Text

0 notes

Text

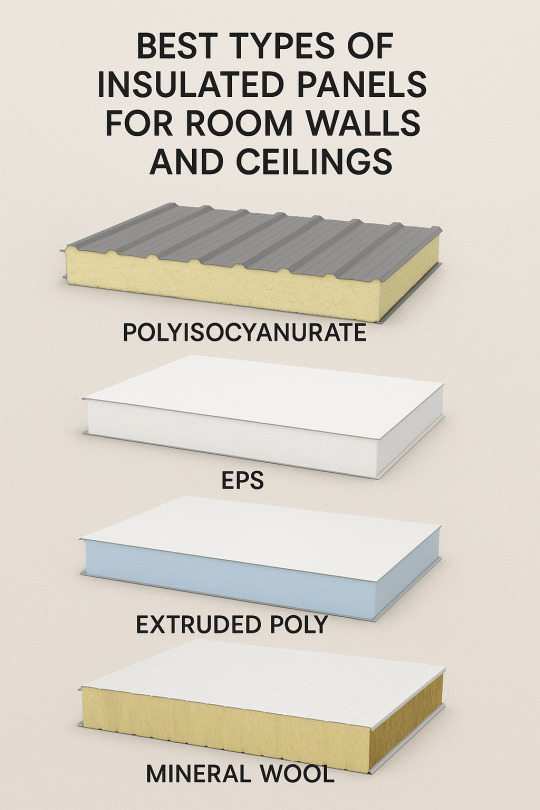

Best Types of Insulated Panels for Room Walls and Ceilings

In modern construction, energy efficiency, durability, and speed are more important than ever. Whether you're building a residential home, commercial office, warehouse, or prefab structure, choosing the right insulation for walls and ceilings is key to maintaining indoor comfort and reducing energy costs.

Insulated panels are prefabricated systems that combine insulation and structural support in a single solution. They’re ideal for temperature control, noise reduction, and structural strength. Here's a look at the best types of insulated panels for room walls and ceilings, each with its own advantages:

1. Polyisocyanurate (PIR) Panels

Polyisocyanurate, or PIR, is one of the highest-performing thermal insulation materials used in construction today. These panels consist of rigid foam sandwiched between two metal or board layers.

Key Benefits:

Superior thermal efficiency – high R-value per inch

Fire resistance – self-extinguishing properties

Lightweight and durable – easy to handle and install

Moisture resistance – ideal for both indoor and outdoor use

PIR panels are ideal for temperature-controlled spaces such as cold storage, server rooms, and industrial buildings.

2. Expanded Polystyrene (EPS) Panels

EPS panels are made from expanded polystyrene foam, known for its excellent insulating properties and cost-effectiveness. These panels are widely used in prefabricated and modular buildings.

Key Benefits:

Affordable insulation solution

Good thermal and acoustic performance

Lightweight and easy to cut or install

Environmentally friendly and recyclable

EPS panels are great for residential rooms, partitions, and standard prefab structures where cost and speed are priorities.

3. Extruded Polystyrene (XPS) Panels

Extruded polystyrene is a denser and stronger form of polystyrene insulation. XPS panels offer excellent thermal performance and resistance to moisture, making them ideal for high-humidity environments.

Key Benefits:

High compressive strength

Excellent moisture and water resistance

Smooth surface finish

Long-term durability

These panels are often used for roofs, ceilings, basements, and cold storage facilities.

4. Mineral Wool Panels

Mineral wool (or rock wool) panels are made from natural stone or slag fibers. Known for their fire resistance and soundproofing qualities, these panels are ideal for buildings where fire safety is a top priority.

Key Benefits:

Non-combustible and fire-resistant

Excellent sound insulation

Resistant to pests, mold, and rot

Eco-friendly and recyclable

They are commonly used in commercial and industrial spaces, especially in applications requiring acoustic control and fire safety.

Conclusion

The choice of insulated panels depends on your building's requirements—whether it’s superior thermal performance, moisture resistance, acoustic insulation, or fire safety.

Polyisocyanurate is best for energy efficiency, EPS offers an economical and lightweight option, XPS excels in moisture-prone areas, and Mineral Wool provides unbeatable fire and sound insulation.

Investing in the right insulation solution helps you reduce energy bills, enhance occupant comfort, and extend the life of your building.

Looking for high-quality insulated panel solutions? Partner with trusted manufacturers like Engko for expert guidance and top-grade materials tailored to your project.

#prefab#pre engineered building manufacturers#prefabricated#peb#prefabricated structure#warehouse#industrial

1 note

·

View note

Text

Prefab Structures vs Pre-Engineered Buildings: What’s the Difference?

In today’s fast-paced construction landscape, Prefab Structures and Pre-Engineered Buildings (PEBs) have revolutionized the way we build. Both methods offer significant benefits over traditional construction—speed, efficiency, cost-effectiveness—but they are not the same. If you're planning a project and trying to decide between the two, understanding the key differences can help you make an informed decision.

What Are Prefab Structures?

Prefab (Prefabricated) Structures refer to buildings or components manufactured off-site in a controlled environment and then transported to the site for assembly. These structures can range from small kiosks to modular homes, site offices, and even industrial shelters.

Key Features of Prefab Structures:

Modular Construction: Built in sections (modules) that can be easily transported and assembled.

Material Variety: Often made from a combination of steel, wood, concrete, and insulation materials.

Highly Customizable: Designs can be adjusted for size, layout, and purpose.

Fast Installation: Reduces on-site labor and construction time drastically.

Versatility: Commonly used for temporary or semi-permanent installations like railway shelters, portable cabins, and remote site offices.

What Are Pre-Engineered Buildings (PEBs)?

Pre-Engineered Buildings are steel structures designed and fabricated in a factory using a predetermined inventory of raw materials and components. These are engineered to exact specifications, ensuring structural efficiency and cost optimization.

Key Features of PEBs:

Steel Framework: Built primarily from structural steel members such as columns, rafters, and purlins.

Engineered Precision: Each component is designed for load, wind, and seismic resistance.

Suitable for Large Spans: Ideal for industrial buildings, warehouses, exhibition halls, and aircraft hangars.

Durability & Strength: Designed to last for decades with minimal maintenance.

Scalable & Expandable: Easy to modify or expand in the future.

Prefab vs PEB: Head-to-Head Comparison

Which One Should You Choose?

Choose Prefab Structures if you're looking for quick deployment, mobility, and flexibility—for example, a site office, temporary housing, or a railway shelter.

Choose PEBs if your project demands long-term durability, large interior spaces, and structural strength, such as warehouses, showrooms, or manufacturing units.

Final Thoughts

While prefab and pre-engineered buildings both offer modern solutions to conventional construction, their uses, strengths, and structures differ considerably. Selecting the right approach depends on your project goals, timeline, budget, and scale.

Still unsure? At Engko, we specialize in both prefab structures and PEBs, and can guide you in choosing the right solution tailored to your needs. Contact us today to discuss your project.

1 note

·

View note

Text

PUF Panel Home Manufacturers: Building the Future of Affordable and Sustainable Living

In a world increasingly seeking cost-effective, energy-efficient, and time-saving construction solutions, PUF panel homes have emerged as a revolutionary alternative to traditional building methods. These prefabricated structures, built using Polyurethane Foam (PUF) panels, are changing the face of residential construction—offering speed, insulation, durability, and sustainability in one package.

What Are PUF Panel Homes?

PUF panels are sandwich panels consisting of a rigid polyurethane foam core between two metal sheets, usually made of steel or aluminum. This structure gives them excellent thermal insulation, structural integrity, and lightweight properties, making them ideal for prefabricated buildings, including homes, offices, site accommodations, and more.

A PUF panel home is essentially a modular structure assembled using these panels. The construction process is much faster than traditional brick-and-mortar homes and can be customized to suit various aesthetic and functional needs.

Why Choose a PUF Panel Home?

Speed of Construction: Homes built with PUF panels can be erected in a matter of days or weeks, not months. All major components are pre-engineered and assembled on-site with minimal labor.

Energy Efficiency: PUF panels offer high thermal insulation, reducing the need for artificial heating or cooling. This translates to lower electricity bills and environment-friendly living.

Cost-Effective: PUF panel homes are more affordable due to reduced construction time, fewer raw materials, and lower labor costs.

Durability & Weather Resistance: These homes are designed to withstand extreme weather conditions, including heavy rains, winds, and temperature fluctuations.

Eco-Friendly: Minimal waste, recyclable materials, and low energy consumption during construction make these homes a green alternative.

Design Flexibility: Modern PUF panel homes can be stylish, contemporary, and personalized to reflect the owner's taste.

Leading PUF Panel Home Manufacturers in India

India is witnessing rapid growth in the prefabrication sector, and several manufacturers are leading the charge in the PUF panel home segment:

1. EPACK Prefab

Based in Greater Noida, EPACK is a major name in PUF panel manufacturing and prefab home construction. They offer turnkey solutions from design to delivery.

2. Interarch Building Products

With decades of experience in PEBs and modular solutions, Interarch manufactures high-quality insulated panels suitable for residential and industrial use.

3. Engko (engko.co.in)

Engko is a rising player known for its innovative approach to prefab infrastructure. With a focus on railway shelters and industrial warehouses, the company is also venturing into PUF panel housing, offering cost-effective, modern living solutions with superior engineering and design standards.

4. TSSC Group

A leading manufacturer across the Middle East and India, TSSC provides top-grade insulated panels and modular building systems, including homes and portable cabins.

Applications Beyond Housing

PUF panel structures are not limited to homes. They're used in:

Site offices

Farmhouses

Labour accommodations

Cold storage rooms

Rooftop extensions

Disaster relief housing

Final Thoughts

PUF panel homes represent a smarter, greener, and faster way to build in today’s rapidly changing world. Whether you’re a homeowner seeking an affordable living space or a builder looking for modular housing solutions, partnering with the right PUF panel home manufacturer can bring your vision to life with efficiency and style.

Looking to explore prefab home solutions? Contact us at Engko Engineering Company to learn how we can design and deliver your dream home using cutting-edge PUF technology.

1 note

·

View note

Text

The Rise of Prefabricated Structures Manufacturers

In the ever-evolving construction world, prefabricated structures are swiftly gaining traction as a game-changing solution. At the heart of this transformation are prefabricated structures manufacturers, who are revolutionizing how buildings are designed, assembled, and delivered.

What Are Prefabricated Structures?

Prefabricated (or prefab) structures are buildings or components that are manufactured in a factory setting and then transported to the construction site for assembly. Unlike traditional construction, which happens entirely on-site, prefab methods leverage off-site fabrication for faster, cleaner, and more efficient project completion.

These structures range from modular homes and office buildings to complex industrial warehouses and railway shelters. The flexibility and scalability of prefabricated construction make it a top choice for modern infrastructure demands.

Role of Prefabricated Structures Manufacturers

Prefabricated structures manufacturers are the backbone of this industry. Their role extends beyond mere production — they are deeply involved in:

Design & Engineering: Utilizing CAD and BIM technologies to create precise, customizable designs.

Material Selection: Choosing high-quality steel, aluminum, composites, or concrete to suit project needs.

Fabrication & Quality Control: Manufacturing components in controlled environments, ensuring consistent quality and reduced waste.

Logistics & Installation: Coordinating the transportation and on-site assembly with precision and safety protocols.

Benefits Delivered by Manufacturers

Faster Project Completion By prefabricating components simultaneously with site preparation, manufacturers help reduce overall project timelines significantly.

Cost Efficiency Factory production minimizes labor costs and material waste, providing cost-effective solutions.

Superior Quality & Durability Controlled factory conditions allow for higher precision, structural strength, and weather-resistant construction.

Sustainability Prefab methods reduce environmental impact through waste reduction, energy efficiency, and use of sustainable materials.

Customizability Manufacturers offer tailored solutions for varied applications, from temporary shelters to permanent commercial buildings.

Key Applications of Prefabricated Structures

Industrial Warehouses Quick to erect and highly durable, prefab warehouses meet the needs of fast-growing industries and logistics companies.

Railway Infrastructure Prefabricated shelters and station components enhance passenger comfort while meeting stringent safety standards.

Commercial & Exhibition Halls Large spans without internal columns make prefab ideal for events, showrooms, and temporary exhibits.

Residential Housing Affordable and quick to build, modular homes are addressing housing shortages worldwide.

The Future of the Industry

With advances in automation, robotics, and sustainable materials, the prefab construction market is expected to grow rapidly. Manufacturers are integrating smart technologies into structures, offering IoT-enabled buildings with improved energy management and user experience.

As urbanization continues and demand for faster, greener building methods grows, prefabricated structures manufacturers are well-positioned to lead the charge in reshaping how we build.

Conclusion

Prefabricated structures manufacturers are no longer just suppliers — they are strategic partners in modern construction. With their innovation, efficiency, and commitment to quality, they are helping developers, governments, and private enterprises build smarter, faster, and more sustainably.

#prefabricated#prefabricated structure#prefabbuildings#peb#pre engineered building manufacturers#prefab#prefabconstruction

1 note

·

View note

Text

Engko: The Best Company for PUF Panels

Regarding high-quality PUF (Polyurethane Foam) panels, Engko stands out as the best company in the industry. With a reputation for excellence in manufacturing prefabricated railway shelters, PEB exhibition halls, and warehouses, Engko has become a trusted name for durable and energy-efficient PUF panels.

Why Choose Engko for PUF Panels?

1. Superior Quality Materials

Engko uses top-grade raw materials to manufacture PUF panels, ensuring high insulation, durability, and strength. These panels are designed to withstand extreme weather conditions while maintaining energy efficiency.

2. Advanced Manufacturing Technology

With state-of-the-art production facilities, Engko employs advanced technology to create precision-engineered PUF panels. This ensures consistency, uniform thickness, and superior bonding between layers.

3. Energy Efficiency & Thermal Insulation

PUF panels by Engko provide excellent thermal insulation, reducing energy costs for cooling and heating applications. This makes them an ideal choice for cold storage, industrial sheds, and commercial buildings.

4. Customizable Solutions

Engko offers a wide range of customization options, including panel thickness, dimensions, and coatings, catering to diverse industry requirements. Whether for commercial or industrial applications, Engko provides tailored solutions.

5. Quick & Hassle-Free Installation

Designed for easy assembly, Engko’s PUF panels enable quick installation, reducing labor costs and project timelines. Their lightweight structure and interlocking mechanism ensure seamless construction.

6. Eco-Friendly & Sustainable

Engko prioritizes sustainability by producing PUF panels that are environmentally friendly. These panels contribute to green building initiatives by enhancing energy efficiency and reducing carbon footprints.

7. Trusted by Industry Leaders

With a strong track record of successful projects, Engko has earned the trust of leading businesses across various sectors, including infrastructure, warehousing, and cold storage.

Applications of Engko PUF Panels

Cold Storage & Refrigeration

Prefabricated Buildings

Industrial & Commercial Warehouses

PEB Structures

Clean Rooms & Controlled Environments

Conclusion

For anyone looking for the best PUF panel company, Engko is the ultimate choice. With its commitment to quality, innovation, and customer satisfaction, Engko continues to lead the industry with top-notch solutions. Visit engko.co.in to learn more about their offerings and get in touch for your PUF panel requirements.

#pre engineered building manufacturers#peb#prefab#puf panel#porta cabin#prefabricated#industrial#warehouse#railway shelters

1 note

·

View note

Text

Engko: The No. 1 PEB Company in India

Pre-Engineered Buildings (PEBs) have emerged as the epitome of efficiency, innovation, and sustainability in the ever-evolving construction industry. Engko, India’s leading PEB company, has redefined the landscape with its state-of-the-art solutions, catering to a diverse range of industries and applications.

Why Choose PEB Solutions?

Pre-Engineered Buildings are revolutionizing the construction sector with their quick assembly, cost-efficiency, and versatility. Unlike conventional construction, PEB structures are manufactured off-site and assembled on-site, saving both time and resources. They are highly customizable, making them ideal for warehouses, exhibition halls, railway shelters, industrial units, and more.

What Makes Engko No. 1?

1. Expertise and Experience

With years of experience in the PEB industry, Engko has built a reputation for delivering unparalleled quality and innovative designs. Our skilled team of engineers and designers ensure that every project meets international standards and exceeds client expectations.

2. Diverse Product Range

Engko specializes in manufacturing a wide array of PEB structures, including:

Railway Shelters: Designed for durability and functionality, our shelters provide safe and comfortable spaces for commuters.

Exhibition Halls: Spacious, aesthetic, and adaptable to various themes and layouts.

Warehouses: Robust and efficient storage solutions tailored to client requirements.

3. Cutting-Edge Technology

Engko leverages the latest advancements in technology to design and manufacture PEBs. Our state-of-the-art facilities and precision engineering ensure that every component is flawless, resulting in structures that are resilient and long-lasting.

4. Sustainability at the Core

Sustainability is at the heart of Engko’s operations. By using recyclable materials and energy-efficient processes, we minimize environmental impact. Our PEBs are designed to reduce energy consumption, contributing to a greener future.

5. Customer-Centric Approach

At Engko, customer satisfaction is our top priority. From conceptualization to completion, we collaborate closely with our clients, ensuring that their vision comes to life. Our commitment to excellence and timely delivery has earned us the trust of clients across India.

Applications of Engko’s PEBs

Engko’s PEB structures are versatile and suitable for various sectors, including:

Industrial Facilities: Cost-effective and durable solutions for factories and manufacturing units.

Commercial Buildings: Modern and aesthetic designs for office spaces and retail outlets.

Agricultural Structures: Weather-resistant storage units and barns.

A Vision for the Future

Engko’s journey to becoming India’s No. 1 PEB company is fueled by innovation, commitment, and a vision to transform the construction industry. As we continue to expand our footprint across the nation, we remain dedicated to delivering excellence in every project.

Partner with Engko

Choosing Engko means choosing quality, efficiency, and reliability. Whether you need a railway shelter, an exhibition hall, or a peb warehouse, Engko has the expertise to bring your vision to life. Partner with us and experience the future of construction today.

For more information about our products and services, visit our website at www.engko.co.in.

#prefab#pre engineered building manufacturers#peb#prefabricated#warehouse#railway shelters#industrial#porta cabin#puf panel

1 note

·

View note

Text

Engko's PUF Panel Innovation: Building a Prefabricated Hospital in Patna

In a remarkable stride toward revolutionizing healthcare infrastructure, Engko is proud to announce the ongoing construction of a state-of-the-art prefabricated hospital in Patna. This project highlights our commitment to providing rapid, durable, cost-effective solutions for modern medical facilities, utilizing advanced PUF (Polyurethane Foam Filled) panels.

Why Prefabricated Hospitals?

Healthcare demands are ever-growing, and the need for scalable, adaptable, and quickly deployable medical facilities has never been more pressing. Prefabricated hospitals offer an ideal solution, enabling healthcare providers to establish high-quality facilities in record time without compromising functionality or safety.

The Project at a Glance

Location: Patna, Bihar, a rapidly growing city with a pressing demand for modern healthcare services.

Structure Type: Prefabricated hospital, fully customized to meet healthcare standards.

Core Material: PUFF panels, are known for their thermal insulation, durability, and eco-friendliness.

Timeline: Accelerated construction schedule, ensuring the hospital is operational in record time.

Key Features of Engko’s Prefabricated Hospital in Patna

Efficient Design: The hospital’s layout is meticulously planned to include specialized areas like operation theaters, patient wards, diagnostic zones, and administrative spaces. Each section is designed for maximum efficiency, ensuring smooth workflows for medical professionals.

PUFF Panels: The Backbone of the Project Our PUFF panels provide exceptional thermal insulation, crucial for maintaining sterile and controlled environments within healthcare facilities. These panels are lightweight yet robust, ensuring structural stability and energy efficiency.

Quick Assembly: The modular components are fabricated off-site, significantly reducing construction time. This method minimizes disruptions to the surrounding area and ensures rapid facility deployment.

Sustainability: Engko is committed to eco-friendly construction. PUFF panels generate minimal waste during production and assembly, and their energy-saving properties contribute to a sustainable operational model.

Tailored to Local Needs: Understanding the healthcare challenges of Patna, the facility is designed to cater to a broad spectrum of medical requirements, from routine checkups to critical care.

Benefits to the Patna Community

This prefabricated hospital will serve as a beacon of advanced medical care, bringing world-class healthcare services closer to the residents of Patna and nearby regions. Its rapid construction ensures timely availability of much-needed medical facilities, particularly in the face of growing population demands.

A Testament to Engko’s Expertise

Engko’s innovative approach to prefabricated construction positions us as a leader in the industry. Our experience in creating prefabricated structures, such as railway shelters and warehouses, provides the foundation for this ambitious project. The hospital in Patna is yet another milestone in our journey to redefine infrastructure development in India.

Looking Ahead

As the project progresses, we remain committed to delivering excellence. The prefabricated hospital in Patna is not just a building; it is a promise of hope, health, and innovation. Stay tuned for updates as we bring this vision to life and continue to make a difference through cutting-edge solutions.

For more information about our prefabricated hospital projects or to explore how Engko can support your infrastructure needs, visit us at engko.co.in.

1 note

·

View note

Text

Reimagining Office Spaces with Porta Cabins

In today’s fast-paced world, businesses constantly seek innovative solutions to meet their dynamic needs. One solution transforming the workspace landscape is porta cabins—portable, prefabricated structures offering flexibility, efficiency, and modern design. Let’s explore how these structures are revolutionizing office spaces.

Why Porta Cabins for Office Spaces?

Porta cabins are not just temporary shelters but a game-changer for companies seeking cost-effective, functional, and aesthetically pleasing office spaces. Here’s why:

1. Flexibility and Portability

Porta cabins are designed to adapt to your changing needs. Need to relocate your office? No problem! Porta cabins can be easily dismantled and moved to a new location without major logistical hassles.

2. Cost-Effective

Compared to traditional construction, porta cabins are significantly more affordable. They minimize labor costs, require less time to set up, and avoid the complexities of long-term construction projects.

3. Eco-Friendly

With sustainability being a key focus, porta cabins are crafted using eco-friendly materials and generate minimal construction waste. Many porta cabins also feature energy-efficient designs, making them a greener alternative.

4. Customization Options

Modern porta cabins offer customizable designs to suit your business requirements. Whether you need a single office unit, a multi-room setup, or even a co-working space, porta cabins can be tailored to match your vision.

Applications of Porta Cabins in Office Spaces

1. On-Site Offices for Construction Projects

Porta cabins are ideal for construction companies that require temporary offices near project sites. These cabins are quick to assemble and provide a fully functional workspace for site managers, engineers, and staff.

2. Start-Up Offices

For startups looking to minimize overhead costs, porta cabins offer an excellent solution. These structures can be set up in a matter of days, providing an immediate and professional workspace.

3. Co-Working Spaces

The trend of co-working spaces can also benefit from porta cabins. Modular and customizable, these cabins can house multiple businesses under one roof while maintaining individual identities.

4. Remote and Rural Offices

For businesses operating in remote areas, porta cabins provide an efficient and comfortable solution. From government outposts to NGO offices, these cabins ensure productivity regardless of location.

The Future of Office Spaces

As technology and design continue to evolve, porta cabins are becoming smarter and more sophisticated. Features like smart lighting, climate control, and modular interiors are being integrated to enhance functionality and comfort.

The rise of hybrid work models and the need for agile solutions further underscore the importance of flexible office spaces. Porta cabins are not just a temporary fix—they are a long-term solution for businesses looking to optimize their operations without compromising on quality.

Why Choose Engko for Your Porta Cabin Office?

At Engko, we specialize in designing and manufacturing premium-quality porta cabins tailored to your unique needs. With a focus on innovation, durability, and aesthetics, our cabins are built to redefine your workspace experience.

Whether you need a compact office or a large modular setup, Engko’s expertise ensures that your project is delivered on time and exceeds expectations.

Final Thoughts

Porta cabins are reshaping the way we think about office spaces. Their portability, affordability, and versatility make them a standout choice for businesses of all sizes. As the demand for adaptable workspaces grows, investing in a porta cabin could be the smart move your company needs.

Looking to transform your office? Explore Engko’s wide range of porta cabin solutions and take the first step toward a reimagined workspace!

Visit us at engko.co.in to learn more.

#prefab#pre engineered building manufacturers#industrial#prefabricated#porta cabin#prefabricated porta cabin

1 note

·

View note

Text

Engko Unveils New State-of-the-Art Warehouse Shed in Chennai

Engko, a leading name in prefabricated structures and PEB (Pre-Engineered Building) solutions, has added another feather to its cap by completing a cutting-edge warehouse shed project in Chennai. This latest achievement reinforces Engko’s commitment to delivering robust, efficient, and sustainable infrastructure solutions to industries across India.

Project Overview

The newly completed warehouse shed in Chennai is designed to meet the growing demands of modern logistics and industrial storage. Spanning over a substantial area, the structure exemplifies the perfect blend of durability, functionality, and contemporary design.

The warehouse features:

Advanced Steel Framework: Built with high-quality prefabricated steel components for unmatched strength and longevity.

Weather Resistance: The shed is engineered to withstand extreme climatic conditions, ensuring year-round protection for stored goods.

Spacious Layout: The optimized design provides ample space for seamless storage and movement, catering to industries such as manufacturing, e-commerce, and logistics.

Eco-Friendly Design: Incorporating sustainable practices, the warehouse includes provisions for natural lighting and ventilation, reducing energy consumption.

A Milestone in Innovation and Efficiency

Engko’s team of engineers and designers collaborated closely with the client to customize the project to their specific requirements. From initial planning to on-site execution, every phase was meticulously managed to ensure timely delivery without compromising quality.

The prefabrication approach not only accelerated the construction process but also minimized waste, highlighting Engko’s dedication to environmentally responsible practices.

Driving Progress in Chennai’s Industrial Landscape

This warehouse shed project aligns with the dynamic industrial growth in Chennai, a city that continues to thrive as a major business and logistics hub in India. By providing robust and reliable infrastructure, Engko empowers businesses to scale operations efficiently.

A Word from the Management

Speaking about the project, Ankit, HOD of Marketing at Engko, said: "At Engko, we aim to set new benchmarks in the prefabrication industry. This project in Chennai reflects our unwavering commitment to delivering innovative and sustainable infrastructure solutions that support our clients' growth."

Why Choose Engko?

Engko stands out for its:

Expertise in prefabricated and pre-engineered buildings.

Timely project delivery and cost-effectiveness.

Sustainable and customizable solutions tailored to client needs.

For more information about Engko’s projects or to explore how we can support your infrastructure needs, visit www.engko.co.in.

Engko’s warehouse project in Chennai is a testament to its vision of building the future of industrial infrastructure, one innovative solution at a time.

0 notes

Text

Sandwich Panels: Undisputed Viability in Prefabricated Construction

In the fast-paced world of modern construction, efficiency, sustainability, and cost-effectiveness are critical. Among the myriad of materials driving this revolution, sandwich puf panels have emerged as an undisputed leader in the prefabricated construction sector. With their remarkable structural properties, versatility, and eco-friendly benefits, sandwich panels are redefining the way we think about building design and implementation.

What are Sandwich Panels?

Sandwich panels are composite materials made up of three layers:

Outer Layers (Skin): Typically crafted from steel, aluminum, or other durable materials, providing rigidity and weather resistance.

Core Material: A lightweight insulating layer, often made from polyurethane (PU), polyisocyanurate (PIR), mineral wool, or expanded polystyrene (EPS).

Adhesive Layer: Ensures the outer layers are firmly bonded to the core, creating a unified, high-strength structure.

This layered design offers exceptional thermal insulation, structural stability, and aesthetic versatility, making sandwich panels a preferred choice for prefabricated buildings.

Key Advantages of Sandwich Panels in Prefabricated Construction

1. Thermal and Acoustic Insulation

Sandwich panels provide superior thermal insulation, reducing energy consumption in buildings. The insulated core minimizes heat transfer, keeping interiors cool in summer and warm in winter. Additionally, these panels offer excellent soundproofing, making them ideal for both industrial and commercial applications.

2. Lightweight and Durable

Despite their lightweight nature, sandwich panels boast exceptional strength, withstanding heavy loads and adverse weather conditions. Their low weight reduces transportation costs and eases installation, contributing to faster project timelines.

3. Quick and Easy Installation

Prefabricated sandwich panels are pre-engineered for swift assembly. Their modular design allows for seamless integration, significantly reducing construction time and labor costs.

4. Cost-Effective Solution

From material costs to long-term savings in energy and maintenance, sandwich panels provide an economically viable solution without compromising quality or performance.

5. Fire Resistance

Sandwich panels made from mineral wool or PIR cores offer excellent fire resistance, adhering to strict building safety standards. This makes them a safe choice for sensitive applications like data centers, warehouses, and healthcare facilities.

6. Sustainability

Many sandwich panels are recyclable and have a long lifecycle, contributing to sustainable construction practices. Their energy efficiency reduces carbon footprints, aligning with global green building initiatives.

Applications of Sandwich Panels in Prefabricated Construction

The versatility of sandwich panels allows their use in diverse construction projects:

Industrial Buildings: Industrial Warehouses, factories, and cold storage facilities.

Commercial Structures: Prefabricated offices, shopping centers, and showrooms.

Residential Projects: Modular homes and housing solutions.

Agricultural Applications: Poultry farms, barns, and storage units.

Cleanrooms and Laboratories: Spaces requiring controlled environments.

The Role of Sandwich Panels in Modern Construction Trends

1. Green Building Initiatives

With growing emphasis on sustainability, sandwich panels are playing a key role in energy-efficient and eco-friendly construction. Their ability to support renewable energy integration, like solar panels, further enhances their green credentials.

2. Resilient Construction

Sandwich panels meet the need for resilient building materials that withstand extreme weather conditions, earthquakes, and other environmental challenges.

3. Aesthetic Flexibility

Available in a variety of finishes, textures, and colors, sandwich panels can be customized to suit any architectural vision, merging functionality with design.

Future Prospects: Why Sandwich Panels are Here to Stay

As prefabricated construction continues to grow, the demand for innovative and reliable materials like sandwich panels will only increase. Technological advancements are improving their performance, cost-efficiency, and environmental impact, ensuring their relevance for years to come.

In the era of rapid urbanization and resource-conscious building practices, sandwich panels are an ideal solution for the construction industry’s evolving needs. Their undisputed viability lies not just in their physical attributes but also in their ability to meet modern challenges, from sustainability to speed of execution.

Conclusion Sandwich panels are a cornerstone of prefabricated construction, delivering unmatched benefits in thermal performance, durability, and design adaptability. Their role in creating efficient, cost-effective, and sustainable structures makes them an essential material for the future of construction.

By embracing sandwich panels, the construction industry is paving the way for smarter, greener, and faster building solutions. The question isn’t whether sandwich panels are viable—it’s how they’ll continue to transform the industry.

If you're considering sandwich panels for your next project, contact us at Engko to explore tailored solutions that meet your requirements.

#prefab#industrial#puf panel#prefabricated#pre engineered building manufacturers#porta cabin#warehouse#peb

1 note

·

View note

Text

Top 5 Reasons to Choose PUF Panels for Your Industrial Building

When it comes to selecting materials for industrial construction, PUF (Polyurethane Foam) panels have become a preferred choice for many builders and business owners. Their unique properties provide both functional and economic advantages. Here are the top five reasons to consider PUF panels for your next industrial building project:

1. Superior Thermal Insulation

One of the standout features of PUF panels is their excellent thermal insulation. The core material, polyurethane foam, has a low thermal conductivity, ensuring that industrial spaces remain cooler in summer and warmer in winter. This helps in reducing energy consumption significantly, leading to lower heating and cooling costs. For warehouses and facilities that need temperature control, this property is particularly beneficial

2. Quick and Easy Installation

Time is a crucial factor in any construction project, and PUF panels help expedite the process. These panels are lightweight and modular, allowing for rapid assembly compared to traditional construction methods. This quick installation process minimizes labor costs and reduces project timelines, allowing businesses to start operations sooner

3. Durability and Structural Strength

Despite their lightweight nature, PUF panels are designed to withstand harsh conditions. They possess a high strength-to-weight ratio, making them suitable for structures that face significant load or environmental stress. Additionally, their corrosion resistance adds to their durability, ensuring longevity even in challenging environments like coastal or industrial areas

4. Enhanced Fire Safety and Water Resistance

Modern PUF panels are developed to meet specific safety standards. They provide good fire resistance, especially if treated with flame-retardant materials, and are designed to prevent the spread of fire, adding an extra layer of safety to industrial buildings

Additionally, PUF panels are typically water-resistant, making them an excellent choice for areas with high humidity or potential water exposure

5. Cost-Effective Solution

When considering the total cost of construction, PUF panels prove to be a cost-effective option. They reduce the need for multiple materials (such as separate insulation and wall systems) and simplify the construction process, which leads to savings on both material and labor costs. Over time, their thermal efficiency also results in lower energy bills, providing long-term economic benefits

Conclusion

PUF panels are more than just a practical choice—they offer a combination of energy efficiency, speed of construction, and safety features that align well with the demands of a modern industrial warehouse. Their proven benefits in terms of insulation, installation speed, durability, safety, and cost make them a strong contender for any industrial construction project.

By choosing PUF panels, you're investing in a solution that not only meets current building standards but also promotes sustainability and long-term operational savings.

#industrial#prefab#pre engineered building manufacturers#puf panel#prefabricated#porta cabin#warehouse

1 note

·

View note

Text

Are PUF Sandwich Panels Improving How Cold Storage Solutions Work?

The need for efficient cold storage solutions has grown exponentially in today's fast-paced supply chain. Maintaining stable temperatures in storage facilities is crucial from pharmaceuticals to food preservation. In this context, PUF (Polyurethane Foam) sandwich panels have become increasingly popular for cold storage construction, offering several advantages that make them ideal for this industry. Let’s delve into how PUF sandwich panels revolutionize cold storage and enhance performance.

1. Superior Thermal Insulation

One of the most critical aspects of cold storage is maintaining consistent internal temperatures, regardless of external conditions. PUF sandwich panels are renowned for their excellent thermal insulation properties due to the high-density polyurethane foam core sandwiched between two metal sheets. This insulation reduces the amount of energy needed to maintain low temperatures, making it easier to achieve the desired temperature levels while reducing energy costs. With their superior R-values, PUF panels significantly outperform traditional building materials like concrete or bricks in terms of insulation.

2. Energy Efficiency and Cost Savings

Cold storage facilities are notorious for their high energy consumption. By using PUF sandwich panels, facility operators can save substantially on energy costs, as the panels minimize heat transfer. The reduced energy expenditure leads to lower operational costs, a benefit that is particularly valuable in industries that rely heavily on cold storage, such as food processing and pharmaceuticals. This energy efficiency also has a positive environmental impact by lowering greenhouse gas emissions associated with high energy usage.

3. Moisture and Vapour Resistance

Maintaining cold storage requires not only controlling temperature but also humidity levels. The design of PUF sandwich panels ensures high resistance to moisture ingress and vapor diffusion, which is essential for preventing condensation within the storage environment. Moisture resistance helps prevent mold growth, which could otherwise compromise product quality. Additionally, PUF panels reduce the risk of corrosion within the facility, extending the overall lifespan of the cold storage structure.

4. Structural Integrity and Durability

PUF sandwich panels are designed to provide structural stability without adding unnecessary weight to the building. They are lightweight, durable, and can withstand environmental stress, making them an excellent choice for various climates. PUF panels offer high structural integrity, which is particularly beneficial in industrial cold storage where reliable construction is essential. Their durability also means lower maintenance costs, contributing to the long-term cost-effectiveness of cold storage facilities.

5. Quick and Easy Installation

Time is a crucial factor when it comes to setting up cold storage facilities. PUF sandwich panels are pre-engineered and modular, making them easy and quick to install. This speed of installation not only saves time and labor costs but also allows facilities to become operational much faster, which is crucial for businesses that need a quick turnaround.

6. Hygiene and Cleanliness

Cold storage facilities must meet strict hygiene standards, especially in the food and pharmaceutical industries. PUF panels are easy to clean, and their smooth surface ensures there are no crevices for contaminants to accumulate. Additionally, PUF sandwich panels have antimicrobial properties, making them ideal for environments where strict hygiene control is essential.

7. Environmentally Friendly Solution

The polyurethane foam core in PUF panels is designed to have a low environmental impact, as many manufacturers use eco-friendly foam formulations. The panels themselves are recyclable, which means they contribute less waste over their lifecycle. Moreover, the energy savings achieved with PUF panels help reduce the carbon footprint of cold storage facilities, aligning with modern sustainability goals.

Conclusion

PUF sandwich panels are indeed transforming the landscape of cold storage solutions. By providing superior insulation, enhancing energy efficiency, resisting moisture, and offering ease of installation, they provide a holistic solution to the cold storage industry’s unique demands. With rising energy costs and an increased focus on sustainable construction, PUF sandwich panels offer a durable, cost-effective, and environmentally friendly solution for modern cold storage facilities.

For industries that rely heavily on temperature-sensitive storage, adopting PUF sandwich panels is a strategic move to improve performance and profitability. Whether for food preservation, pharmaceuticals, or chemical storage, PUF sandwich panels are proving to be an essential component of cutting-edge cold storage facilities.

#prefab#puf panel#pre engineered building manufacturers#porta cabin#prefabricated#industrial#cold storage

1 note

·

View note

Text

The Future of Construction: Why Prefabricated Structures by Engko are a Game-Changer

In today’s fast-paced world, efficiency and sustainability are critical in all industries, especially construction. The demand for quicker, eco-friendly, and cost-effective building solutions has given rise to prefabricated structures—a modern construction approach revolutionizing how we build. At Engko, we’re at the forefront of this innovation, delivering high-quality prefabricated railway shelters, PEB (Pre-Engineered Building) exhibition halls, and warehouses designed to meet the specific needs of our clients.

What Are Prefabricated Structures?

Prefabricated structures, often called prefabs, are buildings or sections of buildings that are manufactured off-site in a controlled environment. These components are then transported to the construction site for assembly. This method offers a wide range of advantages over traditional construction, making it a preferred choice for many sectors, including commercial, industrial, and institutional projects.

Why Choose Engko's Prefabricated Solutions?

At Engko, we understand that construction projects need to be efficient, reliable, and adaptable. Our prefabricated structures offer:

1. Faster Construction Time

Time is money, especially in construction. Prefabrication significantly reduces project timelines because the building components are produced off-site while the foundation is prepared. Once the components arrive, assembly is quick and seamless. This parallel process helps reduce overall construction time by up to 50%.

2. Cost-Effective

One of the biggest advantages of prefabricated structures is their cost efficiency. By reducing on-site labor, minimizing waste, and shortening project timelines, Engko helps you save both time and money. Our precision-engineered components ensure little to no material waste, and the controlled manufacturing environment minimizes the chances of costly errors.

3. Quality Control

Every component we produce is manufactured under strict quality control guidelines. Engko leverages cutting-edge technology and modern techniques to ensure that every element of our prefabricated structures is made to the highest standards. This level of precision is difficult to achieve with traditional on-site construction, where various external factors can affect the outcome.

4. Sustainability

Prefabrication is an eco-friendly construction method. Since the components are produced in a factory, we can minimize waste and reduce the carbon footprint of the construction process. Additionally, transporting materials to the site is more efficient, further reducing emissions. Engko is committed to sustainable practices and continually explores innovative ways to minimize environmental impact.

5. Customization & Flexibility

Our prefabricated structures are highly customizable, giving clients the freedom to design buildings according to their specific requirements. Whether you need a warehouse, an exhibition hall, or a railway shelter, Engko provides bespoke solutions tailored to your unique needs. Our designs are flexible, allowing for future expansions or modifications.

6. Durability

Despite the quick construction process, there is no compromise on quality or durability. Prefabricated structures by Engko are built to last, using high-strength materials that can withstand various environmental conditions. Our railway shelters, warehouses, and exhibition halls are designed to be structurally sound and resistant to wear and tear.

Applications of Engko’s Prefabricated Structures

Our prefabricated solutions are versatile and can be applied across various industries:

Railway Shelters: Engko’s prefabricated railway shelters offer quick installation and can be customized to suit specific station requirements. These shelters provide excellent protection from weather elements and ensure passenger comfort.

PEB Exhibition Halls: For events, trade shows, or large gatherings, Engko’s PEB exhibition halls offer a spacious and durable solution. These halls can be erected in a fraction of the time compared to conventional methods, allowing businesses to host events sooner.

Warehouses: Engko’s prefabricated warehouse manufacturers are designed for optimal storage solutions. These structures can be customized to include features such as insulation, ventilation, and climate control, ensuring the ideal environment for storing goods.

The Engko Difference

At Engko, we don’t just provide buildings; we provide solutions that streamline the construction process, reduce costs, and contribute to a greener future. Our team of experts works closely with clients to understand their needs and deliver tailor-made prefabricated structures that exceed expectations.

Innovation, reliability, and sustainability are at the heart of everything we do at Engko. As we continue to embrace new technologies and methods, we remain committed to pushing the boundaries of what’s possible in construction.

Build with Engko Today

If you’re looking for an efficient, sustainable, and high-quality building solution, Engko is your trusted partner in prefabricated structures. Let us help you bring your vision to life with our cutting-edge prefabricated railway shelters, PEB exhibition halls, and warehouses. Contact us today to discuss how we can make your next project a success.

#prefab#peb#pre engineered building manufacturers#industrial#puf panel#prefabricated#railway shelters#porta cabin#warehouse#security cabin

1 note

·

View note

Text

Engko Engineering: Revolutionizing Construction with Innovative Solutions

Engko Engineering Company is leading the charge with cutting-edge products designed to meet the diverse needs of modern industries. Specializing in Prefabricated Structures, PEB (Pre-Engineered Buildings), and advanced materials like PUF Panels, Engko delivers efficient, durable, and customizable solutions that redefine how we approach construction.

Here’s a closer look at some of the flagship products from Engko that are transforming industries:

1. PUF Panels: Energy-Efficient & Durable

Engko’s PUF (Polyurethane Foam) Panels are an industry favorite for their excellent thermal insulation, durability, and lightweight design. These panels are ideal for various applications, including cold storage units, warehouses, and clean rooms. PUF Panels from Engko are:

Highly Energy-Efficient: Excellent insulation properties help maintain temperatures and reduce the energy required for cooling or heating.

Fire Resistant: Our panels are built with fire safety in mind, providing extra protection for your facilities.

Eco-Friendly: Made with sustainable materials, they contribute to reducing the carbon footprint of any building project.

Whether you're constructing a cold room or a commercial space, Engko’s PUF Panels ensure strength and sustainability without compromising on aesthetics.

2. Porta Cabins: Portable, Flexible, and Cost-Effective

For industries in need of temporary yet durable structures, Porta Cabins from Engko are the perfect solution. These pre-fabricated, portable cabins are designed for versatility and can be used across various sectors, from construction sites to remote offices. Key features include:

Customization: Tailor-made to meet your exact needs, whether it's for accommodation, offices, or storage.

Mobility: Designed to be easily transported and reassembled at any location, ideal for temporary projects.

Durability: Built to withstand harsh environments, from extreme weather conditions to heavy industrial use.

Engko's Porta Cabins provide a cost-effective and time-efficient solution without compromising on quality or durability.

3. PEB Warehouses: Speedy Construction, Long-lasting Performance

When it comes to building large-scale warehouses or industrial buildings, PEB (Pre-Engineered Buildings) are the future of construction. Engko’s PEB Warehouses offer a range of benefits over conventional building methods:

Quick Installation: Pre-engineered components ensure faster construction times, reducing project timelines significantly.

Cost-Efficiency: Optimized design reduces material waste, saving both time and money.

Versatility: These structures can be customized for a variety of uses, from storage to manufacturing units.

Engko’s PEB Warehouses are designed for long-term durability, helping businesses expand their operations with minimal hassle.

4. Railway Shelters: Robust Solutions for Public Infrastructure

Engko specializes in the design and construction of Railway Shelters, providing sturdy and long-lasting protection for passengers and public assets. These shelters are:

Weather Resistant: Built to withstand extreme weather conditions, ensuring safety and comfort for users.

Customizable: We offer a variety of designs, from basic shelters to more complex structures, all tailored to meet specific site requirements.

Low Maintenance: Engineered for longevity, these shelters require minimal upkeep, ensuring long-term savings.

Engko’s Railway Shelters are a blend of functionality and aesthetics, providing essential infrastructure solutions for growing rail networks.

5. Clean Rooms: Precision-Engineered for Controlled Environments

For industries requiring highly controlled environments, such as pharmaceuticals, biotechnology, and electronics, Clean Rooms are essential. Engko’s clean room solutions are designed to meet the strictest hygiene and environmental control standards:

Contamination-Free Environment: Advanced air filtration and sealing techniques ensure a sterile workspace.

Modular Design: Our clean rooms are fully customizable and scalable, offering the flexibility to adapt to your changing needs.

Compliance: Built to meet international standards such as ISO and GMP, ensuring full regulatory compliance for sensitive industries.

Whether it's for research or production, Engko’s clean rooms provide the perfect solution for maintaining product quality and safety.

Why Choose Engko Engineering?

At Engko, we pride ourselves on delivering innovative, high-quality, and sustainable engineering solutions. Our expertise spans various industries, and we are committed to meeting the unique demands of each project with precision and professionalism.

Key Benefits:

Tailored Solutions: We design and manufacture products based on the specific needs of our clients, ensuring that each solution is fit for purpose.

Quick Turnaround: Our prefabricated approach allows for faster deployment and reduced construction times.

Quality Assurance: Each product undergoes rigorous testing and quality checks to meet international standards.

Engko Engineering continues to push the boundaries of what’s possible in the construction and engineering sectors. Whether you need durable shelters for railway stations, energy-efficient panels, or state-of-the-art clean rooms, Engko has the solution for you.

Contact Us today to discuss how we can help with your next project!

#prefab#peb#pre engineered building manufacturers#industrial#puf panel#prefabricated#railway shelters#porta cabin#warehouse#security cabin

1 note

·

View note

Text

What Are PUF Panels? A Comprehensive Guide

In modern construction, innovation is key to building strong, durable structures that are energy-efficient and versatile. One of the materials revolutionizing the construction industry is the PUF panel. Whether you are constructing a commercial facility, an industrial warehouse, or a prefabricated building, PUF panels offer a cost-effective, efficient, and sustainable solution. But what exactly are PUF panels? Let’s dive into their world and explore their benefits and applications.

What are PUF Panels?

PUF stands for Polyurethane Foam, a thermoset plastic known for its excellent thermal insulation properties. PUF panels consist of a core layer of rigid polyurethane foam sandwiched between two outer layers, typically made from metal sheets such as steel or aluminum. These panels are lightweight, easy to install, and highly durable, making them a popular choice in various construction projects.

The Composition of PUF Panels

PUF panels have a three-layered structure:

Outer Layers: These are typically made from galvanized iron (GI), aluminum, or stainless steel sheets that provide strength, durability, and protection from environmental factors like corrosion, UV radiation, and physical impacts.

Core Layer: The core consists of a rigid polyurethane foam that offers excellent insulation properties, reducing heat transmission and helping maintain a stable indoor temperature.

Protective Coating: Many PUF panels come with an additional coating on the metal sheets for added protection against weather, fire, or chemicals.

Key Features of PUF Panels

Thermal Insulation: One of the most important properties of PUF panels is their ability to provide high thermal insulation. This reduces energy consumption for heating and cooling, making them ideal for environments where temperature control is crucial.

Lightweight: Despite being strong, PUF panels are lightweight, which makes them easy to transport, handle, and install. This reduces construction time and labor costs.

Fire-Resistant: Many PUF panels are designed with fire-resistant properties, adding an extra layer of safety to buildings.

Sound Insulation: In addition to thermal insulation, PUF panels also offer excellent soundproofing, making them suitable for noise-sensitive areas such as offices, schools, and hospitals.

Durability: The combination of a strong outer metal layer and a rigid foam core ensures that PUF panels are long-lasting and can withstand various environmental challenges, including moisture, corrosion, and extreme temperatures.

Customizable: PUF panels come in a variety of sizes, thicknesses, and finishes, allowing for customization based on specific project needs.

Applications of PUF Panels

PUF panels have found widespread applications across various industries due to their versatility and effectiveness. Some of the most common uses include:

Cold Storage and Refrigeration Units: The superior insulation properties of PUF panels make them ideal for cold storage units, food processing industries, and refrigerated warehouses.

Prefabricated Buildings: PUF panels are widely used in modular and prefabricated structures, including offices, homes, shelters, and exhibition halls. Their lightweight nature and ease of installation help speed up construction times.

Roofing and Cladding: PUF panels are often used as roofing and cladding materials in industrial and commercial buildings due to their durability, insulation properties, and ability to withstand harsh weather conditions.

Clean Rooms: In industries like pharmaceuticals and electronics, where controlled environments are crucial, PUF panels are used to create clean rooms with precise temperature and humidity controls.

Temporary and Permanent Structures: From exhibition halls and auditoriums to warehouses and factory sheds, PUF panels are used for building both temporary and permanent structures with ease.

Benefits of PUF Panels

Energy Efficiency: The insulation provided by PUF panels helps reduce the need for artificial heating and cooling, which in turn lowers energy consumption and costs.

Faster Construction: Being lightweight and easy to install, PUF panels significantly reduce construction time, helping to meet tight deadlines.

Cost-Effective: PUF panels offer long-term savings by minimizing maintenance costs, reducing energy bills, and ensuring durability.

Eco-Friendly: The reduced energy consumption makes PUF panels an environmentally friendly option. Many panels are also recyclable, further adding to their eco-friendly nature.

Versatility: These panels are suitable for a wide range of applications, from residential and commercial buildings to specialized industrial uses.

Conclusion

PUF panels are a game-changer in the construction industry, offering a host of benefits such as thermal insulation, durability, and versatility. Whether you're looking to build an energy-efficient office space, cold storage facility, or a prefabricated exhibition hall, PUF panels provide a reliable and cost-effective solution.

By combining performance with sustainability, they not only meet today’s construction needs but also contribute to a greener future.

#puf panel#prefab#pre engineered building manufacturers#warehouse#prefabricated#industrial#peb#porta cabin#railway shelters#security cabin

1 note

·

View note

Text

Discover the Versatility and Quality of Engko’s Innovative Solutions

At Engko, we take pride in offering a diverse range of high-quality products designed to meet the evolving needs of various industries. Our innovative solutions, including PUF panels, railway shelters, porta cabins, pre-engineered buildings (PEBs), and warehouses, are built with precision and a commitment to excellence. In this blog, we'll explore the unique features and benefits of each product, showcasing why Engko is the go-to choice for durable, efficient, and customizable building solutions.

PUF Panels: The Perfect Insulation Solution

PUF Panels, or Polyurethane Foam Panels, are an ideal choice for efficient insulation in both commercial and residential buildings. Our PUF panels offer:

Superior Thermal Insulation: Excellent energy-saving capabilities reduce heating and cooling costs.

Lightweight and Durable: Easy to handle and install, yet robust enough to withstand various environmental conditions.

Versatility: Suitable for walls, roofs, and cold storage facilities, among other applications.

Eco-friendly: Made with sustainable materials, contributing to a greener environment.

Railway Shelters: Comfort and Safety for Passengers

Engko's Railway Shelters are designed to provide passengers with comfort and protection while waiting for their trains. Our shelters feature:

Durability: Constructed from high-quality materials to withstand harsh weather and heavy use.

Customizable Designs: Available in various sizes, styles, and colors to match the specific needs of different railway stations.

Quick Installation: Prefabricated components ensure fast and easy assembly.

Passenger Amenities: Options for seating, lighting, heating, and cooling enhance passenger comfort.

Porta Cabins: Flexible and Portable Spaces

Our Porta Cabins are versatile solutions for temporary or permanent space requirements. These portable structures are perfect for offices, site accommodations, classrooms, and more. Key features include:

Mobility: Easily transportable and relocatable to different sites as needed.

Customizable Interiors: Tailored to meet specific functional needs, with options for plumbing, electrical fittings, and more.

Sturdy Construction: Built to withstand tough environmental conditions, ensuring longevity and safety.

Cost-Effective: Affordable solutions with quick setup times, minimizing downtime.

Pre-Engineered Buildings (PEBs): Efficient and Economical

Engko's Pre-Engineered Buildings (PEBs) offer an efficient and economical alternative to traditional construction. Our PEBs provide:

Design Flexibility: Customizable to suit various applications, from industrial warehouses to commercial complexes.

Speedy Construction: Reduced construction time due to prefabricated components.

Cost Savings: Lower overall costs compared to conventional building methods.

High Quality: Adherence to strict quality standards ensures durability and structural integrity.

Warehouses: Optimized Storage Solutions

Our Warehouses are designed to meet the storage needs of diverse industries. Engko warehouses are characterized by:

Space Optimization: Efficient layouts and design maximize storage capacity and operational efficiency.

Durability: High-quality materials and construction techniques ensure long-lasting performance.

Customization: Tailored to specific storage requirements, including temperature control, shelving systems, and more.

Ease of Maintenance: Designed for easy upkeep, ensuring a clean and organized storage environment.

Why Choose Engko?

Engko is committed to delivering innovative, reliable, and high-quality solutions for various building needs. Our products are designed with the end-user in mind, ensuring functionality, durability, and aesthetic appeal. With a focus on customer satisfaction, we provide comprehensive support from design to installation, making the entire process seamless and efficient.

Whether you need PUF panels for insulation, railway shelters for passenger comfort, porta cabins for flexible spaces, PEBs for cost-effective construction, or warehouses for optimized storage, Engko has the perfect solution for you. Explore our product range today and discover why Engko is a trusted name in the industry.

For more information or to request a quote, visit our website or contact our sales team. Let Engko be your partner in building the future

#puf panel#pre engineered building manufacturers#railway shelters#porta cabin#warehouse#prefabricated#prefab#peb

1 note

·

View note