Don't wanna be here? Send us removal request.

Text

The Marvels of 5L Bottle Water Filling Lines

In the dynamic realm of the bottled water industry, the 5L bottle water filling line stands as a technological marvel, streamlining the production process and ensuring the delivery of high - quality bottled water to consumers worldwide. This advanced machinery plays a crucial role in meeting the ever - growing demand for large - volume water packaging.

A 5L bottle water filling line is a comprehensive system designed to handle the entire production process, from bottle sterilization to capping and labeling. It typically consists of several key components. The bottle unscrambler arranges empty 5L bottles in an orderly manner, preparing them for the filling process. The filling machine, the heart of the line, precisely dispenses water into the bottles with high accuracy, minimizing spillage and ensuring consistent fill levels. After filling, the capping machine securely seals each bottle, preventing contamination and leakage. Finally, the labeling machine applies eye - catching and informative labels, enhancing the product's marketability.

One of the significant advantages of a 5L bottle water filling line is its high production efficiency. These lines can operate at remarkable speeds, filling hundreds of bottles per hour, which greatly increases output while reducing labor costs. Moreover, they incorporate advanced hygiene and safety features. Automatic cleaning and sterilization functions maintain a sterile production environment, safeguarding the quality and safety of the bottled water.

5L bottle water filling lines are widely used in various settings, from large - scale commercial water production facilities to smaller regional bottlers. They are ideal for producing water for both household and commercial use, such as for office water coolers and family consumption. As consumer preferences shift towards more sustainable and convenient packaging solutions, the 5L bottle size has become increasingly popular, and the filling lines that support its production are essential for businesses aiming to stay competitive in the market.

In conclusion, 5L bottle water filling lines are indispensable assets in the bottled water industry. Their efficiency, precision, and reliability make them key to delivering high - quality 5L bottled water products that meet the diverse needs of consumers.

0 notes

Text

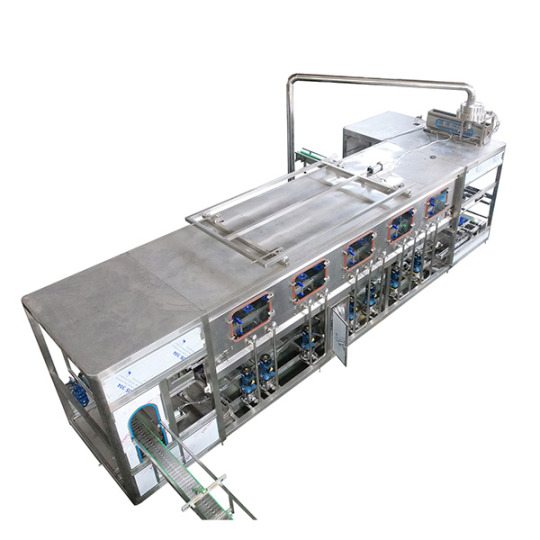

The Washing Filling Capping 3-in-1 Machine: A Revolutionary Bottling Solution

In the fast-paced world of beverage and liquid packaging, efficiency and precision are of utmost importance. The washing filling capping 3-in-1 machine has emerged as a game-changer, streamlining the bottling process and offering numerous benefits to manufacturers.

This innovative machine combines three essential functions - washing, filling, and capping - into a single, integrated unit. By doing so, it eliminates the need for multiple separate machines and reduces the overall footprint of the production line. This not only saves valuable floor space but also simplifies the production process, making it easier to manage and maintain.

The washing section of the 3-in-1 machine is designed to thoroughly clean the bottles before filling. It uses a variety of methods, such as spraying, rinsing, and brushing, to remove any dirt, debris, or contaminants from the interior and exterior of the bottles. This ensures that the final product is safe and hygienic for consumers.

Once the bottles are clean, they are transferred to the filling section. Here, the machine accurately dispenses the desired amount of liquid into each bottle. The filling process can be customized to meet the specific requirements of different products, such as carbonated beverages, still water, juices, or pharmaceuticals. The machine is equipped with advanced sensors and controls to ensure precise filling levels and minimize product waste.

Finally, the filled bottles are moved to the capping section, where caps are applied and tightened to seal the bottles. The capping process is also highly automated, with the machine capable of handling different types of caps, such as screw caps, snap caps, or corks. The capping mechanism is designed to provide a secure and leak-proof seal, protecting the product from spoilage and ensuring its freshness.

One of the key advantages of the washing filling capping 3-in-1 machine is its high speed and productivity. By combining multiple functions into one machine, it can significantly increase the output of the production line. This is particularly beneficial for large-scale manufacturers who need to meet high demand.

In addition to its speed, the 3-in-1 machine also offers excellent accuracy and consistency. The advanced sensors and controls ensure that each bottle is filled and capped to the same high standard, reducing the risk of product variability and improving the overall quality of the product.

Another advantage of the 3-in-1 machine is its versatility. It can be easily customized to handle different bottle sizes, shapes, and materials, as well as a wide range of liquid products. This makes it suitable for use in various industries, including the beverage, food, pharmaceutical, and cosmetic industries.

Furthermore, the 3-in-1 machine is designed with operator convenience in mind. It features a user-friendly interface and intuitive controls, making it easy for operators to set up and operate the machine. The machine also requires minimal maintenance, thanks to its robust construction and high-quality components.

In conclusion, the washing filling capping 3-in-1 machine is a revolutionary bottling solution that offers numerous benefits to manufacturers. Its ability to combine multiple functions into one machine, along with its high speed, accuracy, versatility, and operator convenience, make it an ideal choice for any production line. As the demand for efficient and reliable bottling solutions continues to grow, the 3-in-1 machine is sure to play an increasingly important role in the packaging industry.

0 notes

Text

5L Bottle Water Filling Line: The Core Force of Efficient Production

In the field of bottled water production, the 5L bottle water filling line plays a crucial role. It is an automated equipment integrating a variety of advanced technologies, providing a solid guarantee for the efficient and precise production of 5L bottled water.

The 5L bottle water filling line usually consists of several key components. The bottle rinser is the starting point of the production line. The rotary disc of the rinser is equipped with bottle clamps, which can grip the bottle mouths and flip them 180° along the guide rails, making the bottle mouths face downward. Then, the nozzles of the bottle clamp spray rinsing water to thoroughly clean the inner walls of the bottles, ensuring they are clean and sterile. The rinsed bottles are transferred to the filler via the star wheel. The filler adopts the gravity filling method. When the bottles enter the filler, they are clamped by the bottle plate and rise under the action of the cam. The bottle mouths open the filling valves, and the materials flow through the filling valves by gravity to complete the filling process. After filling, the bottles enter the capper through the neck - holding transfer star wheel. The capping heads of the capper rotate both around a central axis and on their own as cap gripping, cap placing, capping, and cap releasing to complete the capping process. Finally, the finished bottles are transferred to the outfeed conveyor chain by the outfeed star wheel and conveyed out of the three - in - one machine.

This filling line has many significant advantages. It has a high degree of automation, and the entire process from bottle rinsing, filling to capping can be automatically completed, greatly reducing manual intervention. This not only improves production efficiency but also reduces labor costs. The equipment is designed with great attention to hygiene standards. The parts in contact with the materials are all made of stainless steel, with no process dead corners, making it easy to clean and effectively ensuring the quality and safety of bottled water. Moreover, the filling line uses high - speed filling valves, which can achieve precise control of the liquid level, reduce liquid loss, and ensure that each 5L bottle reaches the standard filling volume. At the same time, the equipment is equipped with a complete overload protection device, which can effectively protect the equipment and operators.

In practical applications, the 5L bottle water filling line is widely applicable to multiple industries such as food and oil. It can perfectly handle the filling of various non - carbonated beverages, including purified water, mineral water, and fruit juice. Different manufacturers can customize the filling line according to their own production capacity requirements and product characteristics to meet diverse production needs. With the continuous progress of technology, the 5L bottle water filling line is also constantly being upgraded. In the future, it will play an even more important role in improving production efficiency and ensuring product quality, helping the bottled water industry reach new heights of development.

0 notes

Text

How to Choose the Right Barrel Water Filling Machine for Your Business

Selecting an appropriate barrel water filling machine is crucial for the efficient operation and profitability of your business. Here are several key aspects to consider.

Production Capacity:First, assess your production needs. If you are a small - scale business, such as a local water station serving a small community, a machine with a filling speed of 100 - 300 barrels per hour may be sufficient. Medium - sized enterprises with higher output requirements can opt for machines that can handle 300 - 1000 barrels per hour. For large - scale commercial water - bottling plants, high - speed machines capable of filling 1000 - 2000 barrels or more per hour are necessary to meet mass production demands.

Water Quality Requirements:Different types of water, like purified water, mineral water, and distilled water, may require specific handling during the filling process. Ensure that the machine you choose is compatible with the water treatment and filling requirements of your product. Some advanced machines are equipped with precise flow - control systems and material - resistant components to maintain water quality integrity.

Budget Constraints:Cost is a significant factor. Smaller, less automated machines are generally more affordable and suitable for businesses with limited budgets. However, keep in mind that investing in a higher - quality, more automated machine may offer long - term benefits, such as lower labor costs, higher production efficiency, and better product consistency. Consider the total cost of ownership, including purchase price, installation, maintenance, and potential upgrades.

Machine Structure and Components:Examine the machine's structure. A reliable filling machine should have a robust washing section to thoroughly clean barrels, an accurate filling section to ensure proper volume, and a secure capping section to prevent leakage. Electrical control systems and pneumatic components should be of good quality to ensure stable operation. Look for machines with easy - to - access components for maintenance and repair.

Technical Support and After - Sales Service:Choose a manufacturer or supplier that offers excellent technical support and after - sales service. Regular maintenance is essential for the long - term performance of the machine. Ensure that spare parts are readily available, and there is professional assistance for installation, operation training, and troubleshooting.

By carefully evaluating these factors, you can make an informed decision and select a barrel water filling machine that best suits your business needs, enhancing productivity and competitiveness in the market.

0 notes

Text

The Wide-Ranging Applications of 5 Gallon Filling Machines

5 gallon filling machines have carved out a significant niche in various industries due to their versatility and efficiency in filling containers of a specific, yet widely used, volume.

Beverage Industry

In the beverage sector, 5 gallon filling machines are workhorses. They are extensively used in bottling plants for filling still water, mineral water, and even some types of juices. For water bottlers, these machines ensure that each 5 gallon container is filled precisely with clean, purified water. The high - speed models can handle large - scale production, meeting the demands of both commercial and residential consumers who rely on 5 gallon water jugs for daily hydration. For example, in areas where tap water quality is a concern, companies that provide bottled water in 5 gallon containers use these filling machines to maintain a consistent supply. Some artisanal juice producers also utilize 5 gallon filling machines to package their products in larger volumes for distribution to cafes, restaurants, or for bulk sales.

Food and Culinary Sector

Beyond beverages, the food industry benefits from 5 gallon filling machines as well. They are used to fill containers with products like vinegar, which is often sold in 5 gallon sizes to restaurants, catering services, and food processing facilities. Additionally, certain types of edible oils, such as olive oil or vegetable oil, may be filled into 5 gallon containers for wholesale distribution. In the production of sauces and syrups, these filling machines can accurately dispense the right amount of product, ensuring that each container is filled to the brim, ready for use in kitchens or further processing.

Industrial and Chemical Applications

The industrial and chemical fields also find 5 gallon filling machines indispensable. They are used to fill containers with a variety of liquids, including industrial solvents, cleaning agents, and certain types of liquid adhesives. For instance, in manufacturing plants where large amounts of solvents are required for degreasing or cleaning parts, 5 gallon containers filled by these machines are a common sight. In the automotive industry, 5 gallon containers of antifreeze or windshield washer fluid are filled using such machines. The ability of these filling machines to handle different viscosities and chemical properties of liquids makes them suitable for a wide range of industrial applications.

Pharmaceutical and Healthcare

Even in the pharmaceutical and healthcare industries, 5 gallon filling machines play a role. They can be used to fill containers with liquid medications, antiseptics, or large - volume solutions used in medical facilities. Although strict regulations govern the pharmaceutical manufacturing process, 5 gallon filling machines that meet the required hygiene and precision standards are used to package products that are then distributed to hospitals, clinics, and pharmacies. This ensures that healthcare providers have a ready supply of essential liquid medications and solutions in larger, more cost - effective quantities.

In conclusion, the 5 gallon filling machine's adaptability to different types of liquids and its capacity to fill a commonly used container size make it a crucial piece of equipment across multiple industries, facilitating efficient production and distribution processes.

0 notes

Text

The Vital Role of Water Treatment Plants

In the intricate web of modern urban infrastructure, water treatment plants stand as silent sentinels, safeguarding the quality and safety of water supplies for both domestic and industrial use. These facilities play an indispensable role in transforming raw water from various sources, such as rivers, lakes, and underground aquifers, into clean, potable water that meets strict health and safety standards.

The process of water treatment is a complex and meticulous sequence of steps. Initially, raw water enters the pretreatment stage, where large debris like branches and plastics are removed by screens or grates. Subsequently, the water flows into sedimentation basins, where heavier particles, such as sand and silt, settle to the bottom through gravity.

The next crucial phase is coagulation. Coagulating agents are added to the water to neutralize the electrical charges of tiny suspended particles and colloids, causing them to clump together into larger flocs. These flocs then settle in the sedimentation tanks and are removed by sludge discharge systems. After sedimentation, the water undergoes filtration, passing through layers of sand, gravel, and activated carbon filters. These filters effectively trap any remaining fine impurities, further clarifying the water.

Finally, disinfection is the last line of defense to ensure water safety. Common disinfection methods include chlorination, ultraviolet (UV) disinfection, and ozonation. Chlorination, the most widely used approach, effectively kills harmful bacteria, viruses, and other pathogens, while UV disinfection inactivates microorganisms by damaging their DNA or RNA.

With the rapid advancement of technology, water treatment plants are continuously evolving. Innovations like membrane filtration, advanced oxidation processes, and biological treatment methods are being adopted to enhance treatment efficiency and remove contaminants that traditional methods struggle with, such as emerging organic pollutants and trace heavy metals.

Water treatment plants are not only essential for human health but also for environmental sustainability. By treating wastewater before it is released back into natural water bodies, they prevent pollution and protect aquatic ecosystems. In essence, water treatment plants are the unsung heroes of modern society, ensuring a continuous supply of clean water and contributing significantly to the well - being of both humans and the environment.

0 notes

Text

Bottle Sorting Machines: Revolutionizing Recycling and Production Processes

In today's world, where environmental consciousness and efficient production are of utmost importance, bottle sorting machines have emerged as invaluable tools. These machines play a crucial role in various industries, particularly in recycling and manufacturing.

How Bottle Sorting Machines Work

Bottle sorting machines are equipped with advanced technologies to distinguish between different types of bottles. One common method is through the use of optical sensors. These sensors can detect the color, shape, and material of the bottles. For example, in a recycling plant, when a mixture of plastic, glass, and aluminum bottles is fed onto the conveyor belt of the sorting machine, the optical sensors quickly analyze each bottle. They can identify the chemical composition of the plastic bottles, differentiating between PET, PVC, and other types of plastics based on the unique light absorption and reflection patterns of each material. Another technology used is near - infrared (NIR) spectroscopy. NIR sorters work by emitting near - infrared light onto the bottles. Different materials absorb and reflect this light in distinct ways. This allows the machine to accurately separate materials like separating PVC, PP, PE, ABS, or rubber from PET flakes in the case of plastic recycling.

Applications of Bottle Sorting Machines

Recycling Industry Bottle sorting machines are a game - changer in the recycling industry. They enable recycling centers to handle large volumes of waste bottles more efficiently. Instead of relying on manual labor, which is time - consuming and prone to errors, these machines can quickly sort thousands of bottles per hour. By separating bottles into different categories such as clear glass, colored glass, plastic, and aluminum, they ensure that each material can be recycled properly. This not only increases the amount of recyclable materials recovered but also reduces contamination in the recycling stream. For instance, separating PET bottles from other plastics ensures that the recycled PET can be used to make high - quality products like new bottles or polyester fibers for clothing.

Manufacturing and Packaging IndustryIn manufacturing plants, bottle sorting machines are used to orient and prepare bottles for filling, capping, and labeling processes. They ensure that bottles are in the correct position and orientation, reducing the risk of jams and errors in the production line. For example, Edelstein's bottle sorting machines can collect and orient bottles, supplying them smoothly to bottle rinsers or filling machines. This helps to streamline the production process, increasing productivity and reducing downtime.

Advantages of Bottle Sorting Machines

· Increased Efficiency: Bottle sorting machines can sort bottles at a much faster rate than humans. They can handle large volumes continuously, which significantly speeds up recycling and production processes. · Improved Accuracy: The advanced sensors and technologies used in these machines ensure accurate sorting. This leads to higher - quality recycled materials and fewer mistakes in manufacturing processes. · Cost - Effective: Although the initial investment in a bottle sorting machine can be significant, in the long run, it saves costs. It reduces the need for a large amount of manual labor in recycling and production, and also decreases waste due to incorrect sorting. · Flexibility: Many bottle sorting machines can be updated and adjusted to handle new types of materials or bottle shapes. This makes them adaptable to changes in the market and new packaging designs.

As technology continues to advance, bottle sorting machines are likely to become even more sophisticated. They will be able to handle a wider variety of materials and improve sorting accuracy further, contributing to a more sustainable and efficient future.

0 notes

Text

Bottled Water Filling Machines: The Core Drivers of Modern Packaging Technology

In the fast - paced modern life, bottled water has become a necessity. As the core equipment in bottled water production, bottled water filling machines directly affect production efficiency, as well as product quality and safety.

These highly automated machines integrate multidisciplinary technologies such as mechanics, electronics, and pneumatics to accurately fill processed water into various containers. Comm

on flling methods include atmospheric pressure filling, negative pressure filling, and isobaric filling. Atmospheric pressure filling relies on the gravity of the liquid and is suitable for low - viscosity, non - carbonated liquids. Negative pressure filling creates a vacuum in the container first and then uses atmospheric pressure to fill the liquid, effectively reducing the contact between the liquid and air and preventing oxidation. Isobaric filling is mainly used for carbonated beverages. It first fills the container with gas at the same pressure as the liquid storage tank to equalize the pressure inside the bottle and the tank, and then the liquid is filled into the container under the action of gravity, avoiding the escape of gas in carbonated beverages and ensuring product taste and quality.

Modern filling machines have remarkable advantages. In terms of efficiency, advanced models can fill hundreds or even thousands of bottles per minute. After a well - known brand introduced a high - speed filling machine, its daily output increased by 30%, effectively reducing production costs per unit. In terms of precision, high - precision metering systems ensure minimal errors in filling volume, guaranteeing product consistency. Meanwhile, the machines can quickly change molds, flexibly adapting to various bottle shapes and capacities.

Hygiene and safety are equally crucial. Filling machines are usually made of food - grade stainless steel, which is easy to clean and corrosion - resistant. They are equipped with comprehensive cleaning and disinfection systems, and high - end models even adopt aseptic filling technology, enhancing product safety and shelf life.

With the development of science and technology, filling machines are moving towards the direction of intelligence, energy - conservation, and environmental protection. Artificial intelligence and Internet of Things technologies enable automatic fault diagnosis and early warning, and data interaction with the production management system facilitates decision - making. Efficient drive systems and water circulation treatment systems reduce energy and water consumption, and environmentally friendly designs minimize pollution. Bottled water filling machines will continue to drive the development of the industry through technological innovation.

0 notes

Text

5-Gallon Water Filling Machines: Efficient Production Tools in the Food and Beverage Industry

In the highly competitive food and beverage industry, 5-gallon water filling machines have emerged as key equipment for enterprises to enhance their competitiveness, thanks to their precision, efficiency, and hygiene.

In drinking water production, the automated control system of these machines can clean and disinfect empty barrels, ensuring a sterile filling environment. The high-precision flow control technology guarantees accurate volume, as demonstrated by a brand that saw a 40% increase in daily production and over 99% consistency in volume and hygiene compliance after implementation. In beverage production, the filling machines can adapt to various products like juices and herbal teas through parameter adjustments and component replacements. They minimize oxidation during juice filling and ensure efficient production for herbal teas. Integrated with other equipment, they form automated production lines, significantly reducing labor costs. Additionally, in filling special liquid products such as soy sauce and edible oils, the machines' excellent sealing and anti-drip features ensure accurate and efficient filling.

However, with consumers' growing demand for quality, filling machines face higher challenges in hygiene and precision. The diverse characteristics of different products also require greater flexibility and compatibility. To address these, manufacturers are increasing R&D efforts, adopting new materials, upgrading systems, and developing intelligent maintenance systems. In the future, the integration of IoT and AI will make production management smarter, while the machines will evolve towards energy conservation and low-carbon operation, continuously empowering the food and beverage industry.

0 notes

Text

Methods to improve the filling accuracy of 5L water filling machine

I. Optimization of equipment components

(I) Upgrading filling valves

Traditional filling valve seals are prone to wear and tear, causing liquid leakage. New ceramic or high-strength alloy valves can be used, which have excellent sealing and wear resistance and can significantly reduce dripping. For example, a well-known brand of ceramic valve core valve has a filling accuracy of ±10 ml under normal use, which is far superior to ordinary rubber sealing valves. In addition, the valve should be fully inspected at least once a week to check the condition of the seals to ensure flexible opening and closing, and timely clean and lubricate the stuck valve to avoid filling volume deviation due to slow valve movement.

(II) Optimizing the liquid level sensor

The liquid level sensor is the key to controlling the filling volume. Using capacitive or ultrasonic liquid level sensors has higher resolution and sensitivity. Capacitive sensors can accurately sense small changes in liquid level, and accurately control the timing of valve closing by detecting changes in capacitance value. Compared with traditional float sensors, the accuracy is improved several times. The sensor needs to be calibrated with a standard liquid level container every month, and the surface needs to be cleaned with a special cleaning agent to prevent impurities from affecting the sensing effect, and to avoid situations such as misjudgment of the liquid level and insufficient filling volume due to impurities on the sensor surface.

2. Accurate parameter adjustment

(I) Accurately set filling parameters

Different liquids have different viscosities, densities and surface tensions, which will affect the filling speed and accuracy. For high-viscosity liquids, such as some fruit juice drinks, the filling speed needs to be reduced and the filling time needs to be increased to ensure that the liquid flows smoothly into the bottle; for liquids with low density, the filling pressure needs to be appropriately reduced to prevent overflow. When new equipment is put into use or products are replaced, multiple small-scale tests are required to record the filling volume under different parameters, and statistical methods are used for analysis to find the best filling speed, pressure and time combination to improve filling accuracy.

(II) Stabilize equipment operating parameters

For pressure filling, stable air source pressure is crucial. Install a high-precision pressure stabilizing device, such as a high-precision air compressor equipped with an intelligent pressure regulator, to control pressure fluctuations within ±0.01MPa. At the same time, regularly check the transmission parts of the equipment to ensure that the chains, gears, belts, etc. run smoothly without looseness, wear or jumping. Reduce equipment vibration by installing shock-absorbing pads and adjusting the level of the equipment to ensure filling stability.

III. Control of production environment

(I) Purify production water

Impurities in production water will clog pipes and valves. Establish a multi-stage filtration system, first filter out large particles through a coarse filter, and then remove tiny particles, colloids and organic matter through sand filtration, activated carbon filtration, and precision filtration. Regularly test water quality, including pH, hardness, microbial content, etc. If the water quality does not meet the requirements, adjust the water treatment process or replace the filter element in time.

(II) Control environmental temperature and humidity

Temperature affects the density and viscosity of the liquid. The workshop temperature is controlled at 20-25℃, and air conditioning and automatic temperature control systems are installed to maintain constant temperature. High humidity affects the electrical components of the equipment and may also change the composition of the liquid. The workshop humidity is controlled at 40%-60%, and adjusted by a dehumidifier or humidifier.

0 notes

Text

What is the working principle of the shrink sleeve labeling machine?

Container Conveying Link: Firstly, the containers to be labeled, such as bottles and jars, are placed on the conveyor belt. The conveyor belt runs at a stable and adjustable speed to ensure that the containers can enter each working area of the labeling machine one by one and smoothly. This conveying process is the starting foundation of the entire workflow. The accurate and uniform conveying of the containers is crucial for the precision of the subsequent labeling steps.

Label Feeding Part: The shrink sleeve labeling machine is equipped with a special label unwinding device, and the labels are usually installed on it in a roll form. As the equipment operates, the label roll will unwind slowly and smoothly, conveying the labels to the designated position. During the conveying process, there will be a tension control system that monitors and adjusts the conveying tension of the labels in real time to prevent the labels from being loose or too tight, so as to ensure that the labels can enter the next process smoothly and accurately.

Labeling Operation Process: When the container is conveyed to the labeling position, the label will be accurately placed on the container through a specific mechanical structure. There are two common labeling methods: one is to use the principle of vacuum adsorption. Through a sleeve or drum with vacuum holes, the label is adsorbed on its surface. When the container approaches, the vacuum is released, and the label is then placed on the container. The other is the mechanical labeling method. Through a robotic arm or a similar structure, the label is cut to an appropriate length from the label roll and then directly placed on the container. This step requires a high degree of mechanical precision and timing coordination to ensure that the label is placed in the correct position without any error.

Shrink Forming Stage: The container with the label on it will then enter the shrinking area, which is usually a heating tunnel. In the heating tunnel, uniform and controllable hot air will be generated, or other heating methods such as infrared heating will be used. When the container passes through the heating tunnel with the label on it, the label material (usually heat-shrinkable plastics such as PVC and PETG) will quickly shrink under the action of heat and tightly fit the surface of the container, forming a tight wrapping effect that conforms to the shape of the container. Parameters such as the heating temperature, time, and the conveying speed of the container in the tunnel can all be precisely adjusted according to the label material and the container specifications to achieve the best shrinking effect.

0 notes

Text

The Intricate World of Beverage Production Lines

In the dynamic landscape of the beverage industry, the beverage production line stands as the backbone, orchestrating a seamless symphony of processes that transform raw materials into the refreshing drinks we enjoy daily. This complex system is a marvel of engineering and technology, designed to meet the ever - growing demands of consumers while ensuring high - quality and consistent products.

Components of a Beverage Production Line

1.Raw Material Handling

The journey begins with the careful handling of raw materials. For non - alcoholic beverages like juices, water, and soft drinks, this includes sourcing fruits, purifying water, and procuring syrups and flavorings. In the case of alcoholic beverages such as beer and wine, malt, hops, grapes, and yeast are key raw materials. Specialized storage tanks, conveyors, and dosing systems are used to transport and measure these ingredients accurately. For example, in a juice production line, fruit storage areas are climate - controlled to maintain the freshness of the produce. High - tech weighing scales ensure that the exact amount of sugar or sweeteners is added to achieve the desired taste profile.

2.Mixing and Blending

Once the raw materials are in place, they are combined in precise ratios in the mixing and blending stage. This is a critical step as it determines the flavor, consistency, and quality of the final product. In a soft drink production line, carbonated water is mixed with syrups and flavor concentrates in large, stainless - steel mixers. These mixers are equipped with high - speed agitators to ensure thorough blending. For more complex beverages like energy drinks, multiple ingredients such as caffeine, vitamins, and electrolytes are carefully blended to create a balanced formula.

3.Filtration and Clarification

To remove any impurities and achieve a clear, appealing product, filtration and clarification processes are employed. In a water bottling plant, water is passed through a series of filters, including sand filters, activated carbon filters, and membrane filters. These filters remove particles, microorganisms, and any unwanted chemicals. In the production of wine, clarification agents such as bentonite or egg whites may be used to remove suspended solids and clarify the liquid, enhancing its visual appeal.

4.Bottling and Packaging

The filled and sealed containers are then labeled and packaged for distribution. This involves automated labeling machines that apply product information, branding, and nutritional labels accurately. Packaging materials such as cardboard boxes, shrink - wrap, or pallets are used to group and protect the bottled beverages during transportation. In some cases, secondary packaging may also include promotional materials or multi - pack configurations to attract consumers.

The Significance of Beverage Production Lines

1.Meeting Consumer Demands

Beverage production lines play a crucial role in meeting the diverse and ever - changing demands of consumers. Whether it's the increasing preference for healthy, natural beverages or the demand for convenient, single - serve packaging, these production lines can be quickly reconfigured to produce different product varieties. For example, as the demand for plant - based milk alternatives has surged, dairy - free production lines have been established to meet this market need.

2.Driving Economic Growth

The beverage industry, supported by its production lines, contributes significantly to the global economy. It creates jobs in manufacturing, distribution, and sales. In addition, the growth of beverage production lines stimulates related industries such as packaging, raw material supply, and equipment manufacturing. For example, a new soft drink production line in a region not only provides direct employment but also boosts the local economy by creating business opportunities for suppliers of bottles, caps, and flavorings.

In conclusion, the beverage production line is a complex and highly efficient system that combines art and science to produce the beverages we love. Through continuous technological innovation and adaptation to consumer demands, these production lines will continue to shape the future of the beverage industry.

0 notes

Text

300bph 5gallon water filling line

Automatic de-capper machine BG series automatic de-capper machine is specially designed to match the barreled production line for 5 gallons barreled drinking water, particularly suitable for automatic de-cap before recycling barrels for cleaning. It remarkably improves productivity, reduces the secondary pollution caused by manual cap removal to a larger extent, and lessens the labor intensity of operators. The use of top quality stainless steel for the whole machine guarantees its anti-corrosion and easiness of cleaning.

Working steps: The empty bottle is transported into automatic de-capping machine by conveyor chain .when barrel detected by count sensor ,the barrel blocking cylinder will work and block and stop the barrel which is on conveying belt , then cap removing cylinder works downwards and makes removing heads cover cap . After cap catching cylinder works downwards and catches cap tightly , cap removing cylinder works upwards and removes cap , meantime ,cap blowing electro-magnetic valve open and blow removed cap into container , the barrel removed cap outlets by conveyor belt .

youtube

0 notes

Text

VACGF-15000/32-32-10 bottled water filling machine

15000bph bottled water filling line adopts 32/32/10 washing filling capping 3 in 1 machine .The equipment to absorb the same type of foreign advanced technology products, stable performance, safe and reliable. Applicable to large and medium-sized beverage plant water and non-gas drinks in the high-speed filling. Features of our filling machine 1.air conveyor fan with air filter net ,avoid the dust from air 2.washing nozzel use ss formed pipes ,long time use 3.fast filling valve 4.big screw capping heads 5.solid windows and doors 6.high quality material ,high configuration and good manufacture process

For more info, please contact us at

Web: https://www.water-bottling-line.com

Email:[email protected]

youtube

0 notes

Text

Water Treatment Equipment: The Guardians of Clean Water

The Significance of Water Treatment Equipment

In our daily lives, water treatment equipment is the unsung hero that ensures the water flowing from our taps is safe to drink. Municipal water treatment plants are equipped with a series of processes to purify water sourced from rivers, lakes, or groundwater. Without these facilities, the risk of water - borne diseases such as cholera, typhoid, and dysentery would be significantly higher. In industrial settings, water treatment equipment is equally vital. Industries rely on large volumes of water for various processes. For example, in the food and beverage industry, high - purity water is required to maintain product quality and safety. In power generation, treated water is used for cooling systems to prevent corrosion and ensure efficient operation.

Types of Water Treatment Equipment and Their Working Principles

Filtration Equipment

Filtration is one of the fundamental processes in water treatment. Mechanical filters, like sand filters, use physical barriers to trap suspended particles. Water is passed through layers of sand, and particles larger than the pore size of the sand are retained. Activated carbon filters, on the other hand, work on the principle of adsorption. Activated carbon has an extremely large surface area due to its porous structure. This allows it to attract and hold organic compounds, chlorine, and some heavy metals. Reverse osmosis (RO) systems are a more advanced form of filtration. RO membranes have pores so small that they can reject dissolved salts, heavy metals, and most organic molecules. Water is forced through the membrane under pressure, and only pure water molecules can pass through, leaving contaminants behind.

Disinfection Equipment

Disinfection is crucial for killing harmful microorganisms in water. Chlorination is a widely used disinfection method. Chlorine, when added to water, forms hypochlorous acid, which is a powerful oxidizing agent. This acid penetrates the cell walls of bacteria and viruses, disrupting their metabolic processes and ultimately killing them. Ozone disinfection is another effective method. Ozone is a highly reactive form of oxygen. When introduced into water, it quickly decomposes, releasing oxygen atoms in a highly reactive state. These reactive oxygen atoms attack and destroy the cell walls and membranes of microorganisms. Ultraviolet (UV) disinfection uses UV light in the germicidal range. The UV light damages the DNA or RNA of microorganisms, preventing them from reproducing.

Chemical Treatment Equipment

Chemical treatment equipment is used to adjust the chemical composition of water. For example, in the process of coagulation and flocculation, chemicals such as aluminum sulfate or ferric chloride are added to water. These coagulants neutralize the negative charges on fine suspended particles and colloids, causing them to come together and form larger flocs. Flocculation then involves gentle mixing to promote the growth of these flocs, which can be more easily removed by sedimentation or filtration. pH adjustment is another important aspect of chemical treatment. If the water is too acidic, chemicals like lime can be added to raise the pH. Conversely, if the water is too alkaline, acids such as sulfuric acid can be used to lower the pH.

Applications of Water Treatment Equipment

As mentioned earlier, water treatment equipment has extensive applications in both domestic and industrial sectors. In addition to providing clean drinking water and supporting industrial processes, it also plays a vital role in environmental protection. Wastewater treatment plants use a combination of physical, chemical, and biological treatment processes to remove pollutants from domestic and industrial wastewater before discharging it back into the environment. This helps prevent water pollution and protects aquatic ecosystems.

In conclusion, water treatment equipment is an indispensable part of our modern society. It not only ensures the availability of clean and safe water for various uses but also contributes to environmental sustainability. As water resources become more scarce and polluted, the continuous development and improvement of water treatment equipment will be crucial in meeting the growing demand for high - quality water.

0 notes

Text

Working principle of piston filling machine

In the production and packaging of various liquid products, the piston filling machine is a powerful "assistant". Its working principle is ingenious and efficient.

The core components of the piston filling machine are the piston and the cylinder. When working, the piston reciprocates in the cylinder. Let's look at the liquid suction process first. When the piston is pulled outward, the space in the cylinder becomes larger, the pressure decreases, and a vacuum state is formed. At this time, the external atmospheric pressure "presses" the liquid in the storage tank into the cylinder through the liquid inlet pipe and the one-way valve. Just like sucking a drink with a straw, the pressure decreases after the air in the straw is sucked out, and the drink is sent into the straw by atmospheric pressure.

Then comes the liquid filling link. The piston begins to push inward, the liquid in the cylinder is squeezed, and the pressure increases. The liquid follows the liquid outlet pipe, pushes open the liquid outlet one-way valve, and is accurately injected into the container below waiting for filling. The length of the piston movement directly determines the amount of filling liquid. For example, the longer the piston stroke, the more liquid is pushed out; the shorter the stroke, the less filling volume. The advanced piston filling machine is also equipped with an electronic control system that can accurately control the piston stroke, so that the error of each filling amount is extremely small, ensuring stable product quality.

The one-way valve plays a key role in the entire working process. The inlet one-way valve only allows liquid to flow into the cylinder to prevent the liquid from flowing back into the storage tank; the outlet one-way valve only allows the liquid in the cylinder to flow to the filling container to prevent the liquid in the container from flowing back. With such a simple but exquisite design, the piston filling machine can complete the liquid filling task efficiently and accurately. It is widely used in many industries such as food, medicine, and cosmetics, providing all kinds of beautifully packaged liquid products for our daily life.

0 notes

Text

The Powerhouse of Beverage Industry: Bottle Packing Machine

A bottle packing machine operates based on a combination of mechanical, electrical, and pneumatic systems. First, the machine is designed to receive bottles from the production line. This can be either through a conveyor belt system or an automated feeding mechanism. Once the bottles are in position, the packing process begins.

For carton - based packing, the machine picks up pre - cut and folded cartons. Using suction cups or mechanical grippers, it opens the cartons and positions them accurately. Then, the bottles are grouped according to the packaging requirement (e.g., six - packs, twelve - packs) and pushed or dropped into the cartons. Some advanced models can even perform label - applying operations during the packing process, ensuring that each bottle is properly labeled before being packed.

In the case of shrink - wrap packing, the bottles are first grouped. Then, a plastic film is wrapped around the group of bottles. The film - wrapped bottles are passed through a heat - tunnel, where the heat causes the plastic film to shrink tightly around the bottles, providing a secure and attractive package.

Advantages

High Efficiency: Bottle packing machines can pack a large number of bottles in a short time. For example, a high - speed machine can pack hundreds of bottles per minute, which is far beyond the capacity of manual labor. This high - speed operation significantly increases production output and reduces production time.

Accuracy and Consistency: Machines ensure that each bottle is packed in the same way, with the correct number of bottles per pack and proper alignment. This results in a uniform and professional - looking product on the shelves, enhancing the brand image.

Cost - Savings: Although the initial investment in a bottle packing machine can be high, in the long run, it saves costs. By reducing the need for a large number of manual laborers, companies can cut down on labor costs, including salaries, benefits, and training expenses.

Flexibility: Modern bottle packing machines are designed to be flexible. They can handle different bottle sizes, shapes, and packaging materials. This adaptability allows beverage manufacturers to quickly change their product packaging to meet market demands or launch new products.

In conclusion, the bottle packing machine is an essential part of modern manufacturing processes. Its continuous technological advancements will further enhance its efficiency, flexibility, and application scope, making it an even more vital asset for industries that rely on bottle packaging.

0 notes