Don't wanna be here? Send us removal request.

Text

Best ERP Solutions for Ethanol Manufacturing Industry: A Complete Guide

The ethanol manufacturing industry requires precise coordination across various processes, from raw material procurement to production and distribution. To streamline operations and ensure regulatory compliance, businesses need a robust Enterprise Resource Planning (ERP) system. This guide explores the best ERP solutions tailored for ethanol production and the benefits they offer.

Why ERP is Essential for Ethanol Manufacturing?

Ethanol manufacturing is a complex process that involves multiple stages, including fermentation, distillation, dehydration, and quality control. Managing these operations manually leads to inefficiencies and increased costs. An ERP system helps by:

Automating production processes

Optimizing supply chain management

Enhancing compliance tracking

Reducing operational costs

Improving inventory and financial management

Key Features of ERP for Ethanol Industry

1. Raw Material & Inventory Management

Tracks raw material procurement (corn, sugarcane, biomass).

Monitors stock levels in real time.

Ensures FIFO and LIFO stock management.

2. Production Planning & Automation

Schedules fermentation and distillation processes.

Reduces downtime with predictive maintenance.

Improves energy efficiency and reduces waste.

3. Regulatory Compliance & Reporting

Automates compliance tracking for environmental and safety regulations.

Generates audit reports for government authorities.

Monitors carbon emissions and waste disposal.

4. Financial Management & Cost Control

Tracks expenses, revenue, and profitability.

Manages tax compliance and payroll.

Provides real-time financial insights for better decision-making.

5. Quality Control & Assurance

Conducts lab testing for ethanol purity.

Implements quality check parameters at every stage.

Ensures compliance with industry standards.

6. Supply Chain & Logistics Management

Optimizes transportation and distribution networks.

Automates vendor and supplier management.

Reduces delays in ethanol shipments.

Best ERP Solutions for Ethanol Manufacturing

1. SAP Business One

Best for medium to large manufacturers.

AI-powered analytics for better insights.

Seamless integration with IoT and automation tools.

2. Microsoft Dynamics 365

Cloud-based ERP with flexible scalability.

Advanced supply chain and inventory tracking.

AI-driven reporting for optimized production.

3. Oracle NetSuite

Tailored for process manufacturing industries.

Real-time visibility into financial and operational data.

Automates compliance and regulatory reporting.

4. Infor CloudSuite Industrial

Ideal for ethanol and chemical manufacturing.

IoT integration for predictive maintenance.

Supports multi-plant operations and global supply chains.

5. Tally ERP 9

Budget-friendly for small-scale manufacturers.

Simplifies taxation, invoicing, and accounting.

Basic inventory tracking with easy-to-use interface.

How ERP Improves Ethanol Manufacturing Efficiency?

A well-integrated ERP system can significantly improve efficiency in ethanol production by:

✔ Enhancing resource utilization ✔ Reducing operational and labor costs ✔ Improving supply chain coordination ✔ Ensuring better financial planning ✔ Maintaining compliance with industry regulations

Conclusion: Selecting the Right ERP for Your Business

Choosing the right ERP system for ethanol manufacturing depends on business size, regulatory needs, and budget. Solutions like SAP Business One, Microsoft Dynamics, and Oracle NetSuite offer powerful tools for optimizing production and ensuring compliance.

#ERP#EthanolManufacturing#ERPSoftware#SupplyChain#ManufacturingTech#BusinessAutomation#RegulatoryCompliance#InventoryManagement#ProductionEfficiency#EnterpriseSolutions

0 notes

Text

Best ERP for Ethanol Manufacturing Industry – Streamline Operations

What is ERP?

Enterprise Resource Planning (ERP) is a software solution that integrates various business processes into a single system to streamline operations, improve efficiency, and provide real-time data insights. It helps organizations manage finance, inventory, production, supply chain, and compliance effectively. In the ethanol manufacturing industry, ERP plays a crucial role in automating production, maintaining quality control, and ensuring regulatory compliance.

Why ERP is Essential for Ethanol Manufacturing?

ERP for ethanol manufacturing is a game-changer, offering complete automation, real-time monitoring, and seamless integration of various processes. The ethanol industry involves complex procedures, including raw material procurement, fermentation, distillation, quality control, and distribution. A well-implemented ERP system ensures efficiency, compliance, and profitability.

Key Benefits of ERP in Ethanol Manufacturing

Improved Production Planning

ERP for ethanol manufacturing streamlines production processes by integrating supply chain and inventory data.

Real-time tracking helps in reducing downtime and optimizing raw material usage.

Enhanced Regulatory Compliance

Ethanol manufacturing requires strict adherence to government regulations.

An ERP system ensures compliance with safety and environmental guidelines.

Automated reporting reduces manual errors and speeds up documentation.

Efficient Inventory Management

ERP software provides a real-time view of raw materials, chemicals, and finished ethanol stock.

Helps in maintaining accurate stock levels and prevents wastage.

Quality Control and Traceability

Ensures strict quality checks at every stage of ethanol production.

ERP for ethanol manufacturing maintains a detailed history of batches, making it easier to trace and recall defective products if needed.

Cost Reduction and Financial Management

Reduces operational costs by automating processes.

Tracks expenses, manages budgets, and enhances financial reporting.

Key Features of ERP for Ethanol Manufacturing

1. Raw Material Procurement and Supplier Management

Automates purchase orders based on demand forecasts.

Maintains supplier contracts and pricing for better cost management.

2. Production Process Automation

Integrates fermentation, distillation, and dehydration processes.

Reduces manual intervention and improves accuracy.

3. Compliance and Safety Management

Ensures adherence to environmental and industry-specific regulations.

Maintains records for audits and inspections.

4. Real-time Data Analytics and Reporting

Provides real-time production insights through dashboards.

Generates customized reports for better decision-making.

5. Supply Chain and Distribution Management

Tracks ethanol shipments and deliveries.

Optimizes logistics for cost savings and timely distribution.

Top ERP Solutions for Ethanol Manufacturing

Several ERP software solutions cater to the ethanol manufacturing sector, including:

SAP Business One – Ideal for mid-sized ethanol producers.

Oracle NetSuite – A cloud-based solution with real-time analytics.

Microsoft Dynamics 365 – Offers automation and AI-powered insights.

BatchMaster ERP – Specializes in process manufacturing industries.

Infor M3 – Tailored for the chemical and ethanol industries.

Final Thoughts – Transform Ethanol Production with ERP

Implementing the best ERP for ethanol manufacturing ensures operational efficiency, cost savings, and regulatory compliance. By automating key processes and improving data accuracy, ERP solutions empower ethanol manufacturers to scale and optimize their production seamlessly.

#ERPforEthanolManufacturing#ManufacturingERP#EthanolProduction#SupplyChainManagement#ERPSoftware#ProcessAutomation#QualityControl#RegulatoryCompliance#BusinessEfficiency

0 notes

Text

Top ERP Software for Manufacturing – Enhance Productivity

Looking for the best ERP software for the manufacturing industry? Discover how ERP solutions help in inventory control, production planning, automation, and real-time analytics. From small businesses to large enterprises, ERP streamlines operations and improves efficiency. Learn about the latest cloud ERP trends and AI-driven insights to stay ahead in Industry 4.0. Bookmark now for expert recommendations!

https://www.lighthouseindia.com/manufacturing-erp.html

0 notes

Text

Top ERP for Steel Industry: Boost Efficiency & Profits with Smart Solutions

The steel industry is one of the most complex and competitive manufacturing sectors, requiring advanced resource planning, inventory control, supply chain management, and cost optimization. Managing operations manually or using outdated systems leads to inefficiencies, higher costs, and production delays.

To stay ahead in this competitive landscape, implementing a powerful ERP system for the steel industry is essential. ERP software streamlines business processes, enhances productivity, and improves profitability. In this blog, we will explore the benefits, features, and top ERP solutions for the steel industry.

Why Does the Steel Industry Need ERP?

Steel manufacturing involves raw material procurement, production, inventory management, sales, and distribution. Without a well-integrated system, managing these complex operations becomes a challenge.

A steel industry ERP system centralizes data, automates workflows, and provides real-time insights, helping businesses tackle:

✔ Fluctuating Raw Material Prices – Managing iron ore, coal, and scrap metal price changes. ✔ Complex Production Processes – Handling various grades, alloys, and production cycles efficiently. ✔ Supply Chain Disruptions – Ensuring smooth logistics and timely material procurement. ✔ Regulatory Compliance – Adhering to strict industry safety and environmental regulations. ✔ High Operational Costs – Controlling energy consumption and manufacturing expenses.

Key Benefits of ERP for the Steel Industry

An ERP solution tailored for the steel sector offers multiple advantages, transforming business operations:

1. Streamlined Inventory & Material Management

Monitors real-time stock levels for raw materials, semi-finished, and finished products.

Reduces material wastage and overstocking issues.

Automates stock replenishment alerts to avoid shortages.

2. Optimized Production Planning & Scheduling

Automates batch production scheduling for efficiency.

Reduces downtime and resource wastage.

Tracks real-time production performance for quick adjustments.

3. Enhanced Supply Chain & Logistics Management

Improves vendor management and procurement tracking.

Enhances demand forecasting for better material planning.

Reduces logistical delays and transportation costs.

4. Advanced Quality Control & Compliance

Ensures compliance with ISO, ASTM, and industry safety standards.

Automates quality testing and defect tracking.

Maintains detailed audit reports and regulatory documentation.

5. Cost & Financial Management

Provides real-time expense tracking and budgeting tools.

Helps optimize cost distribution across production stages.

Reduces overall operational and manufacturing costs.

6. Real-Time Business Intelligence & Reporting

Generates customized reports for financials, production, and sales.

Offers AI-powered analytics for better decision-making.

Tracks market trends and demand fluctuations.

Must-Have Features in an ERP for Steel Industry

To ensure maximum efficiency, a steel industry ERP should include:

✔ Material Requirement Planning (MRP) – Optimizes raw material usage. ✔ Production & Process Automation – Streamlines workflows for better output. ✔ Supply Chain & Vendor Management – Enhances procurement and logistics. ✔ Financial Management & Accounting – Tracks costs, revenue, and profitability. ✔ Quality Control & Compliance Management – Ensures product standards and regulations. ✔ CRM & Sales Management – Strengthens customer relationships and sales tracking. ✔ Business Intelligence & Analytics – Provides real-time insights and reports.

Top ERP Solutions for the Steel Industry

Here are some of the best ERP systems designed for steel manufacturers:

1. SAP S/4HANA

✔ AI-driven real-time analytics and reporting. ✔ Best suited for large steel enterprises. ✔ Advanced supply chain and financial management tools.

2. Oracle ERP Cloud

✔ Highly scalable and cloud-based. ✔ Strong integration with third-party applications. ✔ Best for steel manufacturers with complex supply chains.

3. Microsoft Dynamics 365

✔ User-friendly and best for mid-sized steel businesses. ✔ Offers seamless integration with Microsoft tools. ✔ AI-powered business intelligence and data analytics.

4. Infor CloudSuite Industrial

✔ Tailored for process manufacturing industries. ✔ Powerful inventory and supply chain management tools. ✔ Ensures strict quality control and compliance adherence.

5. Epicor ERP

✔ Ideal for steel fabrication and production tracking. ✔ Highly customizable with intuitive dashboards. ✔ Offers excellent cost and energy management features.

How to Choose the Right ERP for Your Steel Business?

When selecting an ERP system for the steel industry, consider the following factors:

✔ Customization & Flexibility – Ensure the ERP can be tailored to your production needs. ✔ Scalability – The software should grow with your business. ✔ User Experience – An easy-to-use system boosts employee adoption. ✔ Integration Capabilities – The ERP should work with your existing systems. ✔ Data Security & Compliance – Protects sensitive business data and ensures regulatory compliance.

The Future of ERP in the Steel Industry

With digital transformation accelerating, modern ERP solutions are integrating AI, IoT, and cloud computing for better efficiency, real-time tracking, and automated workflows. The future of steel manufacturing will be:

✔ Cloud-based for remote access. ✔ AI-driven for predictive analytics. ✔ Automated for increased productivity and cost efficiency.

Implementing an ERP system for the steel industry is no longer an option—it’s a necessity for businesses looking to scale and maximize profits. If you want to revolutionize your steel manufacturing processes, invest in the right ERP today! 🚀

#ERP for steel industry#steel manufacturing ERP#steel ERP software#best ERP for steel industry#ERP for metal industry#steel plant ERP system#ERP solution for steel business

0 notes

Text

🚀 Transform Ethanol Manufacturing with ERP! 🌿🏭

Managing raw materials, production, compliance, and supply chain in the ethanol industry can be challenging. A robust ERP system helps streamline operations, enhance efficiency, and ensure regulatory compliance.

✅ Automate Production & Quality Control ✅ Optimize Inventory & Supply Chain Management ✅ Ensure Regulatory Compliance & Safety Standards ✅ Improve Cost Efficiency & Profitability

🔗 Discover how ERP for Ethanol Manufacturing can boost your business: https://www.lighthouseindia.com/erp-for-ethanol-biofuel-industry.html

📌 Bookmark now & revolutionize your ethanol production with ERP!

1 note

·

View note

Text

Best ERP for Ethanol Manufacturing Industry: Features & Benefits

Introduction to ERP for Ethanol Manufacturing Industry

The ethanol manufacturing industry is a rapidly growing sector that requires robust management solutions to handle complex operations. From raw material procurement to production, compliance, and distribution, an Enterprise Resource Planning (ERP) system plays a crucial role in ensuring efficiency, cost reduction, and regulatory adherence.

Why the Ethanol Industry Needs ERP Software

The ethanol manufacturing industry faces several operational challenges that can be effectively managed with an ERP system:

Raw Material Management: Tracking and managing corn, sugarcane, or other biomass inputs.

Production Process Optimization: Ensuring efficiency in fermentation and distillation.

Quality Control & Compliance: Meeting environmental and safety regulations.

Supply Chain & Inventory Management: Managing logistics and stock levels efficiently.

Financial & Cost Control: Optimizing production costs and improving profitability.

Key Features of ERP for Ethanol Manufacturing Industry

When selecting an ERP solution for the ethanol industry, the following features are essential:

1. Raw Material & Inventory Management

Real-time inventory tracking for raw materials and finished goods.

Automated procurement to optimize supply chain efficiency.

Stock forecasting tools to prevent shortages and overstocking.

2. Production Planning & Process Optimization

Batch-wise production tracking for precise monitoring.

Automated scheduling to optimize resource utilization.

Integration with IoT sensors for real-time process control.

3. Quality Control & Compliance Management

Automated quality checks at multiple production stages.

Regulatory compliance tracking (e.g., environmental and safety standards).

Traceability & audit reporting for legal adherence.

4. Supply Chain & Distribution Management

Seamless integration with suppliers and transporters.

Automated logistics tracking for efficient distribution.

Fleet management tools for transportation efficiency.

5. Finance & Accounting Management

Automated billing & invoicing.

Cost analysis tools to optimize expenditures.

Tax compliance & financial reporting.

6. Sales & Customer Relationship Management (CRM)

Order processing & contract management.

Sales forecasting & demand planning.

Customer feedback tracking for continuous improvement.

Benefits of Implementing ERP for Ethanol Industry

Implementing an ERP system in ethanol manufacturing offers multiple advantages:

Improved Operational Efficiency: Reduces manual work and enhances automation.

Cost Savings: Optimizes resources and minimizes waste.

Regulatory Compliance: Ensures adherence to industry standards.

Data-Driven Decision Making: Provides real-time insights for strategic planning.

Scalability: Supports business expansion and technological upgrades.

How to Choose the Best ERP for Ethanol Manufacturing

When selecting an ERP system for ethanol production, consider:

Customization: Is the ERP tailored for ethanol manufacturing needs?

Integration Capabilities: Can it connect with existing systems?

User-Friendliness: Does it require extensive training?

Scalability: Can it support future business growth?

Cost & ROI: Is it cost-effective and does it offer long-term benefits?

Top ERP Software for Ethanol Manufacturing

Here are some of the best ERP solutions tailored for the ethanol industry:

SAP S/4HANA – AI-driven ERP for process automation.

Oracle NetSuite – Cloud-based ERP with real-time analytics.

Microsoft Dynamics 365 – Scalable and flexible for manufacturing sectors.

Infor CloudSuite Industrial – Designed for process industries like ethanol production.

Epicor ERP – Advanced supply chain management capabilities.

Conclusion: Why Your Ethanol Business Needs ERP Software

Choosing the best ERP for ethanol manufacturing is crucial for optimizing production, compliance, and profitability. A well-integrated ERP system enhances efficiency, automates workflows, and ensures regulatory compliance, making it an essential tool for growth.

#ERPforEthanolIndustry#EthanolManufacturing#ManufacturingERP#SupplyChainManagement#EthanolProduction#EnterpriseResourcePlanning#ProcessAutomation#IndustrialERP#ERPSoftware#qualitycontrol

1 note

·

View note

Text

Best ERP for Steel Industry: Top Features & Benefits You Must Know

Introduction to ERP for Steel Industry

The steel industry is one of the most complex and demanding manufacturing sectors, requiring robust solutions to manage production, inventory, supply chain, and compliance efficiently. Implementing Enterprise Resource Planning (ERP) software tailored to the steel industry can streamline operations, reduce costs, and improve overall efficiency.

Why the Steel Industry Needs ERP Software

The steel industry faces multiple challenges that can be effectively addressed with a specialized ERP system:

Complex Inventory Management: Managing raw materials, semi-finished, and finished goods efficiently.

Quality Control: Ensuring high-quality standards through real-time monitoring.

Production Planning & Scheduling: Optimizing production cycles for better productivity.

Supply Chain Management: Coordinating suppliers, vendors, and distributors efficiently.

Regulatory Compliance: Meeting government regulations and environmental standards.

Key Features of ERP for Steel Industry

When choosing an ERP system for the steel industry, consider the following essential features:

1. Raw Material & Inventory Management

Automated stock tracking to manage coils, sheets, and billets.

Forecasting tools to optimize inventory levels and prevent shortages or excess stock.

Barcode & RFID Integration for real-time tracking.

2. Production Planning & Control

Dynamic scheduling to maximize efficiency.

Bill of Materials (BOM) management for accurate planning.

Real-time monitoring to identify production bottlenecks.

3. Quality Control & Assurance

Defect tracking and rejection analysis.

Automated quality checks at every stage of production.

Compliance tracking for safety standards.

4. Supply Chain & Logistics Management

Seamless integration with suppliers and vendors.

Automated purchase orders and delivery tracking.

Route optimization for efficient distribution.

5. Finance & Accounting Management

Automated invoicing and billing.

Cost analysis tools for profit margin optimization.

Tax compliance & reporting features.

6. Sales & Customer Relationship Management (CRM)

Quotation & order management.

Customer service tracking and feedback integration.

Sales forecasting & analytics.

7. Regulatory & Compliance Management

Environmental regulations tracking.

Occupational safety compliance tools.

Automated documentation for audits.

Benefits of Implementing ERP for Steel Industry

An ERP system brings significant advantages to the steel industry, including:

Enhanced Efficiency: Automates processes and reduces manual intervention.

Cost Reduction: Minimizes waste and optimizes resource utilization.

Better Decision Making: Provides real-time insights through data analytics.

Scalability: Supports business growth and expansion.

Improved Customer Satisfaction: Ensures timely deliveries and quality assurance.

How to Choose the Best ERP for Steel Industry

Selecting the right ERP system for the steel industry involves considering:

Customization: Does the ERP cater to your specific industry needs?

Scalability: Can it grow with your business?

Ease of Use: Is it user-friendly and requires minimal training?

Integration: Does it integrate seamlessly with existing tools?

Cost: Is the pricing structure affordable and value-driven?

Top ERP Software for Steel Industry

Here are some of the best ERP solutions tailored for the steel industry:

SAP S/4HANA – Advanced AI-driven ERP with strong automation capabilities.

Oracle NetSuite – Cloud-based ERP with real-time analytics.

Microsoft Dynamics 365 – Customizable and scalable for large-scale industries.

Infor CloudSuite Industrial – Specially designed for manufacturing sectors.

Epicor ERP – Offers excellent supply chain management features.

Conclusion: Why Your Steel Business Needs ERP Software

Investing in the best ERP for the steel industry is essential for staying competitive in today’s fast-paced market. A well-implemented ERP solution streamlines operations, enhances productivity, and ensures compliance, ultimately leading to higher profitability.

#ERPforSteelIndustry#SteelIndustrySolutions#ManufacturingERP#SteelIndustrySoftware#EnterpriseResourcePlanning#SteelManufacturing#IndustrialAutomation#SupplyChainManagement#ERPImplementation#BusinessEfficiency

0 notes

Text

Best ERP for Steel Manufacturing: How to Improve Efficiency & Reduce Costs

The steel manufacturing industry is a complex sector that requires precise coordination across production, inventory, supply chain, and finance. Without an integrated system, businesses face challenges like rising costs, inefficient workflows, and compliance issues. The best ERP for steel manufacturing can help companies streamline processes, improve productivity, and reduce operational expenses. This blog explores why ERP is essential, its key features, and how to choose the right solution.

Why Steel Manufacturers Need ERP Software

The steel manufacturing process includes raw material procurement, melting, rolling, quality inspection, and distribution. Managing all these manually leads to inefficiencies, wastage, and financial losses. A steel industry ERP system provides:

Real-time production tracking to optimize workflow

Better inventory control to prevent overstocking or shortages

Automated quality checks for regulatory compliance

Financial tracking & cost management to enhance profitability

Supply chain visibility for seamless material movement

Key Features of the Best ERP for Steel Manufacturing

To maximize efficiency, the best ERP for steel industry manufacturing should include:

1. Production & Operations Management

Automates production scheduling

Monitors machine performance & downtime

Tracks work orders and resource allocation

2. Inventory & Material Management

Real-time stock tracking

Demand forecasting to avoid material shortages

Automated supplier coordination for smooth procurement

3. Supply Chain & Logistics Management

Enhances vendor collaboration

Optimizes transportation and delivery schedules

Reduces delays and material wastage

4. Quality & Compliance Control

Automated quality checks at each production stage

Ensures compliance with industry standards

Generates reports for audits and certifications

5. Financial & Cost Control

Tracks production costs in real time

Manages budgets and forecasts revenue

Reduces wastage, improving profit margins

Benefits of Implementing ERP in Steel Manufacturing

1. Increased Efficiency & Productivity

ERP automates repetitive tasks, enabling faster decision-making and improved productivity.

2. Cost Savings & Reduced Wastage

By optimizing resource allocation and inventory, manufacturers reduce unnecessary expenses.

3. Better Compliance & Quality Management

Ensuring regulatory compliance reduces the risk of fines and improves brand reputation.

4. Improved Customer Satisfaction

ERP streamlines order processing, ensuring timely delivery and accurate order fulfillment.

5. Scalability & Future Growth

As the business expands, ERP can scale to accommodate higher production volumes and new market demands.

How to Choose the Best ERP for Steel Manufacturing

When selecting an ERP system, consider:

Customization options to fit your manufacturing process

Integration capabilities with existing tools

Cloud-based vs. on-premise solutions for accessibility and security

User-friendliness for easy adoption by employees

Vendor support & updates to ensure long-term efficiency

Conclusion: Upgrade Your Steel Manufacturing with ERP

Implementing the best ERP for steel manufacturing is a crucial step toward increasing efficiency, reducing costs, and maintaining a competitive edge. With automation, real-time tracking, and compliance management, steel manufacturers can optimize their operations and boost profitability.

Looking for the right ERP solution for your business? Explore top ERP providers today and transform your manufacturing process! 🚀

0 notes

Text

How ERP Transforms Steel Industry Operations

Discover how ERP for the steel industry enhances production efficiency, streamlines inventory management, ensures quality control, and reduces costs. With real-time insights and automation, ERP software helps steel manufacturers optimize supply chains, improve resource planning, and stay ahead in a competitive market. Explore the benefits of implementing an ERP system for seamless and scalable operations.

🔗 Read more: https://www.lighthouseindia.com/erp-for-steel.html

0 notes

Text

Top ERP for Steel Industry: Boost Efficiency & Maximize Profits

The steel industry faces constant challenges, from fluctuating raw material prices to complex production workflows and supply chain disruptions. Implementing an ERP for steel industry can help businesses streamline operations, enhance productivity, and improve cost efficiency.

Why the Steel Industry Needs ERP Software?

Steel manufacturing involves multiple processes like procurement, production, quality control, and logistics. Managing these manually leads to inefficiencies and delays. An ERP for steel industry helps by:

Automating Production Workflows: Reduces manual effort and increases operational accuracy.

Enhancing Inventory Management: Tracks raw materials and finished goods in real time.

Optimizing Supply Chain Operations: Ensures smooth procurement and distribution processes.

Ensuring Compliance & Quality Control: Meets industry regulations and maintains product standards.

Improving Cost Management: Helps monitor and control manufacturing costs efficiently.

Key Features of an ERP for Steel Industry

A robust ERP for steel industry must have specialized features to manage end-to-end operations effectively. Some of the essential features include:

Material Requirement Planning (MRP): Ensures optimal procurement and utilization of raw materials.

Production Planning & Scheduling: Automates manufacturing schedules and resource allocation.

Supply Chain & Logistics Management: Streamlines vendor relations and product distribution.

Quality Control & Compliance Management: Maintains high-quality standards with real-time monitoring.

Financial & Cost Accounting: Tracks expenses, budgets, and financial reports.

Customer Relationship Management (CRM): Improves customer handling and order processing.

Benefits of Implementing an ERP for Steel Industry

Deploying an ERP for steel industry provides several operational and financial advantages:

Increased Productivity: Automation reduces manual errors and enhances process efficiency.

Better Resource Utilization: Optimizes the use of machinery, manpower, and materials.

Real-time Data Insights: Helps businesses make data-driven decisions.

Cost Reduction: Minimizes wastage, controls expenses, and enhances profit margins.

Scalability: Easily adapts to business growth and changing industry demands.

How to Choose the Right ERP for Steel Industry?

Selecting the best ERP for steel industry requires evaluating key factors such as:

Customization & Flexibility: The ERP should be tailored to meet steel manufacturing needs.

Cloud vs. On-Premise: Decide based on business size, accessibility, and budget.

Ease of Integration: The system should seamlessly connect with existing software.

User-Friendly Interface: Ensures smooth adoption and usability across teams.

Vendor Support & Upgrades: Reliable after-sales support and software updates are crucial.

Top ERP Solutions for the Steel Industry

Various ERP solutions cater specifically to the needs of steel manufacturers. Some of the best include:

SAP S/4HANA – AI-powered insights and automation for steel production.

Microsoft Dynamics 365 – Comprehensive ERP with strong financial management.

Oracle NetSuite – Cloud-based ERP with advanced reporting tools.

Lighthouse ERP – Industry-specific ERP designed for steel businesses.

Steps to Implement an ERP for Steel Industry Successfully

A structured implementation strategy ensures smooth ERP adoption. Follow these steps:

Identify Business Requirements: Analyze operational challenges and ERP needs.

Select the Right ERP System: Compare options based on features, scalability, and support.

Plan Data Migration: Ensure seamless transfer of existing business records.

Employee Training: Conduct workshops to help staff adapt to the new system.

Monitor & Optimize Performance: Regularly evaluate system efficiency and make improvements.

Future Trends in ERP for Steel Industry

Technological advancements are shaping the future of ERP for steel industry. Some key trends include:

AI & Machine Learning: Enhances automation and predictive analytics.

IoT-Enabled ERP: Tracks real-time machine performance and material flow.

Blockchain in Supply Chain: Increases transparency and security in transactions.

Cloud-Based ERP: Provides better accessibility and cost efficiency.

Conclusion: Transform Your Steel Business with ERP

A well-integrated ERP for steel industry enhances efficiency, minimizes costs, and drives business growth. Choosing the right ERP solution helps manufacturers stay ahead in a competitive market. To explore a tailored ERP for steel businesses, check out Lighthouse ERP for a robust and industry-specific solution.

#erp#SteelIndustryERP#ManufacturingERP#ERPSolutions#SteelManufacturing#IndustrialERP#SmartManufacturing#ERPSoftware#DigitalTransformation#SupplyChainManagement#AutomationInSteel#BestERPForSteel

1 note

·

View note

Text

Top ERP Solutions for the Steel Industry: Optimize Your Operations!

The steel industry demands an ERP system that can efficiently manage production, inventory, quality control, supply chain, and financials. Here are the top ERP solutions designed specifically for steel manufacturing. These tools will help enhance productivity, reduce operational costs, and ensure seamless compliance. If you're in the steel manufacturing business, these ERP systems could be a game-changer.

Website:https://www.lighthouseindia.com/erp-for-steel.html

#SteelERP#ManufacturingSoftware#ERPforSteel#SupplyChainManagement#SteelIndustry#EnterpriseSolutions#ERPSoftware#BusinessAutomation#SteelManufacturing

0 notes

Text

Steel Industry ERP: Streamlining Operations & Ensuring Quality

Looking for ways to enhance efficiency in the steel industry? ⚙️ ERP solutions integrate production planning, inventory management, supply chain coordination, and quality control to optimize operations and ensure compliance. 🚀 By automating workflows, tracking real-time data, and reducing waste, ERP helps businesses improve decision-making and drive continuous growth.

Stay updated on the latest ERP trends, best practices, and implementation strategies to maximize efficiency and cost savings. Join the discussion and bookmark this for future reference!

https://www.lighthouseindia.com/erp-for-steel.html

0 notes

Text

ERP for Steel Manufacturing: A Game-Changer for Efficiency and Growth

ERP for Steel Manufacturing: A Game-Changer for Efficiency and Growth

The steel manufacturing industry is one of the most dynamic and demanding sectors, requiring precision, efficiency, and cost optimization at every stage. From raw material procurement to production, quality control, and distribution, every aspect of steel manufacturing needs seamless coordination. This is where Enterprise Resource Planning (ERP) comes into play. ERP solutions integrate various business processes, enabling manufacturers to optimize operations and boost profitability.

Challenges in Steel Manufacturing

Steel production comes with unique challenges that require efficient solutions:

Raw Material Volatility – Fluctuating prices of iron ore, coal, and scrap metal impact production costs.

Production Complexity – Managing multiple production lines, grades of steel, and customized orders can be overwhelming.

Inventory and Logistics – Balancing stock levels while ensuring on-time delivery is crucial.

Quality Compliance – Strict industry standards demand thorough quality checks and documentation.

Energy Management – Steel production is energy-intensive, requiring monitoring to control costs.

How ERP Transforms Steel Manufacturing

Implementing an ERP system offers significant benefits, helping steel manufacturers overcome challenges and optimize operations.

1. End-to-End Supply Chain Visibility

ERP solutions provide real-time tracking of raw materials, production processes, and deliveries. This ensures better supply chain management and cost efficiency.

2. Enhanced Production Planning

By automating production schedules based on demand forecasts, ERP minimizes delays, reduces machine downtime, and maximizes output.

3. Improved Quality Control

ERP systems integrate quality management modules that monitor every stage of production, ensuring adherence to industry standards and reducing defects.

4. Optimized Inventory Management

With real-time inventory tracking, manufacturers can minimize excess stock, avoid shortages, and improve warehouse efficiency.

5. Regulatory Compliance and Reporting

An ERP system ensures that all legal and environmental regulations are met, helping manufacturers stay compliant without manual effort.

6. Cost and Energy Efficiency

ERP software enables real-time monitoring of energy consumption and production costs, allowing businesses to optimize resource utilization and improve profitability.

Choosing the Right ERP for Steel Manufacturing

To fully leverage ERP, manufacturers should choose a solution tailored to the industry’s needs. Key features to look for include:

Industry-Specific Modules – Ensure the ERP supports steel manufacturing processes like melting, rolling, and casting.

Scalability – The system should grow with business demands.

Integration with IoT and Automation – Connecting ERP with smart machinery can enhance efficiency.

Data-Driven Insights – Advanced analytics and reporting tools provide actionable business insights.

Final Thoughts

An ERP system is more than just a software solution—it is a strategic investment that streamlines operations, enhances decision-making, and drives growth. With the right ERP solution, steel manufacturers can reduce waste, control costs, and improve efficiency in an increasingly competitive industry.

0 notes

Text

Optimizing Stainless Steel Production with ERP: Features, Benefits, and Future Trends

ERP for Stainless Steel Manufacturing

Steel manufacturing requires perfection and precision in delivering efficiency. Enterprise Resource Planning (ERP) systems streamline complex processes, integrating core business functions such as raw material management, production scheduling, and quality control into a single system. A customized ERP for Stainless Steel Manufacturing ensures cost efficiency, operational excellence, and compliance with industry standards.

Key Features of ERP for Stainless Steel Manufacturing

Inventory Management – Tracks raw materials to minimize waste and optimize stock levels.

Production Scheduling – Automates planning and scheduling for improved efficiency.

Quality Control – Ensures consistent product quality and regulatory compliance.

Supply Chain Coordination – Optimizes procurement and delivery processes.

Real-Time Analytics – Provides data-driven insights for better decision-making.

Benefits of ERP for Stainless Steel Manufacturing

Enhanced Efficiency – Automation reduces manual efforts and boosts productivity.

Improved Traceability – Tracks materials and processes to minimize waste.

Scalability – Adapts to growing business demands and production capacity.

Better Customer Service – Ensures timely deliveries with accurate tracking.

Regulatory Compliance – Helps meet industry standards and reporting requirements.

Future Trends in ERP for Stainless Steel Manufacturing

AI Integration – Provides predictive analytics for better forecasting and decision-making.

IoT Connectivity – Enables real-time monitoring of production processes and equipment.

Cloud-Based ERP – Offers flexibility, cost savings, and seamless remote access.

Implementing an ERP for Stainless Steel Manufacturing is key to optimizing operations, reducing costs, and staying ahead of market demands. As technology advances, AI, IoT, and cloud solutions will further enhance efficiency and competitiveness in the steel industry.

#ERPforSteelIndustry#StainlessSteelManufacturing#SteelIndustrySolutions#SteelManufacturingERP#QualityControl#ERPSoftware#ManufacturingEfficiency#SupplyChainManagement#IndustrialAutomation#SmartManufacturing#ProductionOptimization

0 notes

Text

ERP for the Ethanol Industry streamlines raw material procurement, production, inventory, compliance, and distribution, ensuring efficiency and cost control. It enhances regulatory compliance, optimizes supply chain management, and improves quality control, enabling ethanol manufacturers to achieve higher productivity, reduced waste, and sustainable growth in the renewable energy sector.

https://www.lighthouseindia.com/erp-for-ethanol-biofuel-industry.html

0 notes

Text

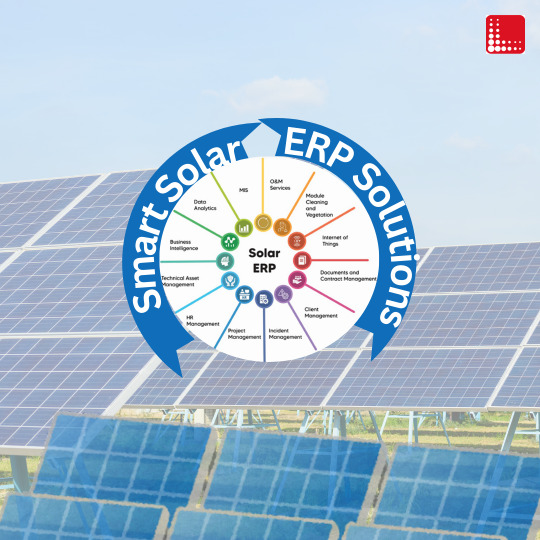

Optimizing Solar Manufacturing with ERP: The Key to Efficiency and Growth

The solar industry is growing rapidly, with increasing demand for renewable energy solutions. To stay competitive, solar manufacturers need efficient, scalable, and integrated business processes. This is where Enterprise Resource Planning (ERP) systems come into play. By implementing an ERP system, solar manufacturing companies can streamline operations, enhance productivity, and improve profitability.

Role of ERP in Solar Manufacturing

ERP systems provide an integrated platform connecting various departments. This allows the smooth flow of communication and data. For the solar manufacturers, this means the real-time tracking of raw materials, production schedules, inventory, and supply chain processes. Here's how ERP benefits the industry:

Supply Chain Optimization To manufacture solar panels, high-quality raw materials such as silicon wafers, glass, and metals are required. ERP systems allow manufacturers to monitor supplier relationships, track shipments, and maintain an optimal inventory level, which results in the prevention of wastage and smooth uninterrupted production.

Production Planning & Scheduling ERP allows manufacturers to schedule production automatically and ensures optimum usage of machinery and labor. Downtime is reduced and productivity is maximized, thereby accelerating the turn-around time for producing solar panels.

Inventory & Warehouse Management With ERP software, inventory levels are tracked in real-time, eliminating stockouts and overstocking. Automated inventory low alerts can maintain the perfect balance, resulting in cost efficiency and better business operations.

Quality Control & Compliance Solar panels operate under strict industrial standards and regulations for quality control. ERP has modules for tracking quality control by safety regulations and production quality to ensure proper audits with documentation.

Cost Management & Financial Planning Massive investment into materials, labour, and logistics is required while manufacturing solar panels. An ERP system provides for financial insights wherein manufacturers can hold the cost level, budget and forecast, as well as develop better financial results.

Real-Time Analytics & Reporting ERP solutions always come with embedded data analytics reporting tools that would provide actionable insight into production efficiency, customer demand, and the market trend; hence, informing the manufacturer with better decisions regarding competition.

Conclusion

The efficiency, reduction of costs, and overall improvement in business processes are some of the changes brought about by ERP systems in the solar manufacturing industry. As demand for renewable energy alternatives continually increases, manufacturers utilizing ERP technology will emerge as strong competitors in the competition in the future. An investment in the right ERP solution today will be a gateway to a more efficient and profitable future in the production of solar manufacutres.

0 notes

Text

Optimizing Solar Panel Manufacturing with ERP Systems

The solar energy industry has been booming and placed very great pressure on solar panel manufacturers to streamline their operations, cut their costs, and enhance their product quality. Among the effective solutions is the enterprise resource planning system(ERP) specifically designed for solar panel manufacturing. ERP systems serve to unify all business processes on a single platform, habiting manufacturers to achieve efficiency, compliance, and profitability.

Why ERP is Essential for Solar Panel Manufacturing

Solar panels need to be manufactured through complex processes ranging from raw material procurement through production, quality control, and distribution. It would cause inefficiency and an increase in cost to overlook the management of these processes. Without proper maintenance, such a systematic approach could be rendered ineffective. Usage of real-time data visibility by the ERP system to automate actions could be beneficial for solar panel producers.

Key Benefits of ERP for Manufacturing Solar Panels:

Efficient Supply Chain Management The tracking of solar panel raw materials which include silicon, glass, and aluminum materials is very possible these days, which leads to efficiency with respect to procurement. This process improves both inventory levels and supplier collaboration, so delays and wasted assets are minimized.

Definitely Beneficial to Production Efficiency ERP systems help solar manufacturers prepare production plans and the timetables for each of the processes to help optimize the use of resources and prevent downtimes. Also, automatic workflow cues complete tasks, making production efficient.

Intensified Quality Control Quality is most critical in the solar panel manufacturing process. It integrates quality checks at each production level; produces products that meet industry standards and consumer expectation; ensures quality throughout the process.

Regulatory Compliance The solar energy industry is heavily regulated, and companies spend out of human labor potential in safety and environmental implications. Compliance reports are automated and compliance is guaranteed according to safety and consumer expectations

Financial Management It uses cost tracking tools together with budget and profitability analysis tools to manage the financial performance of enterprises.

Decision-Making Factored in by Data With advanced analytics, ERP systems for solar panel manufacturing deliver actionable insights. This helps manufacturers identify trends, forecast demand, and make informed decisions to stay ahead in a competitive market.

Features of ERP for Solar Panel Manufacturing

Inventory Management Real-time tracking of raw materials and finished products to prevent stockouts or overstock situations.

Production Planning Tools to optimize production schedules based on demand forecasts and resource availability.

Quality Assurance Integration of quality checks to ensure consistent and reliable solar panels.

Supply Chain Coordination Seamless communication with suppliers for timely procurement of materials.

Compliance Reporting Automated tracking and reporting to meet industry and environmental regulations.

Financial Analytics Insights into production costs, revenue, and profit margins for better financial control.

Implementing ERP in Solar Panel Manufacturing

While the benefits of ERP for solar panel manufacturing are significant, implementing such systems requires careful planning. Manufacturers should: 1. Choose an ERP solution tailored to the unique needs of solar panel manufacturing. 2. Train employees on the use of the system. 3. Partner with experienced vendors to ensure a smooth implementation process.

The Future of Solar Panel Manufacturing with ERP

ERP systems are transforming the solar energy industry by enabling manufacturers to optimize operations, reduce costs, and enhance product quality. In a market driven by innovation and sustainability, ERP for solar panel manufacturing is not just a technological upgrade but a strategic necessity.

By integrating processes, ensuring compliance, and enabling data-driven decision-making, ERP systems empower solar panel manufacturers to meet growing demand while contributing to a sustainable future. Investing in the right ERP solution today will pave the way for long-term success in the renewable energy sector.

#ERPForSolarPanelManufacturing#SolarPanelManufacturing#RenewableEnergySolutions#ERPSystems#SustainableManufacturing#EfficiencyInProduction#SupplyChainOptimization#QualityControl#EnergyCompliance#DataDrivenDecisions#ManufacturingInnovation#GreenEnergySolutions

0 notes