#puf panel manufacturers

Text

PUF Panels and Sandwich Panels: Applications Across Industries

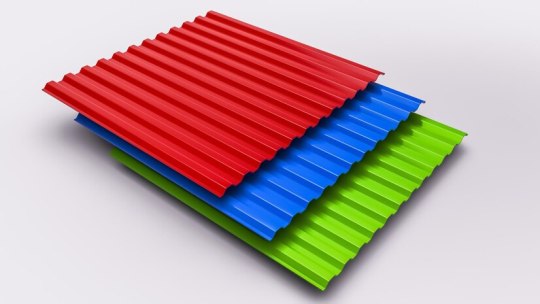

Efficiency, durability, and versatility are essential in the realms of construction and industrial design. One innovation that has revolutionized these aspects is the introduction of Polyurethane Foam (PUF) panels and sandwich panels. These composite materials, consisting of a core sandwiched between two outer layers, offer numerous advantages and are widely used across various industries. In this text, we will explore the different areas where PUF panels and sandwich panels are commonly applied.

Cold Storage and Refrigeration: PUF panels excel in thermal insulation properties, making them ideal for cold storage facilities and refrigeration units. These panels create an efficient barrier against temperature fluctuations, helping to maintain the desired temperature inside the storage area. From food processing plants to pharmaceutical storage facilities, PUF panels ensure the integrity and freshness of perishable goods.

Commercial and Industrial Buildings: The versatility of PUF panels and sandwich panels extends to the realm of commercial and prefab construction. These panels are widely used for roofing, wall cladding, and partitioning in warehouse manufacturers, factories, workshops, and offices. Their lightweight nature facilitates quick installation, reducing construction time and costs. Moreover, their excellent insulation properties contribute to energy efficiency, leading to reduced heating and cooling expenses.

Modular Construction: The modular construction industry heavily relies on PUF panels and sandwich panels for their prefabricated structures. Whether it's modular homes, portable cabins, or temporary shelters, these panels offer a convenient solution for rapid assembly and disassembly. The modular nature of PUF panels allows for easy customization, enabling architects and designers to create versatile spaces tailored to specific needs.

Transportation Sector: PUF panels play a vital role in the transportation sector, particularly in the construction of refrigerated trucks, vans, and containers. These panels help to create insulated compartments that safeguard perishable goods during transit. Additionally, sandwich panels find applications in the aerospace industry for aircraft interiors, providing lightweight yet robust solutions for cabin walls and partitions.

Clean Rooms and Laboratories: Precision-controlled environments such as clean rooms and laboratories require stringent temperature and contamination control. PUF panels offer an ideal solution due to their ability to create airtight enclosures with superior insulation properties. These panels help maintain stable environmental conditions necessary for sensitive manufacturing processes, research, and testing activities.

Agricultural Sector: In agriculture, PUF panels are utilized for constructing storage facilities, cold rooms, and greenhouses. These panels help farmers and growers extend the shelf life of their produce by providing an insulated environment conducive to preservation. Additionally, sandwich panels are employed in livestock housing, offering comfortable and hygienic shelters for animals.

Conclusion: PUF panels and sandwich panels have emerged as indispensable materials across a myriad of industries, thanks to their exceptional thermal insulation, structural strength, and versatility. From cold storage facilities to commercial buildings, from transportation to clean room environments, the applications of these panels are diverse and far-reaching. As technology continues to advance, we can expect further innovations in the design and utilization of PUF panels, driving efficiency, sustainability, and performance across various sectors.

1 note

·

View note

Text

Puf Panels

One of the key advantages of Engko Puf panels is is their lightweight nature coupled with high strength. This makes them easy to handle and install, saving time and labor during construction. Despite their light weight, PUF panels are incredibly durable and can withstand various environmental conditions, including extreme temperatures, moisture, and corrosion. As a result, buildings constructed using PUF panels are resilient and long-lasting.

0 notes

Text

What innovative features are offered by leading PUF Sandwich Panel manufacturers

In the ever-evolving world of construction, innovation is the key to success. At Isoflex, we understand the importance of staying ahead of the curve, which is why we're proud to offer a range of PUF (Polyurethane Foam) Sandwich Panels that are redefining the industry standards. As leading PUF Sandwich panel manufacturers, we're committed to delivering top-notch solutions that not only meet but exceed our customers' expectations. With decades of experience and a passion for excellence, we have become synonymous with quality, reliability, and innovation in the construction industry. Let's delve into the innovative features that set our panels apart.

Thermal Efficiency:

One of the standout features of Isoflex's PUF Sandwich Panels is their exceptional thermal efficiency. By utilizing advanced manufacturing techniques and high-quality materials, our panels provide superior insulation properties, ensuring optimal energy efficiency for buildings. Whether it's extreme cold or scorching heat, our panels help maintain a comfortable interior environment while significantly reducing heating and cooling costs.

Lightweight yet Durable:

Traditional building materials often come with a trade-off between weight and durability. However, Isoflex's PUF Sandwich Panels offer the perfect balance of both. Constructed using lightweight yet robust materials, our panels are easy to handle and install, resulting in faster construction times and reduced labour costs. Despite their lightweight nature, they boast remarkable durability, ensuring long-lasting performance and structural integrity.

Fire Resistance:

Safety is paramount in any construction project, which is why our PUF Sandwich Panels are engineered with fire resistance in mind. Designed to withstand high temperatures and inhibit the spread of flames, our panels provide an added layer of protection for buildings and their occupants. With Isoflex panels, you can have peace of mind knowing that your structure is equipped with top-of-the-line fire-resistant materials.

Customization Options:

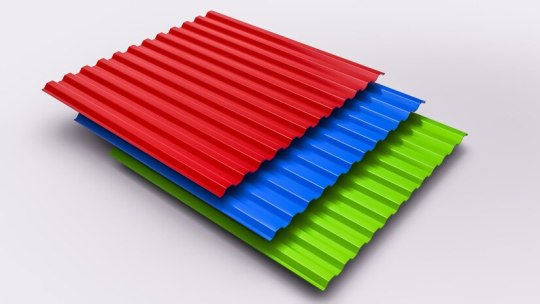

At Isoflex, we understand that every project is unique, which is why we offer a wide range of customization options for our PUF Sandwich Panels. From varying thicknesses and sizes to an array of colours and finishes, we empower our customers to tailor our panels to their specific requirements and aesthetic preferences. Whether it's a commercial complex, industrial facility, or residential building, we have the perfect solution to suit your needs.

Eco-Friendly Construction:

As a responsible manufacturer, we are committed to sustainability and environmental stewardship. Our PUF Sandwich Panels are manufactured using eco-friendly processes and materials, minimizing carbon footprint and reducing environmental impact. By choosing our panels, you're not just investing in high-quality construction materials; you're also contributing to a greener, more sustainable future for generations to come.

Seamless Integration with Building Systems:

In today's interconnected world, seamless integration with building systems is essential. Isoflex's PUF Sandwich Panels are designed with compatibility in mind, allowing for easy integration with various building systems such as HVAC, electrical, and plumbing. Whether it's retrofitting an existing structure or constructing a new building from scratch, our panels facilitate hassle-free installation and integration, saving time and resources for contractors and builders.

Conclusion:

Innovation is at the heart of everything we do at Isoflex, and our PUF Sandwich Panels are a testament to that commitment. With unmatched thermal efficiency, lightweight yet durable construction, fire resistance, customization options, eco-friendliness, and seamless integration, our panels are setting new standards in the construction industry. As leading PUF Sandwich panel manufacturers, we take pride in delivering cutting-edge solutions that empower our customers to build safer, more efficient, and sustainable structures. Choose Isoflex for your next construction project and experience the difference firsthand. With us, the future of construction is brighter than ever before.

0 notes

Text

Puf Panel Manufacturers in UAE: Why MAK Prefab Steel Contracting LLC is the Go-To Choice

One of the most well-known Puf Panel Manufacturers in the UAE is MAK Prefab Steel Contracting LLC. The business specialises in the creation and manufacture of premium insulated panels, which are frequently used in the construction of different buildings like warehouses, cold storage facilities, and clean rooms. We'll go over the advantages of using Puf Panels in this blog article, along with the explanations for why MAK Prefab Steel Contracting LLC is the preferred supplier of Puf Panels in the UAE. Read more : https://medium.com/@makprefab121/puf-panel-manufacturers-in-uae-why-mak-prefab-steel-contracting-llc-is-the-go-to-choice-9e0c88417251

0 notes

Text

Energy Efficiency and Clean Room Doors: Saving Costs Without Compromising Quality

In today's competitive marketplace, businesses are constantly searching for ways to reduce operational costs while maintaining high standards of quality and efficiency. One critical area where companies can achieve significant savings is in their energy consumption. Investing in high-quality clean room doors is a smart move for industries that rely on controlled environments, such as pharmaceuticals, biotechnology, food processing, and electronics manufacturing. Isoflex, a reputable Clean Room Doors Manufacturers, offers solutions that enhance energy efficiency and uphold the stringent standards required in these environments.

The Importance of Clean Room Doors in Controlled Environments

Clean rooms are specialized environments that minimize contamination from airborne particles, microorganisms, and other pollutants. They are essential in various industries where even the smallest contamination can lead to significant product defects, health risks, or regulatory non-compliance. Clean room doors play a vital role in maintaining these controlled conditions by providing a barrier that prevents the ingress of contaminants and helps regulate internal environments.

Energy Efficiency: A Key Consideration

Energy consumption is one of the most pressing concerns for businesses operating clean rooms. Clean rooms typically require extensive HVAC systems to maintain specific temperature, humidity, and particulate levels. These systems can be energy-intensive, leading to high operational costs. However, by investing in high-quality clean room doors from reputable manufacturers like Isoflex, businesses can significantly enhance their energy efficiency and reduce costs.

How Isoflex Clean Room Doors Enhance Energy Efficiency

Isoflex clean room doors are engineered with energy efficiency in mind. Here are several ways in which our doors contribute to energy savings:

Superior Insulation

Isoflex clean room doors are constructed using advanced materials that provide superior insulation. This insulation minimizes heat transfer between the clean room and adjacent areas, reducing the load on HVAC systems. As a result, less energy is required to maintain the desired environmental conditions within the clean room.

Airtight Seals

Our clean room doors are designed with high-performance seals that ensure airtight closure. These seals prevent the leakage of conditioned air, maintaining consistent temperature and humidity levels inside the clean room. Isoflex doors reduce the energy required to compensate for temperature fluctuations by preventing air exchange with the outside environment.

Durable and Reliable Construction

Isoflex doors are built to withstand the demanding conditions of clean room environments. Their durability ensures long-term performance with minimal maintenance. Reliable doors that maintain their integrity over time reduce the need for frequent replacements or repairs, further contributing to cost savings and energy efficiency.

Cost Savings Without Compromising Quality

While the primary focus is often on energy savings, these savings mustn't come at the expense of quality. Isoflex clean room doors offer the perfect balance between cost-effectiveness and uncompromised quality.

Compliance with Standards

Isoflex clean room doors are designed to meet or exceed industry cleanliness and environmental control standards. They comply with regulations such as ISO 14644, which specifies the requirements for clean rooms and associated controlled environments. Investing in doors that meet these standards ensures that your cleanroom operations remain compliant and efficient.

Enhanced Operational Efficiency

High-quality clean room doors from Isoflex enhance overall operational efficiency. With features such as smooth and reliable opening mechanisms, our doors facilitate easy access while maintaining the integrity of the controlled environment. This ease of use reduces downtime and increases productivity, leading to cost savings over time.

Customization for Specific Needs

Every clean room has unique requirements, and Isoflex understands the importance of providing customized solutions. Our clean room doors can be tailored to fit specific dimensions, configurations, and operational needs. This customization ensures you get a product that perfectly suits your application, maximizing efficiency and cost-effectiveness.

Why Choose Isoflex?

When it comes to clean room doors manufacturers, Isoflex stands out for several reasons:

Expertise and Experience

With years of experience in the industry, Isoflex has developed a deep understanding of the needs and challenges faced by cleanroom operators. Our expertise allows us to design and manufacture doors that meet the highest performance and reliability standards.

Commitment to Quality

Quality is at the core of everything we do at Isoflex. From the selection of materials to the manufacturing process and final inspection, we maintain stringent quality control measures to ensure that our products exceed customer expectations.

Comprehensive Support

Isoflex offers comprehensive support to our customers, from initial consultation and design to installation and maintenance. Our team of experts is always available to provide guidance and assistance, ensuring you get the most out of your investment.

Conclusion

Investing in high-quality, clean room doors is a strategic decision that can lead to significant energy savings and cost reductions without compromising the quality of your controlled environment. Isoflex, a reputable manufacturer of clean room doors, offers solutions that provide superior insulation, airtight seals, and durable construction. Our doors are designed to enhance operational efficiency, comply with industry standards, and can be customized to meet your specific needs.

By choosing Isoflex clean room doors, you are making a smart investment in your business's future. Our commitment to quality, expertise, and comprehensive support ensures you receive a product that meets and exceeds your expectations. Make the switch to Isoflex clean room doors today and start saving on energy costs while maintaining the highest standards of quality and efficiency.

For more information about our products and how they can benefit your operations, please visit our website or contact our sales team. Isoflex is here to help you achieve your energy efficiency goals and ensure the success of your cleanroom operations.

0 notes

Text

Cost-Effectiveness of PUF Sandwich Panels in Construction Projects

The construction industry continually evolves, with new materials and techniques being developed to improve efficiency, sustainability, and cost-effectiveness. One such innovation that has gained significant traction is using PUF (Polyurethane Foam) sandwich panels. These panels, produced byIsoflex, a reputable PUF Sandwich Panels Manufacturer, offer many benefits that make them a preferred choice for modern construction projects. This blog will delve into the cost-effectiveness of PUF sandwich panels and explore why they are becoming an integral part of contemporary construction practices.

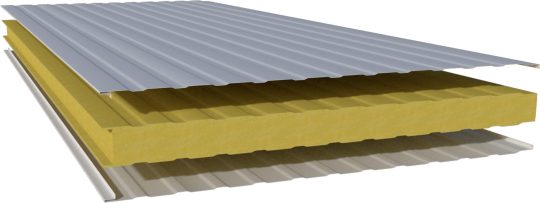

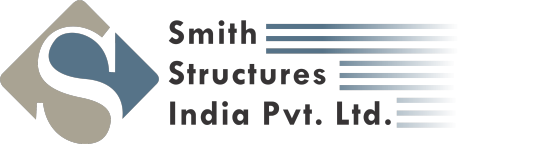

Understanding PUF Sandwich Panels

PUF sandwich panels are composite materials of a lightweight core material, typically polyurethane foam, sandwiched between two layers of durable facing materials such as galvanized steel, aluminium, or other metal sheets. This configuration provides an excellent combination of strength, thermal insulation, and lightweight properties, making them ideal for various applications in the construction industry.

Key Benefits of PUF Sandwich Panels

Before diving into their cost-effectiveness, it's essential to understand the key benefits that PUF sandwich panels offer:

Thermal Insulation: PUF sandwich panels have superior thermal insulation properties, which can significantly reduce heating and cooling costs in buildings.

Lightweight: Despite their strength, these panels are lightweight, reducing the structural load on buildings and simplifying transportation and installation.

Durability: The materials used in PUF sandwich panels are highly durable and resistant to weathering, corrosion, and other environmental factors.

Quick Installation: These panels' modular nature allows for rapid installation,

reducing Labour costs and construction timelines.

Fire Resistance: Many PUF sandwich panels are designed with fire-resistant properties, enhancing the safety of buildings.

Cost-Effectiveness of PUF Sandwich Panels

When evaluating the cost-effectiveness of any construction material, it's crucial to consider both the initial investment and the long-term savings. PUF Sandwich panels excel in both areas, making them a financially savvy choice for construction projects.

Initial Investment

While the upfront cost of PUF sandwich panels might be higher than some traditional materials, their overall value becomes evident when considering the following factors:

Reduced Structural Costs: The lightweight nature of PUF sandwich panels means that buildings require less structural support, leading to savings on foundational materials and labour.

Lower Transportation Costs: Due to their lightweight, transportation costs are significantly lower compared to traditional building materials.

Simplified Installation: The ease of installation reduces labour costs and shortens the construction timeline, leading to faster project completion and earlier occupancy.

Long-Term Savings

The long-term savings associated with PUF sandwich panels are substantial and contribute to their overall cost-effectiveness:

Energy Efficiency: The superior thermal insulation properties of PUF sandwich panels result in significant energy savings.

Maintenance Costs: The durability and resistance to environmental factors mean that buildings constructed with PUF sandwich panels require less maintenance and have a longer lifespan.

Sustainability: Many PUF sandwich panels are made with eco-friendly materials and processes, which can contribute to green building certifications and potential tax incentives.

Applications of PUF Sandwich Panels

The versatility of PUF sandwich panels allows them to be used in various construction projects. Some common applications include:

Commercial Buildings: Office complexes, shopping centers, and warehouses benefit from the energy efficiency and quick installation of PUF sandwich panels.

Residential Buildings: Homes and apartment complexes can achieve better insulation and reduced energy costs with these panels.

Cold Storage: The excellent thermal properties make PUF sandwich panels ideal for cold storage facilities and refrigeration units.

Industrial Buildings: Factories and industrial units require durable and low-maintenance materials, making PUF sandwich panels a suitable choice.

Conclusion

PUF Sandwich panels represent a cost-effective, efficient, and sustainable solution for modern construction projects. Their superior thermal insulation, durability, and lightweight properties make them a valuable addition to any building, offering both initial cost savings and long-term financial benefits. By partnering with Isoflex, a reputable PUF Sandwich Panels Manufacturer, construction companies can use high-quality materials that enhance their projects' overall performance and cost-effectiveness.

The adoption of PUF sandwich panels is not just a trend but a smart investment towards building a more sustainable and economically viable future. Whether for commercial, residential, or industrial applications, these panels offer unmatched benefits that make them a cornerstone of modern construction practices. As the industry continues to evolve, the role of innovative materials like PUF sandwich panels will only become more prominent, driving the construction sector towards greater efficiency and sustainability.

0 notes

Text

Cost-Effectiveness of PUF Sandwich Panels in Construction Projects

The construction industry continually evolves, with new materials and techniques being developed to improve efficiency, sustainability, and cost-effectiveness. One such innovation that has gained significant traction is using PUF (Polyurethane Foam) sandwich panels. These panels, produced by Isoflex, a reputable PUF Sandwich Panels Manufacturer, offer many benefits that make them a preferred choice for modern construction projects. This blog will delve into the cost-effectiveness of PUF sandwich panels and explore why they are becoming an integral part of contemporary construction practices.

Understanding PUF Sandwich Panels

PUF sandwich panels are composite materials of a lightweight core material, typically polyurethane foam, sandwiched between two layers of durable facing materials such as galvanized steel, aluminium, or other metal sheets. This configuration provides an excellent combination of strength, thermal insulation, and lightweight properties, making them ideal for various applications in the construction industry.

Key Benefits of PUF Sandwich Panels

Before diving into their cost-effectiveness, it's essential to understand the key benefits that PUF sandwich panels offer:

Thermal Insulation: PUF sandwich panels have superior thermal insulation properties, which can significantly reduce heating and cooling costs in buildings.

Lightweight: Despite their strength, these panels are lightweight, reducing the structural load on buildings and simplifying transportation and installation.

Durability: The materials used in PUF sandwich panels are highly durable and resistant to weathering, corrosion, and other environmental factors.

Quick Installation: These panels' modular nature allows for rapid installation,

reducing Labour costs and construction timelines.

Fire Resistance: Many PUF sandwich panels are designed with fire-resistant properties, enhancing the safety of buildings.

Cost-Effectiveness of PUF Sandwich Panels

When evaluating the cost-effectiveness of any construction material, it's crucial to consider both the initial investment and the long-term savings. PUF Sandwich panels excel in both areas, making them a financially savvy choice for construction projects.

Initial Investment

While the upfront cost of PUF sandwich panels might be higher than some traditional materials, their overall value becomes evident when considering the following factors:

Reduced Structural Costs: The lightweight nature of PUF sandwich panels means that buildings require less structural support, leading to savings on foundational materials and labour.

Lower Transportation Costs: Due to their lightweight, transportation costs are significantly lower compared to traditional building materials.

Simplified Installation: The ease of installation reduces labour costs and shortens the construction timeline, leading to faster project completion and earlier occupancy.

Long-Term Savings

The long-term savings associated with PUF sandwich panels are substantial and contribute to their overall cost-effectiveness:

Energy Efficiency: The superior thermal insulation properties of PUF sandwich panels result in significant energy savings.

Maintenance Costs: The durability and resistance to environmental factors mean that buildings constructed with PUF sandwich panels require less maintenance and have a longer lifespan.

Sustainability: Many PUF sandwich panels are made with eco-friendly materials and processes, which can contribute to green building certifications and potential tax incentives.

Applications of PUF Sandwich Panels

The versatility of PUF sandwich panels allows them to be used in various construction projects. Some common applications include:

Commercial Buildings: Office complexes, shopping centers, and warehouses benefit from the energy efficiency and quick installation of PUF sandwich panels.

Residential Buildings: Homes and apartment complexes can achieve better insulation and reduced energy costs with these panels.

Cold Storage: The excellent thermal properties make PUF sandwich panels ideal for cold storage facilities and refrigeration units.

Industrial Buildings: Factories and industrial units require durable and low-maintenance materials, making PUF sandwich panels a suitable choice.

Conclusion

PUF Sandwich panels represent a cost-effective, efficient, and sustainable solution for modern construction projects. Their superior thermal insulation, durability, and lightweight properties make them a valuable addition to any building, offering both initial cost savings and long-term financial benefits. By partnering with Isoflex, a reputable PUF Sandwich Panels Manufacturer, construction companies can use high-quality materials that enhance their projects' overall performance and cost-effectiveness.

The adoption of PUF sandwich panels is not just a trend but a smart investment towards building a more sustainable and economically viable future. Whether for commercial, residential, or industrial applications, these panels offer unmatched benefits that make them a cornerstone of modern construction practices. As the industry continues to evolve, the role of innovative materials like PUF sandwich panels will only become more prominent, driving the construction sector towards greater efficiency and sustainability.

0 notes

Text

Your Guide to PUF Panel Portable Cabin and Their Advantages

If you work in construction or any other profession where you need temporary office space on a building site, you understand how important it is to have a workspace that is both practical and comfortable. A movable cabin is among the greatest options for a site office. Numerous advantages that these cabins provide might improve the effectiveness and productivity of your work location.

What materials make up the PUF Panel Portable Cabin?

The polyurethane PUF Panel is a sandwiched panel. It is two metal sheets layered on top of a polyurethane sheet. They come in a range of sizes and can be utilized in industrial environments. They are incredibly adaptable and may be tailored to the needs of the client. Additionally, PUF panels are perfect for cold storage and banana ripening because of their excellent insulating qualities.

Benefits Of A PUF Panel Portable Cabin

Follow are the top benefits of PUF Panel Portable Cabin:

Diminished expense

A less expensive option to a permanent building is a prefabricated site office. Because they use the same production line for multiple projects, vendors typically offer lower prices. Bulk purchases of materials also result in lower costs.

Thermal efficiency and energy conservation

A layer of polyurethane foam is present in PUF panels, and it acts as an insulator between the metal. Additionally, the low heat conductivity of PUF panels might help you save up to 50% on energy costs a year.

https://www.abuildtech.com/porta-cabin.aspx PUF panels are long-lasting, incredibly strong, and durable. Because of this, it is resistant to corrosion and able to withstand harsh weather.

Simple setup

Because PUF panels are quick and easy to install, remove, and reinstall, they are an excellent choice for foundations, roofs, external walls, warehouses, storage units, cubicles, food processing units, and other constructions.

Command over the safety

For on-site work, security is an additional benefit of employing porta cabins. Project holders gain greater control over the project's security with a swiftly constructed on-site office. You receive room for document storage, CCTV footage monitoring, maintaining security personnel, and much more.

Best Portable Cabin Manufacturer in India

Abuild Tech is the best option for you if you're searching for a reputable Portable Cabin Manufacturer in India. Being a top producer of portable cabin offices, they are dedicated to providing specialized solutions that satisfy your unique needs.

Using the newest materials and technologies, their team of knowledgeable and experienced specialists creates a variety of structures, including labor colonies, farmhouses, servant rooms, site offices, and porta cabin homes. PUF panel porta cabins, Everest panel porta cabins, G+1 porta cabins, PVC porta cabin site offices, and Aerocon panel porta cabins are among their specialties.

Abuild Tech takes great satisfaction in their affordable pricing and timely delivery and installation of porta cabins. Being among the leading Portable Cabin Manufacturer in India, they are aware of the value of dependability and quality. They are committed to giving our consumers the best goods and services they can because of this.

Original Source: https://penzu.com/p/20eb3faeb6a229c7

#Portable Cabin Manufacturer in India#Portable Cabin Manufacturers#PUF Panel Portable Cabin#Security Guard Cabin manufacturer#Interior Turnkey Projects#Factory Sheds#Aluminium Door Windows#Prefab cabin manufacturer#Prefab site offices#Porta Cabin in Delhi#Aerocon Panel Porta Cabin#Aluminium work

0 notes

Text

Smith Structure | Leading the Way in Engineering Innovation

Smith Structure, a engineering innovation leader & discover their dedication to excellence, expertise & client satisfaction in every project they undertake

#Puff Panels#puf sheet#puff sheet roofing#puf panel sheet price#puff insulated roof sheet#puf panel for Warehouse#Roofing Sheet manufacturing#industries Warehouse puf panel manufactur#puf panel sheet company#in#vadodara#gujarat#india

0 notes

Text

ENGKO: Revolutionizing Manufacturing with High-Quality PUF Panels in India

In the dynamic landscape of construction, innovation and efficiency are paramount. ENGKO, a pioneering name in the industry, stands out as a leading manufacturer of Polyurethane Foam (PUF) panels in India. With a commitment to quality, sustainability, and cutting-edge technology, ENGKO has emerged as a game-changer in prefab construction.

The Power of PUF Panels

Polyurethane Foam (PUF) panels are at the core of ENGKO Engineering Company offerings, and for good reason. These panels are renowned for their outstanding thermal insulation properties, durability, and versatility. As a leading manufacturer, ENGKO ensures that its PUF panels adhere to the highest industry standards, providing an optimal solution for diverse construction needs.

Energy Efficiency and Sustainability

One of the key advantages of ENGKO PUF panels is their exceptional energy efficiency. These panels act as a formidable barrier against heat transfer, significantly reducing the need for artificial heating or cooling within a structure. This not only contributes to lower energy consumption but also aligns with global sustainability goals. ENGKO is committed to eco-friendly practices, and their PUF panels play a crucial role in creating energy-efficient and environmentally conscious buildings.

Customization for Varied Applications

ENGKO understands that each construction project is unique, with distinct requirements and challenges. The company offers a range of PUF panels that can be customized to suit specific applications. Whether it's for industrial buildings, cold storage, clean rooms, or residential structures, ENGKO PUF panels are designed to meet the diverse needs of the construction industry.

Rapid and Cost-effective Construction

Prefabricated construction, powered by PUF panels, is synonymous with speed and cost-effectiveness. EPACK Engineering Company's panels are manufactured precisely and efficiently, allowing for faster construction timelines. This not only reduces overall project costs but also minimizes the environmental impact associated with traditional construction methods.

Quality Assurance and Certifications

ENGKO places a premium on quality assurance. The company adheres to stringent quality control measures at every stage of production, ensuring that each PUF panel meets the highest durability and performance standards. Additionally, the panels are backed by relevant certifications, providing clients with the assurance that they are investing in a reliable and compliant construction solution.

Contact Detail

ENGKO Engineering Company

Add- DB Plaza, RDC, Near Yes Bank, Ghaziabad INDIA

Phone no- 9319777949

Email: [email protected]

Website- https://www.engko.co.in

3 notes

·

View notes

Text

low pressure PU foaming machine

#PU foaming machines#Polyurethane Foam Making Machine#PU High Pressure Foaming Machine#Rotary Table for thermoware production#Rotary Table for thermoware production in mumbai#Cold room panels#Cold Room PUF Panel#PUF Cold Room Panel Manufacturer#PUF Cold Room Panel Manufacturer in mumbai#PUF Cold Room Panel Manufacturer in india#cold room panels manufacturer#cold room panels manufacturer in mumbai#cold room panels manufacturer in india#clean room panels#clean room panels manufacturers#clean room panels manufacturers india

0 notes

Text

How PUF Sandwich Panels Enhance Energy Efficiency in Buildings

In the quest for sustainable building materials, PUF (Polyurethane Foam) Sandwich Panels stand out as a remarkable innovation. These panels are revolutionizing the construction industry by offering unmatched energy efficiency, durability, and versatility. As PUF Sandwich panels manufacturers continue to refine their products, it's crucial to understand how these panels contribute to enhancing energy efficiency in buildings.

Understanding PUF Sandwich Panels

Before delving into their energy-efficient properties, let's grasp what PUF Sandwich Panels entail. These panels consist of three layers: two external layers typically made of metal such as steel or aluminium, and a core layer composed of polyurethane foam. The unique construction of these panels provides exceptional thermal insulation properties, making them ideal for walls, roofs, and floors in both residential and commercial buildings.

Thermal Insulation: The Key to Energy Efficiency

One of the most significant advantages of PUF Sandwich Panels is their exceptional thermal insulation capability. The polyurethane foam core acts as a highly efficient thermal barrier, significantly reducing heat transfer between the interior and exterior of the building. This insulation not only keeps the interior spaces comfortable year-round but also minimizes the need for excessive heating or cooling, thereby reducing energy consumption and utility costs.

Reduced Energy Consumption

By installing PUF Sandwich Panels, buildings can achieve substantial energy savings. The superior insulation properties of these panels help maintain consistent indoor temperatures regardless of external weather conditions. As a result, heating and cooling systems operate more efficiently, consuming less energy to maintain comfort levels. This translates to lower electricity bills and reduced carbon emissions, contributing to a greener and more sustainable environment.

Enhanced Air Tightness

In addition to thermal insulation, PUF Sandwich Panels also offer excellent air tightness, further improving energy efficiency. The tightly sealed joints between panels prevent air leakage, minimizing heat loss or gain through infiltration. This ensures that conditioned air remains inside the building, reducing the workload on HVAC systems and optimizing energy performance.

Sustainable Construction Solution

PUF Sandwich Panels are not only energy-efficient but also contribute to sustainable construction practices. The manufacturing process of these panels involves minimal waste generation, and they are often fabricated using recycled materials. Additionally, their lightweight nature reduces transportation costs and carbon emissions associated with shipping, making them an eco-friendly choice for builders and developers.

Versatility and Design Flexibility

Beyond energy efficiency, PUF Sandwich Panels offer unparalleled versatility and design flexibility. They can be customized to meet various architectural requirements, allowing architects and designers to create innovative and aesthetically pleasing structures. Whether used in residential homes, commercial buildings, or industrial facilities, these panels provide endless design possibilities without compromising on performance or sustainability.

Long-Term Durability

Another notable benefit of PUF Sandwich Panels is their long-term durability. These panels are engineered to withstand harsh weather conditions, corrosion, and fire, ensuring the longevity of the building envelope. By choosing PUF Sandwich Panels, property owners can enjoy peace of mind knowing that their investment is protected against damage and deterioration, resulting in lower maintenance costs over time. In conclusion, PUF Sandwich Panels are a game-changer in the construction industry, offering a comprehensive solution for enhancing energy efficiency in buildings. As leading PUF Sandwich panels manufacturers continue to innovate and refine their products, the adoption of these panels is expected to rise, driving sustainability and resilience in the built environment. By incorporating PUF Sandwich Panels into construction projects, builders, developers, and property owners can achieve significant energy savings, reduce environmental impact, and create healthier and more comfortable living and working spaces for generations to come.

0 notes

Text

Gupta Iron & Steel Co., We endeavor to revolutionize the industry by fabricating a wide gamut of quality products, which includes Roofing sheet, Color Coated Roofing Sheet, C Z Purlins, Decking Sheet, PUF Panel, GI Corrugated Sheet and Crimp/Curved Roofing Sheet.

Call us 9999740008

#Roofing Sheets#c z purlin manufacturers#color coated roofing sheet#curved roofing sheet#decking sheet manufacturers#puf panel manufacturers#gutpa iron and steel company

0 notes

Text

Proudly Manufacturing Quality PUF Panels: MAK Prefab Steel Contracting LLC

MAK Prefab Steel Contracting LLC is one of the leading PUF panel manufacturers in the UAE. PUF (Polyurethane Foam) panels are a popular choice for building construction due to their excellent insulation properties and durability. These panels consist of an insulating foam core sandwiched between two metal sheets, providing superior thermal insulation and reducing energy consumption.

At MAK Prefab Steel Contracting LLC, we take pride in producing high-quality PUF panels that meet our clients’ exact requirements. Our PUF panels are versatile, lightweight, and easy to install, making them an ideal choice for various applications in construction, including roofing, wall cladding, cold rooms, and more.

We use advanced technology and high-grade materials to manufacture our PUF panels, ensuring their longevity and reliability. We are committed to providing our clients with customized solutions that meet their specific needs while ensuring the highest quality standards.

In addition to PUF panels, we also offer a wide range of other steel products, including steel structures, portable cabins, and prefabricated buildings. With our expertise and experience in the industry, we can provide our clients with innovative and cost-effective solutions for their construction needs.

If you’re looking for reliable PUF panel manufacturers in the UAE, look no further than MAK Prefab Steel Contracting LLC. Contact us today to discuss your project requirements and find out how we can help you with your construction needs.

0 notes

Text

How PUF Sandwich Panels Enhance Energy Efficiency in Buildings

In the quest for sustainable building materials, PUF (Polyurethane Foam) Sandwich Panels stand out as a remarkable innovation. These panels are revolutionizing the construction industry by offering unmatched energy efficiency, durability, and versatility. As PUF Sandwich panels manufacturers continue to refine their products, it's crucial to understand how these panels contribute to enhancing energy efficiency in buildings.

Understanding PUF Sandwich Panels

Before delving into their energy-efficient properties, let's grasp what PUF Sandwich Panels entail. These panels consist of three layers: two external layers typically made of metal such as steel or aluminum, and a core layer composed of polyurethane foam. The unique construction of these panels provides exceptional thermal insulation properties, making them ideal for walls, roofs, and floors in both residential and commercial buildings.

Thermal Insulation: The Key to Energy Efficiency

One of the most significant advantages of PUF Sandwich Panels is their exceptional thermal insulation capability. The polyurethane foam core acts as a highly efficient thermal barrier, significantly reducing heat transfer between the interior and exterior of the building. This insulation not only keeps the interior spaces comfortable year-round but also minimizes the need for excessive heating or cooling, thereby reducing energy consumption and utility costs.

Reduced Energy Consumption

By installing PUF Sandwich Panels, buildings can achieve substantial energy savings. The superior insulation properties of these panels help maintain consistent indoor temperatures regardless of external weather conditions. As a result, heating and cooling systems operate more efficiently, consuming less energy to maintain comfort levels. This translates to lower electricity bills and reduced carbon emissions, contributing to a greener and more sustainable environment.

Enhanced Air Tightness

In addition to thermal insulation, PUF Sandwich Panels also offer excellent air tightness, further improving energy efficiency. The tightly sealed joints between panels prevent air leakage, minimizing heat loss or gain through infiltration. This ensures that conditioned air remains inside the building, reducing the workload on HVAC systems and optimizing energy performance.

Sustainable Construction Solution

PUF Sandwich Panels are not only energy-efficient but also contribute to sustainable construction practices. The manufacturing process of these panels involves minimal waste generation, and they are often fabricated using recycled materials. Additionally, their lightweight nature reduces transportation costs and carbon emissions associated with shipping, making them an eco-friendly choice for builders and developers.

Versatility and Design Flexibility

Beyond energy efficiency, PUF Sandwich Panels offer unparalleled versatility and design flexibility. They can be customized to meet various architectural requirements, allowing architects and designers to create innovative and aesthetically pleasing structures. Whether used in residential homes, commercial buildings, or industrial facilities, these panels provide endless design possibilities without compromising on performance or sustainability.

Long-Term Durability

Another notable benefit of PUF Sandwich Panels is their long-term durability. These panels are engineered to withstand harsh weather conditions, corrosion, and fire, ensuring the longevity of the building envelope. By choosing PUF Sandwich Panels, property owners can enjoy peace of mind knowing that their investment is protected against damage and deterioration, resulting in lower maintenance costs over time. In conclusion, PUF Sandwich Panels are a game-changer in the construction industry, offering a comprehensive solution for enhancing energy efficiency in buildings. As leading PUF Sandwich panels manufacturers continue to innovate and refine their products, the adoption of these panels is expected to rise, driving sustainability and resilience in the built environment. By incorporating PUF Sandwich Panels into construction projects, builders, developers, and property owners can achieve significant energy savings, reduce environmental impact, and create healthier and more comfortable living and working spaces for generations to come.

0 notes

Text

0 notes