Don't wanna be here? Send us removal request.

Text

Shear Blade Factory Wishes You A Happy New Year!

Looking back on the past, we have left deep or shallow footprints in the river of time, with laughter and sweat, all of which are precious treasures of growth. This New Year's Day, the beginning of the new year, may you leap into the sky like a dragon, and the green clouds pave the way for grand plans;

May time be gentle and life always bloom with joy; May the whole family be reunited and happy, and may family warmth melt the cold of time. The auspicious dragon brings blessings, and the New Year brings good luck.

January 1st is the New Year. Shear Blade Factory wishes everyone a happy New Year's Day!

0 notes

Text

How Can Precision Rollers Enhance Efficiency in Work Processes?

Precision rollers can improve efficiency in various ways across different industries and applications. These rollers are designed and manufactured with tight tolerances to ensure accurate and consistent performance, leading to higher productivity and smoother operations. Here are several ways precision rollers can enhance efficiency:

Precision rollers ensure a high level of consistency in the manufacturing process, resulting in better-quality products. These rollers help maintain precise dimensions, reduce friction, and minimize defects in the final product. As a result, companies can deliver higher-quality goods to their customers, which can boost customer satisfaction and loyalty.

Precision rollers can operate at higher speeds without compromising accuracy or reliability. Their smooth and uniform surface reduces friction and wear, allowing for faster production cycles. This increased speed can lead to higher output levels and reduced downtime, ultimately improving overall operational efficiency.

Precision rollers are made from high-quality materials such as stainless steel, aluminum, or specialized polymers to withstand harsh operating conditions. Their durability ensures a longer service life, reducing the frequency of maintenance and replacement. This results in cost savings and improved efficiency by minimizing downtime and production interruptions.

0 notes

Text

What Makes Precision Rollers Environmentally Adaptable?

Heat resistance: For high temperature working environments, Precision Rollers materials should have good heat resistance and be able to maintain their mechanical properties at high temperatures without softening, oxidation, or premature aging.

Cold resistance: In low-temperature environments, materials should have sufficient toughness to prevent cracking caused by embrittlement.

Corrosion resistance: In environments with corrosive media, the Precision Rollers material should have good corrosion resistance or undergo appropriate surface treatment to enhance protection.

Chemical resistance: For applications that come into contact with chemicals, the material should be able to resist the erosion of chemicals and maintain stable performance.

Wear resistance: Depending on the specific application of Precision Rollers bearings, their tolerance to environmental factors such as dust, sand, and moisture may need to be considered.

0 notes

Text

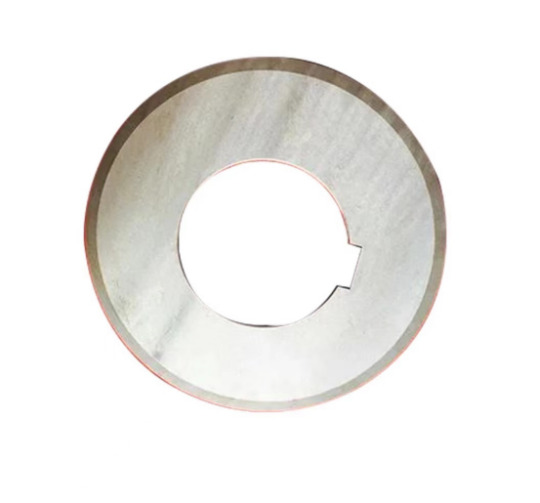

Dingsheng Specializes in Producing Shear Blades

The shear blade is an important component of the shredder, and its quality directly affects the effectiveness and lifespan of the shredder. As a professional shear blade manufacturer, we are committed to producing high-quality, wear-resistant, and durable blades to meet various customer needs.

We have advanced production equipment and a technical team that can customize various specifications and models of blades according to customer needs. We use high-quality alloy steel materials to make blades, which undergo precision machining and heat treatment processes to ensure that the hardness and wear resistance of the blades reach the best level.

Our blades are widely used in various shredder equipment, including household shredders, industrial shredders, metal shredders, etc. Not only can it effectively tear various materials, but it can also maintain the sharpness and stability of the blade, reduce maintenance costs and replacement frequency.

We always adhere to the concept of "quality first, customer first", and wholeheartedly provide customers with high-quality products and fast services. We will continue to work tirelessly to improve our technical and management skills, and create greater value for our customers.

If you are interested in our products or have any needs, please feel free to contact us and we will be happy to serve you! Thank you for your attention and support!

0 notes

Text

How Alignment Rollers Impact Machine Performance

Aligning rollers is a critical aspect of ensuring optimum performance of machines in various industries, including manufacturing, transportation, and material handling. Proper alignment of rollers not only extends the lifespan of the equipment but also helps in achieving higher efficiency, reducing energy consumption, and minimizing wear and tear on the machine components.

Misaligned rollers can cause product defects such as wrinkles, tears, or misalignment in the material being processed. Aligning the rollers ensures smooth and even movement of the material through the machine, leading to improved product quality. This is particularly important in industries such as printing, packaging, and food processing where product quality is a critical factor.

Properly aligned rollers help in achieving smooth and consistent operation of the machine, resulting in increased productivity and efficiency. This is especially important in high speed production environments where any disruption in machine operation can have a significant impact on overall output. By aligning the rollers, you can ensure that the machine operates smoothly without any interruptions, leading to increased production capacity and reduced downtime.

Misaligned rollers can cause excessive energy consumption due to increased friction and resistance in the machine components. By aligning the rollers properly, you can reduce friction and energy consumption, leading to cost savings in the long run. This is especially important in industries where energy costs are a significant factor in overall operating expenses.

0 notes

Text

The advantage of Aligning Rollers in Industrial Settings

Rollers play a crucial role in various industrial settings, from conveyor systems to material handling equipment. Properly aligning rollers is essential to ensure smooth operation and prevent wear and tear on the machinery.

One of the key benefits of aligning rollers is reduced wear and tear on the equipment. When rollers are not properly aligned, they can cause uneven wear on the conveyor belt or other moving parts, leading to premature failure and increased maintenance costs. By aligning the rollers correctly, you can ensure that the load is evenly distributed and reduce the risk of damage to the machinery.

Another important benefit of aligning rollers is increased efficiency. When rollers are misaligned, they can cause friction and drag, which can slow down the movement of materials and decrease productivity. Properly aligned rollers reduce friction and ensure smooth and efficient operation of the equipment, helping to increase throughput and reduce downtime.

Aligning rollers can also help to improve the quality of products being transported. When rollers are misaligned, they can cause products to shift or become damaged during transportation. Proper alignment of rollers ensures that products are securely and evenly transported, reducing the risk of damage and improving overall product quality.

0 notes

Text

How Do Flying Shear Blades Improve Production Efficiency?

Flying shear blades play a crucial role in improving production efficiency in various industrial processes, particularly in the steel and metalworking industries. These blades are essential components of shearing equipment that are used to cut or trim materials as they move continuously along a production line. By cutting materials to the desired size or shape swiftly and accurately, flying shear blades help to optimize production output, minimize waste, and enhance overall efficiency.

One of the key benefits of using flying shear blades is their ability to cut materials while they are in motion. This continuous cutting process eliminates the need for stopping the production line when trimming or cutting materials, which in turn helps to save time and streamline the entire production process. This continuous operation also leads to higher productivity levels as materials can be cut at a faster rate compared to traditional shearing methods.

In addition, flying shear blades are designed to provide precise and clean cuts, ensuring that materials are trimmed to the exact specifications required for each production task. This level of accuracy is crucial for maintaining product quality and consistency, as well as minimizing scrap or rework due to inaccuracies in cutting. By achieving precise cuts quickly and efficiently, flying shear blades help to improve the overall quality of products while reducing the risk of errors or defects.

0 notes

Text

Can Flying Shear Blades Enhance Precision Cutting Techniques?

Flying shear blades play a crucial role in precision cutting within the manufacturing realm. These blades are designed to cut materials in a continuous process, often at high speeds. Their unique design and operation offer several advantages that contribute to accurate and efficient cutting.

One of the main benefits is their ability to provide consistent cut lengths. This is essential in industries where specific dimensions are required, such as in the production of metal sheets for construction or automotive parts. The flying shear blades can be precisely adjusted and controlled to meet the desired length specifications, minimizing waste and ensuring product uniformity.

Moreover, they can handle a variety of materials, from soft metals to tougher alloys. Their sharpness and durability allow for clean cuts without causing excessive deformation or damage to the material being processed. This is vital for maintaining the integrity of the final product and its performance.

However, while flying shear blades are significant, they are not the sole determinant of precision cutting. Other factors like the stability of the cutting equipment, the accuracy of the control systems, and the quality of the material feed also influence the overall precision. But there is no denying that well-designed and properly maintained flying shear blades are a fundamental component in achieving high-quality precision cutting in manufacturing, enabling industries to produce reliable and precisely dimensioned products.

0 notes

Text

Exploring the Role of Cooling Bank Accessories for Efficiency

Cooling Bank Accessories is a very important equipment in the rolling process, mainly used for heating and insulating steel to achieve ideal temperature and plasticity during the rolling process, in order to obtain good rolling effect. Its main functions include the following:

Heating: The Cooling Bank Accessories heats the steel through a heating device to reach a temperature suitable for rolling. During the rolling process, steel needs to maintain a certain temperature to maintain good plasticity and make rolling smoother.

Insulation: The Cooling Bank Accessories can also provide insulation for the heated steel, keeping it at a stable temperature for a certain period of time. This can ensure that the temperature of the steel remains constant throughout the entire rolling process, avoiding situations where temperature fluctuations lead to unstable rolling.

Temperature control: The Cooling Bank Accessories is equipped with various sensors and control systems, which can monitor and adjust the temperature of the steel in real time. By controlling the working parameters of the heating device, the temperature of the steel can be precisely controlled to ensure the accuracy and stability of rolling.

Insulation: During the heating process, the Cooling Bank Accessories can effectively isolate heat conduction, avoiding the impact of heat on the surrounding environment and personnel. At the same time, it can also reduce energy loss, improve heating efficiency, and save energy.

Smoke exhaust and dust removal: The Cooling Bank Accessories produces smoke and exhaust gas during operation. The cold bed is equipped with smoke exhaust and dust removal equipment, which can timely discharge and treat the exhaust gas, protecting the environment and the health of personnel.

In general, the Cooling Bank Accessories plays a crucial role in steel processing, ensuring that the steel reaches the optimal temperature and plasticity during the rolling process through heating, insulation, temperature control and other functions, guaranteeing the smooth progress of the rolling process and the guarantee of product quality. At the same time, Cooling Bank Accessories can improve production efficiency, save energy, and reduce environmental impact, making them an indispensable equipment in modern steel processing.

0 notes

Text

Effective Ways to Maintain Cooling Bank Accessories

Cooling Bank Accessories is an important component in rolling equipment, and its maintenance work has a significant impact on the performance and service life of the equipment. Proper maintenance can ensure the normal operation of equipment, extend its service life, reduce maintenance costs, and improve production efficiency. Below are the maintenance methods and precautions for Cooling Bank Accessories.

1、 Regularly cleaning the Cooling Bank Accessories will accumulate various dust, oil stains, and impurities during use. If not cleaned in time, it will affect the normal operation of the equipment. Therefore, regular cleaning is a very important maintenance task. When cleaning, carefully inspect all parts of the equipment, especially the bearings, transmission devices, and lubrication system, to ensure that there are no foreign objects or damage.

2、 Timely replacement of vulnerable parts: During long-term use, vulnerable parts such as sealing rings and bearings may experience wear and aging, and need to be replaced in a timely manner. Regularly check the wear level of vulnerable parts and replace them in a timely manner according to the situation to ensure the normal operation of the equipment.

3、 The lubrication system of the Cooling Bank Accessories plays a crucial role in lubrication and maintenance. Insufficient lubrication can lead to overheating and wear of the equipment, affecting its normal operation. Therefore, regularly check the working condition of the lubrication system to ensure sufficient and high-quality lubricating oil, and maintain the normal working condition of the lubrication system.

4、 Check the transmission device. The transmission device is a key component of the Cooling Bank Accessories, and its normal operation is crucial to the performance of the equipment. Regularly check the connection of each component of the transmission device to ensure the normal operation of the transmission system, prevent the transmission belt from loosening or breaking, and ensure the safe operation of the equipment.

5、 Regularly inspect the electrical equipment of the Cooling Bank Accessories, which is a key component for controlling the operation of the equipment. Regularly inspect the wiring connections, switches, contactors, and other components of the electrical equipment to ensure its normal operation and avoid equipment shutdown caused by electrical failures.

0 notes

Text

Exploring the Role of Quality Flying Shear Blades

Flying shear blades are an essential component in the steel industry, where they are used to cut and trim steel strips or sheets during the manufacturing process. They play a crucial role in ensuring the quality and accuracy of the final product, making them a critical tool for steel manufacturers.

The importance of quality flying shear blades cannot be overstated, as they directly impact the efficiency and precision of the cutting process. Blades that are dull or poorly maintained can result in uneven cuts, jagged edges, and decreased productivity. On the other hand, high-quality blades that are properly sharpened and maintained can provide clean, accurate cuts that meet the required specifications.

One of the key benefits of using quality flying shear blades is the improvement in the overall product quality. By ensuring that the steel strips or sheets are cut accurately and cleanly, manufacturers can avoid defects and inconsistencies in the final product. This not only enhances the appearance of the finished steel products but also improves their performance and durability.

In addition to product quality, quality flying shear blades also contribute to increased productivity and efficiency in the manufacturing process. Blades that are sharp and properly aligned can cut through steel materials quickly and efficiently, reducing downtime and minimizing production delays. This allows manufacturers to meet production quotas and deadlines more effectively, ultimately leading to improved profitability and competitiveness in the market.

Moreover, maintaining high-quality flying shear blades can also help extend their lifespan and reduce the frequency of blade replacements. By investing in durable, high-performance blades and implementing a regular maintenance schedule, manufacturers can minimize the costs associated with blade replacement and repairs. This not only saves money in the long run but also ensures consistent cutting performance over time.

0 notes

Text

Effective Ways to Assess Shear Blade Welding Quality

In order to ensure shear blade welding quality, the welded blades should be carefully inspected to identify the cause of defects and make improvements. Before inspection, the blade should be sandblasted or lightly ground to remove solder and impurities adhering to the surface of the blade, and cleaned with kerosene. The inspection items and requirements are as follows:

1、Check weld strength: Use a green silicon carbide grinding wheel to grind the back of a blade and check the thickness of the solder layer, which should be below 0.15 millimeters. There should be no air holes or insufficient solder at the bottom surface of the tool tip support. The weld seam that is not filled with solder should not exceed one tenth of the total length of the weld seam. If there are pores, the blade will fall off during cutting.

2、 Check the position of the shear blade in the slot: if the blade is misaligned or sagging beyond the technical specifications, it should be re welded.

3、 Check welding strength: Use a wooden hammer or copper hammer to strike the blade with moderate force, or use an I-hammer to strike the blade with strong force. If the blade does not fall off from the blade body, it is considered qualified. Checking the welding strength of the blades may not be done individually, and spot checks are also used.

4、 Check the flatness of the blade: If there are obvious pits on the blade, it indicates that the blade is overheated and deformed, and should be burned down and re welded with a new blade.

5、 Check for cracks: After cleaning the blade with kerosene, if there are cracks, kerosene will penetrate into the cracks and black lines will appear, which can be observed with the naked eye. It can also be observed with a magnifying glass of 10-40 times.

0 notes

Text

Are Shaft Sleeves Essential for Every Type of Equipment?

Shaft sleeves are not necessary for all equipment, but they can be beneficial for certain types of machinery. Shaft sleeves are used to protect and extend the life of the equipment's shaft by providing a barrier between the shaft and the surrounding environment. They can help prevent corrosion, wear, and damage caused by friction or abrasive materials.

Some equipment that may benefit from the use of shaft sleeves include pumps, compressors, mixers, and agitators. These types of equipment often have rotating shafts that are exposed to harsh conditions, such as high temperatures, corrosive chemicals, or abrasive materials. In these cases, a shaft sleeve can help protect the shaft and ensure smooth and efficient operation of the equipment.

In addition to protecting the shaft, shaft sleeves can also help improve the performance and efficiency of the equipment. By reducing friction and wear on the shaft, shaft sleeves can help reduce maintenance costs and downtime. They can also help improve the reliability and longevity of the equipment, leading to overall cost savings for the operator.

Overall, while shaft sleeves may not be necessary for all equipment, they can provide significant benefits for certain types of machinery. Operators should consider the specific needs and conditions of their equipment to determine whether shaft sleeves would be a valuable investment.

0 notes

Text

Which Shaft Sleeve Materials Last the Longest?

Shaft sleeves are an essential component in many industrial applications, providing protection for rotating shafts and extending the lifespan of equipment. The durability of a shaft sleeve is crucial in ensuring the smooth operation of machinery and preventing costly downtime due to frequent replacements. There are several materials commonly used for shaft sleeves, each with unique characteristics that impact their durability and performance.

One of the most popular materials for shaft sleeves is bronze. Bronze is known for its excellent wear resistance and ability to withstand high temperatures, making it suitable for heavy-duty applications in industries such as mining, manufacturing, and transportation. Bronze shaft sleeves are often used in pumps, compressors, and other rotating equipment where abrasion and corrosion are common challenges. Due to its self-lubricating properties, bronze requires minimal maintenance and can last for several years before needing replacement.

Another commonly used material for shaft sleeves is stainless steel. Stainless steel offers superior corrosion resistance and strength compared to bronze, making it ideal for applications where exposure to harsh chemicals or environmental conditions is a concern. Stainless steel shaft sleeves are widely used in the food and beverage, pharmaceutical, and marine industries where hygiene and cleanliness are paramount. While stainless steel shaft sleeves are more expensive than bronze, they offer long-term durability and reliability in demanding industrial settings.

Polymer shaft sleeves, such as nylon or PTFE, are another option for certain industrial applications that require lightweight and low-friction materials. Polymer shaft sleeves are often used in food processing equipment, medical devices, and automotive components where smooth operation and reduced maintenance are critical. While polymer shaft sleeves may not offer the same level of wear resistance as metal or ceramic materials, they provide cost-effective solutions for non-critical applications where durability is less of a concern.

0 notes

Text

Why is it Important to Use a Shaft Sleeve for Equipment Protection?

A shaft sleeve is a protective covering that is placed over the shaft of a machine or equipment in order to prevent wear and damage. It acts as a barrier between the shaft and surrounding components, reducing friction and prolonging the life of the equipment.

There are several ways in which a shaft sleeve protects equipment:

Wear resistance: A shaft sleeve is typically made of a material that is highly wear-resistant, such as stainless steel or ceramic. This helps to minimize the wear and tear on the shaft caused by friction and abrasion from surrounding components.

Corrosion resistance: In harsh environments where equipment is exposed to moisture, chemicals, or other corrosive substances, a shaft sleeve can provide an extra layer of protection against oxidation and rust. This helps to prevent the shaft from deteriorating over time.

Alignment assistance: In some cases, a shaft sleeve can also serve as a guide for alignment, helping to ensure that the shaft remains properly positioned within the equipment. This can prevent misalignment issues that can lead to increased friction and wear.

Easy replacement: In the event that the shaft does become worn or damaged, a shaft sleeve can be easily replaced without requiring extensive repairs or downtime for the equipment. This makes it a cost-effective and convenient way to protect the shaft and extend the life of the equipment.

0 notes

Text

Proper Installation of a Shaft Sleeve

A shaft sleeve is a crucial component in many industrial applications as it helps protect the shaft from wear and damage. Installing a shaft sleeve properly is essential to ensuring the optimal functioning of the equipment it is being used on.

Step 1: Prepare the equipment Before installing a shaft sleeve, make sure to prepare the equipment properly. This includes ensuring that the shaft is clean and free from any debris or contaminants. It is also important to check the condition of the shaft to identify any signs of wear or damage that may need to be addressed before installing the sleeve.

Step 2: Select the right shaft sleeve It is important to select the right shaft sleeve for the specific application you are working on. Shaft sleeves come in various sizes and materials, so make sure to choose one that is compatible with the shaft and the equipment it is being used on. Additionally, consider factors such as the operating conditions and the level of protection needed when selecting a shaft sleeve.

Step 3: Install the shaft sleeve To install the shaft sleeve, follow these steps:

Apply a thin layer of lubricant to the inner surface of the shaft sleeve to facilitate easier installation.

Carefully slide the shaft sleeve onto the shaft, making sure that it is positioned correctly and aligned with the shaft.

Use a hammer or a press to gently tap the shaft sleeve into place until it is fully seated on the shaft.

Check the alignment and positioning of the shaft sleeve to ensure that it is installed properly and securely.

Step 4: Secure the shaft sleeve Once the shaft sleeve is installed, it is important to secure it properly to prevent it from moving or coming loose during operation. This can be done by using set screws, keyways, or other securing mechanisms that are compatible with the shaft sleeve and the equipment it is being used on.

Step 5: Test the equipment After installing the shaft sleeve, it is important to test the equipment to ensure that everything is functioning correctly. Check for any signs of vibration, noise, or other issues that may indicate a problem with the installation of the shaft sleeve. If any issues are identified, address them promptly to prevent further damage to the equipment.

0 notes

Text

Types of Sprocket Wheels: A Comprehensive Guide for Machinery

There are several different types of sprocket wheels used in machinery, each with unique characteristics and applications. Some of the most common types of sprocket wheels include:

Standard Sprocket Wheel: This is the most basic type of sprocket wheel, typically used in a wide range of machinery and equipment. It has a simple design with teeth spaced evenly around the circumference.

Idler Sprocket Wheel: This type of sprocket wheel is used to guide and tension the chain in a machine. It does not have a shaft or ratcheting mechanism, and is typically mounted on a stationary bracket.

Double Pitch Sprocket Wheel: This type of sprocket wheel has larger teeth that are spaced further apart, allowing for engagement with a chain with larger or heavier links. It is often used in heavy-duty applications.

Taper-Lock Sprocket Wheel: This type of sprocket wheel has a tapered hub that allows for easy installation and removal from a shaft. It is commonly used in applications where frequent maintenance is required.

0 notes