Don't wanna be here? Send us removal request.

Text

Best CRM Software For Small Businesses

"Grow Your Business with the Best CRM Software Solutions for Small Businesses"

Unlock Your Business Potential with the Right CRM Software

As a small business owner, you know that you need to stay on top of your customers and their needs. The best way to do that is with a Top CRM Software system. The best Sales CRM Software system for small businesses will help you keep track of customer interactions, manage customer data, and automate sales processes, all of which can help you grow your small business. But with so many CRM software solutions available, how can you know which one is best for your small business?

Achieving a higher conversion rate through winning the lead will grow your business and generate more revenue. Winning the lead boosts sales and allows you to gain the trust of clients in your products. However, losing the lead helps in knowing the drawbacks and makes you understand why you are not succeeding. The lost lead will also explore the benefits of taking a more proactive approach to target new leads and make them win without repeating mistakes.

To help you choose the right Sales CRM software for your small business, here we’ve put together a list of the best CRM software solutions available. All of these solutions have been chosen based on their features, scalability, and affordability, so you can rest assured that you’re getting the best CRM software for your small business.

1. Salesforce Sales Cloud: Salesforce Sales Cloud is one of the most popular Sales CRM software solutions for small businesses. It’s an all-in-one platform with a wide range of features and tools, including customer segmentation, analytics, and automation. It’s easy to customize so that you can tailor it to your specific business needs. Above all, It also helps teams collaborate and create customer journeys, enabling them to be more productive and consistent in their sales efforts. With Sales Cloud, companies can also automate and streamline their sales process to ensure consistent customer experiences. But Salesforce CRM can be expensive, especially for businesses on a tight budget.

2. Zoho CRM: Zoho CRM is a cloud-based Sales CRM Software CRM solution that’s developed to help small businesses and entrepreneurs manage their sales, marketing, and customer service activities. It includes features like contact management, lead management, and task automation. It also has an intuitive user interface that makes it easy to use.but Zoho CRM has limited customization options compared to other CRM platforms.

3. Freshsales: Fresh sales is a cloud-based Sales CRM Software that’s designed to help small businesses streamline their sales and marketing processes. It includes features like lead management, automated emails, and analytics. It also has a drag-and-drop interface that makes creating customized pipelines and workflows easy. But Freshsales CRM has a limitation in terms of lead generation tools, which are only available with the Enterprise plan. This can be a drawback for businesses that heavily rely on lead generation to drive their sales processes.drawback for businesses that heavily rely on lead generation to drive their sales processes.

4. HubSpot CRM: HubSpot CRM is a powerful CRM solution designed to help small businesses manage their sales and marketing activities. It includes features like contact management, lead scoring, and task automation. Like other Sales CRM Software, this is also globally recognized and known for its benefits of taking a more proactive approach to target new leads and make it win without repeating mistakes. But HubSpot CRM requires additional payment for technical support beyond the basic offerings, which can add to the overall cost of using the platform.

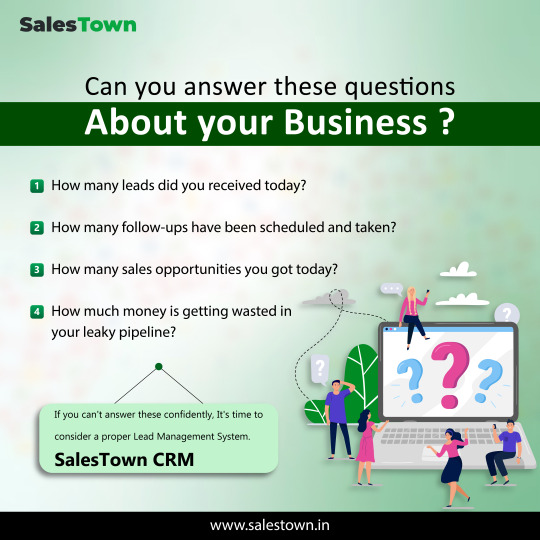

5. SalesTown CRM: This Sales CRM System makes your business more productive with its easy-to-use interface and unique features. SalesTown CRM is powerful customer relationship management software designed to help businesses increase sales, improve customer relationships, and increase efficiency. The software is designed to help businesses track customer data, create sales pipelines, and manage customer relationships in one centralized location. It helps businesses stay organized and efficient.

SalesTown CRM features a wide range of features, including contact management, lead management, sales tracking, and reporting. It also includes an integrated calendar, which helps users keep track of tasks and events. With SalesTown CRM, businesses can create customizable dashboards that provide real-time information and insights into customer behavior. The software also includes a range of analytics tools that let users analyze customer data and trends.

SalesTown CRM is easy to use and intuitive, making it a great choice for businesses of all sizes. If you wish to automate business processes with the right CRM Software, then SalesTown is the best option. Its free version of 15-day trial pack can also be used which is available at its website www.salestown.in

0 notes

Text

Best CRM Software For Small Business

Salestown CRM is a comprehensive customer relationship management software designed to revolutionize your sales process and supercharge your customer relationships. With its powerful features and intuitive interface, Salestown CRM empowers businesses of all sizes to effectively manage their sales pipeline, enhance customer interactions, and drive revenue growth.

0 notes

Text

Best CRM Software for Businesses

Discover the best CRM software for businesses that can help you improve customer relationships streamline processes & increase sales with the best CRM software.

Visit: https://salestown.in/

#Best CRM Software For Small Business#Sales CRM Solutions#Pipeline Management Software In India#Best CRM Software

0 notes

Text

0 notes

Text

#*EDM Graphite Electrodes Manufacturer and Supplier#*EDM Graphite Electrode Suppliers#Top Graphite Product Manufacturers & Dealers#Best EDM Graphite supplier near me

1 note

·

View note

Text

#Continous Casting Dies#best graphite dies company in Delhi ncr#Graphite continous casting dies manufacturer & supplier#Graphite machining

0 notes

Text

#Insulation board#carbon fiber insulation board#graphite die mold in india#electric graphite heater elements#Top Graphite Product Manufacturers & Dealers#Best graphite sintering plates in india

0 notes

Text

#*Best graphite machining company in india#graphite machining#graphite die mold supplier in delhi#graphite products in noida

0 notes

Text

#Graphite machining#best Graphite Product manufacturer & supplier#Best graphite sintering plates in india#graphite die mold in india

0 notes

Text

Best Graphite Machining Product Suppliers

Graphite Heaters & Heating Element

Heating Elements plan and choice is analytic to the appropriate working of any vacuum furnace and is reliant upon various elements: maximum temperature; power load; partial compression and extinguish gases.By far most of vacuum heaters are electrically heated. Graphite Heaters and heating element are produced from a pure carbon composite giving magnificent temperature consistency, life span, mechanical strength and repeatability. The importance of choosing the right alloy for its construction is very critical because of the heat created and transferred by the heating element.

3,000+ Graphite Heaters & Heating Element Products Sold

25+ Serving Companies

8+ Years of Expertise & Experience

Heating Element Selection of Material-

For higher heat yield applications, the thickness of the element increases, which brings down its resistance and permits more electric flow to stream. For vacuum furnaces, the heating elements are wide strips to boost both their physical and glowing surface regions. Stainless steel and nickel-chromium alloys are commonly used for lower temperature applications and at higher partial pressures, while graphite, molybdenum and tungsten are more common for higher temperature processes such as hardening, graphitizing, sintering and nickel or copper brazing.

- Applications -

Vacuum furnaces

Inert gas furnaces

Heat treatment (hardening, carbonization, brazing, etc.)

Carbon fiber production

Cemented carbide production

Sintering applications

Technical ceramic production

CVD/PVD coating

#Graphite Heaters & Heating Element#best Graphite rod manufacturer & supplier#graphite electrode supplier#Graphite machining

0 notes

Text

graphite die mold in india

CFC, C/C Composites

C/C composite (Carbon Fiber Reinforced Carbon Composite) is a carbon-carbon composite material reinforced by high strength carbon fiber, which has superior properties such as lightweight, high mechanical strength, and high elasticity. Since CCM’s strengthened fiber and matrix are both composed of carbon, CCM possesses many advantages over the other conventional carbon-based materials. Furthermore, because it is a fiber-reinforced composite material, CCM shows superior qualities such as excellent compressive strength and flexural strength when compared to other substitutes. Because of their unique features, our C/C composites are used in a wide range of fields such as electronics, environment and energy, general industrial furnaces, and auto mobiles, and other means of transport.

3,000+ CFC, C/C Composite Products Sold

25+ Serving Companies

8+ Years of Expertise & Experience

Features and Benefits of C/C Composites over Graphite and SS

High Mechanical Strength, High Elasticity & High Toughness

Ultra heat resistance

Light-weight and easy to handle

CC composites have low density compared to metallic materials, and therefore, make light weight designing possible.

High thermal conductivity

A thermal conductivity higher than copper has been achieved (in CX. 2002) through the use of carbon structure control technology, which involves our superior chemical vapor infiltration (CVI) treatment.

0 notes

Text

graphite sintering plates near me

EXNP – Expo Needle Punch Carbon Fiber Insulation Boards

Giving Vacuum Furnace Manufacturers and Users a new experience, EXPO presents you with the most suitable carbon fiber insulation boards sketched for your requirement!

EXNP - Only Rigid Insulation Board of the world, made by Needle-punch technology

Pioneer in incorporating Needle-punch technology for making Rigid Insulation Boards

One & only supplier of non-Chinese Carbon Fiber Rigid Insulation Boards in India

Partnership with KORKARB (South Korea), world-renowned manufacturer of Insulation Board, striving to give you the premium essence of it.

3,000+ Insulation Boards Sold

25+ Serving Companies

8+ Years of Expertise & Experience

Our Insulation Boards – EXNP - are made by patented needle-punch technology. This technology is specifically used to make C/C Composite plates and other C/C products. And for the first time in the world, this technology has been incorporated to make Carbon Fiber Insulation boards

Low thermal conductivity and low C.T.E makes our boards high on energy saving

It can be customized to any shape and size as per customers' requirement

Delivery within 7-10 working days, subject to availability of stock

Pioneer in incorporating Needle-punch technology for making Rigid Insulation Boards

EXNP - Only Rigid Insulation Board of the world, made by Needle-punch technology

One & only supplier of non-Chinese Carbon Fiber Rigid Insulation Boards in India

Properties of EXNP Insulation Boards

PropertyUnitValueBulk Densityg/㎤0.14~0.20Flexural StrengthMpa1.0~2.0Compressive StrengthMpa6.0~9.8Thermal ConductivityW/m·k0.1~0.2Electrical ResistivityμΩ·m3.0~4.0Ash (Standard)PPm<100Ash (High Purity)PPm<15Surface TreatmentGraphite CoatingGraphite FoilCarbon Fabric Lamination

Benefits Of Using EXNP Insulation Boards

Low Density, Light weight, easy to carry and install

Long Fiber, Rigid Needle Punch Tecnology makes EXNP boards Tough and Durable with high mechanical strength and high performing product.

Our EXNP boards have low CTE and thermal conductivity. The lower the CTE the less expansion and contraction of the board when heated. This in turn increases the life of the furnace and its parts further increasing the efficiency of the furnace.

Withstand upto 2500 Degrees Celsius

Specifications of EXNP Insulation Boards

#Insulation board#carbon fiber insulation board#graphite die mold in india#electric graphite heater elements#Top Graphite Product Manufacturers & Dealers#Best graphite sintering plates in india

0 notes

Text

Best machining graphite company in Noida

Who We Are

Expo is a one-stop solution for all your Graphite needs. We are one of the largest manufacturers of Graphite Electrodes & Graphite Components and have marked the significance and efficiency of superior quality graphite products in the industry, and are fabricated according to the industry norms. We have partnered with TOYO TANSO CO. LTD, JAPAN for all our Graphite needs. Our products are widely used in numerous industries because of their durability and reliability. We are the right choice for your die & mold making business, and to take your business to the next level.

Since1985

What We Do

EXPO is a global leader in Graphite machining and Graphite EDM Electrodes. We create our products using globally acclaimed manufacturing techniques and provide excellent service while trading with our industry. We have completed more than two decades in the market in machining Graphite and specialize in producing EDM electrodes and Customized Graphite products.

Exclusive Quality Control

Premium Quality Graphite

Best Delivery Services

Customized Machining

0 notes

Text

Graphite Product Manufacturers & Dealers

EDM Graphite Electrodes Manufacturer and Supplier

Transforming the machine and tools market for more than a decade, EXPO presents you with the most suitable graphite electrode sketched for your requirement!

Recognized worldwide for the quality of graphite.

Graphite fabricated according to your industry needs with high-grade raw material.

Exclusive partner for TOYO TANSO(Japan), world-renowned manufacturer of graphite products, striving to give you the premium essence of graphite products.

All products strictly inspected by expert professionals from manufacturing until the final outcome.

6,75,250+ Manufactured Electrodes

1,200+ Serving Companies

20+ Years of Expertise & Experience

The best grades of EDM Graphite Electrodes

Grab your premium quality EDM graphite electrodes now!

ISEM -8

Apt for semi-finished & finished EDM

Forging & Injection Molds, Punch & Dies, Sintered/Powdered Metal Molds,Blow Molds

Bulk Density

mg/m3

1.78

Hardness

HSD

63

Electrical Resistivity

μΩm

13.4

Flexural Strength

MPa

52

Compressive Strength

MPa

106

Tensile Strength

MPa

34

Young's Modulus

GPa

10.1

C.T.E*

10-6/K

5.6

Thermal Conductivity

W/(m.K)

90

Standard Size

(mm)

305 x 620 x 1050

ISO - 63

High hardness & strength. Apt for finished & more detailed EDM

Forging & Injection Molds, Punch & Dies, Sintered/Powdered Metal Molds,Blow Molds

Bulk Density

mg/m3

1.78

Hardness

HSD

76

Electrical Resistivity

μΩm

15.0

Flexural Strength

MPa

65

Compressive Strength

MPa

135

Tensile Strength

MPa

46

Young's Modulus

GPa

12.0

C.T.E*

10-6/K

5.6

Thermal Conductivity

W/(m.K)

70

Standard Size

(mm)

230 x 540 x 1000

TTK - 5

Apt for high precision EDM and Fine Ribs

Plastic Injection Molds, Wire Cutting, Aerospace, Medical, Fine Details/Threaded Electrodes

Bulk Density

mg/m3

1.78

Hardness

HSD

80

Electrical Resistivity

μΩm

15.5

Flexural Strength

MPa

80

Compressive Strength

MPa

150

Tensile Strength

MPa

53

Young's Modulus

GPa

11.6

C.T.E*

10-6/K

5.7

Thermal Conductivity

W/(m.K)

80

Standard Size

(mm)

210 x 510 x 950

#*EDM Graphite Electrodes Manufacturer and Supplier#*EDM Graphite Electrode Suppliers#Top Graphite Product Manufacturers & Dealers#Best EDM Graphite supplier near me

1 note

·

View note

Text

best graphite product manufacturer & Supplier

Machining Graphite

Carbon is an element that can form into several different allotropes including graphite, diamond, and fullerite.Graphite is the most steady type of carbon and is the most well-known, as carbon naturally occurs as graphite under standard conditions. Graphite is generally known for its better conductivity and resistance for high heat and corrosion. This makes it a typical material in high heat, high-pressure circumstances in the aerospace, electrode, nuclear, energy, and military industries. Despite the fact that graphite can deal with extreme high-pressure circumstances effortlessly, it is really an exceptionally delicate, rough, and fragile material. Graphite is ordinarily utilized in the Electrical Discharge Machining (EDM) industry. It can prove tricky to machine, particularly for EDM electrodes that require outstanding accuracy and structural consistency. Graphite Machining has the remarkable capacity to meet the carbon and graphite needs from unrefined substances through filtration and accurately machined parts.EDM Electrodes can have small ribs and elements which require small dia cutters and tools , and graphite is commonly machined without coolant and at high velocities. This makes the ideal machining focus one with high spindle speeds and ideal residue extraction system.

6,000+ Machined Graphite Products Sold

300+ Serving Companies

20+ Years of Expertise & Experience

Graphite Machining Techniques -

As far as machine arrangement, the one significant tip to recollect is to consistently try not to utilize coolant. Graphite is a genuinely permeable material, thus it can ingest coolant and go about as a "coolant wipe," which will cause issues with finished parts. Inside the machine and on the tooling, the coolant can really respond with the graphite dust and make a grating slurry, which will cause issues while machining. A vacuum framework or dust collector is suggested for clearing material while machining graphite. Any other way, covered apparatuses ought to have the option to run dry.

Something else to note while machining graphite is that since graphite doesn't deliver chips, but instead a haze of extremely grating dust, it tends to be destructive to operators and machines without legitimate consideration. Operators ought to be wearing a protective mask to try not to breathe in the graphite dust. Appropriate ventilation and keeping up with air quality in the shop is likewise key for the security of engineers when working in graphite.

Since the graphite dust is likewise incredibly conductive, it can undoubtedly harm non-defensive circuits inside your CNC machine, which can cause major electrical issues. While coolant isn't suggested, a vacuum framework can assist in removing the dust, holding it back from aggregating a lot inside the machine and preventing major issues.

#Graphite machining#best Graphite Product manufacturer & supplier#Best graphite sintering plates in india#graphite die mold in india

0 notes

Text

graphite die mold in india

We are the leading suppliers of Continous Casting Dies.Graphite machining,continous casting dies manufacturer & supplier. across all industry sectors.✅ Needle-Punch Technology ✅ Excellent Performance

0 notes