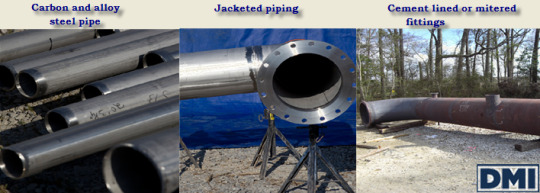

DMI fabricates all carbon and alloy steel pipe systems including jacketed piping, cement lined and mitered fittings.

Don't wanna be here? Send us removal request.

Text

Dedicated Pipe Fabrication Services by DMI Pipe Fab

Pipe fabrication is an essential requirement for a variety of industries, such as power, chemical, water, and petroleum, among others. It is extremely important that the pipe fabrication processes are performed to the highest quality standards. The finished products should be manufactured with industrial grade materials, should meet exact application specifications, and provide immense product durability.

To accomplish this task, you need a service provider who provides dedicated pipe fabrication services. If these are your requirements, then DMI Pipe Fab is the organization for you.

DMI Pipe Fab has been leading the pipe fabrication industry since 1963. The organization specializes in a complete range of design and fabrication services. With many successful project under its belt, the company is regarded as pipe fabrication specialists by customers worldwide.

From DMI to Customers

DMI offers a range of service offerings, from preparation of isometric drawings, material procurement, to complete fabrication, and in-house detailing. This allows the organization to produce a variety of products, including:

Carbon and alloy steel pipe systems

Jacketed piping

Steam jacketed piping

Cement lined or mitered fittings

DMI Pipe Fab also has expertise in pipe support fabrication. Services offered include pipe shoes, sole plates, saddles, base and welded supports, among others.

Excellence as Our Benchmark

To ensure that only industrial grade piping products are delivered to customers, DMI Pipe Fab utilizes superior quality materials, and latest pipe fabrication methods. The company has the capability to create piping structures out of the following materials:

P11

P91

P22

Nickel

Hastelloy

Chrome-moly

Carbon Steel

Stainless Steel

DMI also utilizes varied manufacturing methods to get the desired finished product for creating piping systems:

FCAW

GMAW

GTAW

SMAW

Welding procedures are performed only by certified welders, while adhering to industry welding regulations. Weld pickling and passivation is also another welding capability. This is supported by hydro and non-destructive tests.

DMI Pipe Fab can produce high grade structures to meet intricate industrial piping needs. Customers are assured high levels of quality, performance, and durability with every product.

0 notes

Photo

DMI provide quality, integrity, reliability and exceptional services for industries like power, refining, paper mill, cement plants and chemical industries.

0 notes

Photo

Happy World #Environment day 2015, and best wish’s from www.dmipipefab.com

0 notes

Link

DMI explain you, how to remove rusty pipe fittings step by step. And also give some tips and warning about remove rusty pipe fittings.

0 notes

Link

DMI specializes in providing pipe fabrication & pipe support fabrication services for various industries such as Power, petroleum and chemical industries.

0 notes

Text

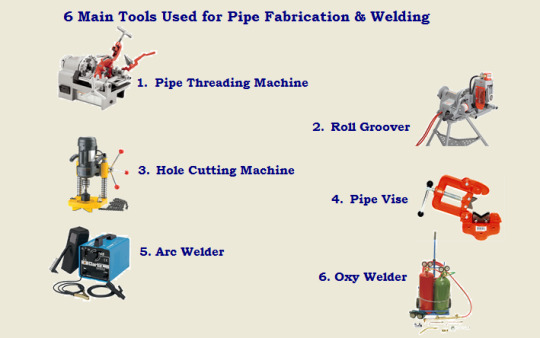

6 Main Tools Used for Pipe Fabrication & Welding

The process of pipe fabrication and welding requires the technician to utilize not only his tools but also his personal skill set. The work achieved with the help of these tools is a direct outcome of the technician’s expertise and understanding of the tools. On the other hand, the technician will be unable to provide brilliant results without being afforded proper tools. Hence, in order to utilize your skills in their entirety, it is important to be armed with the right tools.

6 Main Tools Needed for Pipe Fabrication & Welding

Below are the six tools that are needed to ensure the perfect outcome. These tools will help guide you to providing outstanding results. Technical know-how of their operation and maintenance will allow you to utilize them properly while increasing their life span.

1. Pipe Threading Machine

2. Roll Groover

3. Hole Cutting Machine

4. Pipe Vise

5. Arc Welder

6. Oxy Welder

These tools help make the job of the pipe fabricator much easier. These tools help in reduction of cost as well. The level of finesse achieved by using these tools is incomparable. Depending on the job, you should opt for the tools that help you maximize efficiency.

0 notes

Photo

DMI Pipe Fabrication is an open-shop fabricator and long-time member of Associated Builders and Contractors, we began as a family owned business and, even with our growth, we have retained many of those same core qualities like integrity, reliability and exceptional service.

0 notes

Photo

DMI provides pipe fabrication for different industries specializing in power, petroleum, and chemical industries. We are the leading pipe fabrication company offering fabrication solutions for your most challenging and exacting requirements.

#pipefabrication#industrial piping services#metal fabrication#sheet metal bending#piping services#industrial construction#industrial construction services#industrial services

0 notes

Link

In the process of pipe fabrication, measurement is the most important step. It has to be done precisely using the right tools. There is absolutely no scope for guesswork. For accurate results and a professional job, it is important to measure the angles, cuts, offsets, and other intricacies of...

1 note

·

View note

Text

Importance of Measurement in Pipe Fabrication

In the process of pipe fabrication, measurement is the most important step. It has to be done precisely using the right tools. There is absolutely no scope for guesswork. For accurate results and a professional job, it is important to measure the angles, cuts, offsets, and other intricacies of measurement for fabrication. It is important to familiarize yourself with the terminology and techniques used during fabrication. This will help you in making the most out of your instruments and increasing your efficiency.

The 4 Features of a Pipe Bender Every Pipe Fabricator Should Know

Among other tools used during pipe fabrication, the pipe bender is extremely important. Here are four features of a pipe bender that help you with precise measurement:

· Rim Notch

It is used when making saddle bends. It helps in measuring and finding the middle of the bend.

· Arrow

Stubs of saddle bends utilize this feature. It is used to measure the offsets, and helps in measuring the outer bend.

· Degree Scale

It is used to measure the angle of the bend. It is usually used for saddle bends. It can also be used to measure offsets.

· Star Point

It is used for back bends. It helps in pointing out the location of the back of a 90º bend.

Making use of the above-mentioned equipment is essential to properly fabricate metal pipes and other metal products with optimum accuracy. Since the bends on pipes need to be accurate to fit in an application, measurement is especially important when bending pipes. Make sure that the pipe fabricator you use can perform the job with ease. Accuracy is of the utmost importance. Hence, whether you’re fabricating the pipe, or outsourcing the job to someone else, ensure that the different types of measurement are taken prior to fabrication. This will help you in proper integration of the pipe in the application.

1 note

·

View note

Text

Major Differences between Aluminum & Steel Welding

Steel and aluminum are used in most fabrication shops. It is important to know the differences between the metals and their properties. This will help you weld and fabricate both materials better. Below listed are some of the major differences between aluminum and steel welding :

When steel is being welded, it changes color. This helps the welder keep track of the work done. Aluminum doesn’t really change color by a big extent. It is much more difficult for a welder to keep track of the work.

Most aluminum objects are coated with a thin layer of aluminum oxide. This layer needs to be removed before the welding process begins.

If aluminum was stored in a cool place before welding, its temperature needs to be increased albeit slowly.

Aluminum doesn’t require any treatment post welding. Neither do most steels. On the other hand, some high carbon steels require heat treatment after welding.

Despite all the differences, the edges of both aluminum and steel that need to be welded should be cleaned thoroughly. The techniques involved in fabricating these materials are different as well. In-depth knowledge of these processes should equip you to weld both materials effectively.

0 notes

Photo

Wish You a Great, Prosperous, Blissful, Healthy, Bright, Delightful, Energetic and Extremely Happy, HAPPY NEW YEAR 2015 !!!

0 notes

Photo

May this Christmas bring more happy memories and joy to you and your family !! Merry Christmas !!!

0 notes

Text

How Jacketed Piping Increases Productivity & Safety in Industries

Jacketed piping is created by attaching a jacket (protective covering) to steel tubes or piping. The result is a tube in tube kind of product. This jacket protects the tubing while assisting in smooth functioning. The materials used for the jacket vary according to the application. Stainless steel tubes with jacketing are needed in the food and beverage industry like dairy, confectionery, and food handling. It is also used in oil, power, petroleum, and other industries. It is used in manufacturing, packaging, assembling, and many other processes.

Need for Protective Jacketing for Steel Tubes

There are several advantages of using jacketed tubing. Some of these are listed below:

It can be cleaned easily.

It does not absorb moisture.

It can endure rough handling.

It provides a hygienic environment.

It ensures safety since they are almost leak proof.

It safeguards the product being transported in the pipe.

It is durable and can withstand the rigors of production.

Materials resistant to chemicals, abrasions, corrosion and many other factors are available for the jacket.

Sometimes the processes or products produce heat, or function at high temperatures. Protective jacketing is able to protect the pipes or tubing from being damaged. Jacketed tubings are capable of functioning under extreme temperatures.

Jacketed piping can easily be attached to walls, floors, and ceilings. If you are thinking of updating your tubing or installing new tubing, jacketed tubing can easily be integrated into existing systems.

0 notes

Photo

Wishing you the gift of faith and blessing of hopes this Thanksgiving Day!!!

0 notes

Text

Process & Instructions for Pipe Bending

When fabricating pipes and other equipment, pipes or tubes often need to be bent. When bending pipes, the first most important step is to measure the tubes and carefully mark the place where you need to make the bend. This process needs to be performed meticulously. There is absolutely no room for mistakes. The place where you bend the tube or pipe is dependent on the angle at which it is being bent and the length of the tube or pipe.

Several tools like a rim notch, degree scale, and star point are available in the market to help you locate and mark the ideal location to bend the pipe.

Instructions on How to Apply Manual Pressure

When bending a tube placed on the floor, ensure that you place your foot on the pipe and apply heavy pressure.

When bending a tube suspended in air, exert pressure by holding the pipe or tube close to your body.

If after bending the tube, you think that it has been over bent, there is no need to panic. Most pipe bending machines are equipped with an expanded end for this very purpose. You can use either the expanded end or a back pusher to unbend the tube to the desired angle.

Many professional companies provide the service of pipe bending. You can outsource your pipe bending requirements to them, for a refined finish.

0 notes

Video

vimeo

How to Improve Quality of Pipe Fabrication ?

0 notes