#extruded rubber seals uk

Text

Thermoplastic Polyester Elastomer Market – Forecast (2021-2026)

Thermoplastic Polyester Elastomer Market size is forecast to reach US$1.22 billion by 2026, after growing at a CAGR of 3.8% during 2021-2026. Thermoplastic Polyester Elastomers, (TPE-E) combines the properties of high-performance elastomers and flexible polymers. These high-strength materials, also known as thermoplastic rubbers, are known for their ability to withstand multiple flex cycles and their resistance to a variety of solvents and lubricants. TPE-Es have a strong impact strength even at low temperatures and can withstand temperatures up to 300°F. PET resin is one of the most frequently used thermoplastics, especially in the packaging industry. In outdoor conditions, thermoplastic elastomers (TPE) and ethylene propylene diene monomer (EPDM) rubber both provide sealing and insulation. They can be molded into specific shapes or produced from sponge or solid material sheets and extrusions. Polyester (polyethylene terephthalate (PET)) is the most common fiber used in automobile textile production. The growing use of TPE-Es in suspension bushings for automotive performance applications because of its greater resistance to deformation when compared to regular rubber bushings is expected to drive the market in the forecast period.

COVID-19 Impact

Currently, due to the COVID-19 pandemic, the Plastic and the rubber industry were affected in multiple ways. There was a supply disruption of raw materials. A delay in farming activities and latex collection further exacerbated the problem. Critical inputs like plastic, carbon black, and rubber compounds were in short supply due to global economic turmoil and import restrictions. For a sector dominated by MSMEs that do not often have solid business continuity planning, the delay in farming activities also resulted in liquidity and working capital concerns. They rely on consistent cash flows to cover their working capital needs and pay their employees. The industry's prospects were further harmed by worldwide market volatility. During the pandemic, however, the market is steadily rebounding due to the growth of TPE (Thermo Plastic Elastomer) in the medical, as well as food and beverage packaging industries.

Thermoplastic Polyester Elastomer Market Report Coverage

The report: “Thermoplastic Polyester Elastomer– Forecast (2021-2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the Thermoplastic Polyester Elastomer market.

By Application: Rubber seals, Belting, Tubing, Bushing and Gears, Conveyer, Geophysical, Industrial, Material Handling, Wire and Cable, Others.

By End-Use Industry: Aerospace, Automotive (Passenger Vehicles (PV), Light Commercial Vehicles (LCV), Heavy Commercial Vehicles (HCV)),Electrical and Electronics (Medical Devices, Smart Phones, Computer Electronics, Home Appliances, and Others), Marine,Sports and Leisure, Energy (Wind Energy, Solar Energy, and Others), and Others

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa)

Key Takeaways

The Thermoplastic Polyester Elastomer (TPE-E) market in Asia-Pacific is dominated by the region's rising use in a variety of applications in the automotive, medical, construction, and other industrial markets.

The varieties of TPE-Es and their modification options provide the foundation for a wide range of material qualities, allowing for cost-effective processing in a wide range of industries.

TPE-E is easy to mold or extrude onto rigid thermoplastic materials, making it ideal for product soft-touch grips. TPE-Es can also be used to make bottle cap liners and seal rings. It's also good for vehicle parts, wire and cable insulation, HVAC systems, and home appliances.

The biggest opportunity for this market in practically every key industry is increasing need for TPE-Es in densely populated nations like China and India, where demand is growing every day.

Request Sample

Thermoplastic Polyester Elastomer Market Segment Analysis – By Application

Belting segment held the largest share in Thermoplastic Polyester Elastomers Market in 2020 and is growing at a CAGR 4.5% during 2021-2026. Drive Belts, Conveyor Belts, Weighing Belts, Process Belts, Vacuum Belts, Vacuum Timing Belts, Thermo Belts, Food Processing Belts, ATM-Bill Ejector Belts, and Credit Card Transfer Belts are all made with Hytrel, a thermoplastic polyester elastomer with great durability and flexibility. A metal and x-ray detecting conveyor belt is being developed using DuPont Hytrel TPC-ET thermoplastic elastomer. DuPont Performance Materials teamed up with Esbelt, a conveyor belt manufacturer, to develop a unique, effective polymer that allows for food contamination detection. The new conveyor belt improves food makers' capacity to demonstrate due diligence by controlling the quality of the product on the belt using metal and x-ray detection. Based on the special properties of TPO and TPEE coatings, Habasit P line belts were designed specifically for the tobacco industry. Belt surfaces are critical in tobacco processing because they must serve a variety of functions while enduring harsh environmental conditions such as humidity, sand or dirt, and mechanical impacts. As a result, the increased use of TPEEs across a variety of core sectors is expected to boost the market in the next years.

Thermoplastic Polyester Elastomer Market Segment Analysis – By End-Use Industry

Automotive segment held the largest share in the Thermoplastic Polyester Elastomer market in 2020 and is growing at a CAGR of 6.2% during 2021-2026. Polyester (polyethylene terephthalate (PET)) is the most common fibre used in automobile textile production. According to the SVOA Materials Science & Technology Journal, global TPEEs manufacturing capacity surpassed 150,000 tons per year in 2019, while market demand surpassed 120,000 tons. TPE-E (thermoplastic polyester elastomer) is a thermoplastic polyester elastomer (TPE-E) that is utilized in fabric designs for car seating. Arnitel's TPEEs resin has been utilized on numerous Ford vehicles, including the Mondeo, S-Max, Galaxy, and Focus, and Arnitel's TPEEs have recently been selected as the vacuum brake tube material for Fiesta cars. Thus the growing use of TPEEs in Automotive is evidently going to flourish the market in the forecast period.

Thermoplastic Polyester Elastomer Market Segment Analysis – By Geography

Asia-Pacific region held the largest share in the Thermoplastic Polyester Elastomer Market in 2020 up to 43%, owing to the accelerating automotive industries in the region. According to the International Organization of Motor Vehicle Manufacturers, China produced 25.2 million automobiles in 2020, while India produced 3.9 million, with 25.7 million and 3.8 million automobiles sold in China and India, respectively. China remains the world's largest vehicle market, with the Chinese government projecting that car production will hit 30 million units by 2020 and 35 million by 2025. In 2018, nearly 27 million automobiles were sold in China, according to the China Association of Automobile Manufacturers. The Made in China 2025 program, which aims to transition the country's industry from low-cost mass production to higher-value-added advanced manufacturing, includes automobiles, including new Energy Vehicles (NEVs). The government's target for NEVs is to create 1 million electric and plug-in hybrid cars in China by 2020, with local production accounting for at least 70% of the market. Chinaese government is making a huge investment in the automotive industry which can lead to Thermoplastic Polyester Elastomer Market growth in the forecast period.

Inquiry Before Buying

Thermoplastic Polyester Elastomer Market Drivers

Increasing Automotive Production

Thermoplastic Polyester Elastomers are increasingly being used to replace their equivalents in the production of the inside and exterior of automobiles due to their specific strength and modulus. Thermoplastic Polyester Elastomers are becoming more popular in the vehicle industry due to their superior strength-to-weight ratio and are used in a range of applications in the industry, including automotive hoses, seats, gears, and brake systems, among others. China is the world's largest automobile market, with the Chinese government projecting that car production will reach 30 million units in 2020 and 35 million by 2025. As a result, increased automation will necessitate more automotive components, which will drive the Thermoplastic Polyester Elastomers market during the forecast period.

Use of Thermoplastics in Commodity Sector

Commodity The term thermoplastic refers to the least priced thermoplastics, such as polypropylene and certain grades of polyethylenes, that account for the majority of total plastic production. Elastomeric polymers have a high degree of elasticity, which makes them less prone to breaking or cracking. In fact, depending on the substance, elastomers can reversibly extend up to 700 percent. Wires and cables, photographic and magnetic tape, apparel, reusable bags, medical trays, and seeding trays are all examples of commodity products that can benefit from the high tensile strength and tear resistance of elastomers. period. As a result of the diverse uses of commodities in everyday life, the plastics market is predicted to grow, which would favorably impact the Thermoplastic Polyester Elastomers market over the forecast period.

Thermoplastic Polyester Elastomer Market Challenges

Higher Price of raw materials:

Extrusion and injection molding are the two most common TPE manufacturing processes. Injection molding allows for incredibly quick and cost-effective fabrication. The TPE-raw E's material costs are substantially greater. The reason for this is its high production cost; while producing TPE-E, the apparatus and equipments used are more expensive, and they also demand a lot of maintenance. As a result of this feature, the product has a greater price than its alternative materials, which tends to limit the market's growth.

Buy Now

Thermoplastic Polyester Elastomer Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Thermoplastic Polyester Elastomer Market. Thermoplastic Polyester Elastomer Market top companies include:

1) A. Schulman, Inc.

2) BASF SE

3) Celanese Corporation

4) Chang Chun Group

5) Covestro AG

6) DuPont

7) Entec Polymers

8) LG Chem

9) Mitsui Chemicals Inc

10) PolyOne Corporation and others.

Relevant Reports

Thermoplastic Elastomers Market

Report Code: CMR 0098

Thermoplastic Elastomer (TPE) Gaskets Market

Report Code: CMR 1056

For more Chemicals and Materials Market reports, please click here

#Thermoplastic Polyester Elastomer Market#Thermoplastic Polyester Elastomer Market Size#Thermoplastic Polyester Elastomer Market Share

0 notes

Link

#automotive extruded rubber seals#custom extruded rubber seals#extruded foam rubber seals#extruded rubber door seals#extruded rubber edging#extruded rubber products manufacturers#extruded rubber seals#extruded rubber seals uk#extruded rubber strips#extruded rubber trim seals#extruded rubber tube#extruded rubber tubing#Extruded Rubber Window Seals#extrusion extruded rubber seals#extrusion rubber#rubber extrusion shapes#stock rubber extrusions

0 notes

Text

Fluoroelastomers Market Analysis Outlook, Opportunities and Forecast Report 2021-2027

Introduction of Fluoroelastomers Market :

The Global Fluoroelastomers Market size is expected to reach US$ 1.98 Bn. by 2026 from US$ 1.57Bn. in 2019, at a CAGR of 3.4% during the forecast period.

Maximize Market Research report is a user-based library of a Fluoroelastomers Market report database, delivers comprehensive reports with a detailed analysis of changing market trends, key segments, top investment organisations, value chain, regional landscape, and competitive scenario.

Each and every insights presented in the reports published by expert group of Maximize Market Research, which is derived from primary interviews with top officials from leading companies of the domain concerned. Report’s secondary data research methodology includes deep online and offline research and discussion with expert professionals and analysts in the industry. In report, Fluoroelastomers Market reports, industry trends have been explained on the macro level, which is expected to help to finding outline market landscape and probable future issues.

Request for free sample:

https://www.maximizemarketresearch.com/request-sample/316

COVID-19 Impact on Fluoroelastomers Market :

The report has identified detailed impact of COVID-19 on Fluoroelastomers Market in regions such as North America, Asia Pacific, Middle-East, Europe, and South America. The report provides Comprehensive analysis on alternatives, difficult conditions, and difficult scenarios of Fluoroelastomers Market during this crisis. The report briefly elaborates the advantages as well as the difficulties in terms of finance and market growth attained during the COVID-19. In addition, report offers a set of concepts, which is expected to aid readers in deciding and planning a strategy for their business.

Ask your queries regarding the report:

https://www.maximizemarketresearch.com/market-report/fluoroelastomer-market/316/

Fluoroelastomers Market Segmentation:

Fluoroelastomers Market size is studied using various approaches and analyses in this research report to provide reliable and in-depth information about the industry. It is segmented into numerous segments to cover various aspects of the market for a better understanding.

Fluoroelastomers Market Regional Insights:

Asia-Pacific (Vietnam, China, Malaysia, Japan, Philippines, Korea, Thailand, India, Indonesia, and Australia)

Europe (Turkey, Germany, Russia UK, Italy, France, etc.)

North America (the United States, Mexico, and Canada.)

South America (Brazil etc.)

The Middle East and Africa (GCC Countries and Egypt.)

Key players:

The research report includes the current Fluoroelastomers Market size of the market and its growth rates based on 5-year statistics and records with company summary of Key players:

• The Chemours Company

• Solvay SA

• 3M

• Asahi Glass Company

• Daikin Industries

• DuPont

• Honeywell International Inc.

• Garlock

• Lauren manufacturing

• Vanguard Products Corp.

• Precision Associates

• Accutrex Products

• Standard Rubber Products Co.

• Stockwell Elastomerics, Inc.

• Minor Rubber Co., Inc.

• Northwest Rubber Extruders, Inc.

• Ames Rubber Manufacturing Company

• All Seals, Inc.

• I. G. Marston Co., Inc.

• Hennig Gasket & Seals, Inc.

• Chambers Gasket & Manufacturing Co.

• IGS Industries

• Mikron Rubber

• Tompkins Industries, Inc.

• Gujarat Fluorochemicals Limited

Prime Reasons to purchase a Fluoroelastomers Market research report:

The goal of this research report is to help consumers to gain a more information and clearer understanding of the industry. The Fluoroelastomers Market growth analysis includes development trends, competitive landscape analysis, investment plan, business strategy, opportunity, and key regions development status for international markets.

The Fluoroelastomers Market overview and the analysis of several affecting elements such as drivers, restraints, and opportunities.

Porter's Five Force Analysis and SWOT analysis are used to define, characterise, and analyse the market competition landscape, with a focus on key players.

Extensive analysis into the global Temperature Sensor competitive landscape

Identification and analysis of micro and macro elements that influence and will influence market growth.

A comprehensive list of major market players in the global Temperature Sensor industry.

In the Fluoroelastomers Market , it provides a descriptive study of demand-supply chaining.

Statistical study of certain key economic statistics

Figures, charts, graphs, and illustrations are used to clearly describe the market.

About Us:

Maximize Market Research provides syndicate as well as custom made business and market research on 12,000+ high growth emerging technologies & opportunities in Chemical, Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defense and other manufacturing sectors.

0 notes

Text

Global Gold Potassium Cyanide Market Research Report Market - Global Trends, Growth, Opportunities, and Forecast 2021-2026

The Global Gold Potassium Cyanide Market 2021-2026 report is planned through some remarkably characterized essential just as optional research strategies to speak to the business situated information all the more precisely. The research report provides a complete assessment of the competitive atmosphere, including firm profiling of driving players encouraging in the Gold Potassium Cyanide industry. By referring to this study report, the record clarifies assessed revenue and sales volume development, Gold Potassium Cyanide market share evaluations, and CAGR. The report on the Gold Potassium Cyanide research offers efficiently produced statistics observing a comparison of the essential gauges over the whole forecast session. The report on the Gold Potassium Cyanide Market highlights nitty gritty bits of knowledge and profound research. The report presents the significant factors which drive the development of the Gold Potassium Cyanide market, undiscovered opportunities for the makers, current patterns, and advancements molding the Gold Potassium Cyanide market and different factors across different key segments.

The worldwide Gold Potassium Cyanide market report gives definitions, characterizations, Gold Potassium Cyanide industry inclusion. The Gold Potassium Cyanide market is separated into item types, regions, applications, and key players. This partition is recommended to offer the peruser a short understanding of the Gold Potassium Cyanide industry and the crucial components that support the Gold Potassium Cyanide industry. This permits you to more describe the threats, drivers, openings, and limitations. The report offers a quantitative analysis of the world Gold Potassium Cyanide market regarding a progression of components, for example, profound estimations, present industry patterns, Gold Potassium Cyanide market share, and key elements of the Gold Potassium Cyanide market size from 2021-2026 so as to perceive the main Gold Potassium Cyanide market opportunities.

Get Free Sample PDF (including Complete TOC, Tables and Statistics) of Gold Potassium Cyanide Market @ https://www.futuristicreports.com/request-sample/103895

The Gold Potassium Cyanide Report Assesses the Spectral Range of Business perpendicular. The Major Players Covered in this Report:

(Prominex Precious Mineral ResourcesSreenivasa IndustriesBarrick Gold CorporationBangalore Refinery Private LimitedKinross Gold CorporationItalpreziosiGFS Chemicals)

All the players running in the global Gold Potassium Cyanide market are expounded completely in the Gold Potassium Cyanide market report based on restrictive advancements, circulation channels, industrial penetration, manufacturing procedures, and revenue.

By Type, the Segment is Split as:

By Product Type

Cables

Molded and Extruded Product Types

Rubber Compounds

Gloves

Hoses

Belts

Seals and O-rings

Adhesives and Sealants

Foamed Product Types

Others

By the End-Users/Application, Sub-Segments are:

Medical Anticorrosion

Gold Plating

The study report assesses the point by point profiling of appropriation channels, items just as administrations close by the financial exhibition of key producers working the world Gold Potassium Cyanide industry. To expand serious threats and break down different segments of the global Gold Potassium Cyanide industry, our experts have utilized resourceful methodologies like PESTLE and SWOT analysis. It gives strategic methodologies, assessment of merger, relationship, just as procurement targets and contender points of view for execution checking.

Regional Analysis for COVID-19 Impact on Gold Potassium Cyanide Market:

North America (The United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Spain etc.)

Asia-Pacific (China, Japan, Korea, India, Australia and Southeast Asia etc.)

South America (Brazil, Argentina, Colombia and Chile etc.)

Middle East & Africa (South Africa, Egypt, Nigeria and Saudi Arabia etc.)

Grab Exclusive Discpunt on the Report: https://www.futuristicreports.com/check-discount/103895

What the report offers:

=> Market share appraisals for the regional and country-level segments

=> Key suggestions for the new participants

=> Market Trends (Drivers, Constraints, Opportunities, Threats, Challenges, Investment Opportunities, and proposals)

=> Vital analysis: Drivers and Constraints, Product/Technology Analysis, PESTLE analysis, SWOT analysis, and so on.

=> Key proposals in key business segments dependent available estimations

=> Competitive landscaping mapping the key regular patterns

=> Organization profiling with nitty-gritty techniques, financials, and late turns of events

=> Supply chain patterns mapping the most recent technological progressions

Global Gold Potassium Cyanide Industry Market Research Report

1 Gold Potassium Cyanide Introduction and Market Overview

1.1 Objectives of the Study

1.2 Definition of Gold Potassium Cyanide

1.3 Gold Potassium Cyanide Market Scope and Market Size Estimation

1.4 Market Segmentation

1.5 Market Dynamics

1.6 Industry News and Policies by Regions

2 Industry Chain Analysis

2.1 Upstream Raw Material Suppliers of Gold Potassium Cyanide Analysis

2.2 Major Players of Gold Potassium Cyanide

2.3 Gold Potassium Cyanide Manufacturing Cost Structure Analysis

2.4 Market Channel Analysis of Gold Potassium Cyanide

2.5 Major Downstream Buyers of Gold Potassium Cyanide Analysis

3 Global Gold Potassium Cyanide Market, by Type

3.1 Global Gold Potassium Cyanide Value ($)

and Market Share by Type (2015-2021)

3.2 Global Gold Potassium Cyanide Production and Market Share by Type (2015-2021)

3.3 Global Gold Potassium Cyanide Value ($)

and Growth Rate by Type (2015-2021)

3.4 Global Gold Potassium Cyanide Price Analysis by Type (2015-2021)

4 Gold Potassium Cyanide Market, by Application

4.1 Global Gold Potassium Cyanide Consumption and Market Share by Application (2015-2021)

4.2 Downstream Buyers by Application

4.3 Global Gold Potassium Cyanide Consumption and Growth Rate by Application (2015-2021)

5 Global Gold Potassium Cyanide Production, Value ($)

by Region (2015-2021)

5.1 Global Gold Potassium Cyanide Value ($)

and Market Share by Region (2015-2021)

5.2 Global Gold Potassium Cyanide Production and Market Share by Region (2015-2021)

5.3 Global Gold Potassium Cyanide Production, Value ($)

, Price and Gross Margin (2015-2021)

5.4 North America Gold Potassium Cyanide Production, Value ($)

, Price and Gross Margin (2015-2021)

Set Inquiry for Before Buying or Customization of Report at: https://www.futuristicreports.com/send-an-enquiry/103895

Contact:

Futuristic Reports

Tel: +1-408-520-9037

Email: [email protected]

Media Release: https://www.futuristicreports.com/press-releases

Follow us on Blogger @ https://futuristicreports.blogspot.com/

0 notes

Text

Outlook On The Nitrile Butadiene Rubber Market SWOT Analysis by Segmentation from 2020-2027

This report on Nitrile Butadiene Rubber market, published by ASA market research , is an in-depth analysis that studies crucial aspects of the market, which can assist clients to form right decision about their business investment plans and methods. The market report entails an in depth information regarding the key segments and sub-segmentations including the merchandise types, applications, and regions by examining the emerging market size, performance, and scope of every segment of the Nitrile Butadiene Rubber.

Book Your Sample Copy of the Report here: https://www.asamarketresearch.com/request-sample/998458

Nitrile Butadiene Rubber Market landscape and market scenario include:

Current market size estimate

Revenues by players – Top 5 Companies

Market size by product categories

Market size by regions/country

The Nitrile Butadiene Rubber industry development trends and market channels are analyzed.

Global Prominent key Vendors:

East West Copolymer

Lanxess AG

Industrias Negromex

Zeon Chemicals LP

Kumho Petrochemical Co., Ltd.

Omnova Solutions

Synthos S.A.

Nitriflex S.A. Indústria e Comércio

PetroChina Company Limited

Sibur Holding

By Product Types:

Type 1

Type 2

For End-User/Applications Segments:

Hose, belting & cable

Adhesive & sealants

Industrial & medical gloves

Seals & O-rings

Molded & extruded products

Others

Leading Geographical Regions in Nitrile Butadiene Rubber market Report:

North America, Asia-Pacific, UK, Europe, Central & South America, Middle East & Africa

The Global Nitrile Butadiene Rubber market research report is specially offered for the regional and native markets. Likewise, development policies and plans are broadly analyzed during this research study. Price structures and manufacturing procedures also are presented during this report. Also, the worldwide Nitrile Butadiene Rubber Market study states cost, prices, demand, export and import data, and grows margins, supply figure, and revenues. The study also delivers the detailed analysis of the Nitrile Butadiene Rubber Market.

Get Attractive Discount on Report at: https://www.asamarketresearch.com/check-discount/998458

Customization of this Report: This Nitrile Butadiene Rubber report could be customized to the customer's requirements. Please contact our sales professional ([email protected]), we will ensure you obtain the report which works for your needs.

0 notes

Text

Automotive Elastomers Market - Future Analysis, Share, Growth, Trends, Company Profiles and Forecast 2025

Automotive Elastomers are useful for various manufacturing operations. A new report on the Global Automotive Elastomers Market, published by Market Research Future (MRFR), predicts that this market could grow between 2016 and 2023. In terms of value, the market can be worth USD 4,317.10 Mn by the end of the forecast period.

The primal market driving factor for the Global Automotive Elastomers Market growth is the use of Automotive Elastomers as sealants, adhesives, and flexible molded parts in automotive manufacturing. Surging sales of passenger cars in emerging economies have created growth opportunities for Automotive Elastomers. Other market driving factors include increasing purchasing power of the consumers, the rising standard of living, strict emission regulations in developed economies, subsequent increasing usage of high-performance, lightweight materials in the automotive industry, and lastly, the rapid rise in demand for both commercial and passenger vehicles.

Key Players:

Prominent players in the Global Automotive Elastomers Market include Arlanxeo (Netherlands), BASF SE (Germany), The Dow Chemical Company (USA), Exxon Mobil Corp. (USA), Kraiburg TPE GmbH & Co. Kg (Germany), Kuraray Co. Ltd. (Japan), LG Chem Ltd. (South Korea), Mitsui Chemicals Inc. (Japan), Nizhnekamskneftekhim PJSC (Russia), Saudi Basic Industries Corporation (Saudi Arabia), Solvay S.A. (Belgium), Sumitomo Chemical Co. Ltd. (Japan), Teknor Apex Company Inc. (USA), and Versalis S.P.A (Italy).

Latest Industry News:

Mitsubishi Chemical has developed thermoplastics elastomer material called extrusion-grade styrenic copolymer (TPS). It is a single auto-foamable core grade that can be extruded at around 190 to produce foamed-core profiles. 8 AUG 2019

Get Free Sample @ https://www.marketresearchfuture.com/sample_request/4992

Market Segmentation:

Global Automotive Elastomers Market segmentation encompasses Application, Type, and Vehicle Type. MRFR's take on the market explores various facets of the market in-depth.

The Application-Based Segmentation of this market covers exterior application, interior application, and tire application. The exterior segment has been sub-segmented into bumper fascia, front end body panel, rocker panel, and roof molds & window shields. The interior application has been sub-segmented into airbags, breaks & suspensions, dashboards, door panels, hoses & seals, instrument & soft-touch panels, seatings, and transmission & conveyor belts. The tire segment holds 61.4% of the market share.

By Type, the market has been segmented into thermoplastic elastomers (TPE) and thermoset elastomers (TSE). The TSE segment has been sub-segmented into acrylic rubber or alkyl acrylate copolymer (ACM), butyl rubber or isobutylene isoprene rubber (IIR), chlorinated elastomers, ethylene propylene diene monomer (EPDM), fluoroelastomers, natural rubber, nitrile butadiene rubber (NBR), polybutadiene rubber (BR), silicone rubber (Q), and styrene butadiene rubber (SBR). The TPE segment has been sub-segmented into copolyamides (COPA), copolyesters (COPE), polyether block amide (PEBA), styrene block copolymer (SBC), thermoplastic olefins (TPO), thermoplastic polyurethane (TPU), and thermoplastic vulcanizates (TPV).

Based on Vehicle Type, light commercial vehicle (LCV), medium & heavy commercial vehicle (M/HCV), and passenger cars.

Regional Segmentation:

A Geographical Outlining of the Global Automotive Elastomers Market covers Asia Pacific, Europe, North America, Latin America, and the Middle East & Africa (MEA).

Browse Key Industry Insights spread across 449 pages with 327 market data tables & 26 figures & charts from the report, “Automotive Elastomers Market Information: By Type, Application and Region – Growth Potential, Price Trends, Competitive Market Share & Forecast 2025” in detail along with the table of contents: https://www.marketresearchfuture.com/reports/automotive-elastomers-market-4992

During the forecast period, the Asia Pacific region has the strongest chance to stand tall as the principal regional market due to the growing standards of living and rising disposable income of the consumers in developing economies namely China, India, and South Korea. These economies are incentivizing automotive production to meet the increasing demand in their respective countries. Japan is another major country-specific market as some important market players in the Asia Pacific region are based in Japan. Indonesia is another sizable country-specific market in this region. An analysis of the remaining countries in the Asia Pacific region featured in this report estimates the huge contribution to market revenue from some other countries.

Europe is the second-largest regional market due to technological advancement and a strong automotive industry in countries like Germany. Some of the key market players are based in Europe. Other critical country-specific markets in this region are France, Italy, Poland, Russia, and the UK. An observation of the remaining countries in Europe featured in this report speculate the huge addition to market revenue from some other countries.

North America is another important regional market due to the strong automotive industry, strong economy, technological advancement, and the presence of most of the key market players. USA and Canada generate maximum revenue in this market.

Latin America and the MEA region, hold the smallest market shares in the global market. Latin America is a bigger market than the MEA region as the automotive industry is stronger in this region. Argentina, Brazil, and Mexico are the biggest country-specific market in this region. An audit of the remaining countries in Latin America featured in this report speculate the huge addition to market revenue from some other countries. In the MEA region, market is limited due to limited scope for the automotive industry. In this region, the biggest country-specific markets are Saudi Arabia, Turkey, and UAE. A scrutiny of the remaining countries in the MEA region featured in this report calculates the increase to market revenue from some other countries.

Read our Blogs @ http://mrfrblog.com

Related Chemicals and Materials Market Research Report @ https://www.marketresearchfuture.com/categories/chemicals-market-report

NOTE: Our team of researchers are studying Covid19 and its impact on various industry verticals and wherever required we will be considering covid19 footprints for a better analysis of markets and industries. Cordially get in touch for more details.

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by Components, Application, Logistics and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Contact:

Market Research Future

+1 646 845 9312

Email: [email protected]

0 notes

Text

Fluorosilicone (FVMQ) Rubber Market Share: Size, Growth, Trends, Demand, Industry Analysis, Key Player profile and Regional Outlook by 2025

According to the MRFR analysis, the Fluorosilicone (FVMQ) Rubber Market was valued at more than USD 120 Million in 2018 and is projected to reach over USD 190 Million by the end of 2025 at a CAGR of 5.51%.

Fluorosilicone (FVMQ) rubber is an elastomer made of a silicone polymer chain with fluorinated sidechains. This structure provides the elastomer with a wide number of characteristics that make it a perfect choice of material for the automotive and aerospace industries. It is widely used in various demanding applications where fuel resistance, high-temperature performance, and low-temperature performance are required. It offers a varying range of properties such as superior extreme-temperature (low/high) performance, prolonged resistance to fuels, oils, solvents and aggressive fluids, ability to be fabricated by extrusion, compression molding, injection molding, and calendaring, good balance of tensile, elongation, and tear resistance, and good heat stability with good tear retention.

The prominent factors driving the growth of the global market are increasing demand for both passenger and commercial vehicles and growing commercial aircraft production.

Browse Full Report Details @ https://www.marketresearchfuture.com/reports/fluorosilicone-rubber-market-8479

Regulatory Analysis and Trade Analysis

OEM specifications for exhaust gas recirculation systems (where fluorosilicone rubbers are required):

BMW GS97018:2008-11

Fiat 902139

Ford AZ 102-02

GM GME 8688

VW PV3936

Some of the regulatory standards (ASTM) requirements for FVMQ properties:

Source: ASTM, Company Brochure, and MRFR Analysis

The overall silicone rubber exported in its primary form increased by around 18% from USD 5,351.6 million in 2017 to USD 6,335.2 million in 2018, whereas total silicone rubber imported increased by around 18% from USD 7,548 million in 2017 to USD 8,938 million in 2018.

The HS Code for the FVMQ is “39100090”.

SEGMENTATION

By Processing Technology

Compression Molding: Compression molding of flurosilicone rubber to mold it into various end-use products is one of the most widely used processing techniques. This process is mainly used for low to medium volume applications such as O-rings, seals, and gaskets, as well as for some specialty high volume components. Some of the major benefits offered by the process include less complex tooling and lower costs to construct, lower percentage material runner scrapes as compared to traditional injection or transfer molding process, and the process is suitable for most elastomers and cure systems.

The segment held the largest share accounting for over 35% of the market in 2018.

Liquid Injection Molding: Liquid injection molding offers easier processing, high level of automation, faster cycle times, and better end-product performance. It is mainly used for liquid fluorosilicone rubber for molding high-quality parts. The main products manufactured using the process include gaskets, O-rings, seals, precision molded parts, and cushioning pads in electronic portable devices. LIM is used to craft high-performance parts in industries ranging from automotive to aerospace.

Calendaring: This segment covers the consumption of fluorosilicone consumed for manufacturing end-use products using calendaring. These products (sheets) include industrial and automotive components.

Extrusion: The extrusion segment accounted for a minimal share of the global market. The use of the extrusion process offers several merits such as a large variety of shapes that can be obtained, relatively economical, minimal waste material produced, and high efficiency. The process is used to produce various extruded FVMQ products including gaskets, sealing components, and other intricate profiles.

3D Printing: The 3D printing segment is expected to register healthy growth in the coming years. It is still not used on a large scale, is however gaining popularity, majorly in North America. Major developments are taking place in the market, for instance, in August 2018, Wacker Chemie AG announced the launch of new liquid fluorosilicone rubber for 3D printing applications.

By End-Use Industry

Automotive: The automotive segment held the largest share of the market with more than 50% in 2018, owing to the surging demand for smaller engine compartments, increased exhaust gas recirculation and decreased airflow, and the high-end temperatures in under-the-hood environments (requiring efficient and temperature resistant materials) in the automobiles coupled with the increasing automotive production in the emerging economies. Moreover, considering the current automotive trends for small engine designs and increased efficiency, the increase in design flexibility as a result of innovative materials like FVMQ is boosting the demand for these rubbers in the automotive industry.

The components manufactured include fuel and air system component parts, fuel line safety seals, O-rings, gaskets, connector seals, flexible diaphragms and valves, and turbocharger hose liners.

Aerospace & Defense: The aerospace & defense segment is the other major end-use industry consuming FVMQ products. Fluorosilicone rubber seals offer outstanding resistance to ozone, sunlight, and weathering, making it the perfect compound to use in aircraft. FVMQ elastomers have outstanding solvent and fuel resistance and high-temperature stability, owing to which are majorly used for static seals in the aircraft fuel systems. With the significant growth of the aerospace & defense industry across the emerging economies and developed economies, the demand for fluorosilicone rubber is expected to increase in the years to follow.

Oil & Gas: In the oil & gas industry, seals are widely used in various stages such as well drilling, well completion, and well production. The seals used have to cope with the harsh conditions of deeper wells as well as with the different solvents and chemicals. Moreover, these seals are exposed to extremely high temperatures and to a wide range of aggressive chemicals. Fluorosilicone rubber is one of the preferred choices for the manufacture of these seals. With the increasing demand for energy, the oil & gas industry is growing at a healthy rate. This is expected to boost the demand for FVMQ during the forecast period.

Electronics & Semiconductors: This segment includes the use of FVMQ in the EMI shielding applications and other electronic applications.

Others: The other segment covers medical and food & beverage.

By Region

North America: The growth of the automotive and aerospace industries is the primary driver for market growth.

Europe: Germany, France, the UK, and Russia are the major contributors to the regional market growth and the growing automotive industry supports the regional market growth.

Asia-Pacific: The largest and fastest-growing regional market for fluorosilicone (FVMQ) rubber, with China and India being the leading country-level markets.

Latin America: A small but growing automotive industry is likely to fuel the demand for fluorosilicone (FVMQ) rubber in the coming years.

Middle East & Africa: High growth potential of the automotive manufacturing hub in Egypt, UAE, and Saudi Arabia, may propel the regional market growth during the forecast period.

Get a Free Sample Now@ https://www.marketresearchfuture.com/sample_request/8479

NOTE: Our team of researchers are studying Covid19 and its impact on various industry verticals and wherever required we will be considering covid19 footprints for a better analysis of markets and industries. Cordially get in touch for more details.

COVID-19 Study in Detail:

COVID-19 Impact Analysis on Polyvinyl Chloride (PVC) Market

COVID-19 Impact on 3D Printing Materials Market

COVID-19 Outbreak Impact on Carbon black Market

0 notes

Text

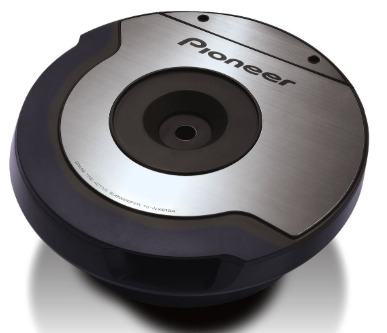

Best Car Subwoofer Uk

Best powered subwoofer car

Best Car Subwoofer Uk

DB Audio XTINCT15 5000Watts 15-inch SubwooferJL-Audio 12 W3 V3 Car SpeakerVibe Slick SLR12TA-V2 Twin 12" Sub Subwoofer 2400W Active Amplified EnclosurePioneer TS WX70DA Space-Saving Class-D Active SubwooferKicker tcomprt10 Pre-Loaded Subwoofer 400 WPioneer TS-WX610A Bandpass Spare Tyre Subwoofer 200w MaxJBL CS1204B PACK GX A602 Powerful and Compact

Driving a car with poor sound or deep bass isn't something a music lover wants. You need a subwoofer that recreates low frequencies which is what speakers do basically. So if you want to change or improve the vehicle bass, our best car subwoofer UK for quality assurance.

Our list of subwoofers showcases the best subwoofer for deep bass, which has top performances and designed by top brands. You should check your car radios single din and double din head unit. This is to ensure you have important outputs before you order one.

Top Best Car Subwoofer UK

1. DB Audio XTINCT15 5000Watts 15-inch Subwoofer

This car subwoofer has an RMS power wattage of 1500 watts and a 5000 watts, it is a 15-inch subwoofer and 3 hi-temp 4-layer voice coil.

Made from high-quality materials, and also has the best quality sound with a red finish die-cast basket and Kevlar has woven nonpress paper cone with EROM foam surround.

2. JL-Audio 12 W3 V3 Car Speaker

This car subwoofer delivers a powerful, accurate and quality bass, with a medium-power amplifier. The design is smooth with a precise cone movement that can use any power level. It has cooling features which keep heat out of the internal motor and structures and has long durability and reduced distortion. RMS is 500 watts, the peak is 1000 Watts. It is designed to ease the stress from rubber surround while the cone moves. It has a removable and customizable trim ring if you want it repainted to fit your car.

3. Vibe Slick SLR12TA-V2 Twin 12" Sub Subwoofer 2400W Active Amplified Enclosure

This car subwoofer has an inbuilt amplifier, and with Vibe's renowned bass reflex enclosure technology for deep bass and loudness. The sealed design enclosure produces a perfect performance, and the SLR is up to 6dB. If you are looking for the loudest and deep bass, this subwoofer will deliver you to the hands of sweet music.

The powerbox amplifier has an extruded aluminum heatsink, this is for cooling. Both for the low-level RCA inputs and high-level speaker. It has an 800 watts RMS power, quality audio output, and twin subwoofers.

4. Pioneer TS WX70DA Space-Saving Class-D Active Subwoofer

This car subwoofer has an integrated digital bass control. A Pioneer woofer with RCA and speaker input, a powerful sound with a built-in class D Amp. It has a built-in digital bass control, with precise bass levels.

There is also a 2 bass selection, the deep bass and dynamic bass, and a 200 watts bass. It has a cable remote control, for free control while driving. An ultra-slim and scratch-resistant design which doesn't consume space.

5. Kicker tcomprt10 Pre-Loaded Subwoofer 400 W

This car subwoofer is perfect if you have a compact space in the car, and can be installed in the truck also. Design for maximum performance with a rugged sealed box, with big bass from a CompRT sub. It has a rigid cone which helps eliminate distortion and built to last.

It has a 4-ohm impedance which allows connection with a wide range of amplifiers, and a 400 watts bass sound.

6. Pioneer TS-WX610A Bandpass Spare Tyre Subwoofer 200w Max

This car amplified subwoofer is an ideal speaker for boot space. It is an all-in-one in-car bass solution, that fits in small enclosures. It has a dynamic and powerful sound, with 2.10 Dual Voice Coil speakers and a 200 watts MOSFET amplifier.

Because of the die-cast aluminum frame construction enclosure, you will get less distorted and stronger sound.

7. JBL CS1204B PACK GX A602 Powerful and Compact

This car subwoofer is 280 watts, and a 2 channel car Hi-Fi amplifier. Also has a 2 x 60 watts RMS and 30cm subwoofer with double magnet sealed type enclosures, and it fits most spaces.

The dome twitters are good, powerful sound, a heat sink, built-in electronic crossover networks, and a switchable bass boost.

More Recommendation

WIRELESS & BLUETOOTH SPEAKERS

Best Sylvania Bluetooth SpeakersBest Bluetooth Speakers Under 100Best Bathroom Waterproof Bluetooth SpeakerBest Budget Bluetooth SpeakersBose Surround Sound Speakers Review

POPULAR POSTS

Best Sylvania Bluetooth SpeakersBose QuietComfort 35 II Headphone ReviewNoise Cancelling Earbuds To SleepBest Bluetooth Speakers Under 100Best Wireless TV Headphones For Hard Of Top 10 Best Soundbars Under 300111 Total SharesBest Pc Speakers Under 100103 Total SharesPortable Speakers Top 10102 Total SharesBest Bookshelf Speakers Under 50040 Total SharesBest Car Subwoofer Under 20032 Total SharesBest Sylvania Bluetooth Speakers22 Total SharesBest Bookshelf Speakers Under 40019 Total SharesBest Bookshelf Speakers Under 30018 Total SharesBest Bluetooth Speakers Under 10017 Total SharesTop 10 Best Open Back Headphones Under 30016 Total Shares

The 10 Best TweetersBest Sylvania Bluetooth SpeakersBest Car Speakers For Bass Without A …Best Bluetooth Speakers Under 100Best Bathroom Waterproof Bluetooth Speaker

BEST SOUNDBAR SPEAKERS

10 Best Wireless Surround Sound Speakers For …Best Budget Sound Bar Under 100Best Wireless TV Speakers For Hard Of …Top 10 Best Soundbars Under 200Top 10 Best Soundbars Under 300

GAMING HEADPHONES

Noise Cancelling Earbuds To SleepBose QuietComfort 35 II Headphone ReviewTop 10 Best Open Back Headphones Under …Top 10 Best Open Back Headphones With …Top 10 Best Open Back Headphones Under …

RECENT POSTS

The 10 Best TweetersBest Sylvania Bluetooth SpeakersBest Car Speakers For Bass Without A SubwooferBest Bluetooth Speakers Under 100Best Bathroom Waterproof Bluetooth SpeakerBest Budget Bluetooth SpeakersBose Surround Sound Speakers Review10 Best Wireless Surround Sound Speakers For TVBest Wireless Bedside TV SpeakersBest Home Theater Speakers Under 300

Read the full article

0 notes

Text

Global Fluoro Elastomers Market 2019 Share and Forecast to 2023: 3M, etc.

The Global Fluoro Elastomers Market Report 2019 aims to deliver an explicit evaluation of the market. The report offers sweeping insights extracted by thoroughly analyzing historical and current developments in the market. It also provides par excellence futuristic estimations for various vital factors including Fluoro Elastomers market size, share, net profit, sales, revenue, and growth rate.

The market competition by top manufacturers/players, with sales volume, price (USD/Unit), revenue (Million USD) and market share for each manufacturer/player

The report covers the market study and projection of Fluoro Elastomers market on a territorial along with worldwide point . The report establishes subjective and quantitative valuation by industry examiners, direct information, help from industry specialists alongside their latest verbatim and every industry producers through the market value chain. The examination specialists have also evaluated the by and large sales and income creation of this specific market. Moreover, this report additionally conveys broad examination of basic market drift, many key essentials while overseeing macro-economic indicators, combined with market enhancements according to each section.

Get more information, Ask for Free Sample Copy of this Report@ https://www.acquiremarketresearch.com/sample-request/124833/

Some of the most prominent Key Vendors: 3M, AccuTrex Products, All Seals, Ames Rubber Manufacturing, AGC, Chambers Gasket & Manufacturing, Chenguang Fluoro & Silicone Elastomers, Daikin, Dongyue, DowDuPont, Eagle Elastomer, Garlock, Halopolymer, Hennig Gasket & Seals, Honeywell, I. G. Marston, IGS, Lanxess, Lauren, Mikron Rubber, Minor Rubber, Northwest Rubber Extruders, Omni Seals, Precision Associates, Shanghai 3F New Material, Vanguard Products, Solvay, Zeon, Zhonghao Chenguang Research Institute of Chemical, Zrun

Regions covered in the market report: North America (United States, Canada and Mexico), Europe (Germany, France, UK, Russia and Italy), Asia-Pacific (China, Japan, Korea, India and Southeast Asia), South America (Brazil, Argentina, Colombia etc.), Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

Applications Segment Analysis: Automotive, Aerospace, Process Industries, Energy & Power, Electronics Superconductors)

Product Segment Analysis: Fluorocarbon Elastomers, Fluorosilicone Elastomers, Perfluorocarbon Elastomers

Key questions answered in this report

• What will the market size be in 2023 and what will the growth rate be?

• What are the key market trends?

• What is driving this market?

• What are the challenges to Fluoro Elastomers market growth?

• Who are the key vendors in this market space?

• What are the Fluoro Elastomers market opportunities and threats faced by the key vendors?

• What are the strengths and weaknesses of the key vendors?

For detailed information regarding Fluoro Elastomers market, Contact Us: https://www.acquiremarketresearch.com/industry-reports/fluoro-elastomers-market/124833/

Reasons to Purchase this Report

• Analyzing outlook of the Fluoro Elastomers market with the recent trends and Porter’s five forces analysis

• Market dynamics which essentially consider the factors, which are impelling the present market scenario, along with growth opportunities of the market in the years to come

• Market segmentation analysis, including qualitative and quantitative research incorporating the impact of economic and non-economic aspects

• Regional and country level analysis integrating the demand and supply forces that are influencing the growth of the Fluoro Elastomers market

• Competitive landscape involving the market share of major players, along with the key strategies adopted for development in the past five years

• Comprehensive company profiles covering the product offerings, key financial information,

Our experts and analysts evaluate the vendors in the Fluoro Elastomers market and provide understandings to articulate current and future market trends, innovation, customer expectations and competitive forces. The overviews, SWOT analysis and strategies of each vendor in the market provide understanding about the Fluoro Elastomers market forces and how those can be oppressed to create future opportunities.

0 notes

Text

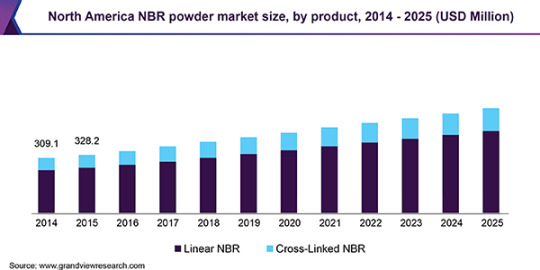

Nitrile Butadiene Rubber Market Size Worth $2.59 Billion By 2025

The global nitrile butadiene rubber market size is expected to reach USD 2.59 billion by 2025, growing at a CAGR of 3.3%, according to a new report by Grand View Research, Inc. Asia Pacific is expected to provide ample scope for the industry growth of nitrile butadiene rubber (NBR) by the end of 2025. China, India, and Southeast Asian countries are likely to reflect a strong growth scenario in the future.

NBR is one of the versatile synthetic rubbers that is highly consumed in high end applications, which require the product to be highly sustainable to varying operational and climatic conditions. This makes the product suitable for use in a wide array of industries.

NBR demand in China and India is expected to be driven by significant industrial developments of key end-use sectors in the region including automotive & transportation, metallurgy & mining, oil & gas, equipment & machinery, and medical sectors. These recent developments have propelled the requirements of mechanical goods such as cables, belts, gaskets, and seals.

Rise in the consumer disposable income and purchasing power in ASEAN countries including Indonesia and Thailand, has led to a rapid growth of the automotive industry as well as a strong increase in aftermarket activities. Moreover, increase in the healthcare expenditure in these countries is another key factor that is expected to boost the consumption of nitrile gloves by 2025.

For More Details Please Visit @:

http://www.grandviewresearch.com/industry-analysis/nitrile-butadiene-rubber-market

Further key findings from the report suggest:

· In terms of volume, the seals & O-rings segment is expected to rise at a CAGR of 2.9% from 2017 to 2025. This category is expected to generate a NBR market revenue of nearly US$ 491.3 million by the end of the forecast period.

· Consumption of nitrile gloves is estimated to increase at the fastest growth rate over the years ahead, as a consequence of significant product utilization in the healthcare & hygiene sector

· Wide production expanse particularly in China and India is likely to drive the NBR consumption in mechanical engineering applications including vibration dampening materials, impact machinery, pumps, hydraulic equipment, and compressors

· Europe accounted for the second-largest revenue share of over 20.0% of the global nitrile butadiene rubber market in 2016. CIS countries mainly Russia, are likely to witness fast paced industry growth owing to significant use of hoses, and seals & O-rings in the oil & gas sector.

· Companies are aiming to strengthen their positions in the global industry through acquisition, technology licensing, and collaborations

· In June 2014, Sinopec Corp jointly ventured with SIBUR, a Russian petrochemicals and gas processing company for the construction of a nitrile rubber plant with an annual production capacity of 50 kilo tons at the Shanghai Chemical Industry Park, Shanghai

Grand View Research has segmented the global nitrile butadiene rubber market on the basis of product, application, and region:

Nitrile Butadiene Rubber Product Outlook (Volume, Kilo Tons; Revenue, USD Million, 2014 - 2025)

· Hoses

· Belts

· Cables

· Molded & Extruded Products

· Seals & O-rings

· Rubber Compounds

· Adhesives & Sealants

· Gloves

· Foamed Products

· Others

Nitrile Butadiene Rubber Application Outlook (Volume, Kilo Tons; Revenue, USD Million, 2014 - 2025)

· Automotive

· Mechanical Engineering

· Oil & Gas

· Metallurgy & Mining

· Construction

· Medical

· Others

Nitrile Butadiene Rubber Regional Outlook (Volume, Kilo Tons; Revenue, USD Million, 2014 - 2025)

· North America

o U.S.

· Europe

o Germany

o UK

o CIS

· Asia Pacific

o China

o India

· Central & South America

o Brazil

· Middle East & Africa

0 notes

Text

Nitrile Butadiene Rubber (NBR) Market Segmentation & Market Analysis Research Report 2018

Nitrile Butadiene Rubber (NBR) Market:

Asia Pacific regional market ruled the global market concerning revenue as well as volume. Asia Pacific region was the leading consumer and is prone to be the top growing NBR market during the forecast years. Speedy industrialization, along with expansion in the automotive section is expected to fuel NBR market in emerging countries like China and India during the next few years. The North American market was the second major market due to elevated NBR demand from the healthcare industry. Though, fiscal recession in Europe and North America has affected the growth of NBR market during the last few years. European regional NBR market is projected to expand at a reasonable rate during the next few years since it is still getting better from the economic recession.

Competitive Outlook and Trend Analysis:

The major market players for nitrile butadiene rubber (NBR) market are Zeon Chemicals, Lanxess AG, Synthos S.A., Omnova Solutions, Kumho Petrochemical Co., Versalis, Sibur Holding, and JSR Corporation. Lanxess supplies an extensive series of NBR products involving BAYMOD, PERBUNAN, and KRYNAC with high oil resistance, easy processing, high viscosity, high density, high abrasion resistance, and low-temperature flexibility for several end-user industries involving machine construction, automotive, plastic modification, gas/oil exploration, footwear, and electronics.

Click Your Sample Copy of the Report here @ https://www.crystalmarketresearch.com/report-sample/CM11354 .

The global nitrile butadiene rubber (NBR) market is segmented as follows –

By Product-

Hose, belting and cable

Adhesives and sealants

Industrial and medical gloves

Seals and O-rings

Molded and extruded products

Others

By End User-

Automotive

Machinery

Cots & aprons

Construction

Plastic modification

Wires & cables

Others

Regional Analysis:

North America: U.S, Canada, Mexico

Europe: Germany, France, UK, Italy, Spain, Rest of Europe

Asia-Pacific: Japan, China, Australia, India, South Korea, Rest of Asia Pacific

Rest of the World: Brazil, South Africa, Saudi Arabia, United Arab Emirates, Others

Industry Trend Analysis:

In 2012, the Global Nitrile Butadiene Rubber (NBR) Market was evaluated around USD 1.69 billion and is expected to reach approximately USD 3.29 billion by 2022 while registering itself at a compound annual growth rate (CAGR) of 6.86% over the forecast period on account of growing requirement for high-quality plasticizers due to their brilliant mechanical characteristics. Additionally, rising NBR demand in the production of several automobile components involving dash boards, kick panels, brake pads, and brake lining is projected to drive the growth of the global market. NBRs capability to uphold an extensive temperatures range makes it the best material for the applications in aerospace industry. Expansion in the aerospace industry, particularly in emerging regions is expected to fuel the global NBR market during the forecast period. Also, stiffness and hardness of NBR make it a perfect material for nuclear industry applications. NBR is chemical resistant as well as heat resistant and hence it is used over an extensive range of industrial and automotive applications.

For more information, click on the below link @ https://www.crystalmarketresearch.com/report/nitrile-butadiene-rubber-nbr-market .

NBR is used as a substitute to latex materials owing to its high strength, puncture resistant and excellent flexibility properties. Major applications of NBR are; the manufacturing of medical & industrial gloves, adhesives, hose, sealants, cables, and belting. Moreover, speedy industrialization along with infrastructure expansion in several regions is expected to fuel the growth of NBR market in emerging countries during next few years. The rising utilization of NBR gloves in industrial & medical applications for protection purposes is projected to drive its market during the forecast period. Though, fluctuating costs of raw material along with ecological concerns are expected to hamper the growth of global NBR market.

Table of Contents:

1.Introduction

2.Executive Summary

3.Market Overview

4.Nitrile Butadiene Rubber (NBR) Market, By Application

5.Nitrile Butadiene Rubber (NBR) Market, By End User

6.Nitrile Butadiene Rubber (NBR) Market, By Region

7.Company Profiles

Ask Questions to Expertise at @ https://www.crystalmarketresearch.com/send-an-enquiry/CM11354 .

Major applications of NBR observed in this report involve molded & extruded products, belting & cable, hose, adhesive & sealants, seals & O-rings, industrial & medical gloves, and others involving oil field products, cement, weather stripping cables and gaskets. Medical & Industrial gloves are expected to be the top growing application section while, belting, cable & hose has been the leading application section of the global NBR industry. NBR is widely utilized in oilfields for various applications such as, blow out preventers, seals, and Packers. Also, NBR is widely used in the automobile sector for the production of underhood components where temperatures constantly vary owing to compress airflow inside small engine compartments.

List of Figures:

Figure 1.Global Nitrile Butadiene Rubber (NBR) Market Share, By Application, 2012 & 2022

Figure 2.Nitrile Butadiene Rubber (NBR) Market, By End User, 2016, ($Million)

Figure 3.Nitrile Butadiene Rubber (NBR) Market, By Region, 2016, ($Million)

Figure 4.DSM: Net Revenues, 2014-2016 ($Million)

Figure 5.DSM: Net Revenue Share, By Segment, 2016

To avail discount, please click on the link @ https://www.crystalmarketresearch.com/check-discount/CM11354 .

About Crystal Market Research:

Crystal Market Research is a U.S. based market research and business intelligence company. Crystal offers one stop solution for market research, business intelligence, and consulting services to help clients make more informed decisions. It provides both syndicated as well as customized research studies for its customers spread across the globe. The company offers market intelligence reports across a broad range of industries including healthcare, chemicals & materials, technology, automotive, and energy.

Contact Us:

Judy

304 South Jones Blvd, Suite 1896,

Las Vegas NV 89107,

United States

Toll Free: +1-888-213-4282

Email: [email protected]

0 notes

Text

Nitrile Butadiene Rubber Powder Market Analysis To Reach $2.59 Billion By 2025

San Francisco, 24 September 2018 - The global nitrile butadiene rubber (NBR) market is expected to reach USD 2.59 billion by 2025, growing at a CAGR of 3.3%, according to a new report by Grand View Research, Inc. Asia Pacific is expected to provide ample scope for the industry growth of NBR by the end of 2025. China, India, and Southeast Asian countries are likely to reflect a strong growth scenario in the future.

NBR is one of the versatile synthetic rubbers that is highly consumed in high end applications, which require the product to be highly sustainable to varying operational and climatic conditions. This makes the product suitable for use in a wide array of industries.

NBR demand in China and India is expected to be driven by significant industrial developments of key end-use sectors in the region including automotive & transportation, metallurgy & mining, oil & gas, equipment & machinery, and medical sectors. These recent developments have propelled the requirements of mechanical goods such as cables, belts, gaskets, and seals.

Rise in the consumer disposable income and purchasing power in ASEAN countries including Indonesia and Thailand, has led to a rapid growth of the automotive industry as well as a strong increase in aftermarket activities. Moreover, increase in the healthcare expenditure in these countries is another key factor that is expected to boost the consumption of nitrile gloves by 2025.

Browse Research Report On Nitrile Butadiene Rubber Powder Market :

www.grandviewresearch.com/industry-analysis/nitrile-butadiene-rubber-market

Further key findings from the report suggest:

In terms of volume, the seals & O-rings segment is expected to rise at a CAGR of 2.9% from 2017 to 2025. This category is expected to generate a market revenue of nearly US$ 491.3 million by the end of the forecast period.

Consumption of nitrile gloves is estimated to increase at the fastest growth rate over the years ahead, as a consequence of significant product utilization in the healthcare & hygiene sector

Wide production expanse particularly in China and India is likely to drive the NBR consumption in mechanical engineering applications including vibration dampening materials, impact machinery, pumps, hydraulic equipment, and compressors

Europe accounted for the second-largest revenue share of over 20.0% of the global market in 2016. CIS countries mainly Russia, are likely to witness fast paced industry growth owing to significant use of hoses, and seals & O-rings in the oil & gas sector.

Companies are aiming to strengthen their positions in the global industry through acquisition, technology licensing, and collaborations

In June 2014, Sinopec Corp jointly ventured with SIBUR, a Russian petrochemicals and gas processing company for the construction of a nitrile rubber plant with an annual production capacity of 50 kilo tons at the Shanghai Chemical Industry Park, Shanghai

View more reports of this category by Grand View Research at

www.grandviewresearch.com/industry/plastics-polymers-and-resins

Grand View Research has segmented the global nitrile butadiene rubber (NBR) market on the basis of product, application, and region:

Product Outlook (Volume, Kilo Tons; Revenue, USD Million, 2014 - 2025)

Hoses

Belts

Cables

Molded & Extruded Products

Seals & O-rings

Rubber Compounds

Adhesives & Sealants

Gloves

Foamed Products

Others

Application Outlook (Volume, Kilo Tons; Revenue, USD Million, 2014 - 2025)

Automotive

Mechanical Engineering

Oil & Gas

Metallurgy & Mining

Construction

Medical

Others

Regional Outlook (Volume, Kilo Tons; Revenue, USD Million, 2014 - 2025)

North America

US.

Europe

Germany

UK

CIS

Asia Pacific

China

India

Central & South America

Brazil

Middle East & Africa

Browse Press Release of this Report:

www.grandviewresearch.com/press-release/global-nitrile-butadiene-rubber-market

About Grand View Research

Grand View Research, Inc. is a U.S. based market research and consulting company, registered in the State of California and headquartered in San Francisco. The company provides syndicated research reports, customized research reports, and consulting services. To help clients make informed business decisions, we offer market intelligence studies ensuring relevant and fact-based research across a range of industries, from technology to chemicals, materials and healthcare.

For More Information: www.grandviewresearch.com

0 notes

Text

Nitrile Butadiene Rubber Market | Industry Growth, Trends and Forecast Upto 2025

The global nitrile butadiene rubber (NBR) market is expected to reach USD 2.59 billion by 2025, growing at a CAGR of 3.3%, according to a new report by Grand View Research, Inc. Asia Pacific is expected to provide ample scope for the industry growth of NBR by the end of 2025. China, India, and Southeast Asian countries are likely to reflect a strong growth scenario in the future.

NBR is one of the versatile synthetic rubbers that is highly consumed in high end applications, which require the product to be highly sustainable to varying operational and climatic conditions. This makes the product suitable for use in a wide array of industries.

NBR demand in China and India is expected to be driven by significant industrial developments of key end-use sectors in the region including automotive & transportation, metallurgy & mining, oil & gas, equipment & machinery, and medical sectors. These recent developments have propelled the requirements of mechanical goods such as cables, belts, gaskets, and seals.

Rise in the consumer disposable income and purchasing power in ASEAN countries including Indonesia and Thailand, has led to a rapid growth of the automotive industry as well as a strong increase in aftermarket activities. Moreover, increase in the healthcare expenditure in these countries is another key factor that is expected to boost the consumption of nitrile gloves by 2025.

Full Research Report On Global Nitrile Butadiene Rubber Market By Grand View Research:

www.grandviewresearch.com/industry-analysis/nitrile-butadiene-rubber-market

Further key findings from the report suggest:

In terms of volume, the seals & O-rings segment is expected to rise at a CAGR of 2.9% from 2017 to 2025. This category is expected to generate a market revenue of nearly US$ 491.3 million by the end of the forecast period.

Consumption of nitrile gloves is estimated to increase at the fastest growth rate over the years ahead, as a consequence of significant product utilization in the healthcare & hygiene sector

Wide production expanse particularly in China and India is likely to drive the NBR consumption in mechanical engineering applications including vibration dampening materials, impact machinery, pumps, hydraulic equipment, and compressors

Europe accounted for the second-largest revenue share of over 20.0% of the global market in 2016. CIS countries mainly Russia, are likely to witness fast paced industry growth owing to significant use of hoses, and seals & O-rings in the oil & gas sector.

Companies are aiming to strengthen their positions in the global industry through acquisition, technology licensing, and collaborations

In June 2014, Sinopec Corp jointly ventured with SIBUR, a Russian petrochemicals and gas processing company for the construction of a nitrile rubber plant with an annual production capacity of 50 kilo tons at the Shanghai Chemical Industry Park, Shanghai

Browse More Reports Of This Category By Grand View Research:

www.grandviewresearch.com/industry/plastics-polymers-and-resins

Grand View Research has segmented the global nitrile butadiene rubber (NBR) market on the basis of product, application, and region:

Product Outlook (Volume, Kilo Tons; Revenue, USD Million, 2014 - 2025)

Hoses

Belts

Cables

Molded & Extruded Products

Seals & O-rings

Rubber Compounds

Adhesives & Sealants

Gloves

Foamed Products

Others

Application Outlook (Volume, Kilo Tons; Revenue, USD Million, 2014 - 2025)

Automotive

Mechanical Engineering

Oil & Gas

Metallurgy & Mining

Construction

Medical

Others

Regional Outlook (Volume, Kilo Tons; Revenue, USD Million, 2014 - 2025)

U.S.

Germany

UK

CIS

China

India

Brazil

Access Press Release Of This Research Report By Grand View Research:

www.grandviewresearch.com/press-release/global-nitrile-butadiene-rubber-market

About Grand View Research

Grand View Research, Inc. is a U.S. based market research and consulting company, registered in the State of California and headquartered in San Francisco. The company provides syndicated research reports, customized research reports, and consulting services. To help clients make informed business decisions, we offer market intelligence studies ensuring relevant and fact-based research across a range of industries, from technology to chemicals, materials and healthcare.

For More Information: www.grandviewresearch.com

0 notes

Text

Fast Curing NBR Market Report Provides An Analysis Of The Industry Trends In Each Of The Sub Segments From 2014 To 2025

Global Fast Curing Nitrile Butadiene Rubber (NBR) Market is expected to reach approximately USD 581.2 million by 2025, according to a new report conducted by Grand View Research, Inc. Favorable outlook for the automotive manufacturing sector in emerging economies such as China, India, and Mexico, as a result of increasing domestic consumption of four-wheeler vehicles, is expected to promote the market growth. Furthermore, the rising demand for lightweight automotive materials with excellent mechanical strength on account of shifting preference from metal to polymers amid the growing importance of driver comfort and aesthetics characteristics is expected to keep high penetration of the application over the next eight years.

Oil & gas is projected to foresee volume growth at a predicted CAGR of 3.7% from 2017 to 2025. The upscaling requirements of consumables and products for sensitive conditions concerning temperature and pressure fluctuations are expected to play a crucial role in increasing the activity about high-temperature molding. This trend is projected to promote the usage of fast curing NBR products in the form of hoses, seals, and O-rings in the petroleum industry.

Full Research Report on Global Fast Curing Nitrile Butadiene Rubber (NBR) Market Analysis:

http://www.grandviewresearch.com/industry-analysis/fast-curing-nitrile-butadiene-rubber-nbr-market

Further key findings from the report suggest:

Global fast curing NBR demand was 132.4 kilo tons in 2016 and is expected to reach 181.6 kilo tons by the end of 2025, expanding at a CAGR of 3.6% from 2017 to 2025.

Rising concerns over mold fouling during polymer processing in automotive, and oil & gas industry is expected to force the buyers to procure products with fast curing rates. However, increasing market size of silicone elastomers with good conductive properties and excellent mechanical characteristics is expected to pose a credible threat to fast cured polymers over the projected period.

Disposable gloves are expected to foresee volume growth at a CAGR of 3.8% from 2017 to 2025. The introduction of disposable gloves in developed economies including Germany and the UK which are used on a single patient became very popular owing to the low risk of contamination. These products are based on polymers including latex, rubber, nitrile rubber, neoprene and vinyl which are capable of protecting patients and physicians from cross-contamination during medical examinations.

Asia Pacific is expected to witness fastest revenue growth at a CAGR of 4.4% from a period of 2017 to 2025. The government of China announced funding of USD 1.1 trillion for infrastructure improvement in March 2015. This announcement is expected to increase the demand for fast curing NBR based sealants.

Key industry participants include Lanxess, JSR, Kumho Petrochemicals and Zeon Chemicals. Product innovation and the establishment of a strategic partnership with buyers are expected to remain critical success factors for the industry participants.

View more reports of this category by Grand View Research at: http://www.grandviewresearch.com/industry/automotive-and-aerospace-interior-materials

Grand View Research has segmented the Global Fast Curing NBR Market on the basis of product, application, and region:

Fast Curing NBR Product Outlook (Volume, Kilo Tons; Revenue, USD Million; 2014 - 2025)

Hoses

Belts

Cables

Molded & Extruded Products

Seals & O-rings

Rubber Compounds

Adhesives & Sealants

Gloves

Foamed Products

Others

Fast Curing NBR Application Outlook (Volume, Kilo Tons; Revenue, USD Million; 2014 - 2025)

Automotive

Mechanical Engineering

Oil & Gas

Metallurgy & Mining

Construction

Medical

Others

Fast Curing NBR Regional Outlook (Volume, Kilo Tons; Revenue, USD Million; 2014 - 2025)

U.S.

Germany

UK

Russia

China

Japan

Brazil

View Press Release of this research report by Grand View Research: http://www.grandviewresearch.com/press-release/global-fast-curing-nitrile-butadiene-rubber-nbr-market

About Grand View Research

Grand View Research, Inc. is a U.S. based market research and consulting company, registered in the State of California and headquartered in San Francisco. The company provides syndicated research reports, customized research reports, and consulting services. To help clients make informed business decisions, we offer market intelligence studies ensuring relevant and fact-based research across a range of industries, from technology to chemicals, materials and healthcare.

For More Information: www.grandviewresearch.com

0 notes

Text

Fluorosilicone (FVMQ) Rubber Industry: Size, Growth and Share by 2025

According to the MRFR analysis, the Fluorosilicone (FVMQ) Rubber Market was valued at more than USD 120 Million in 2018 and is projected to reach over USD 190 Million by the end of 2025 at a CAGR of 5.51%.