Don't wanna be here? Send us removal request.

Link

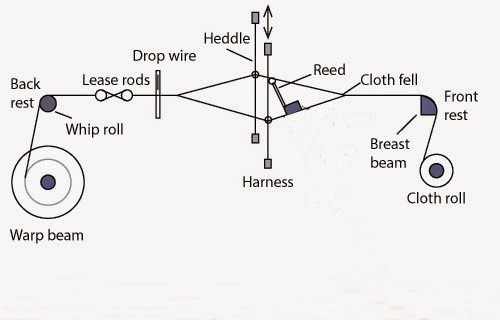

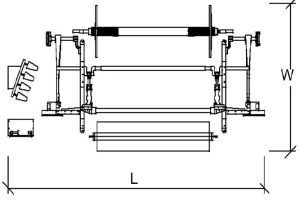

A general sketch of threads and woven fabric’s flow on the loom is shown in the below figures:

#weaving machine manufacturer in India#Textile Machinery Manufacturers#Shuttle Loom Manufacturers#Loom Manufacturers#Dobby Machine#Loom Underpick Manufacturers#Loom Overpick Manufacturers#Dobby Fabric Manufacturers#Dobby Machine Part

0 notes

Link

It is not possible to run different kinds of basic weaves with the help of Tappet Shedding similar to that of Shuttle loom.

Mainly there are two reasons clarifying this ‘NO’:

(1) Not possible to accommodate more than 4 heald frames with Shuttle loom type Tappet Shedding. Where as many of weaves and combination of weaves need 5 or 6 or 7 heald frames at least.

(2) This kind of traditional Tappet Shedding have fixed cam shedding mechanism, means there is fixed drive / fixed rotation ratio to Tappet motion from loom and hence not possible to run different kind of basic weaves.

For making fabric of many weaves and combination of weaves, one must have weaving machine equipped with separate cam shedding mechanism in which weavers can achieve different basic weaves by just replacing concerned cams.

#weaving machine manufacturer in India#Textile Machinery Manufacturers#Shuttle Loom Manufacturers#Loom Manufacturers#Dobby Machine

0 notes

Link

Apparel Industry

Suiting

Shirting

Linen

Light Denim

Sarees

Dress Materials

Corduroy

Bottom weight

Synthetic Sportswear

Household Fabrics

Furnishing

Bed sheets

Shawls

Curtains

Technical Fabrics

Glass Fiber

Leno / Gauze fabric

Nets

Packaging Fabrics

High Density Poly Ethylene (HDPE)

High Tenacity Poly Propylene (HTPP)

APPARELSCorduroy

Corduroy is a fabric, usually made of cotton, with a cut-pile weave construction. Extra sets of filling yarns are woven into the fabric to form ridges of yarn on the surface. The ridges are made so that clear lines can be seen when the pile is cut.

This particularly dense fabric construction is ideally suited for production on the SHIVA DR II PLUS machine. when equipped with a dobby. All type of corduroy weave is possible.

Light Denim

Denim was originally workwear. Fashion shifted from blue open-end jeans to different colors and a softer touch (lyocell, ring spun), elastic jeans (elastane), jeans with quite different fashion yarns. SHIVA DR II PLUS Rapier Weaving Machine

Light Denim can be woven on the SHIVA DR II PLUS machine i.e. 190 cm wide loom. Equipped with a double pressure roller on the sand roller take-up, which prevents any reverse slippage of the fabric.

Handkerchief & fancy poplin

Handkerchief may be plain or barred and can be white, dyed or printed. Poplin is a medium spun style, with rectangular construction, mostly plain weave.

Trendy Rapier Weaving Machine The Trendy Rapier Weaving Machine has acquired a reputation for efficient weaving of fine cotton fabric constructions, such as fancy shirting and handkerchiefs. The shed geometry and the gripper and tape guiding system lend themselves to dobby weaves with a large number of harnesses. Constructions with quite different warp tension levels in the main body of the fabric and a border or rib with another weave pattern are handled easily. The SHIVA DR II PLUS is designed to allow the weaver maximum freedom with textile settings.

High twist

High twist is a light filament style. It is also called crepe or crepe de chine and is mainly used in ladies’ wear.

SHIVA DR I Rapier Weaving Machine Crepe-like fabrics with highly twisted warp and weft yarns in extremely complex harness and draw patterns are ideally suited for the SHIVA DR I Machines. They show good performance figures, as their maximum speed is always attainable, even when the shedding motion is made to work very hard.Man-made fibre suitings:

Suiting is a general term for fabrics used for coats and suits for both men and women. Man-made fibre suiting fabrics can either be woven with airjet or rapier weaving technology.

SHIVA DR I & SHIVA DR II PLUS rapier weaving machine Weaving synthetic suiting materials is fairly straightforward and poses no problem with the SHIVA DR I weaving machine. To add value to such fabrics, dobby and the name selvedge is often used. This makes the fabric look as if it were produced with all the attention normally devoted to worsteds.

An enhancement is possible by creating a name selvedge. This can be done in a limited way using extra harnesses from the dobby.

The Elecronic Piezo Sensor (weft braking sensor), with which the SHIVA DR I is equipped to weave such fabrics, also helps to give the fabric that essential touch by making it possible to modify the weft tension during insertion and thereby the hand of the fabric.

Sport shirting, Gingham & Poplin

Poplin is a medium-spun style, with rectangular construction, mostly plain weave. Gingham is yarn-dyed or printed medium poplin. It is a medium-weight, plain-weave fabric with a plaid or check pattern. Poplin is popular for shirting, as also is fancy poplin.

Trendy, SHIVA DR I, SHIVA DR II PLUS rapier weaving machine

The shed geometrics of the SHIVA DR II PLUS are designed to yield the best possible treatment of the warp yarns. With finer yarn counts, this immediately results in fewer warp stops.Worsted & Wool-like Fabrics

Worsted is a tightly woven fabric made by using only long staple, combed wool or wool-blend yarns.

SHIVA DR II PLUS Rapier Weaving Machine

Wool-like fabrics are made from worsted blends. They are very much the vogue today since the major fibers used – nylon and polyester – provide very good service to the consumer.

0 notes

Link

TECHNICAL SPECIFICATIONS Type: Electronic Jacquard HEJ11

Applicable: Shuttle Looms, Rapier Looms, Projectile Looms & Air Jet Looms

Format: 1408/2688/3072/5376/6144/7680/9216/10240 Hooks

Electronic Controls: Controlled by independent controller synchronized with the weaving machine

0 notes

Link

TECHNICAL SPECIFICATIONS

Type: Electronic Jacquard HEJ80

Applicable: Shuttle Looms, Rapier Looms, Projectile Looms & Air Jet Looms Format: 640 Hooks Electronic Controls: Controlled by independent controller synchronized with the weaving machine

0 notes

Link

TECHNICAL SPECIFICATIONS

Model: VELVETO WEAVING MACHINE

Machine Type: High Speed Shuttle Loom 1 X 1

Picking Type: Under Pick Motion

Loom Width: 60” (Inches)

Working Width: 2” less than loom width

Reed: Fast

Shuttle Box: 1 X 1

Shedding Motion: Cam / Tappet, Dobby, Jacquard

Weft Control: Electronic Weft Detector

Let-Off: Single or Double (Ground & Top) Let Off with an independent Motor,

Electronically controlled through independent Load Cell & Micro-Controller.

Pile Motion: Pile Motion with an independent Motor, Electronically controlled by Micro-Controller.

Take Up: Take Up with an independent Motor, Electronically controlled by Micro-Controller.

Cloth Roll Dia.: 320 mm on Loom

Pile Cutting Motion: Linear Guide Motion

TECHNICAL FACETS OF VELVET LOOM

Save Electricity Due to Electro-Magnetic Brake: In-built Electromagnetic Brake System with Main Motor helps to save electricity as motor stops instantly at loom stoppage. Less Number of Bobbin Changes, Enhances Productivity: Big size of Shuttle (35mm X 45mm X 16.5 inch) results in to less number of Pirn change.

User Friendly Electronic Shedding: Shedding Mechanism with 20 shafts Electronic Dobby helps to weave dobby design Velvet Fabric. Easily & Quickly Make, Edit, Transfer and Weave Designs using Electronic Dobby.

Controlled & Effective Electronic Let-off @ Almost Zero Maintenance: Electronic Let-off Motion with Load-Cell & Heavy Whip Roller (Double) helps to weave the beam at almost constant beam tension and at continuous unwinding speed (MPM) from full to empty beam. Less & efficient components lead to nearly Zero Maintenance.

Variable Speed of Take Up, Fly High with Infinite Creativity: Electronic Take up Motion synchronized with Electronic Dobby helps weaver to run 5 different / variable density designs (Pick range: 40 to 250). Customer can weave value addition product by using this unique feature of the loom

Precise & Adaptable Pile Motion Technology: Electronic Pile Motion helps for continuous unwinding of Pile Beam at required speed. Have less number of Durable Components hence requires less maintenance, User friendly operation.

Fill Two Needs with One Deed: Linear Motion leads to EVEN Cutting of piles throughout the width in bottom as well as top fabric “ON LOOM”.

#weaving machine manufacturer in India#Textile Machinery Manufacturers#Textile Machinery Spare Part Manufacturers#Shuttle Loom Manufacturers#Textile Machinery Part Dealers#Textile Machinery Spare Part Dealers#Loom Manufacturers#Dobby Machine#Shuttle Loom

0 notes

Link

TECHNICAL SPECIFICATIONS

Model: GANESHA PICK N PICK

Machine Type: Semi Automatic Drop Box Shuttle Looms

Picking: Under pick motion

Loom Width: 45”, 52”, 56”, 60”, 64”, 68”, 72”, 80”

Working Width:2” less than loom width

Reed:Fast

Shuttle Box: 4×4, PICK N PICK

Shedding motion: Tappet, Dobby, Jacquard

Weft Control:Weft fork system or electronic infra-red filler system (optional)

Warp Control:Electrical or Mechanical warp Stop (optional)

Let-Off: Semi Positive attached / separate beam type / electronics

MACHINE CONTROL (OPTIONAL)

Microprocessor based control panel

Electro-magnetic brake motor

Push Button system: i.e. START/STOP/ONE PICK / INCHING / REVERSE

Pick counting

Predetermined stop

RPM indictor

Beam over tension stop

Take-Up:Seven wheel take-up mechanism

Cloth roll: VTM system / Spring Loaded (Optional)

Applicable Yarns: Synthetic, Silk, Polyester

Lubrication: Centralized lubrication system (Optional)

Installed Power: 0.33 Kw to 0.75 Kw

0 notes

Link

The Andaman Islands are an archipelago in the Bay of Bengal. These approximately 300 islands are known for their palm-lined, white-sand beaches, mangroves and rain-forest interiors. Only about 38 of them are inhabited. Surrounded with coral reefs that support marine life including sharks and rays, they are ideal destinations for scuba diving and snorkeling; as well as water skiing, windsurfing and fishing. Oceanside camping and hiking is also possible on some islands.

Historically, the British government founded a penal settlement there for deportation of freedom fighters from mainland India; which came to be known as Kala Pani (black waters). Today, this is a tourist attraction, where a sound & light show is held at night. The scenic stretch, popular known as Emerald islands, is fast emerging as a popular tourist destination. The capital Port Blair, is a commercial hub and a fine base for exploring around.

Places to visit: Cellular jail, Gandhi Park, Corbyn’s Cove, Mahatma Gandhi Marine International Park, Mount Harriet National Park, Sippighat farm

GETTING THERE By air: Port Blair is linked by air with Madras/Chennai (1300 km) and Calcutta/Kolkata (1330 km)

By sea: Sailing is possible from Chennai (1190 km), Kolkata (1255 km) and Vishakapatnam (1200 km)

Official website: http://www.andamans.gov.in/

11 Thrilling Water Sports Adventures In Andaman: No Swimming Required!

The facilities for these water sport activities are available in Port Blair and other islands. Andaman & Nicobar Islands, which is surrounded by rich coral reef eco system, offers unique life time diving experience. The Rajiv Gandhi Water Sports Complex at Port Blair, offers Safe water sports activities and also[…]

Read more

Arts & Crafts of Andaman & Nicobar

The Andaman & Nicobar Islands are a long chain of islands located in the southeastern part of the Bay of Bengal. Wood and other forest products are available here in abundance. Padauk, Badam and Gurjan are the main varieties of useful timbers found on these islands. Canes and bamboo are[…]

Read more

Fair and Festivals in Andaman and Nicobar

Island Tourism Festival Island Tourism Festival is a 10-day festival that which are full of events ranging from dance to drama. There are many Exhibitions, and art displays along with added attraction of aqua sports and para sailing. One can get the feel of splendid culture of Andaman and Nicobar,[…]

Read more

Sippighat farm

If agriculture & farming is what interests you, you could visit the Sippighat Agriculture Farm. Established in 1959 as the ‘Soil Conservation and Demonstration Center’ & converted into a Horticulture farm in 2003, the Sippighat farm is spread over a sprawling 80 acres. A mass of cultivated greenery, it is[...]

Read more

Mount Harriet National Park

The national park spreads over an area of 46. 62 sq. km and it is proposed to increase by 25.55 sq. km by adding Mount Harriet peak and other surrounding areas to the park. It is located at a distance of 20 kms from the capital twon of Port Blair.[...]

Read more

Corbyn’s Cove

The Corbyn’s Cove is one of the more busy beaches in the Andaman Islands. This is the closest beach to the Port Blair, a mere 8 kms from the City center. The drive to the beach is a stunning visual treat. You will get quite a view of the Marina[...]

Read more

Mahatma Gandhi Marine International Park

Mahatma Gandhi Marine National Park is a national park of India in Wandoor on the Andaman Islands. Situated 29 km. fromPort Blair, the park covers 281.5 km² made up of 15 islands and the open sea creeks running through the area. There is a chance for ecotourism on the islands Jolly Buoy[...]

Read more

Cellular Jail

The Cellular Jail, also known as Kālā Pānī (derived from Sanskrit words 'Kal' which means Time or Death and 'Pani' which means Water), was a colonial prison in the Andaman and Nicobar Islands, India. The prison was used by the British especially to exilepolitical prisoners to the remote archipelago. Many[...]

Read more

Currency Converter

0 notes

Link

Andhra Pradesh (divided recently further into Telangana) is a blend of antiquity and modernity; comprising monuments, memorials, shrines, nature and wildlife. The land of the mighty rivers, Krishna and Godavari, is also known for its rich heritage of the arts, crafts, literature, music, dance and drama. The antiquity of ‘Andhra’ dates back to 236 BC; amid its forts, citadels, archaeological & architectural masterpieces – stately structures that reflect the craftsmanship and culture of the land.

Temples and pilgrimage shrines are some of the main destinations of tourist traffic. Museums and archaeological treasure houses showcase historic collections of antiques, artefacts, weapons and a wide range of objects that symbolise the territory’s history. The state is studded with a host of off-beat centres as well. While ‘Andhra’ has the longest eastern coastline, it also possesses virgin beaches and a trail of sites from the Buddhist period. Hyderabad, the common capital of both states, retains its medieval charm and has emerged as a major educational and IT centre.

Of later development are the theme parks, hi-tech hub, cine city, fun islands, fantasy worlds, golf course, adventure parks, cruises and water sports. Rural tourism is particularly given thrust to showcase arts, crafts, sculpture, handloom, textiles and other skills. Environmental sustainability having assumed larger importance, eco-tourism projects have been developed. Tourism attributed to medical services, health, wellness and education is also growing significantly.

Some of the unique spots worth checking out are: the five ancient Hindu temples of Shiva; the summer resort of Horsley hills; Konaseema on the east Godavari, with its lush paddy fields and coconut groves; Kolleru lake, one of the largest freshwater bodies in the country; the Borra caves near Vishakapatnam, 800-1300 ft. above sea level and known for their million year old stalactite and stalagmite formations; and the 2000-year-old Stupa, Amravathi, the largest in India, locally known as the ‘hillock of lamps.’

The region also boasts of Kuchipudi, the renowned, classical dance form; the Etikoppaka toys with their ages-old tradition of wooden carving; the world’s finest Ponduru khadi; and Budithi brassware, with its charming shapes, created out of alloys. Finally, the state is known for its excellent communication network.

State capital: Hyderabad

Places to visit: Charminar, Salar Jung Museum, Makkah Masjid, Qutb Shahi tomb, temples (Tirumala Venkateswara, Mallikarjuna, Kanaka Durga), Nagarjunasagar-Nagarjunakonda, HI-Tec City, ,

GETTING THERE: By air: The domestic and international airports are at Begumpet By rail: Hyderabad and Secunderabad, the two major cities, are connected with major cities of India By road: Well-connected

Official website: www.aptourism.gov.in

Arts and Crafts of Andhra Pradesh

Culture of Andhra Dance Rich culture is always prevalent in the state of Andhra Pradesh. A huge collection of performing arts emerged from this state including music, drama and dance to our world. Dance being the most significant type of performing arts is constantly encouraged since centuries in our country.[…]

Read more

Andhra Pradesh Fairs & Festivals

Shankaranti Pongal Date is the winter solstice in the Hindu solar calendar. It is marked by the passing of the sun into the sign Capricorn. Pongal is celebrated on this date itself and also to celebrate the coming of spring. There are several ways of calculating the Hindu solar calendar,[…]

Read more

Adventure in Andhra Pradesh

Andhra Pradesh, seeking avenues for adventure are not disappointed as there are umpteen numbers of choices for thrilling activities like trekking, river rafting, parasailing, water skiing, rock climbing, rappelling, kayaking, forest safaris, wildlife photography and many more. Trekking & rock climbing River Rafting Parasailing Water Skiing Rappelling Kayaking Forest Safaris

Read more

9 Best Beaches in Andhra Pradesh

Yarada Beach: The Yarada beach of Andhra Pradesh is a beauty! It is about 15 kilometers away from Visakhapatnam and is one of the best beaches to be seen in this coastal region. This place would be great for those who would like to learn more about Andhra Pradesh’s culture,[…]

Read more

Major wildlife sanctuaries and reserves of Andhra Pradesh

Alisagar Deer Park Alisagar Deer Park is located in Nizamabad district of Andhra Pradesh. The Nizam constructed the Alisagar reservoir in 1931. Flanked by natural hillocks and lovely flower gardens, the lake and its surroundings are rich in scenic beauty. Near the reservoir is situated the Alisagar Deer Park, which[…]

Read more

HITEC City in Hyderabad

The Hyderabad Information Technology and Engineering Consultancy City, abbreviated as HITEC City is a major High tech business district, which is one of the leading Information Technology, Engineering, Health informatics, andBioinformatics hubs of India. HITEC City is spread across 200 acres (81 ha) of land under suburbs of Madhapur, Gachibowli,Kondapur, Manikonda, and[…]

Read more

Tourist attractions in Hyderabad

The city of smiles, of lights, of a thousand faces, endearingly called the Pearl City, Hyderabad offers a variety of tourist attractions ranging from Heritage monuments, Lakes and Parks, Gardens and Resorts, Museums to delectable cuisine and a delightful shopping experience. To the traveller, Hyderabad offers a fascinating panorama of[…]

Read more

0 notes

Link

Quality

At Dynamic Looms we use cutting-edge technologies and softwares for manufacturing our products, making it possible to maintain high quality standards. We provide ISO compliant products and From start to completion each and every machinery component goes through several stages of quality checking. We have a dedicated team of engineers for ensuring each machine is made with perfection and durability.

Quality and innovation goes hand in hand. Facilitating innovations we have our own R&D team for making our products more better.

Infrastructure

At Dynamic looms we make each and every single part of machinery using own infrastructural facilities. Spanning over a 1,50,000 Sq. Ft. industrial shed built on a 2,60,000 Sq. Ft plot the facility houses most advanced machineries to accommodate quality products.

We use Induction Furnaces for manufacturing casting products and then each part goes through CNC machine processing for cutting, milling & turning and thus we ensure accuracy, proficiency and endurance.

Our shop floor is assisted not only by modern machineries but we also have a dedicated team of R&D Professionals with years of experience. Our expertized design team uses latest designing software ‘Solid Edge ST4’ which is known for keeping Industrial standard for PLM.

Our infrastructural capacity helps us to reflect our concept of achieving customer satisfaction by delivering them quality products.

0 notes

Link

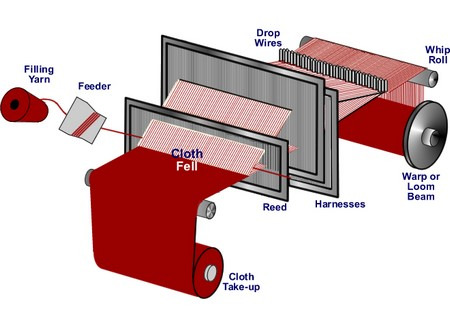

What is Weaving?

Weaving is a process of making fabric with two separate sets of yarns called the Warp and the Weft. The Warp yarns in the form of sheet (called warp sheet) are wrapped on the beam and runs the length of the fabric. The Weft yarn is entirely separate yarn than the Warp yarns and it is laid between two layers / sheets of the Warp yarns (called Shed) across the width of the fabric. A new shed is then formed in accordance with the desired weave structure, with some or all of the ends in each sheet moving over to the position previously occupied by the other sheet. In this way the Weft is gripped between two layers of the Warps. Here one Warp yarn is called an End and one Weft yarn is called a Pick.

How is the industrial revolution happened in Weaving?

There was a significant development in 1733 when John Kay (Born in Lancashire, England) developed and patented the “Flying Shuttle” with metal capped ends, wheels and a pirn of weft thread for the hand loom.

Then Edmund Cartwright (Born in Nottinghamshire, England) designed his first power loom in 1784 and patented it in 1785, but it proved to be valueless. In 1789, he patented another loom which served as a model for later inventors to work upon.

What are Primary and Secondary Motions in Weaving process?

The weaving process consists of 3 basic / primary motions: Shedding, Picking & Beat-up.

Shedding: Separating the Warp yarns into 2 layers by lifting and lowering the shafts, to form a tunnel is called the Shed. See the Shedding in below mentioned figure A:

Picking: Passing the Weft yarn (Pick) across the Warp threads through the shed is called Picking. See the Picking in below mentioned figure B:

Beat-up: Pushing the newly inserted Weft yarn (Pick) into the already woven fabric (at fell of the cloth) using the Reed is called Beat-up. See the Beat-up in below mentioned figure C:

The weaving process consists of 2 secondary motions: Let-off & Take up.

Let-off: This motion delivers Warp yarns to the weaving area at the required rate and at a constant tension by unwinding it from a flanged tube known as the weaver’s beam or warp beam.

Take up: This motion draws the woven fabric from the weaving area at a constant rate (this rate is depending upon required PPI) then winds it onto a cloth roller.

Which are essential Auxiliary functions in Weaving process?

Mainly 2 Auxiliary functions are required for the weaving: Warp Stop Motion & Weft Stop Motion.

Warp Stop Motion: This mechanism is responsible to stop the loom when a Warp yarn breaks or excessively loose.

Weft Stop Motion: This mechanism is responsible to stop the loom when a Weft yarn breaks or the Weft runs off the Weft Package.

What is general Weaving diagram?

A general sketch of threads and woven fabric’s flow on the loom is shown in the below figures:

What is Yarn Count?

Yarn Count is a numerical value, which express the diameter (Coarseness or Fineness) of the yarn and also indicates relationship between length and weight (the mass per unit length or the length per unit mass) of that yarn.

There are two types of Yarn Count Systems: Direct Count System & Indirect Count System.

Direct Count System: Here, the length is fixed. The weight per unit length is the Yarn Count. All Direct Count Systems are having fixed length of the yarn and weight of the yarn varies according to its diameter.

Numbering SystemUnit of Length (I)Unit of Weight (W)

Tex (T)1000 metersNo. of Grams

Denier (D)9000 metersNo. of Grams

Deci Tex (dtex)10000 metersNo. of Grams

Jute Count14400 yardsNo. of Pounds (lb)

i.e., 40 Tex of filament yarn means 1000 meters of yarn weigh 40 grams.

Indirect Count System: Here, the weight is fixed. The length per unit weight is the Yarn Count.All Indirect Count Systems are having fixed weight of the yarn and length of the yarn (in form of Hanks / Coils) varies according to its diameter.

Numbering SystemUnit of Length (I)Unit of Weight (W)

English Cotton Count (Ne)840 yards1 Pound (lb)

Metric Count (Nm)1000 meters1 kg

Woolen Count (YSW)256 yards1 Pound (lb)

Jute Count14400 yardsNo. of Pounds

Which are regular or basic weaves?

Regular / Basic weaves give even and easily identified appearance to the woven fabric. Some of the commonly used regular weaves are as below:

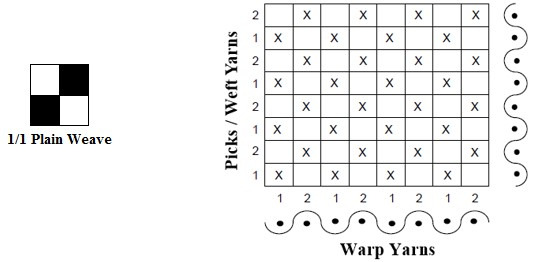

1/1 Plain: Plain weave is the most commonly used weave in the weaving industry.

The principle involved in the construction of plain cloth is the interlacement of any two continuous threads either warp or weft in an exactly contrary manner to each other, with every thread in each series passing alternately under and over consecutive threads of other series interlaces uniformly throughout the fabric. By this plan of interlacement, every thread in each series interlaces with every thread in the other series to the maximum extent, thereby producing a comparatively firm and strong texture of cloth.

Set of the Warp Yarns, skipping one warp yarn alternatively, making up and down movement one by one creates a shed and this is what being done in plain weave. It means 50 % of total Warp Yarns remains up and rest of 50 % of them remains down always.

A complete unit of the plain weave occupies only two ends of warp yarns and two picks of weft yarns.

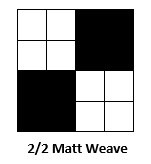

2/2 Matt: In case of regular matt weave, the plain weave is extended equally in the warp and weft directions in bunch of 2 or 3 or 4 warp and weft yarns.

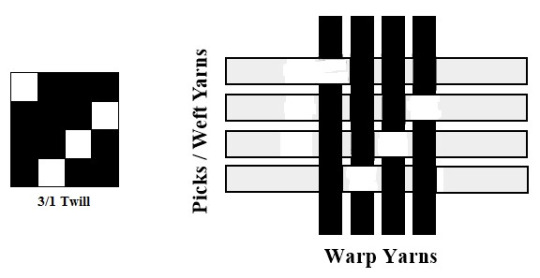

Twill Weave: Twill weave is done by passing the weft yarn under the 2 or more warp yarns and then over the one warp yarn and so on. Twill weave distinguishes from other weaves is because of the presence of visible diagonal lines that run across the width of the woven fabric.

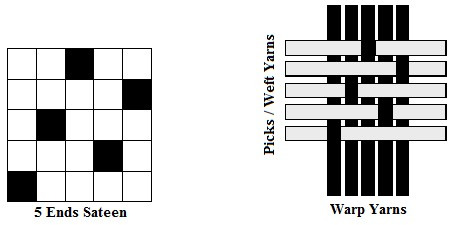

Satin and Sateen Weaves: Satin is the Warp faced rearranged twill and Sateen is the Weft faced rearranged twill. Thus satin is the reverse side of the Sateen weave. The highlighted feature of these weaves are their brightness / lustrous appearance and smoothness.

Which loom / machine is suitable for weaving basic weave / weaves?

For weaving different kind of Regular / Basic weaves, loom / machine must be equipped with at least separate Cam Shedding mechanism with minimum 7 heald frames accommodation.

With above loom specifications, weavers can able to weave a fabric with basic weaves like 1/1 Plain Weave, 2/2 Matt Weave, 2/1 Twill Weave, 3/1 Twill Weave, 3/1 Broken Twill Weave, 1/3 Twill Weave, 1/3 Broken Twill Weave, 2/2 Twill Weave, 4/1 Twill Weave, 5 Ends Satin, 5 Ends Sateen, Combination of 1/1 & 2/2 Weave, Combination of 1/1 & 3/1 Weave, Combination of 2/1 & 1/1 Weave, Combination of 5 Ends Satin & 1/1, Combination of 5 Ends Satin & 2/2, Combination of 5 Ends Sateen & 1/1, Combination of 5 Ends Sateen & 2/2, etc.

Is it possible to produce the fabrics with basic weaves with the help of Tappet Shedding similar to that of Shuttle loom? If not, why?

It is not possible to run different kinds of basic weaves with the help of Tappet Shedding similar to that of Shuttle loom.

Mainly there are two reasons clarifying this ‘NO’:

(1) Not possible to accommodate more than 4 heald frames with Shuttle loom type Tappet Shedding. Where as many of weaves and combination of weaves need 5 or 6 or 7 heald frames at least.

(2) This kind of traditional Tappet Shedding have fixed cam shedding mechanism, means there is fixed drive / fixed rotation ratio to Tappet motion from loom and hence not possible to run different kind of basic weaves.

For making fabric of many weaves and combination of weaves, one must have weaving machine equipped with separate cam shedding mechanism in which weavers can achieve different basic weaves by just replacing concerned cams.

#weaving machine manufacturer in India#Textile Machinery Manufacturers#Textile Machinery Spare Part Manufacturers#Shuttle Loom Manufacturers#Textile Machinery Part Dealers#Textile Machinery Spare Part Dealers#Loom Manufacturers#Dobby Machine

0 notes

Link

GET IN TOUCH WITH US

We bring a personal and effective approach to every project we work on.

Contact InfoPlot no. 2, Road no. 1, Phase – 1, GIDC, Kathwada, Ahmedabad – 382 430. Gujarat, India.+91-79-22901522

+91-79-29707124

+91-9925039411

+91-9825413411

+91-98789 44411

0 notes

Link

Apparel Industry

Suiting

Shirting

Linen

Light Denim

Sarees

Dress Materials

Corduroy

Bottom weight

Synthetic Sportswear

Household Fabrics

Furnishing

Bed sheets

Shawls

Curtains

Technical Fabrics

Glass Fiber

Leno / Gauze fabric

Nets

Packaging Fabrics

High Density Poly Ethylene (HDPE)

High Tenacity Poly Propylene (HTPP)

APPARELS

Corduroy

Corduroy is a fabric, usually made of cotton, with a cut-pile weave construction. Extra sets of filling yarns are woven into the fabric to form ridges of yarn on the surface. The ridges are made so that clear lines can be seen when the pile is cut.

This particularly dense fabric construction is ideally suited for production on the SHIVA DR II PLUS machine. when equipped with a dobby. All type of corduroy weave is possible.

Light Denim

Denim was originally workwear. Fashion shifted from blue open-end jeans to different colors and a softer touch (lyocell, ring spun), elastic jeans (elastane), jeans with quite different fashion yarns.

SHIVA DR II PLUS Rapier Weaving Machine

Light Denim can be woven on the SHIVA DR II PLUS machine i.e. 190 cm wide loom. Equipped with a double pressure roller on the sand roller take-up, which prevents any reverse slippage of the fabric.

Handkerchief & fancy poplin

Handkerchief may be plain or barred and can be white, dyed or printed. Poplin is a medium spun style, with rectangular construction, mostly plain weave.

Trendy Rapier Weaving Machine The Trendy Rapier Weaving Machine has acquired a reputation for efficient weaving of fine cotton fabric constructions, such as fancy shirting and handkerchiefs. The shed geometry and the gripper and tape guiding system lend themselves to dobby weaves with a large number of harnesses. Constructions with quite different warp tension levels in the main body of the fabric and a border or rib with another weave pattern are handled easily. The SHIVA DR II PLUS is designed to allow the weaver maximum freedom with textile settings.

High twist

High twist is a light filament style. It is also called crepe or crepe de chine and is mainly used in ladies’ wear.

SHIVA DR I Rapier Weaving Machine Crepe-like fabrics with highly twisted warp and weft yarns in extremely complex harness and draw patterns are ideally suited for the SHIVA DR I Machines. They show good performance figures, as their maximum speed is always attainable, even when the shedding motion is made to work very hard.

Man-made fibre suitings:

Suiting is a general term for fabrics used for coats and suits for both men and women. Man-made fibre suiting fabrics can either be woven with airjet or rapier weaving technology.

SHIVA DR I & SHIVA DR II PLUS rapier weaving machine Weaving synthetic suiting materials is fairly straightforward and poses no problem with the SHIVA DR I weaving machine. To add value to such fabrics, dobby and the name selvedge is often used. This makes the fabric look as if it were produced with all the attention normally devoted to worsteds.

An enhancement is possible by creating a name selvedge. This can be done in a limited way using extra harnesses from the dobby.

The Elecronic Piezo Sensor (weft braking sensor), with which the SHIVA DR I is equipped to weave such fabrics, also helps to give the fabric that essential touch by making it possible to modify the weft tension during insertion and thereby the hand of the fabric.

Sport shirting, Gingham & Poplin

Poplin is a medium-spun style, with rectangular construction, mostly plain weave. Gingham is yarn-dyed or printed medium poplin. It is a medium-weight, plain-weave fabric with a plaid or check pattern. Poplin is popular for shirting, as also is fancy poplin.

Trendy, SHIVA DR I, SHIVA DR II PLUS rapier weaving machine The shed geometrics of the SHIVA DR II PLUS are designed to yield the best possible treatment of the warp yarns. With finer yarn counts, this immediately results in fewer warp stops.

Worsted & Wool-like Fabrics

Worsted is a tightly woven fabric made by using only long staple, combed wool or wool-blend yarns.

SHIVA DR II PLUS Rapier Weaving Machine Wool-like fabrics are made from worsted blends. They are very much the vogue today since the major fibers used – nylon and polyester – provide very good service to the consumer.

#Worsted is a tightly woven fabric made by using only long staple combed wool or wool-blend yarns. SHIVA DR II PLUS Rapier Weaving Machine Wo#weaving machine manufacturer in India#Textile Machinery Manufacturers#Textile Machinery Spare Part Manufacturers#Shuttle Loom Manufacturers#Textile Machinery Part Dealers#Textile Machinery Spare Part Dealers#Loom Manufacturers#Dobby Machine

0 notes

Link

Production Facility

Our Foundry

We have built foundry in the year 1984. At Dynamic we have own foundry for material casting. We are member of ‘The Institute of Indian Foundry men’- affiliated member of the International Committee of Foundry Technical Association.

This not only caters to the needs of our organization but we have also been doing casting work for other industries. At our foundry we processes metals such as Cast iron, S.G. Iron etc. and later does finishing through machining process in CNC & VMC machines. Various specifications of our foundry facility is given below.

MELTING SHOP:

Induction Furnace: 500 Kg, 300 Kg & 150 Kg Crucible

MOLDING:

Machine Molding:-

– Parts Weight: Up to 11 Kg – Sand system: Green sand

Hand Molding:-

-Parts Weight: 0.500 Kg to 100 Kg -Sand system: River Sand, Molasses

CAST IRON METALS:

-Commercial Casting CI, SG Iron -Spheroidal: Graphite (Grade 400-700)

We have also implemented sand testing equipment as well as have harness testing machines for checking casting grade. Each product’s quality is thus checked in our foundry before passing through the next phase of machine finishing.

Laser Cutting Machines

Let it be CNC, VMC, Laser cutting, Software or any other technology, we believe in quality hence have installed world’s most advanced technologies in our entire unit. We uses laser cutting machine of Mitsubishi EX edition. This machine built on a heavy duty, single platform runs faster, with powerful piercing capacity and helps us to deliver products with high accuracy and longevity.

Alongside making components for our internal purpose we also does job work for many leading organizations.

Cutting Capacity in our laser cutting division is given below:-

Mild Steel :- 18 MM Stainless Steel:- 12 MM Aluminum:- 8 MM Acrylic:- 16 MM.

At Dynamic, customer can get all machining processes under one roof. We do Bending process in Denier 3Axis machines & Tapping in conventional machines.

#weaving machine manufacturer in India#Textile Machinery Manufacturers#Textile Machinery Spare Part Manufacturers#Shuttle Loom Manufacturers#Loom Manufacturers

0 notes

Link

Quality

At Dynamic Looms we use cutting-edge technologies and softwares for manufacturing our products, making it possible to maintain high quality standards. We provide ISO compliant products and From start to completion each and every machinery component goes through several stages of quality checking. We have a dedicated team of engineers for ensuring each machine is made with perfection and durability.

Quality and innovation goes hand in hand. Facilitating innovations we have our own R&D team for making our products more better.

Infrastructure

At Dynamic looms we make each and every single part of machinery using own infrastructural facilities. Spanning over a 1,50,000 Sq. Ft. industrial shed built on a 2,60,000 Sq. Ft plot the facility houses most advanced machineries to accommodate quality products.

We use Induction Furnaces for manufacturing casting products and then each part goes through CNC machine processing for cutting, milling & turning and thus we ensure accuracy, proficiency and endurance.

Our shop floor is assisted not only by modern machineries but we also have a dedicated team of R&D Professionals with years of experience. Our expertized design team uses latest designing software ‘Solid Edge ST4’ which is known for keeping Industrial standard for PLM.

Our infrastructural capacity helps us to reflect our concept of achieving customer satisfaction by delivering them quality products.

#weaving machine manufacturer in India#Textile Machinery Manufacturers#Loom Manufacturers#Shuttle Loom Manufacturers#Dobby Machine

0 notes

Link

TECHNICAL SPECIFICATIONS

Model: GANESHA

Machine Type : Semi Automatic Drop Box Shuttle Looms

Picking : Under pick motion

Loom Width : 45”, 52”, 56”, 60”, 64”, 68”, 72”, 80”

Working Width : 2” less than loom width

Reed : Fast

Shuttle Box : 4×4, PICK N PICK

Shedding motion : Tappet, Dobby, Jacquard

Weft Control : Weft fork system or electronic infra-red filler system (optional)

Warp Control : Electrical or Mechanical warp Stop (optional)

Let-Off : Semi Positive attached / separate beam type / electronics

MACHINE CONTROL (OPTIONAL)

Microprocessor based control panel

Electro-magnetic brake motor

Push Button system: i.e. START/STOP/ONE PICK / INCHING / REVERSE

Pick counting

Predetermined stop

RPM indictor

Beam over tension stop

Take-Up : Seven wheel take-up mechanism

Cloth roll : VTM system / Spring Loaded (Optional)

Applicable Yarns : Synthetic, Silk, Polyester

Lubrication : Centralized lubrication system (Optional)

Installed Power : 0.33 Kw to 0.75 Kw

SPACE REQUIRED FOR INSTALLATION:

Reed Space : 45”52”56”60”64”68”72”80”

Length (ft) : 8’ 8”9’ 4”9’ 8”10’10’ 4”10’ 8”11’11’ 8’’

Width (ft) : 6’6’6’6’6’6’6’6’

0 notes

Link

TECHNICAL SPECIFICATIONS

Model: SHIVA DR II PLUS

Machine Type: Heavy Duty Flexible Rapier Loom

Loom Width: 170, 190, 230, 280, 330 CM

Working Width: 50 MM less than loom width

Width Reduction: Up to 400 MM (300 MM for 170 CM loom) Weft Insertion Rate: 400 to 525 MPM Weft Colors: 2, 4, 6, 8 operated by Microcontroller (Optional) / Synchronized with Electronic Dobby or Electronic Jacquard

Warp Control: Electrical 6 Rows / Infrared (Optional)

Shedding Motion: Cam Motion (Plain, Twill, Sateen, Matt Weave) / Electronic Dobby / Electronic Jacquard

Take up: 7 Wheel / with an independent motor, Electronically controlled by Microcontroller

Weft Density: 10 to 128 Picks per Inch / Up to 250 Picks per Inch (Optional), Variable Density up to 5 (Optional) / Cramming (Optional) / Fringing (Optional)

Cloth Roll: Up to 400 MM Dia

Lubrication: Centralized

Installed Power: 1.5 KW / 3.3 KW

Special Attachment (Optional): Suction Device

Applicable Yarns: Blended Cotton: 2s Ne – 100s Ne

Filament: 20 D – 2000 D

Pure Silk: 20 D – 500 D

SPACE REQUIRED FOR INSTALLATION:

Reed Space: 170 CM 190 CM 230 CM 280 CM 330 CM

Length (ft): 12’ 9”13’ 5”14’ 10”17’ 11”19’ 7”

Width (ft): 6’ 7”6’ 7“6’ 7”6’ 7”6’ 7”

#Loom Manufacturers#Loom Manufacturers in India#weaving machine manufacturer in India#Textile Machinery Manufacturers#Shuttle Loom Manufacturers

0 notes