Don't wanna be here? Send us removal request.

Text

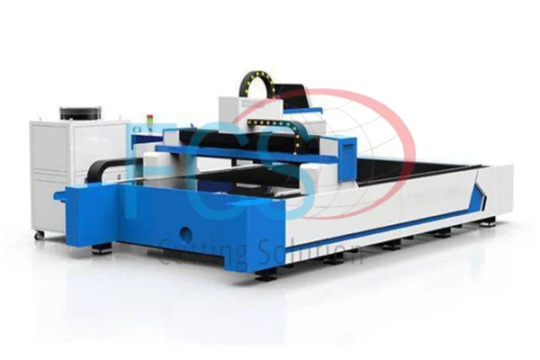

8x4 Laser Cutting Machine price in India

Looking for an 8x4 Laser Cutting Machine price in India? Fine Cutting Solution offers high-performance laser cutters designed for precision and efficiency. Our 8x4 laser cutting machine is ideal for cutting metal sheets, acrylic, MDF, and more with unmatched accuracy. With advanced fiber laser technology and low maintenance, it’s perfect for both small workshops and large-scale industries. The price in India typically ranges from ₹12 lakhs to ₹25 lakhs, depending on power capacity and features. We ensure excellent after-sales support and fast delivery. Choose Fine Cutting Solution for reliable machines and competitive pricing tailored to your needs.

#LaserCutting#FineCuttingSolution#LaserMachine#MetalCutting#Manufacturing#IndustrialMachinery#LaserTechnology#IndianIndustry#CNC#Fabrication#SteelCutting#Engineering#Metalworks#PrecisionCutting#MachinerySales#Productivity#MadeInIndia

0 notes

Text

3kW Laser Cutting Machine Price in India – Fine Cutting Solution

3kW Laser Cutting Machine Price in India – Fine Cutting Solution

Laser cutting technology has revolutionized the metal fabrication industry, offering unmatched precision, speed, and efficiency. Among the various power ratings available in the market, the 3kW laser cutting machine stands out as a balanced choice for medium to heavy-duty industrial applications. In India, Fine Cutting Solution provides state-of-the-art 3kW laser cutting machines equipped with advanced features and technology, ensuring high performance and productivity. If you're searching for accurate information about the 3kW laser cutting machine price in India, this guide will help you understand key factors that influence the cost and what to expect when investing in a laser cutting solution.

Overview of a 3kW Laser Cutting Machine

A 3kW fiber laser cutting machine is designed to cut through a wide range of metals such as mild steel, stainless steel, aluminum, brass, and copper with high accuracy. It offers a great balance between cutting speed, thickness capacity, and operational cost, making it ideal for industries like automotive, fabrication, signage, and machinery manufacturing.

Key Features:

Power Output: 3000W (3kW) fiber laser

Cutting Thickness: Up to 20 mm (mild steel), 10-12 mm (stainless steel), and 8 mm (aluminum)

Cutting Speed: High-speed performance with excellent edge quality

Automation: CNC control, auto-focus laser head, nesting software

Low Maintenance: Fiber laser source offers longer life and reduced servicing

3kW Laser Cutting Machine Price in India

The price of a 3kW laser cutting machine in India varies depending on several factors such as the brand, configuration, software, table size, laser source, and after-sales support. On average, the cost ranges between ₹25 Lakhs to ₹45 Lakhs.

Price Breakdown:

Category

Approximate Price Range

Entry-Level Machines

₹25 – ₹30 Lakhs

Mid-Range Industrial Models

₹30 – ₹38 Lakhs

High-End Machines with Automation

₹38 – ₹45 Lakhs

Note: Prices are indicative and may vary based on customization, import duties, and technical features.

Why Choose a Fine Cutting Solution?

At Fine Cutting Solution, we are committed to delivering precision-driven laser cutting solutions that cater to Indian manufacturers' evolving needs. Our 3kW fiber laser cutting machines are built using premium components, including Raycus/IPG laser sources, automatic laser heads, and user-friendly CNC systems.

Our Value Offerings:

Affordable Pricing: Competitive rates with no compromise on quality

Custom Solutions: Machine bed sizes, power capacity, and add-ons tailored to your needs

On-Site Support: Installation, training, and AMC services across India

Trusted Brands: Tie-ups with leading global manufacturers for key components

Warranty & Service: Standard warranty with prompt technical support

Factors That Affect the Price of 3kW Laser Machines

When evaluating the cost of a 3kW laser cutting machine, consider the following aspects:

1. Laser Source Brand

Reputable laser sources like IPG (Germany) or Raycus (China) influence price significantly. IPG offers longer life and better stability but comes at a premium.

2. Cutting Bed Size

Standard sizes (e.g., 1500x3000 mm) are economical, but larger custom beds (e.g., 2000x6000 mm) increase cost due to frame strength and mechanics.

3. Control System

Advanced CNC systems like CypCut, HypCut, or FSCUT offer better integration, higher automation, and faster processing — often priced higher.

4. Build Quality

Machines built with rigid steel structures, high-precision linear guides, and anti-vibration frames will cost more but last longer and perform better.

5. Software & Automation

Nesting software, auto-focus heads, shuttle tables, and camera alignment systems add to productivity but also increase the investment.

Applications of 3kW Laser Cutting Machines

3kW machines are versatile and widely used in the following industries:

Metal Fabrication: For cutting MS, SS, and aluminum sheets

Automotive Parts: Frames, brackets, and enclosures

Electrical Cabinets: Control panels and switchboards

Signage Industry: Decorative elements and letter cutting

Agricultural Equipment: Blades, arms, and heavy parts

Return on Investment (ROI)

Investing in a 3kW fiber laser cutting machine offers a strong ROI due to:

Faster job completion

Lower running cost per cut

Reduced manual labor

Minimal maintenance

High resale value

For medium to large businesses, the payback period is typically between 1.5 to 3 years depending on usage and production volumes.

Why Fiber Laser Over CO₂?

While CO₂ laser machines are still used in some sectors, fiber lasers dominate due to:

Higher electrical efficiency

Lower maintenance

Faster cutting of thin to medium sheets

Better compatibility with metals

Compact and modern design

A 3kW fiber laser significantly outperforms a CO₂ machine in terms of speed, quality, and cost-efficiency.

Final Thoughts

Choosing a 3kW laser cutting machine is a strategic decision for businesses looking to upgrade their metal fabrication capabilities. With Fine Cutting Solution, you not only get high-performance machines at the best price in India but also reliable service, training, and technical support that ensures smooth operation from day one.

If you're looking for the best deal on a 3kW laser cutting machine, contact Fine Cutting Solution today. Our team is ready to guide you with free consultations, demo sessions, and custom pricing based on your application needs.

#LaserCuttingMachine#FiberLaserCutting#LaserCuttingIndia#MetalFabrication#SheetMetalCutting#3kWLaser#CNCcutting

0 notes

Text

3kW Laser Cutting Machine Price in India from Fine Cutting Solution offers a perfect balance of precision, speed, and affordability for Indian industries. Designed for high-accuracy cutting of metals like mild steel, stainless steel, and aluminum, this machine ensures clean edges with minimal material wastage. Its robust design and advanced laser technology help you tackle diverse fabrication projects efficiently. The 3kW model is ideal for both small and large production setups, delivering consistent output with low maintenance costs. Priced competitively in India, it’s the perfect investment to enhance your business’s productivity and cut operating expenses without compromising on quality. Fine Cutting Solution promises dedicated support and service.

#LaserCutting#3kWLaser#FineCuttingSolution#LaserMachine#MetalCutting#Manufacturing#IndustrialMachinery#LaserTechnology#IndianIndustry#CNC#Fabrication#SteelCutting#Engineering#Metalworks#PrecisionCutting#MachinerySales#Productivity#MadeInIndia

0 notes

Text

3kW Laser Cutting Machine Price in India

3kW Laser Cutting Machine Price in India – Fine Cutting Solution

3kW laser cutting machine is a powerful and versatile tool widely used across industries for precision metal cutting applications. With a fiber laser source of 3000 watts, it delivers high-speed and accurate cutting on a wide range of materials, including mild steel, stainless steel, aluminum, brass, and copper. The 3kW laser cutting system strikes a balance between power and energy efficiency, making it a popular choice for small to medium-scale manufacturers looking to boost productivity without excessive operational costs.

This machine is especially suitable for cutting medium-thickness sheets with smooth edges and minimal heat-affected zones. A well-designed 3kW laser cutter ensures consistent performance, faster cutting speeds, and lower maintenance, owing to the fiber laser’s solid-state design. It can cut mild steel up to 16mm, stainless steel up to 8mm, and aluminum sheets up to 6mm with excellent edge quality. Integrated features like automatic focus, high-precision servo motors, nesting software, and a user-friendly interface enhance operational ease and material optimization.

One of the major advantages of a 3kW laser cutting machine is its adaptability to both heavy-duty industrial needs and precise artistic or custom fabrication work. It is also compatible with automation systems like shuttle tables, robotic arms, and smart dust collection systems, increasing overall workflow efficiency. Many Indian manufacturers now offer 3kW fiber laser cutting machines with localized support, spare parts availability, and training, making them a cost-effective investment for long-term manufacturing.

For businesses in industries such as automotive, signage, fabrication, electrical enclosures, kitchenware, and more, a 3kW laser cutting machine offers reliability, precision, and scalability. With advancements in laser technology and growing domestic production in India, this machine offers a perfect blend of performance, durability, and return on investment for modern fabrication needs.

In today’s fast-evolving manufacturing landscape, precision, speed, and cost-efficiency are paramount. Among the many tools revolutionizing metal fabrication and industrial cutting, 3kW laser cutting machines have emerged as a reliable choice for medium to heavy-duty applications. If you're looking for a high-performance solution that balances cost and capability, understanding the 3kW laser cutting machine price in India is crucial. At Fine Cutting Solution, we provide the latest laser cutting technologies tailored to your business needs, without compromising on quality or affordability.

What is a 3kW Laser Cutting Machine?

A 3kW laser cutting machine uses a high-power fiber laser to cut through various materials such as stainless steel, mild steel, aluminum, copper, and brass. With 3000 watts (3kW) of laser power, these machines are ideal for small to large-scale production setups that require fast, clean, and precise cutting. The strength of the laser ensures deeper penetration and faster cutting speeds, even for thicker materials.

3kW fiber lasers are commonly used in industries like:

Automotive and aerospace

Agriculture equipment manufacturing

Construction and infrastructure

Sheet metal fabrication

Electrical enclosure manufacturing

Furniture and interior design

Why Choose a 3kW Machine?

1. Balanced Power and Efficiency

A 3kW laser cutting machine hits the sweet spot between affordability and cutting capacity. It can handle sheets up to 16 mm thick (mild steel) and up to 10 mm thick (stainless steel or aluminum), depending on the machine configuration and gas type.

2. Reduced Operational Costs

Fiber lasers are more energy-efficient compared to CO₂ lasers. With optimized beam quality, lower maintenance, and fewer consumables, 3kW fiber machines deliver better ROI for Indian manufacturers.

3. High-Speed Cutting

With the right setup, 3kW machines achieve fast cutting speeds, improving throughput and reducing job turnaround time—vital for competitive industries.

3kW Laser Cutting Machine Price in India

The price of a 3kW laser cutting machine in India varies based on several factors, including machine size, brand, configuration, and additional features like automation, dual-platform exchange beds, and software compatibility. On average, here’s what you can expect:

Basic 3kW Fiber Laser Cutting Machine (without automation): ₹22 lakh – ₹30 lakh

Mid-range Models (with features like automatic pallet changers, better controllers): ₹30 lakh – ₹40 lakh

High-End Models (with imported components, advanced cooling systems, dust collectors, etc.): ₹40 lakh – ₹55 lakh

Prices also depend on the bed size. Common configurations like 1500mm x 3000mm (5x10 feet) or 2000mm x 4000mm (6.5x13 feet) will influence the cost. Custom configurations are also available for specific industry needs.

Factors Influencing Price

At Fine Cutting Solution, we believe in transparency and helping customers make informed decisions. Here are the major factors that influence the pricing of a 3kW laser cutting machine:

Laser Source Brand – Brands like IPG, Raycus, MaxPhotonics, and JPT vary in cost and performance.

Bed Size and Structure – Larger beds and heavier machine structures (cast iron or steel frame) increase the price.

Controller and Software – Popular CNC controllers such as CypCut, FSCUT, or Beckhoff add different costs depending on their capabilities.

Automation Features – Auto-focus heads, dual-exchange tables, tube cutting attachments, etc., can significantly increase the overall price.

Warranty and Support – Machines with longer warranties and local service support may come at a premium but offer long-term value.

Fine Cutting Solution – Your Partner in Precision

At Fine Cutting Solution, we specialize in offering reliable and high-performance 3kW laser cutting machines suited for Indian manufacturers. We provide:

Customized machines based on your production needs.

Affordable pricing with flexible EMI and leasing options.

Fast installation and local technical support.

Training and after-sales service to ensure smooth operation.

Options for integrated dust collection, automation, and remote diagnostics.

We also offer comprehensive demos and factory visits, so you can see the machine's performance before purchase.

Cost-Effective Ownership

Buying a laser cutting machine is an investment. Beyond the upfront price, you should consider:

Power consumption – 3kW lasers consume significantly less power than older CO₂ systems.

Maintenance costs – Fiber lasers are known for their minimal maintenance.

Material usage efficiency – High precision reduces waste and increases yield.

Production time savings – Faster cutting means more jobs completed per shift.

All these factors contribute to a lower cost-per-part over time, making 3kW machines a smart investment for growing Indian manufacturers.

Government Support & Financing

With the Make in India initiative and MSME benefits, small and medium-scale industries can avail government subsidies, depreciation benefits, and bank financing for purchasing industrial machinery like laser cutters.

Fine Cutting Solution can assist with documentation and eligibility verification for:

NSIC or MSME certification

GST benefits

Trade-in and upgrade options

Final Thoughts

If you're considering upgrading or investing in a fiber laser cutting machine, a 3kW laser cutter offers the ideal balance of performance and price. With machines starting from ₹22 lakh and scaling up depending on your production needs, you can significantly enhance your operational efficiency and production quality.At Fine Cutting Solution, we’re here to guide you through the process—from selection to installation, and ongoing support. Whether you're cutting mild steel, stainless steel, or aluminum, we have the perfect 3kW solution tailored for Indian conditions.

#3kWLaserCuttingMachine#LaserCuttingIndia#FiberLaserCutter#MetalCuttingMachine#CNCFabrication#SheetMetalCutting#FineCuttingSolution#LaserTechnology#IndustrialMachinery#MakeInIndia#PrecisionCutting#FabricationIndustry#LaserCutterIndia#SmartManufacturing#MetalFabrication

0 notes

Text

Fiber Laser Cutting Machine Manufacturers - Fine Cutting Solution

At Fine Cutting Solution, we are proud to be one of the leading fiber laser cutting machine manufacturers in India, offering state-of-the-art solutions for precision metal cutting. Our fiber laser cutting machines are designed to deliver high speed, exceptional accuracy, and minimal maintenance, making them the perfect choice for industries such as automotive, aerospace, electronics, and metal fabrication.

Using advanced fiber laser technology, our machines ensure clean, burr-free cuts on a variety of metals including stainless steel, carbon steel, aluminum, and brass. With energy-efficient performance and low operating costs, our systems help businesses boost productivity while maintaining the highest quality standards.

In addition to fiber laser machines, Fine Cutting Solution is also a renowned Gantry Plasma Cutting Machine Manufacturer, offering heavy-duty plasma systems capable of handling large and thick metal sheets with ease. Our gantry plasma machines are built for durability, precision, and high-speed performance across large work areas.

Whether your project requires the fine precision of fiber laser cutting or the robust power of gantry plasma systems, we provide cutting-edge solutions tailored to your needs. Choose Fine Cutting Solution for reliable technology, expert support, and unmatched cutting performance.

#Fiber Laser Cutting Machine Manufacturers#Best Fiber Laser Cutting Machine Manufacturers#Top Fiber Laser Cutting Machine Manufacturers#No1 Fiber Laser Cutting Machine Manufacturers#Fiber Laser Cutting Machine Manufacturers in India

0 notes

Text

CNC Plasma Cutting Machine Manufacturer - Fine Cutting Solution

At Fine Cutting Solution, we specialize in delivering high-quality, precision-engineered CNC plasma cutting machines that cater to a wide range of industrial applications. As a trusted CNC plasma cutting machine manufacturer, we are committed to providing advanced cutting solutions that ensure accuracy, efficiency, and durability.

Our CNC plasma cutting machines are designed for superior performance, making them ideal for industries such as metal fabrication, automotive, construction, and shipbuilding. With user-friendly interfaces and customizable configurations, our machines are built to handle both small-scale projects and heavy-duty production demands.

What sets Fine Cutting Solution apart is our dual expertise. Not only are we leaders in CNC technology, but we are also recognized as a reliable Gantry Plasma Cutting Machine Manufacturer. Our gantry models are specially engineered for large-format cutting, offering high-speed operation and excellent stability across wide workspaces.

We prioritize customer satisfaction by offering robust after-sales support, maintenance services, and expert technical guidance. When you choose a Fine Cutting Solution, you’re investing in precision, performance, and long-term value.

Partner with us for your next cutting-edge solution and experience the power of innovation in metal cutting technology.

#Best CNC Plasma Cutting Machine Manufacturer#Top CNC Plasma Cutting Machine Manufacturer#No.1 CNC Plasma Cutting Machine Manufacturer#CNC Plasma Cutting Machine Manufacturers in India

0 notes

Text

CNC Laser Cutting Machine Manufacturers - Fine Cutting Solution

In today’s fast-paced industrial landscape, precision and efficiency are key to staying ahead. At Fine Cutting Solution, we take pride in being one of the leading CNC laser cutting machine manufacturers in India. Our advanced laser cutting solutions are designed to deliver high-speed, high-accuracy performance for a wide range of materials including metal, plastic, and wood.

CNC laser cutting technology offers unmatched precision, reduced material waste, and lower production costs. Whether you are in the automotive, aerospace, or fabrication industry, our machines are built to meet your toughest production demands. Our team of experts ensures that every machine is manufactured with the highest quality components and tested for durability and performance.

In addition to CNC laser solutions, Fine Cutting Solution is also a trusted Gantry Plasma Cutting Machine Manufacturer. Our gantry plasma cutting systems are known for their robust design, easy operation, and ability to handle heavy-duty cutting tasks with ease.

Partner with Fine Cutting Solution for reliable, cutting-edge technology that powers your business forward. Whether you need CNC laser precision or high-performance gantry plasma systems, we deliver machines that match your vision and scale.

#CNC Laser Cutting Machine Manufacturers#Best CNC Laser Cutting Machine Manufacturers#Top CNC Laser Cutting Machine Manufacturers#No1 CNC Laser Cutting Machine Manufacturers#CNC Laser Cutting Machines Manufacturers

0 notes

Text

Spot Welding Machine Manufacturers in India

In the evolving world of metal fabrication and precision joining, Fine Cutting Solution proudly stands as one of the most trusted Spot Welding Machine manufacturers in India. With a commitment to delivering cutting-edge technology and consistent quality, we design and supply spot welding machines that cater to the diverse needs of industries like automotive, electronics, furniture, and construction.

Website: https://finecuttingsolution.in/spot-welding-machine-manufacturers-in-india/

0 notes

Text

CNC Profile Cutting Machine Manufacturers

As a leading CNC profile cutting machine manufacturer, we specialize in designing and manufacturing cutting-edge machines that cater to various industries. In this blog, we’ll explore the benefits of our CNC profile cutting machines and what sets us apart from other manufacturers.

Our CNC machines ensure clean cuts, reduced manual work, and consistent quality in high-volume operations. At Fine Cutting Solution, we offer high-performance CNC profile cutting machines that are designed for precision, power, and productivity. These machines are perfect for cutting complex shapes and profiles from a variety of metals, including mild steel, stainless steel, and aluminum, with extreme accuracy and minimal waste. We specialize in used and refurbished CNC profile cutting machines that offer the same performance at a lower investment, complete with installation, service, and support throughout India.

Website: https://finecuttingsolution.in/cnc-profile-cutting-machine-manufacturers/

0 notes

Text

Used CNC Laser Machine Manufacturers

At Fine Cutting Solution, we specialize in providing reliable, high-performance used CNC laser machines that meet the needs of diverse industries. These machines have revolutionized how we work with materials — offering unmatched precision, speed, and versatility. But how exactly are they used in real-world applications?

CNC laser machines are versatile tools used in cutting, engraving, and marking a wide range of materials with unmatched precision.

Website: https://finecuttingsolution.in/used-cnc-laser-machine-manufacturers/

0 notes

Text

Fiber Sheet Metal Laser Cutting Machine Manufacturers

At Fine Cutting Solution, we bring you cutting edge technology introducing our Fiber Sheet Metal Laser Cutting Machine, engineered to deliver exceptional performance across all your sheet metal cutting needs. Our Fiber Sheet Metal Laser Cutting Machine, designed to provide outstanding performance for all of your sheet metal cutting requirements. Whether you’re working on thin sheets or thick plates, our machines are designed to deliver clean cuts, tight tolerances, and smooth edges, drastically reducing post-processing work.

Fiber Sheet Metal laser cutting is the modern standard in metalworking. Utilizing a high-powered fiber laser beam, this technology can cut through various metals—like stainless steel, carbon steel, aluminum, brass, and copper—with incredible accuracy and minimal waste.

Website: https://finecuttingsolution.in/fiber-sheet-metal-laser-cutting-machine/

0 notes

Text

SPLB 3015 Fiber Laser Cutting Machine Manufacturer

At Fine Cutting Solution, we proudly offer the SPLB 3015 Fiber Laser Cutting Machine, a high-performance solution designed for cutting mild steel and other metals with unmatched precision. Whether you need intricate designs, bulk production, or high-speed cutting, this machine ensures superior quality and productivity.

The SPLB 3015 is an advanced fiber laser cutting machine that utilizes a high-powered laser beam to cut through mild steel, stainless steel, aluminum, and other materials with extreme precision. Its high-speed operation and low maintenance requirements make it ideal for industrial applications, metalworking shops, and large-scale production units.

In modern metal fabrication, precision, speed, and efficiency are key factors in ensuring high-quality production. The SPLB 3015 Fiber Laser Cutting Machine, offered by Fine Cutting Solution, is an advanced industrial-grade laser cutter designed to deliver superior cutting accuracy, reduced production time, and maximum efficiency. Whether you are working with mild steel, stainless steel, aluminum, or other metals, this machine provides seamless performance for a wide range of applications.

Website: https://finecuttingsolution.in/splb-3015-fiber-laser-cutting-machine-manufacturer/

0 notes

Text

Mild Steel Laser Metal Cutting Machine Manufacturer

In today’s fast-moving manufacturing industry, clarity, speed, and efficiency are crucial for metal fabrication. At Fine Cutting Solution, we specialize in providing high-performance Mild Steel Laser Metal Cutting Machines designed for accurate, clean, and efficient metal cutting. Our cutting-edge laser technology ensures superior quality, minimal wastage, and high productivity, making it the perfect solution for a variety of industries.

A Mild Steel Laser Cutting Machine uses a high-powered laser beam to precisely cut, engrave, or shape mild steel with extreme accuracy. This non-contact cutting method ensures smooth edges, reduced material distortion, and high cutting speeds, making it ideal for industrial, commercial, and custom fabrication needs.

Website: https://finecuttingsolution.in/mild-steel-laser-metal-cutting-machine-manufacturer/

0 notes

Text

M-Code Commands: Meanings, Commands and Simulators

M-code commands are essential for controlling various functions of the machine during the cutting process. M-code is a part of the language that AutoCAD and CAM, computer aided manufacturing, use to input instructions into CNC machines. G-codes and M-codes work in unison for positioning a workpiece and guiding the machine‘s actions. M-codes, miscellaneous or machine codes, control the operations of the equipment telling it when to operate or cease operation. While the G-code can direct a machine to move in a line or arc, once the tool is positioned, it won‘t know to stop, change tools, add coolant, or complete any other actions, which are provided by M-codes. Instructions for a tool to turn on or off is part of the M-code language. When working with advanced equipment like a CNC laser cutting machine, understanding M-code commands is crucial to achieving high precision and efficiency in cutting materials.

Also Read Us: Fibre Laser Cutting Machine

In this blog, we will explore the meanings and functions of M-code commands, some common examples, and how CNC laser cutting machines utilize them for optimized performance.

Website:- https://finecuttingsolution.in/m-code-commands-meanings-commands-and-simulators/

0 notes

Text

Laser Cutting Machine Price

Fine cutting solution is a leading manufacturer and supplier of Laser cutting machines in India. We provide the machines at affordable prices. Fine cutting solution is an advanced cutting machinery manufacturer based in Faridabad, Haryana, India. The company specializes in providing high-precision CNC laser cutting machines and associated services to meet diverse industrial requirements.

About CNC laser cutting machine:

Laser cutting machines catering to various industrial needs with their advanced technology and robust performance. These machines are designed for 2D cutting, 3D cutting, and tube cutting, providing flexibility and precision in manufacturing processes. The cost of laser cutting machines varies based on several factors, including the type of laser, power, and material compatibility. For instance, entry-level fiber lasers for metal cutting start around ₹15 lakh, with professional models exceeding ₹50 lakh. Similarly, Fine Worth Engineers & Services offers fiber laser cutting machines starting from ₹10 lakh.

0 notes

Text

Compressed Air Cutting Benefits and Limitations

When it comes to precision cutting, industries across the globe are constantly seeking methods that ensure accuracy, speed, and cost-efficiency. One of the innovative techniques gaining traction is compressed air cutting. In laser beam cutting, the gas plays a major role in making the material to eject through the beam kerf path. Gas used in laser beam cutting is often named as “Assist gas”. Based on the application, sometimes reactive gas is used (Oxygen, O2) and sometimes non-reactive gas / inert gas is used (like Nitrogen (N2) / Argon (Ar).

Also Read Us: What is a Flame or Flashback Arrestor? How it Works?

What is Compressed Air Cutting?

Compressed air cutting involves using pressurized air to drive a cutting tool, such as a nozzle, to cut through materials. This technique is commonly used in industries where precision cutting of softer materials like foam, rubber, or plastics is required. The cutting tool is powered by compressed air that provides the necessary force to achieve clean, efficient cuts without causing material deformation.

Role of Assist gas

The functions of assist gas during laser cutting are as follows

To maintain the constant material removal by uniformly involving into the process

To involve in the reaction if reactive gas is used (Exothermic reaction)

To blow out the melt if inert gas is used (Fusion Cutting)

Purpose of Compressed Air cutting

Compressed Air is a commonly used gas in any industry. So far, air has come across a wide range of applications starting from loading and lifting to cleaning and dusting. To emphasize on the part of thermal cutting, still in plasma, compressed air is used in cutting mild steel. With a compressor, there is no need for a power tool, a pneumatic one can do the job just as well, if not better. Bringing multiple benefits to the domestic and professional user, from hammering and sawing to spray-painting and tyre inflation, compressed air is easy to use and can boost productivity. The major reason behind that is as follows

This is available abundantly

Cost of acquiring this is very low

There is already a compressed air generator available in 99% of industries

There is no waiting time and no supply chain involved

There is Shortage of Oxygen and Nitrogen due to Pandemic and it is the major reason for all customers switching to Air cutting from Oxygen , Nitrogen cutting

Benefits of Compressed Air Cutting

Cost-Effective Solution One of the main advantages of compressed air cutting is its affordability. It provides a more economical solution. The equipment required for this technique is generally more affordable compared to other advanced cutting methods such as laser or water jet cutting. This makes it an attractive option for businesses that need an economical solution for precise cuts without high operational costs.

Precision and Clean Cuts Compressed air cutting offers high precision, especially when dealing with softer materials. It provides smooth edges and minimizes the risk of distortion, ensuring that your materials maintain their integrity. At Fine Cutting Solutions, we utilize advanced technology to ensure that each cut meets your exact specifications, providing you with exceptional results every time. Almost the speed of the nitrogen is achieved in air cutting

Minimal Material Waste The high precision of compressed air cutting minimizes material waste. Because the air nozzle is directed exactly where it’s needed, there’s little to no overcutting or wasted material. This efficiency not only reduces the environmental impact but also contributes to cost savings in your production process.

Versatility Compressed air cutting can be used for a variety of materials, including foam, rubber, plastic, and textiles. Whether you’re working with thick or thin materials, this cutting method offers versatility to suit your specific production needs. At Fine Cutting Solutions, we tailor our compressed air cutting services to handle a wide range of materials with ease.

No Heat-Affected Zones Unlike traditional methods such as laser or plasma cutting, compressed air cutting doesn’t generate heat. This is particularly beneficial when working with materials sensitive to high temperatures, such as certain plastics and foams, as it prevents any heat-affected zones (HAZ) that could compromise the material’s structure.

Quick Setup and Operation Compressed air cutting systems typically have a faster setup time compared to other cutting techniques, making them ideal for high-volume production. Once the system is in place, it’s ready to cut materials quickly and efficiently, helping businesses meet tight production deadlines without sacrificing quality.

Limitations of Compressed Air Cutting

Limited to Softer Materials While compressed air cutting is excellent for softer materials like rubber, foam, and plastics, it may not be suitable for tougher materials such as metals or thick composite materials. For harder materials, more robust cutting techniques like laser cutting, water jet cutting, or plasma cutting may be required.

Edge Quality May Vary Though compressed air cutting can produce clean cuts, the edge quality may not always meet the high standards of other cutting methods like laser cutting, especially when working with certain types of materials. For applications where edge finish is critical, this method may have limitations.

Air Supply Requirements Compressed air cutting relies heavily on a continuous, reliable air supply. If the air pressure or supply fluctuates, it can affect the precision and efficiency of the cutting process. Regular maintenance of the air compressor is necessary to maintain consistent results.

Not Suitable for Complex Shapes While compressed air cutting is precise, it may not be ideal for cutting intricate or highly complex shapes. Other techniques like laser cutting or water jet cutting may be better suited for highly detailed designs that require sharp corners or fine cuts.

Limited Cutting Depth The cutting depth of compressed air cutting can be limited, particularly when dealing with thicker materials. For deeper cuts, you may need to consider alternative cutting methods that can handle more substantial material thickness.

Noise Level Compressed air cutting can generate a significant amount of noise, especially when used in large-scale industrial applications. Proper hearing protection and noise reduction measures are essential to ensure a safe and comfortable working environment.

Some more Limitation: Limitations of compressed air cutting

In the case of Mild steel, there is a little dross but that is very low. The dross can be wiped. There is a black oxide layer formed on the cut surface.

In the case of Stainless steel, there is a yellowish / blackish colour on the cut surface.

During weld processing stainless steel after air cutting, the surface needs to be cleaned as the weld seam quality on the surface will not be proper.

The major disadvantage is that the quality of air cutting depends on the laser power. The higher the laser power the speed and quality of the cutting can be improved. Also the thickness limitation is also based on the laser power.

For certain application, the air cutting is undesired, as the oxidation on the surface is prolonged to react to its environment. Like aerospace, food processing, chemical tanks, vessels etc. where the surface is exposed to its environment. Because the cutting is done with air and oxidation is already on the surface, which continues to react and loses the original property of material (Corrosive resistance).

It requires proper maintenance of air generation setup on a periodic basis, else the optics in the cutting head may fail quickly.

Why Choose Fine Cutting Solutions?

At Fine Cutting Solutions, we understand that each project is unique and requires a tailored approach. Our team of experts specializes in providing precise and cost-effective cutting solutions, including compressed air cutting, for a variety of industries. With our advanced technology, experienced technicians, and commitment to quality, we ensure that your cutting needs are met efficiently and to the highest standards. The product range includes CNC plasma cutting machines and laser welding machines from hand guided machines right up to special machines for shipbuilding as well as machines and equipment for CNC laser cutting machine, cutting, brazing, soldering and heating. Spare parts, repairs, modernisation, maintenance and service as well as environmental technology round out the product portfolio.

Conclusion

Compressed air cutting offers a cost-effective, efficient, and precise solution for cutting softer materials like foam, rubber, and plastics. With benefits such as minimal material waste, no heat-affected zones, and quick setup times, it’s an attractive option for businesses looking for reliable and economical cutting methods. However, it does have limitations, particularly when it comes to cutting harder materials or achieving highly intricate shapes. It is one alternative way using assist gas in the laser cutting process by which you gain competitive speeds in production and reduce cycle time. Thereby reducing cost of production. However, the speed and quality of cutting depends on the laser power. If the application of air cutting prevails, then it is a good alternative with proper setup.

At Fine Cutting Solutions, we specialize in delivering high-quality compressed air cutting services tailored to your specific needs. Our team ensures precision and quality, helping you achieve optimal results for your projects. Whether you’re working with softer materials or looking for an affordable and fast cutting solution, you can trust us to provide the best results.

Website: https://finecuttingsolution.in/compressed-air-cutting-benefits-and-limitations/

0 notes

Text

What is a Flame or Flashback Arrestor? How it Works?

In industries that work with gases, welding, or any form of combustion, safety is a primary concern. Accidents involving flames or explosions can be disastrous, especially when dealing with highly flammable gases. One of the key safety devices used to prevent these dangerous situations is a flame or flashback arrestor. Most flame arrester applications are in systems that collect gases emitted by liquids and solids. These systems, commonly used in many industries, may be called vapor control systems (VCS). The gases typically vented to the atmosphere or controlled via vapor control systems are flammable. If the right conditions are such that ignition occurs, a flame inside or outside of the system could result, with the potential to do catastrophic damage.

Also Read Us: Laser Welding Machine Manufacturers What is a Flame or Flashback Arrestor?

Flashback arrestors are also known as Flash arrestors. It is a gas safety device. It is a device used in welding and cutting to stop the reverse flow of gas as well as flash back into the supplier’s line. This device protects the user and the equipment from any damage or from getting the gas cylinder exploded. Flashback arrestors are found in the market in different sizes and flow rates. In earlier days wet flashback arrestors were used, but nowadays mainly dry flashback arrestors are used in the industries.

When a flammable mixture of fuel gas and oxygen or air is present in a gas line upstream of a welding or cutting blowpipe, flame can travel backwards in the form of flash back into the gas line, and there is the possibility of a serious accident.

These devices are commonly used in welding, gas cutting, and in applications involving the use of gases like oxygen, acetylene, and other flammable gases. Flashback arrestors can be installed on regulators, hoses, or on the welding torch itself to ensure that flames are stopped before they can reach the gas source or cylinders.

Website:https://finecuttingsolution.in/what-is-a-flame-or-flashback-arrestor-how-it-works/

#Flame or Flashback Arrestor#What is a Flame or Flashback Arrestor#How Does a Flame or Flashback Arrestor Work?#What is a Flame or Flashback Arrestor? How it Works?

0 notes