Text

Why Medical Industry Preferred Silicone Tubing?

Silicone tubing: A preferred choice in the medical industry. From its resistance to bacteria and ease of sterilization to its compatibility with various materials, medical-grade platinum-cured silicone tubing meets the highest quality standards. Ideal for sensitive applications, it plays a crucial role in managing diverse medical procedures and transportation needs. #MedicalInnovation #SiliconeTubing

#conductive silicone tubing manufacturer#high-temperature silicone rubber tubing#silicone rubber tubing#conductive silicone rubber tubing#conductive silicone tubing suppliers#rubber tubes suppliers#custom medical tubing

0 notes

Link

What is EPDM? EPDM is Ethylene Propylene Diene Monomer. It is an artificial rubber that is used in a variety of different applications. EPDM is most often utilized in the construction and automotive industries for seals of various kinds due to its outstanding resistance to environmental elements like UV, Ozone and weathering.

#antimicrobial silicone#closed cell silicone foam#closed cell silicone sponge#epdm rubber gasket#epdm rubber seals#extruded rubber tubing#extruded silicone gasket#extruded silicone rubber#high temperature silicone rubber sheet#high temperature sponge#open cell silicone foam#silicone extrusion#silicone foam#silicone foam sheet#silicone rubber extrusion#silicone rubber foam#silicone rubber manufacturer#silicone rubber sheet#silicone rubber sheet suppliers#silicone sheet#silicone sponge extrusion#silicone sponge gasket#silicone sponge rubber#silicone sponge rubber sheet#silicone sponge sheeting#silicone sponge tube#sponge silicone rubber

0 notes

Link

#door and window sealing#expert silicone rubber manufacturer#extruded rubber window and door seal#extruded rubber window gaskets#extruded rubber window seals#extruded rubber window seals and gaskets#home window seals and gaskets#house window rubber gasket#marine window gaskets and seals#metal detectable extruded rubber gaskets#metal detectable extruded rubber seals#nsf-51 extruded rubber seal and gaskets#rubber gasket#rubber gasket material#rubber seal strip#rubber seals#rubber strip seal#rubber weather stripping#rubber window seals and gaskets#rv window seals and gaskets#silicone rubber products#silicone rubber seal#window and door seals#window gasket material#window gasket suppliers#window glass rubber seal#window seals and gaskets#window weather stripping

0 notes

Link

#extruded rubber seals#extruded rubber strips#food grade rubber silicone tubing#food grade silicone gaskate#food grade silicone rubber cord#food grade silicone tubing#manufacturer of custom and stock tubing#medical grade platinum cured silicone#medical grade rubber tubing#plagtinum cured silicone tubing

0 notes

Link

#benefits platinum cured silicone tubing#medical grade platinum cured silicone#platinum cured silicone#platinum cured silicone chemical compatibility#platinum cured silicone gasket#platinum cured silicone hose#platinum cured silicone sheet#platinum cured silicone tubing#platinum cured silicone tubing manufacturer#platinum-cured silicone rubber

0 notes

Link

#automotive extruded rubber seals#custom extruded rubber seals#extruded foam rubber seals#extruded rubber door seals#extruded rubber edging#extruded rubber products manufacturers#extruded rubber seals#extruded rubber seals uk#extruded rubber strips#extruded rubber trim seals#extruded rubber tube#extruded rubber tubing#Extruded Rubber Window Seals#extrusion extruded rubber seals#extrusion rubber#rubber extrusion shapes#stock rubber extrusions

0 notes

Link

#conductive silicone rubber tubing#custom die cut gaskets#custom rubber o-rings#custom silicone o-ring#custom silicone rubber o-rings#die cutting rubber gaskets#food grade silicone tubing#metal detectable oring#rubber die-cut gasket

0 notes

Link

#conductive silicone rubber tubing#conductive silicone tubing manufacturer#conductive silicone tubing suppliers#extruded silicone rubber tubing#food grade rubber silicone tubing#high-temperature silicone rubber tubing#medical grade silicone rubber tubing#nsf-51 approved silicone rubber tubing#peristaltic pump rubber tubing#silicone tubing transparent#soft silicone rubber tubing#usp-vi silicone rubber tubing

0 notes

Link

There are various types available in the market for purchasing silicon rubber windows and door seals. Read this blog and know more about how Extruded Rubber is beneficial for windows and door seals.

For more details Kindly call us on +1-614-841-4400 or visit our website https://elastostar.com/ for more products details.

0 notes

Link

#conductive silicone rubber tubing#silicone rubber tubing#high-temperature silicone rubber tubing#medical grade silicone rubber tubing#food grade silicone rubber tubing#nsf-51 approved silicone rubber tubing#conductive silicone rubber tubing manufacturers#conductive silicone rubber tubing suppliers#extruded silicone rubber tubing#peristaltic pump rubber tubing#silicone tubing manufacturer#silicone tubing suppliers#silicone tubing transparent#soft silicone rubber tubing

0 notes

Text

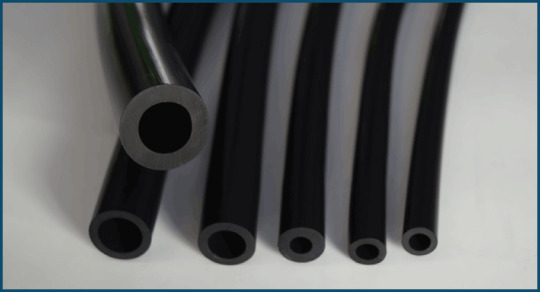

Benefit Of Electrically Conductive Silicone Rubber Tubing

Impressive biocompatibility, flexibility, wide temperature range stability and resistance to weathering are some of the key characteristics which make silicone rubber an ideal material for manufacturing rubber tubing. Although pure silicone is an electrical insulator, we can be your one-stop solution as one of the best conductive silicone tubing manufacturers and suppliers. With the help of some additives, the material can achieve some more attractive features like electrical conductivity, making it the best choice for many industrial applications.

How Pure Silicone is Made Electrically Conductive?

The electrically conductivity feature is enabled by adding carbon or other additives, to the raw material before the process of fabrication. The result is the super material that is used to manufacture Electrically Conductive Silicone Rubber Tubing. The material serves the purpose which is to prevent the build-up of static in Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) shielding. Moreover, it has many experimental and industrial applications. Extruded Silicone Rubber Tubing which is a result of the extrusion process gives highly pure and non-toxic material. This material is used in the manufacture of highly sophisticated components, especially for Medical purposes.

The soft silicone rubber tubing acts as insulators for high and low temperatures, with anti-aging and corrosion-resistant performance properties, to protect the bare wiring. It also prevents electrical outages.

Salient Features

This material has an impressive set of features

Conductive

High levels of flexibility and elasticity

Biocompatibility

Temperature Resistant (high-temperature silicone rubber tubing is ideal for chemical and food industries)

Chemical Resistant

USP Class VI Silicone Rubber Tubing

Transparency and Translucency (Transparent silicone tubing provide easy monitoring of the liquids)

Ultraviolet and Ozone Resistant

Food Grade and Medical Grade Material (NSF-51 Approved Silicone Rubber Tubing)

Read More:- https://elastostar.com/benefit-of-electrically-conductive-silicone-rubber-tubing-and-its-applications/

#conductive silicone tubing#conductive silicone tubing manufacturer#conductive silicone tubing suppliers#Custom Silicone Tubing#FDA Approved Silicone Rubber Tubing#high-temperature silicone rubber tubing#medical silicone rubber tubing#silicone rubber tubing#transparent silicone tubing

0 notes

Text

Explore The Versatile Silicone Rubber Cord

What is Silicone Rubber Cord?

Silicone Rubber Cord is a synthetic elastomer made by blending the elements, carbon, oxygen, hydrogen. It finds its applications across various industries owing to its unique physical properties.

Types of Silicone Rubber Cord

Depending upon the flexibility and durability required, the uncured silicone rubber is treated under different methods and temperatures.

Solid Silicone Rubber (HTV) – To obtain this high-vulcanising rubber the silicone rubber needs to be cured at very high temperatures. It finds its use in various industrial sectors like

Automotive and Aerospace

Mechanical and Plant Engineering

Electrical Engineering

Consumer Goods and Food industry

Transmission and Distribution Cables

Health Care and Medical Technology

Construction

Liquid Silicone Rubber (LSR) – It is also a high-vulcanising rubber, a two-part compound, in the liquid state which needs to be cured along with a catalyst. It has low viscosity and a quick cycle time. Its versatility allows it to be appropriate for the most sensitive of sectors for making the medical industry.

Room Temperature Vulcanizing – This silicone rubber cures at room temperature. It can be manufactured both in one part and two-part compound form. Like LSR, this RTV also needs a catalyst tin platinum or peroxide for curing. RTVs are usually used to make silicone molds and casts.

Read More: https://elastostar.com/explore-the-versatile-silicone-rubber-cord/

#food grade silicone rubber cord#metal detectable silicone rubber cord#nsf-51 approved silicone rubber cord#silicone rubber cord#ul approved silicone rubber cord#transparent silicone cord#solid silicone rubber cord#silicone rubber cord manufacturers

0 notes

Text

Advantages Of Platinum Cured Silicone Tubing

For pharmaceutical and biotechnology applications platinum-cured silicone tubing is an outstanding choice for fluid transfer. It offers high-temperature resistance and fewer potential leachables. Silicone provides superior biocompatibility and chemical inertness to maintain the purity of sensitive fluids. This tubing also has flat exteriors and reduces protein binding levels.

Elastostar tubing is manufactured to extremely close tolerances that ensure accurate, repeatable flow and long tubing life. It is factory-tested and optically inspected. This platinum-cured silicone tubing has slightly better clarity than peroxide-cured tubing. Tubing available in cut to length. Available Wall Thickness range of tubing 0.010 inches to 0.750 inches. The smallest size we can extrude tubing from 0.020 inch ID x 0.050 inch OD.

Elastostar Rubber Corporation’s manufacture of Platinum Cured silicone Standard and custom size tubing complies with FDA CFR 177.2600 requirements for high-purity Silicone rubber tubing intended for repeated use. This part of the U.S. Code of Federal Regulations (CFR) is reserved for rules established by the Food and Drug Administration (FDA). Section 177.2600 lists allowable materials such as elastomers and additives and sets the extraction limits.

Platinum cured silicones also comply with USP Class VI requirements for the biocompatibility of materials. used in medical devices and equipment. As part of the U.S. Pharmacopeial Convention (USP), USP Class VI is regarded as one of the most stringent requirements in medical device manufacturing. Platinum Cured silicones also comply with the European Union’s Restriction of Hazardous Substances (RoHS) Directive 2002/95/E.

Read More: - https://elastostar.com/advantages-of-platinum-cured-silicone-tubing-elastostar-corp/

#benefits Platinum cured silicone tubing#conductive silicone tubing#conductive silicone tubing california#conductive silicone tubing manufacturer#conductive silicone tubing suppliers#Platinum cured silicone hose#Platinum cured silicone tubing#Platinum cured silicone tubing manufacturer#Platinum cured silicone tubing suppliers#use of Platinum cured silicone tubing

0 notes

Text

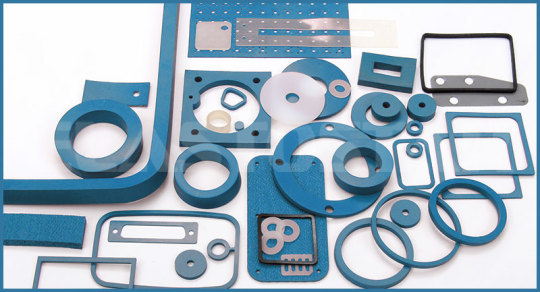

What Is A Die Cutting Gasket? Applications Of Die Cut Gasket

What Is A Die Cutting Gasket?

As the term ‘gasket’ suggests, a die cutting gasket is meant for industrial purposes.

Let’s focus on the definition of die-cutting gaskets and know what it is.

Die cutting gasket basically plays the role of a seal in between two surfaces that are different from each other. When the bolt load is just enough, it creates a compressive force. Compressive force is the force that occurs when another physical force pushes an object inward so much that it results in the object to be compressed or compacted. This compression can last temporarily or permanently, depending on the type of material the force is being exerted on. There may be different results due to the amount and type of force exerted and the direction towards which the force is exerted.

This is where a die cutting gasket comes in use. The die cutting gasket seals the gap left between the two different surfaces. This gasket also possesses the characteristic of filling up the imperfections or flaws in the mating surfaces. This stands to act as an advantage since it helps in solving or erasing existing and potential defects and application errors.

As already mentioned, these die cutting gaskets are meant for industrial purposes. Few of them are listed down below:

Plumbing

Medical instruments

OEM (Original Equipment Manufacturers)

Commercial purposes and applications

Aerospace industry

Automotive

Agricultural purposes including irrigation

Electrical purposes involving lighting, electronics, etc

Controls and other gadgets like valves, bearings and pumps

Now, since we have already discussed briefly the definition and applications of die cutting gasket, let us talk about the characteristics of die cutting gaskets.

Read More: - https://elastostar.com/a-complete-guide-on-die-cutting-gasket/

#Die Cut Gasket#die cutting gaskets california#die cutting gaskets manufacturer#die cutting rubber gaskets#die cutting rubber gaskets suppliers

0 notes

Link

#electrically conductive silicone tubing#conductive silicone tubing manufacturer#conductive silicone tubing suppliers#custom silicone tubing#fda approved silicone rubber tubing#high-temperature silicone rubber tubing#medical silicone rubber tubing#silicone rubber tubing#transparent silicone tubing

0 notes

Link

#food grade silicone rubber cord#metal detectable silicone rubber cord#nsf-51 approved silicone rubber cord#silicone die cut gasket#silicone rubber cord#silicone rubber cord manufacturers#solid silicone rubber cord#transparent silicone cord#ul approved silicone rubber cord

0 notes

Text

CUSTOM DIE CUT GASKETS BEST SOLUTION FOR RANGE OF APPLICATIONS

In this blog today we will talk about Die cut Gaskets that is reliable for various applications, customizable and most important its cost effective. As a manufacturing method, die cutting associations confirmed technologies with effective methods to gasket creation.

Custom Die Cut Gaskets

We at Elastostar Rubber Corp die-cut gaskets offer more time as well as a best price solution for small to large production runs. The benefits of die-cutting lie within the ease of the development. Most methods require only two core mechanisms a metal tool or die as it is also known and the cutting machine itself. This importance in consistent acceptances with a slight margin of mistake. It is worth noting, but, that for more compound gaskets we would normally suggest using CNC Machine Cutting.

Elastostar Rubber Corp die cuts silicone rubber materials made by expanded silicone products. Our all silicone rubber are high quality products for custom die cutting. We are a leading manufacturer of solid and cellular silicone sheets. We offer best quality silicone rubber gaskets, sheet, seal with different durometers and width.

We strongly believe in providing quality work thus we will directly work with you in order produce a cutting die that match your application needs. We having vast experience to provide you reliable advice on the best cutting result. Our specially designed steel dies are able to offer tight tolerance through a broad range of sizes.

Another good thing is that we can reuse the die for any future production runs. And it will ultimately save your time and money in long run.

KEY Benefits

Best Quality material

Wide functioning temperature range

Good weathering, UV & Ozone resistance

Outstanding sealing abilities

Good toughness& elasticity properties

Preserves elasticity in low temperatures

Food excellence& other grades available

Wide selection of hardness’s

Material Grades at Elastostar

Our silicone rubber tubing gaskets are obtainable in a varied range of material grades and shore hardness’s to suit even the most precise applications. It is permanently important to select the right material and grade to suit your application and working location. This will not only safeguard that the gasket is able to function correctly, but may also help to upsurge the service life of the gasket. We have comprised a list below of our most general silicone gasket scores.

About Elastostar Rubber Corp

Elastostar Rubber Corporation fabricates custom extruded rubber profiles and products in all shapes, sizes and lengths from a wide range of rubber compounds. Our holistic capabilities and services include design, engineering, custom die making and manufacturing of elastomer products that allow us to manufacture products that match with your existing samples or products either from design or through prototype based reverse engineering and template duplication.

0 notes