#LaserCuttingMachine

Explore tagged Tumblr posts

Text

Display Gears

Machine: ACMER P2 33W

Material: 3mm Plywood

Cutting Speed: 400mm/min

Cutting Power: 100%

File link: https://www.instructables.com/Laser-Cut-Display-Gears/

#ACMER#EngraveYourLoveWithACMER#laserengraving#lasercutting#laserengravingmachine#lasercuttingmachine#lightburn#DIY#VernierCaliper

2 notes

·

View notes

Text

Disrupt Project

16th Oct 23’

I took part in a laser cutting workshop where we learned how to use the machines and how to construct materials that were cut with a laser. We used words that were associated with our project for disrupt and put them into different fonts on Adobe illustrator before cutting them.

We also looked at using images and how they would cut with a laser but unfortunately didn’t have enough time.

While we waited for each person to cut their own pieces out we attempted to construct a piece that was cut with a laser but I found it so hard and confusing and would definitely need instructions to do so again.

3 notes

·

View notes

Text

youtube

💥 Powering Vietnam’s Steel Industry!

Big thanks to our amazing Vietnam client for trusting AORE Laser! Their workshop is now running at full power with our GR Series 20000W laser cutting machine – large-format precision, modular flexibility & intelligent cutting for heavy-duty steel.

✅ Massive work area ✅ Smart automation ✅ Thick-sheet mastery

Proud to partner with forward-thinking manufacturers in Southeast Asia!

Learn more: https://www.aorelaser.com/

#AORELaser#LaserTech#SteelFab#IndustrialTech#heavydutymetal#fiberlasercuttingmachine#lasercuttingmachine#Youtube

0 notes

Text

The fabric laser cutting machine has become a game-changer, offering unmatched accuracy and versatility for manufacturers. As we move into 2025, advanced technologies are transforming how industries approach fabric cutting.

#fabriclasercuttingmachine#lasercuttingmachine#fabriccuttingmachine#fabriclasercuttingmachinemanufacturer#lasermachine

0 notes

Text

Unlock Precision and Speed with Expert Laser Cutting Machine Manufacturers

Boundless Innovation in Each Cut with the Best Laser Cutting Machine Manufacturers.

Discover our dual-pallet laser cutting machines, engineered for high-speed production and reduced downtime. As reliable Laser Cutting Machine Manufacturers, we ensure that our machines come with simultaneous load/unload features to streamline workflow without sacrificing top cut quality. Optimized nesting software provides precision, burr-free cuts up to 50mm thickness, with no warping or tapering.

Key Performance Features of your most trusted Laser Cutting Machine Manufacturers.

As premier Laser Cutting Machine Manufacturers, we provide high-performance systems for efficiency, accuracy and flexibility. Our machines include a double pallet system, enabling quick job changing with simultaneous loading and unloading to increase throughput.

With micron-grade precision, they are ideal for fine detailing and precise contour cutting. Higher cutting speeds utilizing high-speed fibre lasers and motion control units allow greater productivity for various applications. The capacity to cut multi-materials is assured to deliver clean and precise cuts in mild steel, stainless steel, aluminium, copper and others.

A streamlined, user-friendly interface constantly improved by software updates and user input guarantees usability. Heavy-duty construction delivers vibration-free stability, even in continuous working situations and power-saving fibre lasers reduce long-term operating expenses.

Integrated safety solutions, such as emergency stop functionality and safety enclosures, guarantee safe operation. Available in configurations with different laser powers and table sizes, our equipment fulfils unique workflow needs.

Cut quality is sustained at high velocities with Fly Cut technology and our end-to-end support features technical support, web-based troubleshooting and predictive maintenance software.

Technical Specifications of the best Laser Cutting Machine Manufacturers at a Glance.

The Winarc two-pallet fibre laser sheet cutting machine is designed to deal with an extensive series of sheet sizes with a work length from 3000 mm to 8000 mm and a width from 1500 mm to 3000 mm. It has an axis speed up to 120 meters per minute, yet at the same time achieves a delicate positional accuracy of ±0.03 mm, which is ideal for bulk precision processing.

Driven by Ethercat networking, it provides real-time responsiveness for precise and efficient functioning. The machine accommodates laser powers ranging from 2 kw to 20 kw, with the flexibility to cut materials of different thicknesses. It is also fully integrated with CypNest, Radan and SigmaNest CAD-CAM software to enable precise nesting, seamless programming and optimum material utilization.

Winmaster dual-pallet laser cutting machines are equipped with globally recognized components to ensure maximum durability, accuracy and productivity in demanding industrial environments.

Fibre Laser Source

Brands: Raycus, IPG, Max, Trumpf

These best-in-class sources provide superior beam quality, low maintenance and reliable performance across metals.

CNC Control System

Brands: Cypcut, Eckelmann

User-friendly interfaces paired with high-speed processing allow for responsive and precise control.

Linear Guides & Bearings

Brands: Hiwin, CPC

Engineered for precision motion and long-lasting stability, ensuring high accuracy with every cut.

Servo Motors & Drives

Brand: Yaskawa

Renowned for fast acceleration and pinpoint control, boosting both speed and reliability.

Cooling Unit

Brands: Hanli, Hexacool, S&A

Ensures thermal stability, safeguards core components and extends service life.

Laser Cutting Head

Brands: Precited, Ray tools, WSX, Bochu

Designed for clean, efficient cutting with adaptive focusing and edge sharpness across material types.

0 notes

Text

High-Speed Fiber Laser Cutting – देखिए Cutting के अलग-अलग Types!

youtube

#machine#fiberlaser#trending#viralvideo#reels#latestreelsvideo#cncmachine#viral#viralreels#instagram#instagood#trendingreels#trend#twitter#youtubeshorts#metal#lasercuttingmachine#FiberLaser#LaserCutting#CNCMachine#MetalCutting#LaserTechnology#PrecisionCutting#FiberLaserCuttingMachine#LaserCuttingMachine#CNCFiberLaser#SheetMetalCutting#LaserWeldingMachine#MetalFabrication#Manufacturing

0 notes

Text

Fiber Laser Metal Cutting Machine Supplier

A fiber laser metal cutting machine is an industrial device that processes, cuts, and engraves materials using a powerful laser beam. They can cut a variety of materials and provide high precision, high speed, and low operating costs. To cut through materials, a computer-controlled laser is used in fiber laser technology.

0 notes

Text

Discover the fascinating world of Laser Engraving! From cost-effectiveness to user-friendly technology, explore these intriguing facts about laser engraving.

For more details, visit - https://www.parulinduscorp.com/products/laser-cutting-engraving-service

0 notes

Text

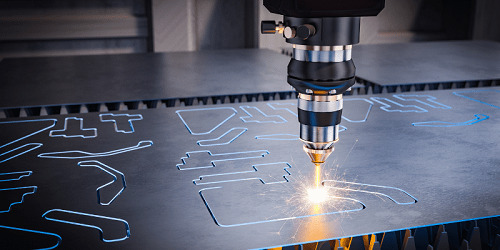

Laser Cutting CNC Machines: Revolutionizing Precision Fabrication

In the realm of modern manufacturing, precision and efficiency are paramount. One technology that has significantly advanced these aspects is laser cutting CNC (Computer Numerical Control) machines. These remarkable tools have revolutionized fabrication processes across various industries, from automotive to aerospace, by offering unmatched accuracy, speed, and versatility. This article delves into the workings, applications, and benefits of laser cutting CNC machines, highlighting their pivotal role in shaping the future of manufacturing.

Understanding Laser Cutting CNC Machines

At their core, laser cutting CNC machines utilize high-powered laser beams to precisely cut through materials with exceptional accuracy. These machines operate under the guidance of computerized control systems, which interpret digital design files and translate them into precise cutting instructions. This fusion of laser technology and computer control enables intricate and complex cuts to be executed with remarkable consistency and efficiency.

The Working Principle

The operation of a laser cutting CNC machine begins with the generation of a concentrated beam of light produced by a laser resonator. This intense beam is directed through a series of mirrors and lenses, focusing it into a narrow, high-energy beam. The material to be cut is positioned on a flat surface within the machine’s workspace, known as the cutting bed.

As the material is exposed to the focused laser beam, it experiences rapid heating, causing localized melting, vaporization, or combustion. The CNC system precisely guides the laser beam along the predetermined cutting path, resulting in clean, accurate cuts through the material. Depending on the specific requirements of the application, laser cutting CNC machines can handle a wide range of materials, including metals, plastics, wood, and composites.

Applications Across Industries

The versatility of laser cutting CNC machines has led to their widespread adoption across a diverse range of industries. In the automotive sector, these machines are utilized for precision cutting of sheet metal components, such as body panels and chassis parts. Similarly, in the aerospace industry, laser cutting CNC machines are employed to fabricate intricate components for aircraft and spacecraft, including turbine blades, fuselage sections, and engine parts.

Beyond traditional manufacturing sectors, laser cutting CNC machines have found applications in fields such as electronics, signage, jewelry, and medical device manufacturing. Their ability to produce intricate designs with high precision makes them indispensable tools for creating custom prototypes, intricate artwork, and intricate medical implants.

Advantages of Laser Cutting CNC Machines

The widespread adoption of laser cutting CNC machines can be attributed to several key advantages they offer:

Precision: Laser cutting CNC machines can achieve exceptionally tight tolerances, ensuring consistent and accurate cuts even for complex shapes and intricate patterns.

Speed: The high-speed cutting capabilities of laser machines enable rapid production cycles, reducing lead times and increasing overall productivity.

Versatility: These machines can process a wide variety of materials, including metals, plastics, ceramics, and composites, making them suitable for diverse applications.

Minimal Material Waste: Laser cutting produces narrow kerfs, resulting in minimal material wastage compared to traditional cutting methods, thereby optimizing material usage and reducing costs.

Automation: The integration of CNC technology allows for fully automated operation, reducing the need for manual intervention and enhancing workflow efficiency.

Future Outlook

As technology continues to evolve, the capabilities of laser cutting CNC machines are expected to further expand. Advancements in laser technology, such as the development of higher-power lasers and improved beam delivery systems, will enable even faster cutting speeds and greater precision. Additionally, the integration of artificial intelligence and machine learning algorithms could further optimize cutting processes, allowing for adaptive control and predictive maintenance.

In conclusion, laser cutting CNC machines represent a pinnacle of precision fabrication technology, offering unmatched capabilities for a wide range of manufacturing applications. Their ability to deliver precision, speed, and versatility has made them indispensable tools in modern manufacturing facilities, driving innovation and enabling the realization of increasingly complex designs and products. As technology continues to advance, laser cutting CNC machines are poised to play an ever-expanding role in shaping the future of manufacturing.

0 notes

Text

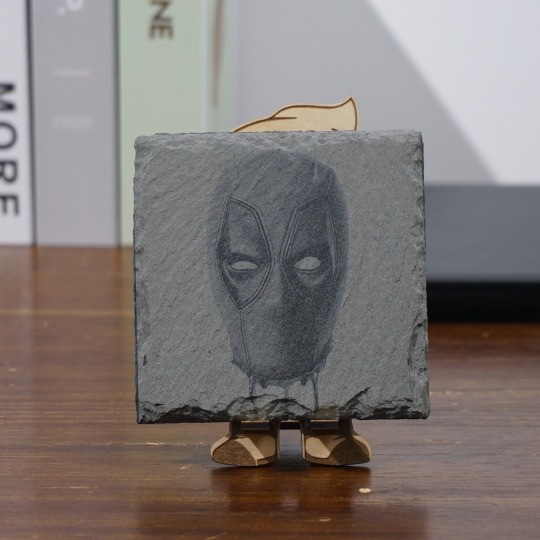

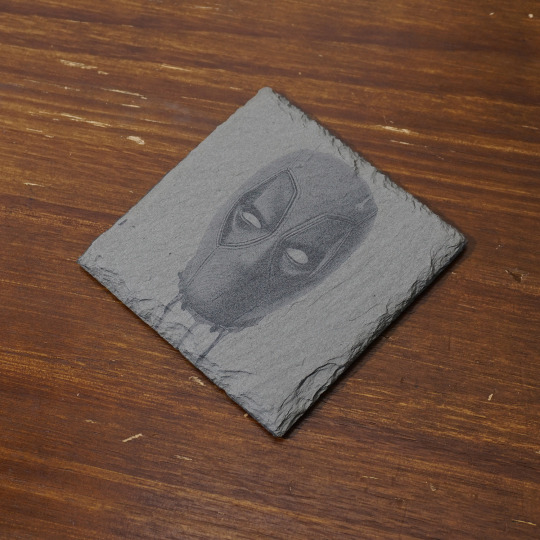

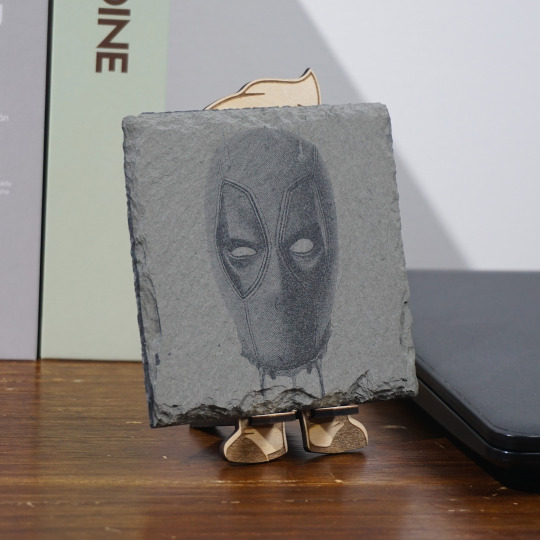

Deadpool Rock Decor

Machine: ACMER P2 33W

Material: Rock Slab

Cutting Speed: 20000mm/min

Cutting Power: 65%

#ACMER#EngraveYourLoveWithACMER#environment#earthday#laserengraving#lasercutting#laserengravingmachine#lasercuttingmachine#deadpool

2 notes

·

View notes

Text

Discover high-performance Metal Laser Marking Machine pune with Truway Machinery. Our precision solutions elevate industrial marking standards. Contact us for advanced marking technology!

0 notes

Text

Due to the highly reflective nature of some metallic surfaces like copper and steel, a laser cutting machine can perform efficiently with high precision. A laser cutter beam cuts the chosen cutting edges to form the complex design.

#copperlasercutting#brasslasercutting#stainlesssteellasercutting#lasercuttingmachine#lasercutting#lasercutstainlesssteel#steellasercutting#1kwlasercuttingmachine#2kwlasercuttingmachine#3kwlasercuttingmachine#4kwlasercuttingmachine#6kwlasercuttingmachine#hindcam

0 notes

Text

youtube

V12 High-speed Tube Laser Cutting Machine

🚀 Laser Tube Cutting – Smarter, Faster, Stronger!

⚡ Ultra-Fast Cutting 🤖 Intelligent Stability ♻️ Less Waste, More Profit 🎯 Precision That Never Quits

🔥 Upgrade to the V12 – Cut Smarter! Learn more: https://www.aorelaser.com/product/High-speed-Tube-Laser-Cutting-Machine-V12--436.html

#AORELaser#Tubecutting#PrecisionEngineering#lasercuttingmachine#metallasercutter#tubelasercutting#Youtube

0 notes

Text

Terron India is a leading laser machine manufacturer, known for engineering high-performance, reliable, and cost-efficient machines. Whether you run a boutique operation or a large textile manufacturing unit, we provide machines designed to deliver consistency and durability.

0 notes

Text

Tube Laser Cutting Machine Manufacturers

Tube laser cutting machine manufacturers specialize in designing, producing, and supplying high-precision laser cutting systems for metal and non-metal tubes or pipes. These machines utilize advanced laser technology to deliver accurate cuts, intricate designs, and seamless finishes on tubular materials such as steel, aluminum, copper, and more.

Manufacturers often focus on innovative features like CNC integration, automated loading and unloading systems, and support for various tube sizes and shapes (round, square, rectangular, or custom profiles). Their products are widely used in industries such as automotive, aerospace, construction, furniture, and metal fabrication, where precision, speed, and efficiency are critical.

Key manufacturers also prioritize offering customized solutions, user-friendly interfaces, energy efficiency, and after-sales services, including maintenance and technical support, to meet diverse client needs.

#TubeLaserCutting#LaserCuttingMachine#PrecisionCutting#TubeFabrication#MetalCuttingTechnology#IndustrialMachinery#MetalFabrication#LaserCuttingExperts#CNCManufacturing#TubeProcessing#AdvancedManufacturing#MetalworkingMachines#InnovativeCuttingSolutions#FabricationTechnology#AutomationInManufacturing

0 notes

Text

Laser Cutting Machine Market Evolution: Historical Analysis and Future Projections

The global laser cutting machines market size is expected to reach USD 10,351.0 billion by 2030, registering a CAGR of 5.5% over the forecast period, according to a study conducted by Grand View Research, Inc. Over the forecast period, it is anticipated that the growing trend of automation in the manufacturing sector and the rising demand for the end-use industry will increase demand for these machines. The growing application of CO2, fiber, and Yttrium Aluminum Garnet (YAG) lasers in various applications, such as industrial sectors and consumer electronics, is predicted to boost the demand for laser cutting machines. Industries such as consumer electronics are contributing to the market growth owing to the increasing use of lasers in material processing operations such as pruning, welding, and engraving. Furthermore, the requirement for high-power input and performance-based cutting tools drives demand and market growth for laser cutting machines over the forecast period.

Laser Cutting Machines Market Report Highlights

During the forecast period, the gas laser technology segment is expected to witness the highest CAGR of 6.1 %. The growth is attributed to the increasing demand for these lasers for better machine tools and equipment for laser printing, dye laser pumping, reading barcodes, and producing holograms

The fusion cutting is expected to register the highest CAGR of 6.1 % from 2023 to 2030. The advantage of fusion cutting is that it creates a cutting edge that is practically oxide-free and ideal for cutting thin sheets, which is expected to contribute to the growth of the segment

Over the course of the forecast period, the industrial sector is expected to dominate the laser cutting machine industry. It held a market share of 39.8 % in 2022. The need for laser cutting equipment is rising as industrial processes increasingly become automated. These tools consistently and quickly cut parts and patterns with precision

The rising GDP and quickening growth of the region's manufacturing sector, the Asia Pacific region is anticipated to continue growing. Additionally, businesses that use laser cutting to create semiconductors, consumer electronics, and automotive components are experiencing rapid regional growth. The need for laser cutting equipment in this area is rising along with the expansion of these industries

For More Details or Sample Copy please visit link @: Laser Cutting Machines Market Report

The development of innovative process lasers to maximize the manufacture of tailored three-dimensional glass elements, as well as a shift out of traditional semiconductor lasers and towards quantum cascade lasers, will likely drive up the demand for laser cutting machines. Continuous developments in laser technology enable manufacturers to engage in R&D to obtain a competitive advantage. Furthermore, due to the demand for high-speed and precision cutting and drilling the integration of the Internet of Things, Artificial Intelligence, and automation software with drilling machines is also supporting the laser cutting machine industry’s growth.

Major players are resorting to strategies such as product launches, mergers & acquisitions, and expansions to gain greater market shares. For instance, in May 2022, Yamazaki Mazak Pvt. Ltd. announced the launch of 3D based fiber laser cutting machine for cutting steel products- FG -400 NEO. The 3D laser is equipped with an efficient laser fiber oscillator which offers efficient energy conversion and enhanced productivity.

The laser is also compatible with cutting copper, brass, and aluminum. The laser is outfitted with a feature that enables users to easily modify the laser beam's diameter and form, enabling the cutting of sheets of different thicknesses. The oscillator's maximum output is limited to 4 kW, along with a rapid input rate on the X, Y, and Z axes is 60, 36, and 30 m/min, respectively. The continuous launch of advanced products is contributing to the laser cutting machine industry’s growth.

#LaserCuttingMachine#CuttingEquipment#CNCMachines#PrecisionCutting#MaterialProcessing#Metalworking#Fabrication#IndustryInsights#TechnologyTrends#MarketForecast#BusinessStrategy#InvestmentOpportunities#SupplyChain

0 notes