Don't wanna be here? Send us removal request.

Text

Public works – Gard-based companies on the path to decarbonisation

Public works companies in Gard are committed to reducing their greenhouse gas emissions, as part of the national low carbon strategy. They should benefit from public investments linked to the decarbonization of transport and energy.

How can we achieve a 40% reduction in carbon emissions by 2030, then achieve carbon neutrality in 2050, as part of the national low carbon strategy? Public Works in Gard[1] is working on it. Two companies were highlighted on December 11 in Nîmes for having already reduced their greenhouse gas emissions by 40%. Pellet, based in Barjac[2], specializing in quarries and public works, installed solar panels in 2017. It has been using organic fuels since 2022 and has set up a waste sorting centre, we read in Midi Libre. Another example highlighted: Valette, based in Alès[3] and specialized in the design and execution of electrical network and equipment works, has installed photovoltaic shade structures.

More generally, several actions are planned with members of the Regional Federation of Public Works (FRTP) in the Gard: “reducing the carbon impacts of the materials used and emissions due to fuel consumption, strengthening the circular economy loop , support CSR initiatives, limit the impact of construction sites on biodiversity, and support innovation,” explains Christophe Ruas, president of the Gard delegation of the Occitanie Public Works Federation[4].

“A flood of investments”

Public works activity in France represents 3.5% of greenhouse gas emissions. “But 50% of emissions are linked to the use of transport infrastructure,” explained Olivier Giorgiucci, president of FRTP Occitanie, during his speech at the TP Regional Conference in November in La Grande-Motte. “We build roads, bridges, we maintain roads, structures, networks… This heritage is largely a public domain. For the future, these communities must commit to respecting a public policy to reduce greenhouse gases. The pressure will increase, it is inevitable. If we want to achieve this, we must simply transform our infrastructures, and therefore decarbonize them,” he explained. “This implies a flood of investments: tramway, cycle paths, buses with a high level of services, offshore wind turbine projects, hydrogen production… Infrastructure must also adapt to climate change, by adapting it to the increasing scarcity of water resources, flooding and marine submersion. And these investments do not only concern major works, far from it,” he insisted.

Source

Hubert Vialatte, Travaux publics : les entreprises gardoises sur la voie de la décarbonation, in: Les Echos, 22-12-2023 ; https://www.lesechos.fr/pme-regions/occitanie/travaux-publics-les-entreprises-gardoises-sur-la-voie-de-la-decarbonation-2043051

[1] Gard is a department in Southern France, located in the region of Occitanie. It had a population of 748,437 as of 2019; its prefecture is Nîmes. The department is named after the river Gardon. In recent decades of the 21st century, local administration and French speakers have returned to the original Occitan name of the river, Gard. It is part of a revival of Occitan culture.

[2] SAS Pellet is a renowned public works company, operating in the North of Gard (30) and South of Ardèche (07) sectors. With its expertise and experience, our company offers a wide range of services and products for meet the needs of individuals and professionals. Whether for road construction, landscaping, or the installation of sanitation networks, the Pellet company implements tailor-made solutions, adapted to the requirements of each project. Our qualified and passionate team is committed to providing quality work, respecting deadlines and current standards. https://sas-pellet.fr/une.entreprise.de.travaux.publics.familiale-361900-2-1-19.php

[3] Located in Alès, our company specializes in the design and construction of electrical network and equipment work. Strongly anchored in the region since its creation in 1969, the VALETTE company plays an essential role in regional planning and contributes to the development of the local economy. We work on behalf of communities, private companies and individuals in the Languedoc region and particularly in Gard (30). Our know-how is divided into 3 main activities:Electrical networks, Roads and Miscellaneous Networks, Lighting. https://www.valette-ete.fr/qui-sommes-nous/

[4] A professional organization dedicated to the development of the Profession, FRTP Occitanie represents Public Works companies of all sizes, specialties in the Occitanie region. Public Works offers 18 professions, great development opportunities, rewarding remuneration and projects useful to society, the environment and the economy. https://www.frtpoccitanie.fr/#

0 notes

Text

Gen Z - sustainability is often just a facade

According to a study on Gen Z conducted in Italy by Zelo, those born after 1997 would be more sensitive to sustainable issues in words than in concrete facts.

Members of Gen Z express their 'green' soul more with hashtags than with actions. This was revealed by a study conducted by the consultancy firm Zelo[1] which involved a sample of 2 thousand young people aged between 17 and 24. Although more than 70% of those interviewed recognise the value of being sustainable, there are very few, in fact, who actually do something, apart from separate waste collection.

In particular, only 15% of the sample states that they feel truly and concretely sustainable in their behaviours and choices. 17% admit, however, that their 'eco' commitment is limited to separate waste collection while 33% declare that they do not feel as sustainable as everyone would think. 35%, although considering themselves aware and informed, have no idea what to do.

Distrust prevails towards companies that talk about sustainability. 59% of those interviewed don't believe what they say and 19% say they would only remember a campaign if it referred to a really 'cool' project. 17% of the sample believes that companies always say the same things while 5% appreciate and prefer brands that talk about environmental sustainability.

Pragmatic and impulsive, the approach to shopping of members of Gen Z would, in turn, favour the much despised 'fast fashion'. Among the factors that would influence the choices of young people, in addition to the reduced economic availability, there would be, finally, the evaluations of 'creators' and 'influencers', committed to promoting hundreds of 'must haves' every day. For 29% of the sample, not surprisingly, what matters is keeping up with social media.

Source

Salvo Cagnazzo, Gen Z, spesso la sostenibilità è solo di facciata in: La Repubblica, 19-12-2023; https://www.repubblica.it/economia/rapporti/osserva-italia/trend/2023/12/19/news/gen_z_spesso_la_sostenibilita_e_solo_di_facciata-421697163/?ref=search

[1] Zélo was born from the offshoot of a historic company, Odoardo Zecca srl, active in the field of energy distribution and sales since 1905. ZÉLO, therefore, strengthened by the tradition of the parent company, combines the over one hundred year old expertise with the enthusiasm of the first day. Determined to always do better, the time has come to face the new challenge of the free market. https://zeloenergia.it/pages/zelo-e/

0 notes

Text

Mending clothes would make sense, but: “It feels like you have to reinvent the wheel every day.”

Mending clothes requires a lot of manual work and is difficult to automate.

The criticism of “fast fashion” is getting louder. Likewise the demand to repair defective clothes and give them a second life. But that's easier said than done, as the story of a Norwegian startup shows.

As Ingvill Kerob[1] sat at home with her third child, who had just been born, she thought about her future. She thought about what else she wanted to achieve professionally. It soon became clear that she would want to continue the tradition of her family, which has been working in the textile sector for four generations. But in their own way. So not with the production of new textiles, but with repairing them. And not as an employee, but as her own boss.

Interface for customers and companies

Today Kerob says: "It's risky to have children - you have so much time to think of." Because what she imagined back then at home could not easily be implemented. The road to independence was bumpy. The first step: hang up notes on notice boards in kindergartens. She offered the parents the opportunity to organise the mending of clothes that children of kindergarten age always have a hole in somewhere.

The second step was to submit applications for government aid. The promise to the donors: to use a technological platform to help clothes last longer. Courtship was easier than expected. «I met all the criteria: woman, founder, sustainability, technology. Whatever funding I applied for, I got it," says Kerob on the sidelines of an event at the Gottlieb Duttweiler Institute (GDI)[2], where she is presenting her company.

Sustainability has always played a central role in the professional life of the 44-year-old Norwegian, who once worked for the food company Mondelez in Opfikon, Zurich for four years.[3] Before starting her own business, she set up the recycling system for Nespresso capsules for Nestlé in Norway and Denmark. What she achieved with coffee capsules, she now also aimed for with clothes: a resource-saving circular economy, only it was no longer about recycling, but about repairing.

There is often talk of a “repair revolution” at the moment. Reference is made to the many repair cafés[4] that are springing up around the world. However, Kerob's startup has not yet sparked a revolution. But at least the company called Repairable, founded in 2016, is still alive. The business model: Repairable offers companies access to a digital platform that connects all players in the repair of clothes, shoes and leather goods.

Customers can book repairs on the platform, regardless of whether they pay for the repair themselves or whether the manufacturer does so due to a warranty claim. The companies get access to tailors or shoemakers who know how to get things back into shape. The platform can be integrated into the company's e-commerce system and provides data on the quality of the products and which parts - zippers, buttons, seams - cause problems. For all of this, companies buy a subscription from Repairable, which varies in price depending on the scope of services.

Second-hand clothing on trend

The company hasn't really taken off yet. “Even after seven years, Repairable still considers itself a startup,” says the economist. In fact, the number of employees is manageable. In addition to the two company founders, there are six software developers in India. There are no more employees, especially since the repair companies work independently on their own account. Currently we are only operating in Norway. According to the plan, other Nordic countries and Germany will soon follow.

No matter how difficult the business may be. Repairable hits a nerve of the times. The pursuit of sustainability has been gaining in importance in the textile industry for years. Criticism of the excesses of fast fashion is becoming louder, and interest in long-lasting clothes is increasing. This is also reflected in the market structure. While the market for textiles grew by 4 percent worldwide last year, the market for second-hand clothes grew by an impressive 28 percent.

But despite the trend towards second-hand clothing, repairing textiles is often not very lucrative. This is also because the work is hardly scalable and promises few economies of scale. Every problem is a little different and requires different approaches. Repair businesses are mostly small or individual businesses. The possibilities for cost-saving division of labour are limited. The productivity of the activity is correspondingly low.

“The materials differ, as do the damages that need to be repaired and even more so the demands of the customers,” says Kerob. “It feels like you have to reinvent the wheel every day.” The only thing that connects the many repair companies is that the work is hard and offers little reward. Unsurprisingly, the industry is struggling to find enough qualified staff for the technically demanding but poorly paid work.

Just a fig leaf for H & M?

The startup entrepreneur has adjusted her expectations over time. She had to realise that not every broken piece of clothing promises a deal. There seem to be two invisible price barriers for most customers: firstly, most people are only willing to repair if the original price of the goods was more than 100 euros. Secondly, you only send a dress for repair if the cost is less than 50 percent of the original price.

Kerob discovered these barriers, among other things, when working with H & M. The Swedish fashion group was Repairable's first major customer. However, the business relationship was short-lived. It soon became clear that repairing cheap 20-euro shirts made little business sense. The project to operate an open repair workshop in the middle of a Norwegian H & M flagship store was also cancelled.

Looking back, the question arises as to whether Repairable only served as an ecological fig leaf for the global fast fashion manufacturer.[5] Sometimes it felt like that, says Kerob. But H & M is quite serious about its commitment to sustainability. And the company also has the budget for corresponding projects. «The collaboration with H & M was not initially planned as a PR campaign. But the result may have been a PR move.”

The matter is complicated for retailers and fashion chains. When customers have clothes mended, this reduces sales of new products. Anyone who promotes repairs is cannibalizing their business. In addition, repairs are rarely profitable. «In Norway, many fashion houses now offer repairs. But most admit that they have to subsidize this offer. Many companies cannot afford this subsidy,” says Kerob.

More government aid and regulation

Does this mean the state has to intervene? Do we need more support and stricter regulation? If you look at Europe's capitals, you might think so. Sweden, for example, has reduced VAT on repairs. And in France, where unsold textiles have no longer been allowed to be destroyed since 2022, a repair bonus[6] was introduced in November: Anyone who has clothes or shoes mended there receives a subsidy of between 6 and 25 euros.

The EU goes even further. She wants to introduce a “right to repair”[7] in the Union. First of all, it's primarily about electrical appliances such as washing machines, televisions or vacuum cleaners. While such items could previously be easily replaced if they were defective, customers will now be able to request repairs for a fee. For companies, this would mean that they would have to keep spare parts in stock for significantly longer.

The topic is also current in Switzerland. In November, the Council of States unanimously approved a revision of the Environmental Protection Act[8] with the aim of creating more favourable conditions for a circular economy. The repairability of products should also be promoted. However, Switzerland goes much less far in this goal than the EU, that takes a strong interventionist approach to the economic freedom of companies.

So a lot is happening politically. However, one problem for repairers remains that clothes have become increasingly cheaper in recent decades. Buying new textiles is therefore usually more cost-effective than mending them. And people buy in large quantities: Swiss people buy an average of 60 new items of clothing per year. However, around 40 percent of them are never worn or worn a maximum of four times. Switzerland ranks second in the world after Luxembourg in per capita spending on clothing and shoes.

The pitfalls of psychology

How many clothes are repaired and what people spend on them is hardly known. “Nobody collects data,” complains Kerob. Accordingly, the industry is in the dark. What we do know is that customers' loyalty to brands is also explained by customer service after the purchase. The industry hopes that this after-sales service will always include repairs in the future. “Repairing needs to become as natural as brushing your teeth,” says Kerob.

But ultimately it's not just about money, data or customer loyalty. Psychology is also important. “We don’t buy a tenth pair of jeans because we need them, but because we want to treat ourselves and because when we buy them, the happiness hormone dopamine is released,” says Kerob. Little can be done against such vanity. “Our appeal is not very sexy: do nothing, stick with what you have, repair it and wear it again. It doesn’t trigger a dopamine rush.”

Source

Thomas Fuster, Kleider flicken wäre sinnvoll, aber: «Es fühlt sich an, als müsse man jeden, in: Neue Zürcher Zeitung, 22-12-2033; https://www.nzz.ch/wirtschaft/kleider-flicken-waere-sinnvoll-aber-es-fuehlt-sich-an-als-muesse-man-jeden-tag-das-rad-neu-erfinden-ld.1769371

[1] It’s fair to say that Ingvill Kerob knows a thing or two about project management, having spent the best part of a decade working various project management roles for two of the world’s largest food groups (Nestle and Mondelez). She’s also quite handy at the whole recycling game, due to the lead role she had helping Nespresso recycle its capsules in both Norway and Denmark. With all of this solid experience (and factoring in her solid academic career in economics), it probably came as a surprise to no-one when she struck out on her own in 2017 by founding Repairable. Ingvill’s ambition for the company is simple – she wants to vastly reduce the waste in the fashion sector by encouraging all of us to repair our clothes and shoes instead of throwing them away when faults appear. To this end, she has launched a great online repair and alteration service in Norway’s capital. Customers input their repair orders (shoes, dresses, zips, coats, hats, you name it) and then Repairable takes over. It sorts out the price, the transport of goods to certified repairers and follows the entire process to completion. Simple, sustainable, circular fashion has arrived. https://www.globallyspotted.com/profiles/ingvill-kerob/

[2] The Swiss retail pioneer Gottlieb Duttweiler laid the foundations for the Gottlieb Duttweiler Institute, GDI, in 1962. His goal was to establish an institute where free thought about the future of the world took centre stage, an institute that contributed to economic and social progress and that put people before profit. The GDI focuses its activities on the industries retail, food and health and examines them from the perspectives of consumption, society, technology and the environment. https://gdi.ch/en/about-us/gdi/what-we-do

[3] Read also: https://www.tumblr.com/earaercircular/654312790081814528/aluminum-coffee-capsules-can-be-recycled-forever?source=share

[4] https://www.repair-cafe.ch/; read also: https://www.tumblr.com/earaercircular/698433553891049472/plastics-manufacturers-want-to-get-rid-of-oil?source=share

[5] Read also: https://www.tumblr.com/earaercircular/720260226679488512/hms-answer-about-the-dumped-clothes-article?source=share

[6] https://www.bbc.com/news/world-europe-66174349

[7] Read also https://www.tumblr.com/earaercircular/720378340978180096/repaired-electro-is-successful-we-are-happy-with?source=share & https://www.tumblr.com/earaercircular/661118774058123264/repairing-electrical-appliances-is-becoming-easier?source=share; https://www.nzz.ch/wirtschaft/recht-auf-reparatur-die-eu-kommission-will-dass-hersteller-in-der-eu-staubsauger-mobiltelefone-fernseher-und-waschmaschinen-fuenf-bis-zehn-jahre-nach-dem-kauf-noch-flicken-ld.1731687;

[8] The revision of the Environmental Protection Act (USG) is intended to provide binding regulations for the investigation and renovation of public children's playgrounds and green spaces. 60 percent of the costs of the remediation would be covered by the contaminated sites fund of the Ordinance on the Levy for the Remediation of Contaminated Sites (VASA). https://www.admin.ch/gov/de/start/dokumentation/medienmitteilungen.msg-id-92243.html#:~:text=Mit%20der%20Revision%20des%20Umweltschutzgesetzes,von%20Altlasten%20(VASA)%20erfolgen.

1 note

·

View note

Text

Obligation to offer reusable food packaging? - Call for improvements

By law, disposable plastic packaging for take-away food should be curbed. But the obligation to offer reusable food has remained practically ineffective, is the complaint of environmental and consumer advocates.

Almost a year after the obligation to offer reusable food for take-away food came into force, environmental and consumer advocates complain about a lack of implementation and a lack of controls. Thomas Fischer, head of circular economy at the German Environmental Aid[1], for example, speaks of an “ aborted starter" and calls for improvements.

"What started badly at the beginning of the year unfortunately continued like a thread until the end of this year," Fischer told the German Press Agency. During several rounds of test visits, catering companies reported reusable quotas in the low single-digit percentage range. Measured against the original goals, these are "dismal results".

Since the beginning of the year, restaurants, bistros and cafés that sell food to go have had to offer reusable packaging in addition to disposable packaging - provided they use disposable plastic packaging. There must be a reusable alternative for all types of drinks. Exceptions apply to smaller shops that are no larger than 80 square meters and have a maximum of five employees. However, customers there must be given the opportunity to have their own containers filled. Violations can result in fines of up to 10,000 euros.

Lack of controls, lack of sanctions

According to Fischer, the law suffers primarily from a lack of controls and a lack of sanctions for violations. "Without pressure, without coercion, nothing will change the fact that many restaurateurs do not take the obligation to offer reusable containers seriously." In addition, consumers are still poorly informed, and they often do not even notice information about reusable containers. The providers are apparently trying "to deliberately keep reusable containers at bay by making the information poor and easy to overlook."

The simplest lever for better customer information - namely verbal information from sales staff - was not found in a single case during almost 100 test visits throughout the year, said Fischer. "This active customer information does not exist." The legislator must therefore define the information requirements much more narrowly.

The many different reusable containers are also problematic. "Many retailers do not work together, but basically work side by side with their own systems," which is not consumer-friendly. It is important to get away from this confusion - and towards a uniform industry solution with a comprehensive network of return options, said Fischer.

Improvements to the law are necessary

He also believes that financial incentives are important, as in the case of Tübingen. The packaging tax on disposable packaging, crockery and cutlery that applies there was found to be permissible by the Federal Administrative Court in Leipzig in May. A franchisee of the fast food chain McDonald's filed a constitutional complaint against this, and a decision is still pending.

The North Rhine-Westphalia consumer advice centre[2] also sees serious shortcomings in the law - above all the fact that it only applies to disposable plastic packaging for food, although other types of packaging are just as bad or even worse ecologically, says Philip Heldt, resource protection officer at the North Rhine-Westphalia consumer advice centre. This leads to people switching to cardboard packaging. "So that's a huge loophole that the legislature has given to catering businesses," said Heldt.

The consumer protection agency examined around 400 businesses. Given their size and circumstances, around half of them should have offered reusable takeaway food, but only around half of them actually did so. "That's pretty crazy, of course. If you consider that with other laws, 50 percent of those affected would not comply with the law," said Heldt, insisting on improvements to the law.

Regulations unclear

The fact that there are hardly any checks is not only due to the understaffing of the supervisory authorities, but also to the complex regulations of the law, which also raises questions. There is a lack of "clear enforcement instructions on how exactly to proceed", which limits the authorities' ability to act.

The catering association Dehoga[3] also considers the regulations to be unclear. It was not until May 2023 - months after the law came into force - that an official guide was published. "But unfortunately this did not answer all the questions that arise in practice during implementation, so that legal uncertainties still exist," explained Uta Stenzel, speaker for food and consumer protection law at the industry association Dehoga.

In general, the law means considerable effort and costs - "and all this in times of further major challenges that companies are currently having to overcome." Demand for reusable items is still limited in most classic restaurants and cafés. In order to increase the rate of reusable products and their acceptance, structures and processes need to be improved - from easy-to-handle containers to return. A system similar to that for deposit bottles would be desirable. As an example, Stenzel referred to the Reusable To-Go initiative[4], which is testing the uncomplicated return of reusable systems for food in pilot markets in Hesse and Rhineland-Palatinate.

Source

Christine Schultze, Mehrweg-Angebotspflicht? - Ruf nach Nachbesserungen; in: Süddeutsche Zeitung, 20-12-2023; https://www.sueddeutsche.de/panorama/umwelt-mehrweg-angebotspflicht-ruf-nach-nachbesserungen-dpa.urn-newsml-dpa-com-20090101-231220-99-357180

[1] Deutsche Umwelthilfe e.V. (DUH, using the English name Environmental Action Germany) is a non-profit environmental and consumer protection association, supported by public and private project grants and donations. It is a member of the European Environmental Bureau, in Brussels. It has the legal right to represent group claims in court against projects that it considers a threat to the environment. The group also aims to provide a forum for dialogue between environmental organizations, politicians and business people.

[2] We provide information and advice on the diverse questions of everyday consumer life. We also support consumers in asserting their legitimate interests against providers. Every year we protect thousands from being taken advantage of. We pave the way to enforce consumer rights. We are committed to economic, health and digital consumer protection towards politicians, administration and associations. Whether in hearings, legislative processes or in professional exchanges with stakeholders - we advocate for fair markets, safe products and services, for transparent consumer information and for the practical design of consumer rights. https://www.verbraucherzentrale.nrw/ueberuns-nrw/wie-wir-arbeiten

[3] Who else stands up for the interests of the hotel and catering industry in Germany? The DEHOGA Federal Association is the only industry association that has represented the hospitality industry as a whole for over 70 years. Locally, regionally, statewide and nationwide. With more than 60,000 members, DEHOGA is one of the leading business associations in Germany. The DEHOGA Federal Association represents the interests and mouthpiece of the hospitality industry towards politicians, the press and the public. Entrepreneurial actions, corporate responsibility and willingness to take risks require constructive support and appreciation from politicians. This is what DEHOGA is committed to. https://www.dehoga-bundesverband.de/ueber-uns/

[4] The Reusable To-Go initiative has set itself the goal of creating the basic requirements for reusable food systems nationally and internationally for use-related and system-independent returns for all distribution points. The initiative's advisory board includes representatives of the national associations Pro Mehrweg, the Federal Association of Beverage Wholesalers, the DEHOGA Federal Association, the Reusable Working Group and the initiators. There is close exchange with other associations. https://promehrweg.de/initiative-reusable-to-go-startet-pilotmarkt-fuer-food-mehrwegsysteme/

0 notes

Text

Dreaming of a less wasteful holiday

It’s the season of parties, gifts and lots and lots of food. It’s also the season of buying more than we can use or eat, and then throwing it away.

Household garbage tends to increase around 25 percent in the weeks between Christmas and New Year’s Day in the United States, according to the Environmental Protection Agency[1]. The same is true in Canada[2] and other countries. And that’s not counting the stuff we will throw away in the near future, like a cheap T-shirt that falls apart after a few washes, or a plastic toy that quickly gets discarded. While we often think of the world’s environmental problems as being primarily about the toll of fossil fuels on the climate, they are also about the burden created by the absolute tonnage of stuff we buy and consume — the packaging, the toys, the fast fashion, which are often made with petroleum byproducts, and moved around the world by burning fossil fuels. And that’s especially true of the holiday frenzy of presents and parties.

We can, of course, do a lot better: Buying well-made, durable goods, giving experiences instead of objects, minimising food waste and composting the leftovers. Being thoughtful is the first step, said Daniel Hoornweg, a professor at the Ontario Tech University who has been studying waste for four decades. “When you buy something, think about where it came from and where it’s going,” he told me. “That’s half the battle.”

Moving the focus away from stuff

First, let’s look at some numbers.

The British waste 30 percent or more food during Christmas than at any other time of the year.[3]

In Canada, 540,000 metric tons of wrapping paper and gift bags are thrown out after Christmas each year.[4]

Holiday lights in the United States (as measured in 2008) consumed more electricity than El Salvador used in an entire year.[5]

There is room for improvement. We can be more mindful of the recycling and reusing potential of what we buy, plan on how we will use leftovers, and buy LED lights, which last longer and consume 90 percent less energy than incandescent bulbs.[6]

We can also move away from the need to buy so much stuff, by re-evaluating what we consider to be valuable. Typically, the richer people are, the more household waste they generate. Wealthy people rely more packaged foods, discard more cell phones and buy more toys that will soon break. The remedy may be giving a concert ticket instead of a gadget. (We have a guide for buying experiences rather than things from last year’s holiday season.)

A less wasteful lifestyle

There is no correlation between happiness and more stuff, as measured by waste generation, Hoornweg said. While happiness is hard to measure, we can compare countries by their human development index, which covers many dimensions of quality of life, like income, life expectancy and access to education.

Take Japan and Canada. Canadians produce about twice as much waste per person than the Japanese.

Japan is a lot more dense, people have smaller homes and don’t need cars to travel great distances as much, while in Canada people have bigger cars, bigger houses and eat more at fast-food restaurants that come with several layers of packaging. And yet, both countries have very similar human development numbers.

A lot of it comes down to culture.[7] My family is Brazilian, and we always serve multiple times the amount of food that is needed when we throw a party. My aunt’s husband, who is German, tries to serve roughly the amount that people will eat. When he cooks, the whole family collectively holds their breath in fear there won’t be enough food. But there always is.

Silpa Kaza, who studies waste at the World Bank, told me she once carried all her waste in her bag for a month to internalize how much she was producing. It made her more mindful. “I was so conscious of every decision I made,” she said. Today, she takes a collapsible container to a restaurant to bring leftovers home and no longer uses plastic produce bags in the supermarket. She told me cities and countries can take into account culture to induce better behaviour. For example, after South Korea implemented a collection system in the 1990s that charges people according to how much they throw away, total household waste generation fell by half.

We may need policies like that to change the trajectory of waste generation. Right now, it is expected to skyrocket from 2.24 billion tons in 2020 to 3.88 billion tons in 2050.[8] But a little mindfulness around the holidays is a good place to start.

Source

Manuela Andreoni, Dreaming of a less wasteful holiday, in: New York Times , 19-12-2023, https://www.nytimes.com/2023/12/19/climate/dreaming-of-a-less-wasteful-holiday.html?smid=nytcore-ios-share&referringSource=articleShare

[1] https://archive.epa.gov/students/web/html/holiday.html?campaign_id=54&emc=edit_clim_20231219&instance_id=110553&nl=climate-forward®i_id=141866830&segment_id=153010&te=1&user_id=866583fecd30716f23f05f6d735f1807

[2] https://zerowastecanada.cdn.prismic.io/zerowastecanada/b8e24cb2-634c-4c28-8fa7-5adaab50e12d_Zero-Waste-Christmas.pdf?campaign_id=54&emc=edit_clim_20231219&instance_id=110553&nl=climate-forward®i_id=141866830&segment_id=153010&te=1&user_id=866583fecd30716f23f05f6d735f1807

[3] https://www.nlwa.gov.uk/24-days-waste-free-christmas/day-1

[4] https://www.thestar.com/news/canada/canadians-will-throw-out-540-000-tonnes-of-wrapping-paper-and-gift-bags-this-christmas/article_21d40957-7387-5c1f-8a39-ccce898cfc80.html

[5] https://www.cgdev.org/blog/us-holiday-lights-use-more-electricity-el-salvador-does-year

[6] https://www1.eere.energy.gov/buildings/publications/pdfs/ssl/ssl_mypp2008_web.pdf

[7] https://www.who.int/europe/news/item/01-06-2022-can-culture-bring-new-meaning-to-waste

[8] https://openknowledge.worldbank.org/entities/publication/ba7feea4-0abe-59fb-bc60-ce6b60eb1ceb?campaign_id=54&emc=edit_clim_20231219&instance_id=110553&nl=climate-forward®i_id=141866830&segment_id=153010&te=1&user_id=866583fecd30716f23f05f6d735f1807

0 notes

Text

The world of toys in the midst of an ecological shift

In order to continue to please children and parents alike, the toy industry is redoubling its efforts to reduce its environmental impact over the entire lifespan of its products.

In the windows, life-size dolls and teddy bears collide amid the illuminations. Christmas is quickly approaching and the toy stores are always full. But this end-of-year holiday magic comes at a cost. According to Ademe[1], nearly 100,000 tonnes of games and toys are thrown in the trash each year. In February 2020, the Agec law[2], relating to the fight against waste and the circular economy, took the problem head on through the establishment of a toy sector. Since January 1, 2022, the sector has been encouraged to reduce these tons of waste through the collection of used toys, reuse and even repair.

Farmers, teachers, pirates or explorers: since the 1970s, these little plastic characters have been transmitted from generation to generation. “I can no longer count the number of grandparents who come to tell me they keep these toys for their grandchildren,” laughs Bruno Bérard, general director of Playmobil[3]. These figurines stay in people's hearts for a very long time. » For him, there is no doubt, this emotional dimension is the first criterion of an ecological toy that lasts over time.[4]

Reuse, a priority

But not all toys follow the same destiny as our Playmobils. According to Ecomaison[5], the organisation approved by the French Government to take charge of the collection, reuse and recycling of toys, “half of the toys ends up in household waste, around 45% is collected in public recycling centres and less than 5% is reused”. In 2023, the priority was to optimise the reuse of toys, via donation or resale. Five thousand collection points have been set up across the country from associations, recycling centres or stores themselves. The objective is now to triple reuse by 2027.

However, many brands did not wait for the Agec law to roll up their sleeves. “We weren't starting from scratch,” says Jean Kimpe, general delegate of the Federation of shops specialising in toys and children's products (FCJPE)[6]. Above all, the law made it possible to coordinate and develop pre-existing initiatives. » In 2011, Oxybul[7] launched IDTroc[8], collection points to collect used toys from customers. “The criteria of sustainability and responsibility have been part of our brand DNA from the beginning,” says Anne Fauveau, product director of Oxybul Eveil et Jeux. Our toys are as scalable as possible in order to last over time. » The brand assumes that it places itself outside fashion trends, preferring timeless designs and colour charts in order to offer durable toys.

In spring 2021, King Toy[9] followed the movement by launching its King Okaz brands. There are now around ten of them throughout France. Toys are returned in exchange for a voucher valid in all of the brand's stores. “We see that we are responding to a real demand,” assures Coralie Gueydon, CSR manager of the group. Unlike platforms like Vinted[10], we provide a guarantee of quality. Not only is the item guaranteed to be repurchased, but they are then cleaned, repaired and checked before being put back into circulation. »

But if the brands promise more qualitative and safer reuse than that allowed by second-hand platforms, the latter currently benefit from a certain notoriety. “We have just inserted ourselves into a behaviour where, originally, specialist brands did not necessarily have their place,” recognises Coralie Gueydon. At the moment, our stores operate largely through word of mouth. » The brand also offers a repair service whereas Playmobil currently offers 20,000 spare parts in order to make their products last longer.

The big challenge of recycling

Between solar panels and characters on bicycles, the ecological farm proposed by Playmobil does not hesitate to play with the codes of a more sustainable society. Above all, like the Wiltopia collection launched in 2022, the product is made with more than 80% recycled or biosourced materials. Most come from recycled refrigerators. “Three additional ranges will be des

igned in this way in 2024,” indicates Bruno Bérard, who recalls that the German group’s objective is to be climate neutral in 2027.

Generally speaking, toys made from recycled plastic materials are still struggling to find a place under the sun. Often less solid and dull, they remain difficult to reuse to make new toys. Lego quickly noticed this. “So far, we have tested more than 300 alternative materials for our famous brick,” explains Sylvain Bouchès, Lego France marketing director. Some have been successful, such as bio-PE, and we are proud to have been able to develop this first alternative. Other materials showed their potential, but did not meet our requirements for quality, safety and durability, or help reduce our carbon footprint. That's the whole difficulty. » Last September, the brand announced that it was abandoning the use of recycled PET because it would have resulted in greater carbon emissions over the lifespan of the product. [11]

“When we use recycled material, the range of colours that we can produce is not as rich as when we use raw material coming directly from petroleum products,” recognizes Bruno Bérard. There are technical challenges to resolve. We can't imagine tomorrow that a fire truck will be pastel red. » For a product to be recyclable, it must ideally be as simple and single-material as possible. However, toys are generally made of a multitude of materials in order to promote the sensory awakening of little ones.

All this research takes time. The majority of producers agree that the organisation of recycling sectors in France still has a lot of progress to make. “This is all the more complicated to implement as safety standards are very demanding regarding toys intended for children, particularly at the European level,” adds Coralie Gueydon.

So should we say goodbye to plastic? Not necessarily, tempers Anne Fauveau who regrets a lack of information on the subject. “Disposable plastic is not good,” she explains. But durable plastic that is passed down from generation to generation, which is ten times stronger than wood, is not necessarily bad for the environment. » Oxybul has thus adopted the habit of favoring wood only when it can replace the virtues of plastic. “There is no ideal solution,” says Anne Fauveau. For example, biosourced plastic is interesting because it does not use petroleum but it is sometimes manufactured in South America to the detriment of local populations. Ecodesign is undoubtedly what is most complicated today. »[12]

Design differently

While tests to recycle plastic are increasing, others are looking for alternative materials. In 2018, Lego launched the first elements made from sugar cane waste in our play boxes to make elements such as leaves, trees and accessories.

“If we started by making botanical elements from this plastic of plant origin, we have since expanded its use to more than 200 pieces, almost half of our products,” explains Sylvain Bouchès. The treehouse thus includes 180 plastic elements of plant origin. Today, more than 50% of the brand's products contain elements made from biosourced materials.

In terms of eco-design, Oxybul has been doing well for many years. Every month, all the brand's teams participate in a meeting on this issue. The brand multiplies alternatives through the use of FSC-certified wood (by the Forest Stewardship Council)[13], water-based paint and even recycled polyester. This year, she co-created with the Thai brand Plan Toys[14] a range of wooden toys suitable for children aged 12 months and over. “This is one of the first suppliers to have implemented self-managed forests,” explains Anne Fauveau. He works in particular with hevea wood, the rubber tree, which is a plant that grows back very quickly. This avoids deforestation problems. »

The brand also wanted to be a pioneer in terms of reducing its packaging. As early as 2017, the teams decided to readjust them to the size of the products. “At the time, this did not necessarily go in the direction of commerce,” recognises Anne Fauveau. Suppliers generally prefer to have large boxes in order to be clearly visible on the shelves. Initially, this even caused a drop in sales on certain products, which required us to contact the customer to explain our approach. » Now, 80% of the brand's packaging no longer has plastic, replaced by materials such as cardboard and paper. These are intended to be reused, serving as storage boxes for children's toys.

Since then, the idea has caught on. “Ecodesign doesn’t just involve products,” insists Sylvain Bouchès. Today, 93% of Lego packaging is made from cardboard or paper-based material. Single-use plastic bags are gradually being replaced by recyclable paper bags certified by the Forest Stewardship Council. Started in August, the global deployment of new boxes for the mystery minifigures should allow the group to save around 30 tonnes of single-use plastic per year.

And the work of designers and engineers is far from simple. “The paper must be able to withstand transport but also the manufacturing process in all our factories,” explains Sylvain Bouchès. However, this material is more sensitive than plastic to variations in humidity and temperature. The development of these alternative means of production and packaging involves an in-depth transformation of our processes. » Nearly 70 different papers and formats had to be tested. “This requires a lot of research and innovation,” confirms Anne Fauveau. It is important that we can share best practices between brands and be good competitors on this issue, because the solutions will tend to be found by the big players. »

More local… and transparent products

While nearly 90% of toys are imported, local products are back at the top of the bill. “Since the confinements of 2020, the place of manufacturing of toys has become a leading theme for customers,” observes Coralie Gueydon. There has been a very significant new attraction for Made in France. »

In the toy landscape, the Ecoiffier company[15] has been established in France since 1945. At Playmobil, almost all of the products are produced in Europe. “From the beginning of the company, it was a strategic approach, in order to control our manufacturing but also economic, to reduce costs,” explains Bruno Bérard. Recently, the seven Maltese production sites were grouped together in order to avoid travel between different areas. “This factory operates in daylight, which allows us to consume less electricity,” explains the general director. The heat released by the machines is recovered to provide heating when necessary, and the site has a water collector. » For the company, local production goes hand in hand with saving resources.

Faced with this demand for transparency and sustainability, King Toy recently launched the Toy Score in order to guide consumers in their choice. “Today, the toy market is not mature in terms of eco-responsibility,” explains Coralie Gueydon. But even if we are starting from very far away, it seemed important to us to promote the initiatives put in place in the sector. » Using the NutriScore[16] rating system, now well known to the general public, the Toy Score applies a rating system between 0 and 5. It is based on three criteria: the place of manufacture, the efforts made at the level of packaging and materials that make up the toy. Assisted by Ecomaison, the brand has chosen to promote products made from FSC wood and recycled materials.

Since October 26, the Toy Score has been in place in all King Toy stores as well as on their website. It was notably applied to all the toys in the Christmas catalogue. Out of 1,600 products, around 450 have a rating greater than or equal to 2 out of 5. Bioviva[17], known for its board games based on nature, thus obtains the maximum rating. The brand is closely followed by Smoby[18] which manufactures its toys in France from easily recyclable plastic. “By 2025, the objective is that 50% of our toys present real eco-design characteristics and that the criteria are raised,” indicates the CSR manager.

Because the Toy Score also aims to encourage the industry to redouble its efforts to provide more eco-responsible toys. “Many suppliers come to ask us how they can improve,” says Coralie Gueydon. Others allow us to rethink our criteria. The indicator is intended to be scalable thanks to both suppliers and customers. »

Raise consumer awareness

Will Christmas 2023 therefore be placed under the sign of eco-responsibility? Not necessarily, moderate the brands. “We don’t expect consumption habits to really change at Christmas,” admits Coralie Gueydon. It is generally children who choose toys from the catalog, and the eco-responsibility criterion is then not taken into account. »

For the holidays, buying second hand can also remain a hindrance even if brands observe that this reluctance tends to relax in society. “There remains a lot of education to be done, whether on the realities of Made in France or recycled products,” observes Anne Fauveau. And consumers are not necessarily ready to pay more for an eco-designed product. » While the period of inflation weighs on individual baskets, Oxybul has made the bet of not passing on the cost of its research on these sales prices.

“The Agec law has revolutionized many things at the industry level,” assures Coralie Gueydon. This made distributors and suppliers alike aware that we must now think beyond the life of the toy. » Lego is also preparing to triple its spending on sustainable development initiatives to reach $1.4 billion spread over four years until 2025. “Each year, we receive hundreds of letters from children who share their ideas on how we could progress, says Sylvain Bouchès. Having a positive impact on society and the planet, playing a role in building a sustainable future is a major challenge for the group. »

At the same time, Playmobil assures that it wants to pursue an approach of social responsibility. The company still belongs to a private foundation, created by its now deceased founder, which works for the development and protection of children. In addition to offering products that illustrate a more eco-responsible society, the brand also takes into account issues of representativeness and diversity. Equipped with a green roof, the school of the famous figurines is also designed to facilitate access for students with reduced mobility. “We are not lesson givers,” insists Bruno Bérard. But we can help raise children's awareness of important points for our future. And the best way to do that is through the toy. »

The Joyful Discount saves toys from the dumpster

It is one alternative among others to make the world of toys more sustainable. In August 2020, La Remission Enjouée[19] was born in Villeneuve-d'Ascq, in the North. Led by Christelle Cousin, a former specialist educator, the structure offers the collection, repair and then resale of toys in its shop. It currently employs 13 people in integration between 18 and 62 years old. “We work with people of foreign origin as well as with people at the end of their careers, the long-term unemployed or people who have been impacted by the Covid crisis,” says Christelle Cousin. In addition to participating in an ecological approach, employees gain skills and social contact.

The plus of La Remission Enjouée? “This is a real local service,” assures its director. There is an emotional side to toys. People don't want to put it in the trash and like to discuss the history of the object when they come to drop it off. » The structure, which currently depends a lot on subsidies to exist, hopes to develop in the coming years. Next step: online sales.

Source

Charlotte Meyer, Le monde du jouet en plein virage écologique, in : Les Echos, 18-12-2023

[1] The Agence de la transition écologique. (ADEME, Agency for ecological transition) is a public agency under the joint authority of the Ministry for an Ecological Transition and the Ministry for Higher Education, Research and Innovation. At ADEME - The French Agency for Ecological Transition’s role is to mobilise citizens, economic actors and territories towards a fairer, more harmonious, low carbon and resource-efficient society. At every level, their expertise and forecasting capacities serve to guide and inform public policies. https://www.ademe.fr/en/about-ademe

[2] The French law on the fight against waste and the circular economy (Agec) sets a collection rate target for recycling plastic beverage bottles of 77% in 2025 and 90% in 2029. Ambitious targets with regard to the rate collection, which is around 59%. This means that 41% of the 315,000 tonnes of plastic bottles consumed per year end up in the household waste bin (therefore incinerated or buried) or in wild dumps.. https://www.lesechos.fr/idees-debats/editos-analyses/economie-circulaire-la-solution-de-la-consigne-plastique-1946930

[3] Playmobil is a German line of toys produced by the Brandstätter Group (Geobra Brandstätter GmbH & Co KG), headquartered in Zirndorf, Germany. The signature Playmobil toy is a 7.5 cm (3.0 in) tall (1:24 scale) human figure with a smiling face. A wide range of accessories, buildings and vehicles, as well as many sorts of animals, are also part of the Playmobil line..

[4] Read also: https://www.tumblr.com/earaercircular/690821468349775872/coolrec-and-playmobil-turn-old-refrigerators-into?source=share

[5] Created in 2011 – then under the name Eco-mobilier – by 24 French furniture distributors and manufacturers, Ecomaison is now made up of 68 shareholders from the furniture, bedding, DIY, garden and toy sectors. and building. All these actions are made possible thanks to eco-participation, a contribution which applies when purchasing a new product. The amounts paid to Ecomaison finance all services and solutions for reuse, collection, transport, recycling and innovation. Our ambition: to achieve zero waste! https://ecomaison.com/

[6] A historic player in commerce, the fédération des commerces spécialistes des jouets et des produits de l’enfant (FCJPE) (federation of shops specializing in toys and children's products) brings together the stores preferred by young and old, whether independent, branch chains, franchise networks or cooperative groups. From the creation of quality toys to their availability in our stores, the toy sector brings together all the players who allow our children to find what they are looking for. This is why the FCJPE is engaged in constant dialogue with its partners, in order to always better serve our customers.

[7] Oxybul éveil et jeux, formerly Fnac Éveil et jeux (between 2004 and 2011), is a French distribution brand specializing in edutainment games and toys. Éveil et jeux was born in 2004 from the merger of the two subsidiaries of the “youth division” of Fnac: Éveil & jeux created in 1989 by Margaret Milan and Fnac Junior created in 1997. In September 2010, FNAC sold the company to Ïd group. The brand has been operated by the Okaidi company since July 2016.

[8] https://www.idtroc.com/

[9] Specialist in the distribution of games and toys for more than 30 years, King Jouet (King Toy) offers you more than 20,000 toy references. Building games, board games, dolls, stuffed animals, vehicles, circuits or radio-controlled toys, you will definitely find the toy that will please him. More than 240 stores in France, as well as in Switzerland, are waiting for you to find the gift of your dreams or receive it at home by placing an order on www.king-jouet.com. Subsidiaries: Maxi Toys, Poly S.L.U., Teddy Toys, Société Gueydon SAS, Maxitoys International SA. Umbrella organization: Giochi Preziosi https://www.king-jouet.com/fr-lu/

[10] Read also: https://www.tumblr.com/earaercircular/651509379878813696/second-hand-economy-much-bigger-than-expected?source=share

[11] Read also: https://www.tumblr.com/earaercircular/658880330018766848/the-obstacle-course-to-green-lego-blocks?source=share

[12] Read also: https://www.tumblr.com/earaercircular/722715633728569344/europe-is-putting-an-end-to-the-throwaway-culture?source=share

[13] The Forest Stewardship Council A. C. (FSC) is an international non-profit, multistakeholder organization established in 1993 that promotes responsible management of the world's forests via timber certification. It is an example of a market-based certification program used as a transnational environmental policy.

[14] Plan Toys is a toy brand that strives for sustainable playing fun. All the toys that Plan Toys makes are only made from strong, sustainable materials and are produced in an ecologically friendly way. Plan Toys' quality material ensures that children can enjoy the toys for years to come. So, contribute to a sustainable world in a playful way with Plan Toys! https://www.babycompany.be/merken/plan-toys

[15] Since October 2017, Écoiffier products have been labeled “Origine France Garantie”. It is a brand whose principle of obtaining is simple: you must meet two mandatory criteria:

– at least 50% of the unit cost price is French.

– the product takes on its essential characteristics in France

A locally based company, aware of environmental and social issues, Cadeaux Écoiffier offers a complete range of simple toys, without electronics, meeting the primary needs of children at low prices and in a short supply chain. https://ecoiffier.fr/ecoiffier-une-marque-francaise/

[16] The Nutri-Score, also known as the 5-Colour Nutrition label or 5-CNL, is a five-colour nutrition label and nutritional rating system, and an attempt to simplify the nutritional rating system demonstrating the overall nutritional value of food products. It assigns products a rating letter from A (best) to E (worst), with associated colors from green to red. This system was selected by the French government in March 2017 to be displayed on food products after it was compared against several labels proposed by industry or retailers

[17] https://www.bioviva.com/en/mission

[18] Smoby is the largest toy manufacturer in France based in Lavans-lès-Saint-Claude, in the Jura. Buying a toy on our e-store means buying a toy directly from the manufacturer. A solid, robust toy, like our slides or houses, resulting from quality know-how acquired over several decades and respecting European toy standards. https://www.smoby.com/smoby_fr/home/

[19] Christelle Cousin and Pauline Vandenbussche have created an integration workshop in Haute-Borne, where games and toys are cleaned, renovated or completed, to experience a second life. From four, the workforce will increase to twelve before the summer. The workshop has only been operating since January 18, but it’s already off to a strong start. https://www.lavoixdunord.fr/929774/article/2021-02-04/villeneuve-d-ascq-avec-la-remise-enjouee-des-jouets-pour-pas-cher-des-emplois Created in August 2020, the association La Stratégie enjouée collects second-hand toys, which it renovates and resells at low prices in its shop in Villeneuve d'Ascq. A good initiative especially during this period that the Region close to your daily life shares with you. https://www.hautsdefrance.fr/economie-circulaire-pour-les-jouets-aussi/

0 notes

Text

The European Council agrees on a common position on the new regulation that will affect all packaging in the EU

The regulations will prohibit certain types of packaging, force the use of materials to be minimized and promote reuse.

The new Packaging and Waste Regulation that will determine the scales that the packaging of all activities must comply with and that will affect companies, industries and homes has taken another step towards its final form this Monday[1]. After studying the Commission's proposal, the European Council, through a meeting of EU Environment Ministers, has agreed on a common position that must be debated in the European Parliament, where it will undergo final negotiation. The standard will prohibit certain types of single-use packaging, requires reducing the materials used and empty space, and sets mandatory recycling quotas for all types of packaging material.[2]

The agreed approach covers “the entire life cycle of packaging” and sets out requirements to ensure that “it is safe and sustainable,and it requires that all packaging is recyclable and that the presence of substances of concern is minimised,” the EU Council reported in a statement. The position defended by the Member States covers the management of packaging once it is waste, so that it is collected, sorted and recycled following “the highest standards”, with provisions that guarantee that countries have “sufficient flexibility to maintain existing systems that work well.”

“In 2021, each European generated 190 kilos of packaging waste. And this figure will grow by almost 20% in 2030 if things remain the same (...). This regulation is crucial on our path towards a circular economy and a climate-neutral Europe,” declared the Spanish head of Ecological Transition[3], Teresa Ribera, in a statement, representing the Spanish presidency of the Council of the EU.

In a section in which the Council explains how this regulation will affect citizens, its main effects are summarized[4]. The law includes objectives for reducing discarded packaging. Specifically, with respect to 2018 numbers, it is expected to reduce waste by 5% by 2030, 10% by 2035 and 15% by 2040. The objectives will be applied per capita for each State.

“Certain types of single-use packaging would be prohibited[5], such as items for direct consumption in restaurants and cafeterias, condiment sachets, (certain types of) disposable cups and plates, miniature single-use containers for toiletries hotels and single-use plastic containers for fresh fruits and vegetables,” details the Council.

Manufacturers would also need to minimize the amount of material needed for packaging, for example by avoiding double walls and false bottoms, as well as disproportionately large containers for transporting small items. For their part, consumers will be able to reuse, refill and return the containers.[6] “The proposal sets targets for various sectors and packaging formats to increase the possibility of reuse and refilling, whereby end consumers refill their own packaging, including for takeaway food items,” explains the Council.

Regarding recycling objectives, the proposal establishes that by 2025, 65% of all packaging should end up being recycled in general. The threshold amounts to 75% for paper and cardboard, 70% for glass, 50% for plastic and 25% for wood. By 2030, the goal is to recycle 70% of all packaging, 85% of paper and cardboard, 75% of glass, 55% of plastic and 30% of wood.

Many interests at stake

The objective is that the Member States and the European Parliament can agree before the elections to the European Parliament next June on the final modernisation of a file full of technical aspects that has aroused great interest from pressure groups (lobbies), since it affects to many sectors and companies, from fast food to the plastic, paper, wood or recycling sectors, and which was of particular concern to Italy and Finland.

The European Commission, whose original proposal[7] was more ambitious than the positions defended by the EU Council and Parliament, urged finding a “balance” to close a “complicated file,” said Environment Commissioner Virginijus Sinkevicius.

As the Commission explained in its proposal document, the consultation on the initial impact assessment generated 110 responses, and an open public consultation generated 425 responses. “Six stakeholder webinars were held in June 2021 to present and gather feedback on the interim results of the study. More than 950 people (from 250 organisations) participated in these online seminars and around 100 organizations presented documents with detailed responses and presentations,” they detail.

The Council maintains that the proposal covers all packaging, regardless of the material used, and all packaging waste, regardless of its origin (industry, manufacturing, retail or households). The text of the capitals' “general guidance” maintains “most of the sustainability requirements for all packaging placed on the market and the main objectives proposed by the Commission” and strengthens those for substances of “concern”.

The countries ask the Commission to prepare a report “before 2026” to determine if there are substances of concern in packaging that could “negatively affect the reuse or recycling of materials” or have “an impact on chemical safety.”[8]

Member States also agreed that packaging will be considered recyclable “when it is designed for the recycling of materials and when packaging waste can be collected, sorted and recycled on a large scale”, a condition that will apply from 2035.

Among the many sections of the standard, the Council defends, for example, that “tea bags and adhesive labels on fruits and vegetables must be compostable, introducing the option for Member States to require that other packaging” also be compostable, such as coffee capsules or light plastic bags.

Re-use

Countries adopted the Commission's approach to defining “reusable packaging, introducing a minimum number of uses or rotations in its use, with a lower minimum number of rotations for cardboard due to the different characteristics of this material.”

Targets are also proposed for 2030 and 2040, with different speeds for large household appliances, takeaway packaging for food and beverages[9], alcoholic and non-alcoholic beverages (excluding wine), transport packaging (excluding packaging used for dangerous goods or large-scale equipment). and flexible packaging in direct contact with food) and grouped packaging. Cardboard is exempt from these requirements, depending on the position of the countries.

The countries' approach also advocates that by 2029 the separate collection of “at least 90% per year of single-use plastic bottles and metal beverage containers” will be guaranteed, for which deposit return systems will be established[10]. The Twenty-seven also want to tighten the rules on packaging labelling.

Source

Fernando Belinchón, El Consejo Europeo pacta una posición común sobre la nueva regulación que afectará a todos los envases de la UE, in: El País, 18-12-2023, https://cincodias.elpais.com/economia/2023-12-18/el-consejo-europeo-pacta-una-posicion-comun-sobre-la-nueva-regulacion-que-afectara-a-todos-los-envases-de-la-ue.html

[1] https://www.consilium.europa.eu/en/press/press-releases/2023/12/18/packaging-and-packaging-waste-council-adopts-its-negotiating-position-on-new-rules-for-more-sustainable-packaging-in-the-eu/

[2] Read also: https://www.tumblr.com/earaercircular/735974199093559296/unsold-clothing-may-no-longer-be-destroyed-in?source=share & https://www.tumblr.com/earaercircular/734267111128612864/export-of-waste-restricted-eu-can-clean-up-its?source=share

[3] Ministerio para la Transición Ecológica y el Reto Demográfico https://www.miteco.gob.es/en.html

[4] https://www.consilium.europa.eu/en/policies/packaging/#consumers

[5] Read also: https://www.tumblr.com/earaercircular/702883268243128320/europe-introduces-stricter-rules-for-packaging?source=share & https://www.tumblr.com/earaercircular/665281005986414592/no-more-cucumber-in-plastic-france-bans-plastic?source=share

[6] Read also: https://www.tumblr.com/earaercircular/697379617546321920/environmentalists-demand-reusable-refillable?source=share

[7] https://eur-lex.europa.eu/resource.html?uri=cellar:de4f236d-7164-11ed-9887-01aa75ed71a1.0008.02/DOC_1&format=PDF

[8] Read also: https://www.tumblr.com/earaercircular/733593498002030592/with-an-import-of-28-billion-garments-per-year?source=share

[9] Read also: https://www.tumblr.com/earaercircular/733054984877441024/danish-restaurants-call-for-ambitions-for?source=share

[10] Read also: https://www.tumblr.com/earaercircular/734537294852259840/bocoloco-brings-the-deposit-up-to-date?source=share

0 notes

Text

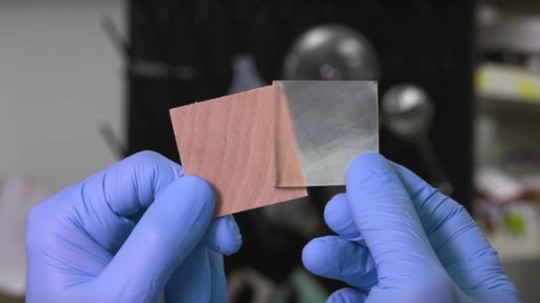

Transparent wood as a biobased alternative for your smartphone screen

Transparent wood can, for example, be used as a display for your smartphone.

When one talks about say transparent wood, one looks at about Siegfried Fink[1]. More than 30 years ago, this German scientist wanted to examine the structure of wood without damaging the material. He eventually succeeded in part by bleaching pigment in plant cells, a technique he later described in a scientific journal about wood.

New research

Years later, Fink's research was dusted off, including by Swedish scientists and researchers at the University of Maryland[2]. After years of experimenting, it now appears that scientists have achieved a breakthrough. This paves the way for the use of transparent wood in applications such as smartphone screens and lamps.

The technique

To understand how the technique works, it is important to zoom in on the structure of wood. Wood consists of a bundle of elongated vertical tubes that are connected to each other with a glue - lignin. Water and nutrients flow through the tubes. If there is a lack of water and nutrition, hollow tubes filled with air remain.

Hollow tubes

To make wood transparent, the brown lignin that binds these tubes together must be adjusted. The scientists from Maryland managed to remove the brown lignin and at the same time preserve the lignin with the properties of glue. The result is a milky framework of hollow tubes. This framework is not yet transparent because light only penetrates the hollow vertical tubes to a very limited extent.

The next step consists of filling the vertical tubes with a material that allows light to pass through better. This was achieved with an artificial resin. The combination of this resin and the modified lignin resulted in wood that transmits 85 percent of light.

Insulation

The scientists discovered that their new material allows sunlight to pass through without causing annoying glare. That is why the researchers think that the material could be very suitable as a lampshade for indoor lighting. The transparent wood also turned out to be a better insulator than glass. This also makes applications possible in buildings.

Biobased

For now, producing transparent wood is still a time-consuming and complicated process. Artificial resin is still used, which means the product is not completely biobased. In the next phase of the research, the scientists want to minimize the use of fossil raw materials and see whether the technology is scalable.

Source

Teun Schröder: Opmerkelijk: transparant hout als biobased alternatief voor je smartphonescherm, in: ChangeInc, 15-12-2023, https://www.change.inc/circulaire-economie/opmerkelijk-transparant-hout-als-biobased-alternatief-voor-je-smartphonescherm-40661

[1] Siegfried Fink (born 1956) is a German Forest ecologist with the main field of Forest botanic. Fink is professor forest-botanic at the Universität Freiburg im Breisgau, Germany. Finks ressarch group takes care of the Foerst-botanic-garden of Freiburg. He and his are working on methods of forest botanic research (mikroskopy and microbiology). The group is doing research on matrixes of wood-decomposing fungi at different kind of woods in vivo an in vitro and other questions concerning the relation of fungus and trees.

[2] https://www.annualreviews.org/doi/10.1146/annurev-matsci-010622-105440?_ga=2.99805918.1709063334.1702929543-1472931476.1658240840

0 notes

Text

Design for the bin: the city of Zurich has its new one

Recycling container partly developed in-house – you can see that. The bureaucratic design of the city of Zurich's future waste bin is an affront to public space and Swiss design culture.

It's not often that a waste bin writes design history. But the garbage shark made of matt shiny chrome steel has conquered the world from Zurich. The trash can is almost as well known as the peeler or the Landi chair. The bucket designed by Zemp + Partner Design[1] is available to over 4,500 customers from Kilchberg to Vienna to Barcelona.

The manufacturer still advertises with the silhouette of the Limmat[2] city in the background, where it all began in 2002. But the luxury bucket no longer meets Zurich's requirements, although it is also available as a multi-bucket called the “Sortershark”[3] and as the “Solar Pressshark,”[4] which compacts the waste using solar power.

As early as 2018, the city began replacing the waste shark with the “Züri-Kübel 110 liters”[5], which has a larger opening and a flat lid and is cheaper. Unlike its predecessor, its pragmatic design will not make it into the Museum of Design.

Now the requirements have increased again, which is why the Zurich disposal and recycling department ordered a new bucket and partly designed it themselves. As with the “Züri-Kübel”[6] before, there was no design competition. This is an impoverishment for Swiss design culture.

The new “recycling container” – as it is officially called – was developed so that the people of Zurich can dispose of waste more sustainably. There are separate slots for PET bottles, aluminum cans and waste. If necessary, a fourth type of waste can be added, such as glass. This helps the circular economy.

But the bucket's construction is conventional: a generic box made of metal with rounded corners. Environmentally friendly here means above all: little energy was wasted on good design. This energy would be used sustainably: attractive design lasts a long time because it stands the test of time and is popular.

Empirically based design

The bucket is inspired by the SBB multi-bucket, which shows its dirty contents to the outside with pictures. A trash can is there to make things disappear that you don't want to see. The city argues that the design is empirically based. She tested three labels: one with photos of the respective type of waste, one with illustrations and one with questions such as: “Is it really PET?” “The separation quality was best when labelling with photos,” writes the city in a media release.

This may be. But effective environmental protection should also appeal to us aesthetically, especially in public spaces. The eye separates with. The ecological balance is measured in numbers, the quality of design is not. Form follows function – and imagination. Good design can encourage us to do the right thing. But if we are repelled by the design of a trash can, let alone its contents, how is this supposed to increase the recycling rate?

Street furniture is part of the cultural heritage, it is part of the history and identity of a place. Successful everyday design triggers something in us, sometimes it is accompanied by a pinch of humour, for example in Berlin. The orange buckets in the German capital may be impractically small, but their bright colour, round shape and wit when throwing them in brighten up everyday life. There are sentences like: “Give it to me!” Or: “Play me the poop song.” The didactic bureaucratic design of the Zurich bucket, on the other hand, aims to instruct rather than delight, even when it comes to humor: “You hit like a world champion!” says a sign on the side.

In short: functionality reigns, design is neglected. This generally applies to civil engineering in Zurich, where the natural stone was removed from Bahnhofstrasse and Europaallee was asphalted instead of paved. The value of beauty seems outdated.

The economy likes numbers, sustainability likes efficiency, the state likes control. You can see where this reduction to functional aspects leads in Paris: out of fear of terrorist attacks, the buckets in the city were dismantled. Instead, a transparent plastic bag attached to a metal ring flutters in the wind.

New buckets in Basel and New York

Zurich is not alone with the waste design problem. In Basel, the population complains about the solar press bucket nicknamed the “waste monster,” which critics say is disfiguring the city. In the summer, the civil engineering department announced that it would remove 110 of the buckets from the cityscape. The majority of politicians came to the conclusion that the solar press buckets were unworthy of this city.

This year, New York has also been using a new bucket that replaces the iconic buckets made of green metal mesh. Functionality is also the top priority here. The base is made of concrete so that the bucket doesn't fall over. The container is closed to keep rats out. The paint is graffiti-resistant. But unlike Zurich, the design was preceded by a competition. In the New York Times, a passerby calls the bucket “beautiful, gorgeous, amazing.” That may be an American overstatement. The Zurich bucket is a Zwinglian understatement[7].

Source

Andres Herzog: Design für die Tonne: Die Stadt Zürich hat ihren neuen Recycling-Behälter teilweise selbst entwickelt – das sieht man ihm an, in: Neue Zürcher Zeitung, 07.12.2023, https://www.nzz.ch/zuerich/zuerich-recycling-behaelter-statt-abfallhai-ist-ein-affront-aufs-schweizer-design-ld.1769362

[1] https://www.stylepark.com/en/designer/zemp-partner

[2] The Limmat is a river in Switzerland. The river commences at the outfall of Lake Zurich, in the southern part of the city of Zurich. From Zurich it flows in a northwesterly direction, continuing a further 35 km it reaches the river Aare. The confluence is located north of the small town of Brugg and shortly after the mouth of the Reuss.

[3] https://www.archiexpo.com/prod/anta-swiss-ag-abfallhai-191002.html

[4] https://a2-solar.com/en/special-solar-panel-for-littersharks/

[5] Zurich is putting an end to world-famous trash shark Why the design bucket has had its day and the city is now relying on a long-serving design. https://www.tagesanzeiger.ch/zuerich-macht-schluss-mit-weltbekanntem-abfallhai-707140742748

[6] The new Züri Kübel ('bucket') which has been gradually installed since January 2021. https://www.core77.com/posts/116596/Behind-the-Design-of-Zurichs-New-Public-Trash-Can

[7] The theology of Ulrich Zwingli was based on an interpretation of the Bible, taking scripture as the inspired word of God and placing its authority higher than what he saw as human sources such as the ecumenical councils and the church fathers. He also recognised the human element within the inspiration, noting the differences in the canonical gospels.

0 notes

Text

Scientists have developed an enzyme that can break down plastic

In 2022 alone, the consumption of polycarbonate was estimated at 4.51 million tons worldwide. Here, plastic bottles make up a large part because they are often based on polycarbonate.

A group of researchers has developed an enzyme that can break down a certain type of plastic, which can then be recycled.

A research team at the Department of Materials and Production at Aalborg University[1] in Denmark has developed an enzyme that can break down plastic of the polycarbonate[2] type, so that it can be recycled and used to produce plastic again.

And according to associate professor from the Department of Materials and Production Evamaria Petersen, it is much more climate-friendly than using the chemical process that is used today. “With chemical decomposition, you use much more energy and a very high temperature of around 300 degrees, whereas you use around 70 degrees to break down plastic by using enzymes”, she says.

The reason for the high heat during the chemical process is that the structure of the plastic must change so that it becomes less hard. And therefore the code for a biological breakdown of plastic, according to Evamaria Petersen, is that the temperature is high and that the enzymes can cope despite the heat.