtesting#bondtestprocess#dieshear#diesheartest#wirepulltest

0 notes

Photo

Best semiconductor manufacturing industry - Oricussemicon.

Oricussemicon is a leading manufacturer of semiconductors. From Oricussemicon, we manufacture a wide range of standard customised requirements.

Wire bonding is the process of using tiny wires composed of materials like gold and aluminium to create electrical links between semiconductors (or other integrated circuits) and silicon chips. Gold ball bonding and aluminium wedge bonding are the two most frequent methods. During semiconductor device manufacture, wire bonding is a process for making electrical connections between a silicon chip and the external leads of a semiconductor device using very fine bonding wire. Copper (Cu), Gold (Au), and Aluminum (Al) are used to make these wires (Al).

ASM AB339 Eagle, ASM Eagle 60 Wire Bonder, ASM Eagle 589 Wire Bonder, MDB-2575 Manual Wedge Wire Bonder, and different valuable Wire Bonding instruments such as Capillary and Wire Clamps are employed. There are various Wire Bond methods which are as follows: 1) Thermocompression Bonding 2) Ultrasonic Bonding 3) Thermosonic Bonding To know more: Visit here

0 notes

Photo

Alloy Steel Flat Tips are a versatile design that are suitable for a wide range of applications. Flat Tip designs feature a single vacuum hole and a flat contact surface controlled to stringent flatness tolerances.

Oricus manufactures an extensive range of Alloy Steel Flat Tips sizes with central and offset vacuum hole configurations in various sizes.

#dieattach#pickuptools#alloy/specialalloytools#flattipdesign#semicon#oricussemicon#semiconductors#die#semiconductormanufacturing#semiconductor

0 notes

Photo

Non Ferrous Groove Tips are specifically designed for thin die applications with die thickness ≤0.1mm which are primarily used for bonded devices deployed in harsh environments.

Tip designs used for thin die applications require stable vacuum force while maximizing tip to die or device surface contact area.

Our Non-Ferrous Material Group comprises of materials that provide excellent thermal transfer and even heat distribution across the tip area with the appropriate levels of hardness and toughness for precision Die Attach to be performed.

Oricus manufactures a wide range of customized Non Ferrous Groove Tips with sizes and configurations designed to suit your application. We have the capabilities to machine micro grooves with widths <=0.2mm.

#dieattach#semicon#semiconductor#semiconductormanufacturing#semiconductors#pickuptools#nonferroustools#groovedesign

0 notes

Photo

Engineering Plastics Side Contact Tips are suitable for use in applications where tip contact to the surface of the die should be limited or avoided. For these applications, we do not recommend the use of surface contact tip designs in order to safeguard the critical features on the die surface.

The design of our Side Contact Tips features tapered contact angles to contact the selected edges of the die. Our innovative tip geometries ensures the stability and performance for such critical applications during the Pick and Place process.

Oricus manufactures a wide range of customized Side Contact Tips with angle configurations designed and manufactured to fit your die and application requirements. Standard angle configurations of 90° and 120° are available. We are also able to produce customized angles and application specific geometries to your requirements.

#dieattach#pickuptools#semicon#semiconductor#oricussemicon#semiconductormanufacturing#engineeringplastictools#seidecontactdesign#seidecontacttips

0 notes

Photo

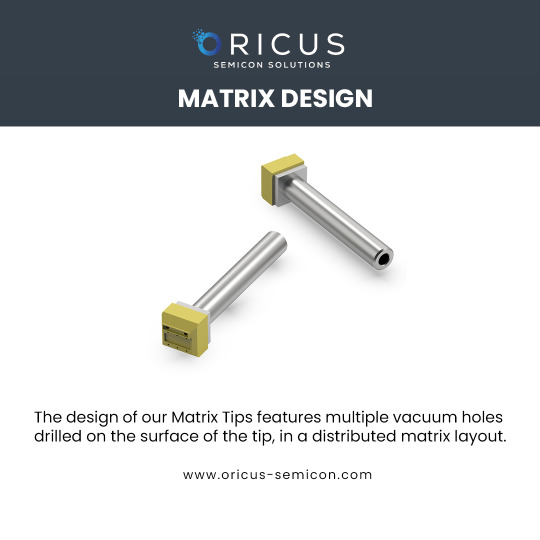

Engineering Plastics Matrix Tip is the superior solution for thin die applications with die thickness ≤0.1mm. Tips used for Thin die applications requires stable vacuum force while maximizing tip to die surface contact area.

The design of our Matrix Tips features multiple vacuum holes drilled on the surface of the tip, in a distributed matrix layout. This design greatly enhances surface contact and stable suction force coverage throughout the surface of the die.

Oricus manufactures a wide range of customized Matrix Tips with sizes and configurations designed to suit your application. Vacuum holes ≤ 0.4mm can be made in the vacuum holes layout of your choice.

#semiconductor#semicon#semiconductormanufacturing#dieattach#pickuptools#engineeringplastictools#matrixdesign

0 notes

Photo

Engineering Plastics Groove Tips are specifically designed for thin die applications with die thickness ≤0.1mm. Tips used for Thin die applications require stable vacuum force while maximizing tip to die or device surface contact area.

The design of our Groove Tips features a central vacuum hole, connected to multiple vacuum channeling grooves on the surface of the tip, which enhance seven and distributed suction force coverage to specific areas of the die or device. Our proprietary groove designs help to hold the thin dies gently and securely during the application process.

Oricus manufactures a wide range of customized Groove Tips with sizes and configurations designed to suit your application. We have the capabilities to machine micro grooves with widths as narrow as 0.2mm.

0 notes

Photo

Plastic Vacuum Relief Tips for enhanced Vacuum Suction.

Engineering Plastics Vacuum Relief Tips are designed to avoid profiles or protrusions on your dies and devices, with a high degree of customization available. The design of our vacuum relief tips features a pocketed opening on the surface of the tip, which creates a reservoir of air to enhance the vacuum suction force during application.

Oricus manufactures a wide range of vacuum relief tip sizes for different applications and die sizes. Customized tip sizes with thin-walled designs featuring central, offset, and spherical relief configurations can be designed and manufactured for your specific application.

#semiconductor#semicon#semiconductormanufacturing#dieattach#pickuptools#engineeringplastictools#vacuumreliefdesign

0 notes

Photo

Engineering Plastic Tools - Oricus Semicon Solutions.

Engineering Plastics Flat Tips are a versatile design that are suitable for a wide range of applications. Flat Tip designs feature a single vacuum hole and a flat contact surface controlled to stringent flatness tolerances.

Oricus manufactures an extensive range of Engineering Plastic Flat Tips sizes with central and offset vacuum hole configurations in various sizes.

#semicon#semiconductor#oricussemicon#semiconmanufacturing#dieattach#pickuptools#engineeringplastictools#flattipdesign

0 notes

Photo

Magnetic Rubber Tip holders are a new design concept that uses magnetic forces instead of mechanical forces to secure the Rubber Tip to the holders. This design alleviates the Automatic Tip Change constraints and limitations faced with our other holder designs.

A magnet is encapsulated within the Rubber Tip during the tip manufacturing process. The magnetic Rubber Tip can be easily installed to the magnetic holder in a matter of seconds while maintaining a securely fitted and aligned tool.

Oricus manufactures a wide range of holders to fit various machines from OEMs such as Datacon, ESEC, ASM, Canon Bestem, Hitachi/Fasford, MRSI, and more. If you require a holder for your machine shank that is not in our standard holder list, get in touch with us and we can customize one for you.

#dieattach#rubberholders#magneticholders#semiconductor#semicon#semiconductormanufacturing#oricusmanufacturing

0 notes

Photo

Compression holders are designed to reduce the size footprint of the assembled tips and holders while offering the same functionality of other holder designs. Compression holders together with compatible tips from our Rubber Tip product line are a popular choice for applications where a small tool footprint is desired due to certain tool size related process limitations.

The design features 4 precision tolerance controlled sidewalls to secure the outer perimeter of the tip. As compared to our Traditional or Tri-Lock holder designs, this design does not require the insertion of the holder into the tip, which greatly reduces the overall footprint of the assembled tool.

Oricus manufactures a wide range of holders to fit various machines from OEMs such as Datacon, ESEC, ASM, Canon Bestem, Hitachi/Fasford, MRSI, and more. If you require a holder for your machine shank that is not in our standard holder list, get in touch with us and we can customize one for you.

#dieattach#rubberholders#compressionholders#semiconductor#semicon#semiconductormanufacturing#oricusmanufacturing

0 notes

Photo

Tri-Lock holders are designed with our three point gripping technology to ensure secure fitment of the Rubber Tip into the holder. The Tri-Lock profile also helps keep the vacuum forces enclosed within the holder and the Rubber Tip, maintaining optimal suction strength by reducing even the slightest vacuum leaks.

When assembled with our Rubber Tips, the horizontal surface of the Tri-Lock mechanism assures the uniformity of bond forces to ensure the highest levels of tip flatness compared to other types of holder design.

Oricus manufactures a wide range of holders to fit various machines from OEMs such as Datacon, ESEC, ASM, Canon Bestem, Hitachi/Fasford, MRSI, and more. If you require a holder for your machine shank that is not in our standard holder list, get in touch with us and we can customize one for you.

#dieattach#rubberholders#tri-lockholders#semiconductor#semicon#semiconductormanufacturing#oricusmanufacturing

0 notes

Photo

Common Rubber Tip Holders are our most versatile range of holders that fits Flat Tips, Vacuum Relief Tips, Groove Tips and Side Contact Tips designs.

Each holder goes through a rigorous design and assessment process to define the ideal geometry of the holder. The holders are then manufactured to exacting standards to ensure that the holders hold on firmly to the tips during the Pick and Place process. All our Traditional Rubber Tip holders are designed to be easily replaceable with new tips.

Oricus manufactures a wide range of holders to fit a wide range of machines from OEMs such as Datacon, ESEC, ASM, Canon Bestem, Hitachi/Fasford, MRSI and more. If you require a holder for your machine shank that is not in our standard holder list, get in touch with us and we can customize one for you.

#dieattach#rubberholders#commonholders#semiconductor#semicon#semiconductormanufacturing#oricusmanufacturing

0 notes

Photo

Rubber Side Contact Tips are suitable for use in applications where tip contact to the surface of the die should be limited or avoided. For these applications, we do not recommend the use of surface contact tip designs in order to safeguard the critical features on the die surface.

The design of our Side Contact Tips features tapered contact angles to contact the selected edges of the die. Our innovative tip geometries ensure the stability and performance for such critical applications during the Pick and Place process.

Oricus manufactures a wide range of customized Rubber Side Contact Tips with angle configurations designed and manufactured to fit your die and application requirements. Standard angle configurations of 5°, 10°, 15° or 20° are available. We are also able to produce customized angles and application specific geometries to your requirements.

#oricussemicon#semiconductor#semiconductormanufacturing#semicon#dieattach#rubbertips#sidecontacttips

0 notes

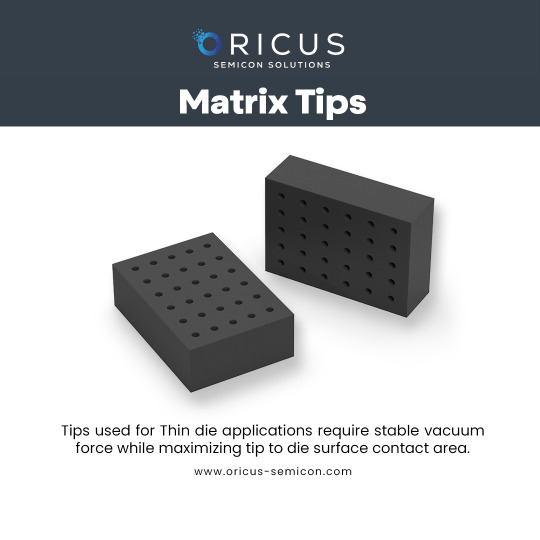

Photo

Matrix Tip is the superior solution for thin die applications with die thickness ≤0.1mm. Tips used for Thin die applications require stable vacuum force while maximizing tip to die surface contact area.

The design of our Matrix Tips features multiple vacuum holes drilled on the surface of the tip, in a distributed matrix layout. This design greatly enhances surface contact and stable suction force coverage throughout the surface of the die. Our Matrix Tip designs, used in combination with our Tri-Lock holders, offer Best-in-Class performance for thin die applications.

Oricus manufactures a wide range of customized Matrix Tips with sizes and configurations designed to suit your application. Vacuum holes ≤ 0.4mm can be made in the vacuum holes layout of your choice.

0 notes

Photo

Rubber Groove Tips are specifically designed for thin die applications with die thickness ≤0.1mm. Tips used for Thin die applications require stable vacuum force while maximizing tip to die or device surface contact area.

The design of our Groove Tips features a central vacuum hole, connected to multiple vacuum channeling grooves on the surface of the tip, which enhances even and distributed suction force coverage to specific areas of the die or device. Our proprietary groove designs help to hold the thin dies gently and securely during the application process.

Oricus manufactures a wide range of customized Rubber Groove Tips with sizes and configurations designed to suit your application. We have the capabilities to machine micro grooves with widths as narrow as 0.2mm.

0 notes