We are manufacturer of high quality Industrial Valve, Bellow Seal Valve, Ball Valve, Butterfly Valve, Lined Valve, and Pipe fitting accessories, Flange etc

Don't wanna be here? Send us removal request.

Text

Reliable PTFE Lined Column Manufacturers for Corrosion-Resistant Process Equipment

In industries where aggressive chemicals and high temperatures are routine, equipment durability is non-negotiable. PTFE lined columns have emerged as a trusted solution for safely handling corrosive media in chemical processing and pharmaceutical manufacturing. Sourcing these components from reliable PTFE lined column manufacturers ensures performance, safety, and long-term value.

What is a PTFE Lined Column?

A PTFE lined column is a vertical process vessel internally coated with Polytetrafluoroethylene (PTFE), a high-performance fluoropolymer known for its outstanding chemical resistance and thermal stability. These columns are essential in applications where direct contact between harsh chemicals and metal surfaces can lead to corrosion, contamination, or failure.

The PTFE lining acts as a protective barrier, isolating the internal media from the metal body—usually made of mild steel or stainless steel. These lined columns are extensively used in gas absorption, distillation, and chemical reaction processes across various industries.

Key Benefits of Choosing PTFE Lined Columns

PTFE lined columns offer a range of advantages that make them ideal for demanding environments:

Exceptional Corrosion Resistance: PTFE is virtually inert to most acids, alkalis, and solvents, even at elevated temperatures.

Temperature and Pressure Tolerance: These columns can operate reliably across wide temperature ranges without degrading or warping.

Low Maintenance: The non-stick, smooth surface of PTFE prevents scale buildup and allows for easier cleaning.

Extended Lifespan: Because they resist chemical attack, PTFE lined columns often outlast unlined metal equipment in aggressive service conditions.

Leak-Proof Sealing: High-quality PTFE linings offer excellent sealing properties, reducing the risk of leaks and operational hazards.

These benefits translate into safer operations, reduced downtime, and better return on investment.

Qualities of Reliable PTFE Lined Column Manufacturers

Not all PTFE lined column suppliers are created equal. When choosing a manufacturer, several key attributes should be considered:

Use of Virgin PTFE Material: High-quality manufacturers use virgin, chemically pure PTFE that meets or exceeds industry standards for durability and resistance.

Advanced Lining Techniques: Precision techniques such as isostatic molding, paste extrusion, and seamless welding are crucial for a uniform, bubble-free lining.

Compliance with Standards: Reliable manufacturers conform to standards like ASME, ASTM, or DIN to ensure dimensional and operational integrity.

Custom Fabrication Capabilities: The ability to fabricate PTFE lined columns in various sizes, diameters, and pressure classes is essential for diverse industrial needs.

In-House Testing and Quality Checks: Trusted suppliers conduct spark testing, hydro testing, and visual inspections to guarantee the integrity of the PTFE lining.

Engineering Support: Technical teams capable of offering design consultation, installation guidance, and post-sales service add significant value.

Industries Served by PTFE Lined Columns

PTFE lined columns are critical to many sectors that deal with aggressive chemical processes. These include:

Pharmaceuticals: For handling highly pure or corrosive chemicals without contamination.

Specialty Chemicals: To ensure safe and consistent processing of aggressive intermediates.

Agrochemicals: Where reaction vessels need to withstand strong acids or caustic solutions.

Water and Waste Treatment: In systems treating wastewater with chemical reagents or oxidizing agents.

In each of these applications, the use of PTFE lined process columns reduces the risk of corrosion-related failures, helping companies maintain operational continuity and compliance.

How to Choose the Right PTFE Lined Column Manufacturer

When selecting a PTFE lined column manufacturer, the following considerations can guide your decision:

Reputation and Experience: Look for manufacturers with proven expertise and a strong track record in delivering lined equipment.

Customization Options: Ensure the supplier can accommodate unique process requirements with tailor-made solutions.

Certifications and Documentation: Demand material test certificates, QA/QC reports, and spark test records to verify quality.

Responsive Support: Reliable after-sales service and technical troubleshooting reflect a manufacturer’s commitment to client success.

Global Reach or Local Presence: Depending on your location, choose a partner who can deliver promptly and offer support without delays.

Conclusion

Investing in high-quality PTFE lined columns is vital for ensuring chemical process safety, efficiency, and regulatory compliance. Manufacturers that use genuine PTFE materials, follow rigorous fabrication protocols, and offer engineering support can make a significant difference in plant performance.

For those seeking corrosion-resistant column solutions, Freture Techno Pvt. Ltd. is a leading PTFE lined column manufacturer in India, known for delivering precision-engineered, long-lasting equipment to industries worldwide.

0 notes

Text

Comparing Inlet Vane Dampers vs. Variable Frequency Drives in Airflow Management

In the debate between inlet vane dampers vs. variable frequency drives (VFDs), it’s important to understand the distinct advantages each offers in industrial airflow management. While VFDs adjust motor speed, inlet vane dampers regulate airflow at the source—before it enters the fan.

Energy-efficient inlet vane damper solutions reduce energy by lowering the air pressure the fan needs to manage. They offer a cost-effective method for airflow control in existing systems without significant retrofitting. This makes them a viable choice for facilities with tight upgrade budgets.

On the other hand, VFDs may offer more granular motor control but often come with higher initial and maintenance costs. Additionally, VFDs can cause harmonic distortion in electrical systems, requiring additional filters or correction equipment, further increasing costs.

Inlet vane dampers, in contrast, present a mechanical solution that’s easy to integrate into existing ductwork and fan systems. They’re ideal for dynamic environments where fast, responsive airflow control is necessary. Examples include chemical processing, pharmaceutical plants, and food production units.

These dampers are also easier to maintain, with fewer electrical components that could fail under harsh operating conditions. In many cases, inlet vane dampers serve as an excellent first step toward airflow optimization, especially when combined with basic automation controls.

Freture Techno Pvt. Ltd. is a leading manufacturer of inlet vane dampers in Mumbai, India, providing energy-saving solutions with low operational costs.

0 notes

Text

Earth Day 2025: Engineering a Sustainable Future with Emission-Free Valve Solutions

Every year on April 22, Earth Day serves as a global reminder of the need to protect the planet and pursue more sustainable practices in every aspect of human life. For the industrial sector, especially in high-stakes environments such as oil & gas, pharmaceuticals, and food processing, this translates to reducing emissions, preventing leakages, and improving operational efficiency. Freture Techno Pvt. Ltd., a leading industrial valve manufacturer in India, stands at the forefront of this green transformation.

Sustainability at the Core of Valve Engineering

Freture Techno Pvt. Ltd. has redefined what it means to be environmentally responsible in the field of flow control. With a deep understanding of the challenges faced by complex industrial applications, the company designs and manufactures high-performance valves that not only meet technical demands but also contribute to environmental protection.

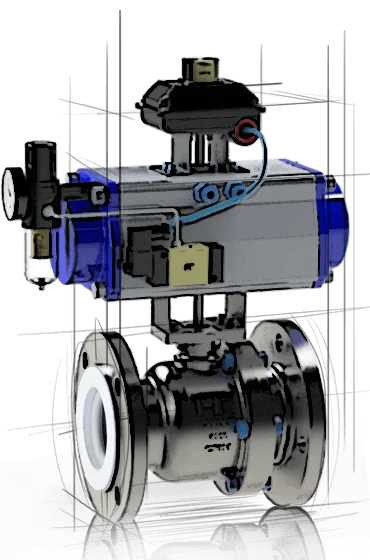

Specializing in advanced solutions such as bellow sealed valves, double block and bleed (DBB) valves, lined valves, and rotary actuators, Freture ensures each product is engineered with leak-proof precision. These valves help industries curb fugitive emissions, reduce process losses, and maintain safe operations, thereby aligning daily industrial functions with long-term sustainability goals.

Precision That Protects

In sectors like oil and gas, valve failure or leakage can result in catastrophic environmental and financial consequences. Freture Techno’s Bellow sealed valves are engineered for zero leakage, ensuring containment of hazardous fluids under high-pressure conditions. This technology prevents volatile organic compounds (VOCs) from escaping into the atmosphere, aligning with both international environmental standards and the broader Earth Day mission.

For the pharmaceutical industry, contamination-free processing is a necessity. Freture’s sanitary-grade, emission-free valves support cleanroom operations by eliminating the risk of leakage and ensuring high-purity water systems and sterile product lines.

Likewise, in food and beverage plants, Freture’s lined valves play a critical role in maintaining hygienic flow, resisting corrosion, and preventing material degradation. The result is an eco-conscious production cycle that prioritizes both quality and safety.

Designing for Eco-Efficiency

Freture Techno doesn’t just manufacture valves—it engineers sustainability. Its modular valve designs allow for easy customization, repair, and longer product lifecycle, effectively reducing material waste. Each valve is crafted using durable materials that extend operational longevity, minimizing the frequency of replacements and contributing to lower resource consumption.

The company’s energy-efficient manufacturing processes and use of recyclable components reinforce its responsibility toward eco-friendly operations. Moreover, all valves undergo stringent testing for leakage, durability, and compliance with emission standards, guaranteeing that only the most sustainable solutions reach industrial pipelines.

A Partner in Sustainable Progress

Across industries, the shift toward sustainability is no longer optional—it is essential. Freture Techno Pvt. Ltd. partners with clients not just to meet compliance but to foster innovation that makes industrial operations cleaner, safer, and more responsible.

From supporting greenfield pharma projects to upgrading legacy oil & gas installations, Freture’s valves are trusted wherever precision and sustainability intersect. With expert consultation and customized solutions, the company helps clients navigate increasingly strict environmental norms without compromising on performance.

Earth Day Commitment: Today and Tomorrow

As the world observes Earth Day 2025, Freture Techno Pvt. Ltd. reiterates its ongoing commitment to sustainable engineering. Each valve designed is a pledge—to nature, to industry, and to future generations. The company believes that operational excellence should not come at the planet’s expense, and its innovations reflect that philosophy every day.

On this Earth Day and beyond, industries are encouraged to adopt zero-emission valve solutions, embrace green engineering, and invest in eco-efficient technologies that promote long-term planetary health. Freture Techno Pvt. Ltd. remains ready to lead that charge—one valve at a time.

0 notes

Text

Maintenance and Troubleshooting of Industrial Damper Valves

Industrial damper valves, like all mechanical components, require regular maintenance to ensure optimal performance and avoid system failures. A well-maintained damper not only extends equipment life but also contributes to process efficiency and safety.

Importance of Regular Maintenance

Scheduled maintenance helps identify and correct minor issues before they escalate into major problems. Maintenance practices vary based on the type of damper valve, operating conditions, and application. However, some universal tasks include cleaning, lubrication, alignment checks, and inspection of moving parts.

Common Maintenance Procedures

1. Visual Inspection: Check for any signs of wear, corrosion, or physical damage. Look for deformed blades, misalignment, and structural integrity of the housing.

2. Lubrication: Lubricate all moving parts including linkages, actuators, and bearings. Proper lubrication reduces friction and prevents premature wear.

3. Actuator and Control Check: Inspect actuators (manual or automated) for proper operation. Electrical connections, air supply (in pneumatic actuators), and hydraulic fluid levels should be verified.

4. Seal and Gasket Inspection: Examine seals and gaskets for cracks or leaks. Replace if they show signs of deterioration to prevent leakage.

5. Cleaning: Remove dust, soot, or other particulates that may impede movement or airflow. In exhaust or combustion systems, this is especially critical.

Troubleshooting Common Issues

1. Valve Sticking or Jamming: Often caused by debris buildup, inadequate lubrication, or misaligned components. Cleaning and realignment usually resolve the issue.

2. Leakage: Check for worn gaskets, seals, or damaged blades. In high-performance systems, ensure that the valve type meets the required leakage standards.

3. Inconsistent Actuation: This could stem from actuator malfunctions, low air pressure in pneumatic models, or signal loss in electrical units. Verify actuator settings and inputs.

4. Noise or Vibration: Loose components or imbalance can cause noise. Tighten hardware and check for uniform airflow.

Maintenance Frequency

Monthly: Visual inspections and light cleaning.

Quarterly: Full operational testing and lubrication.

Annually: Detailed inspection, part replacements if needed, and performance testing.

Documentation and Record Keeping

Maintain a detailed log of inspections, repairs, and replacements. Documentation helps track performance trends and schedule future maintenance more effectively.

Proper maintenance and timely troubleshooting of industrial damper valves ensure uninterrupted operation, reduce downtime, and prolong the life of both the valve and the entire system. A proactive approach to care and service is key to achieving long-term reliability and efficiency.

#Industrial damper hvac#Industrial damper working principle#Industrial damper types#Industrial damper manufacturers

0 notes

Text

Sanitary Valve Standards in the Dairy Industry: Meeting Regulatory and Safety Requirements

The dairy industry operates under some of the strictest hygiene and safety protocols due to the perishable nature of its products. As a result, every piece of equipment—especially valves used in milk and dairy processing systems—must comply with rigorous sanitary standards. These valves play a pivotal role in ensuring the safety, quality, and consistency of dairy products.

In this article, we will explore the key sanitary standards governing dairy valves, how these requirements impact valve design and manufacturing, and why compliance is essential for modern dairy operations.

The Importance of Sanitary Valves in Dairy Processing

Valves in dairy facilities regulate the flow of milk, cream, yogurt, whey, and other fluid ingredients. Since these products are prone to bacterial contamination, any component that comes into contact with them must be easy to clean, non-reactive, and designed to eliminate the risk of contamination.

Sanitary valves are distinguished by:

Hygienic internal surfaces with no dead zones

Use of FDA-approved materials

Compliance with global standards such as 3-A Sanitary Standards, EHEDG, and FDA CFR 21

Resistance to repeated CIP (Clean-In-Place) and SIP (Sterilize-In-Place) cycles

Key Regulatory and Industry Standards for Dairy Valves

1. 3-A Sanitary Standards

The 3-A Sanitary Standards Inc. (3-A SSI) sets specific requirements for the design and fabrication of dairy equipment in the U.S. market. Valves must have smooth, cleanable surfaces and be constructed from non-toxic materials such as 316L stainless steel. They must also be easy to disassemble for inspection or cleaning.

Why it matters: 3-A certification assures end users that the valve is safe for dairy use and will not harbor microbial growth.

2. EHEDG (European Hygienic Engineering & Design Group)

EHEDG promotes hygiene in the design and maintenance of food processing equipment, particularly in Europe. Its guidelines emphasize cleanability, hygienic construction, and validation testing to ensure that valves do not contribute to product contamination.

Why it matters: EHEDG compliance is essential for exporting to the European market and for global companies adhering to strict hygiene protocols.

3. FDA Compliance (CFR Title 21)

The U.S. Food and Drug Administration regulates food contact materials through CFR Title 21. All elastomers, gaskets, and seals used in dairy valves must be FDA-approved and certified for food contact.

Why it matters: FDA compliance ensures that materials used in valves will not leach harmful substances into dairy products.

Sanitary Design Considerations

To comply with these standards, dairy valve manufacturers incorporate several hygienic design features:

Polished internal surfaces (typically Ra < 0.8 µm) to prevent bacterial adhesion

Self-draining flow paths to avoid product pooling

Dead-leg-free construction to eliminate stagnant zones

Seals and seats made of EPDM, PTFE, or silicone—all FDA-approved

Tri-clamp ends or DIN connections for easy removal and reassembly

Inspection, Validation, and Documentation

Modern dairy facilities demand full traceability and documentation. Certified valves often come with:

Material Test Reports (MTRs)

Pressure and leak test results

Surface roughness certificates

Welding validation reports (where applicable)

These documents help meet both internal quality audits and external inspections from food safety authorities.

Impact on Dairy Operations

By using valves that meet global sanitary standards, dairy processors can:

Achieve faster cleaning cycles

Reduce downtime and maintenance

Extend product shelf life

Avoid costly product recalls due to contamination

Most importantly, compliant valves enable dairy plants to operate with confidence, knowing they are protecting public health and maintaining regulatory integrity.

Conclusion

Sanitary valve standards form the backbone of safe and efficient dairy processing. Whether it's 3-A, EHEDG, or FDA compliance, each requirement ensures that the valves used are designed to meet the highest levels of cleanliness, durability, and safety. Working with manufacturers who understand and implement these standards is crucial for dairy processors looking to stay competitive and compliant.

Freture Techno Pvt. Ltd. is a leading Dairy Industry Valves Manufacturer in Mumbai, India.

0 notes

Text

How PTFE Lined Ball Valves Enhance Chemical Processing Efficiency

Industrial processes rely on durable, corrosion-resistant components to handle aggressive chemicals. PTFE lined ball valves play a vital role in ensuring chemical processing efficiency, offering leak-proof operation, minimal friction, and enhanced durability. These properties make them ideal for applications where chemical purity, longevity, and operational safety are key concerns.

How PTFE Lining Improves Performance

Exceptional Chemical Compatibility: Prevents chemical breakdown and degradation.

Reduced Friction & Clogging: Ensures smooth flow and minimizes blockages.

Extended Valve Lifespan: Resists wear, reducing replacement and maintenance costs.

Key Benefits for Chemical Plants

PTFE lined ball valves are indispensable in chemical plants, where exposure to corrosive fluids poses operational risks. The protective PTFE barrier prevents leaks and ensures safe, contamination-free processing.

Leak-Proof Design: Minimizes hazardous spills and improves workplace safety.

High Temperature & Pressure Tolerance: Ideal for extreme processing conditions.

Long-Term Cost Savings: Reduced downtime and maintenance enhance plant efficiency.

The FDA-approved PTFE lining further supports industries requiring strict hygiene compliance, including pharmaceutical and food processing sectors. With versatile end connections and configurations, PTFE lined ball valves cater to diverse industrial needs, ensuring seamless integration into processing systems.

Investing in PTFE lined ball valves guarantees long-term operational efficiency, safety, and cost savings. Their non-stick, non-reactive properties make them a superior choice over conventional ball valves, particularly for industries dealing with highly aggressive fluids. With the ability to maintain purity, prevent contamination, and withstand extreme conditions, these valves continue to set the standard for chemical processing applications.

Choosing a trusted PTFE Lined ball valve manufacturer ensures high-quality solutions tailored to specific industry requirements, enabling businesses to optimize their operations and enhance overall system reliability.

#PTFE Lined Ball Valve#FEP Lined Ball Valve#Lined Ball Valves#manufacturers#suppliers#india#freturetechno

0 notes

Text

Why Indian Check Valve Manufacturers Are Gaining Global Recognition

The Indian industrial valve industry is rapidly expanding, positioning the country as a global leader in check valve production. With rising exports and increasing adoption of advanced manufacturing techniques, Indian check valve manufacturers are competing with global giants in the market.

Growth of the Indian Valve Industry

India’s industrial sector has witnessed significant growth, particularly in:

Oil & Gas – Indian manufacturers supply valves to refineries worldwide.

Pharmaceuticals – High-purity valves are in demand for sterile processes.

Water Treatment – The demand for reliable water treatment valves has surged.

Key Factors Behind India’s Success in Valve Manufacturing

1. Cost-Effective and High-Quality Production

India’s competitive manufacturing costs make its products more affordable while maintaining high quality.

2. Advanced Technology Adoption

CNC machining for precision manufacturing.

Automated quality control measures.

Compliance with global safety standards.

3. Expanding Export Capabilities

Indian manufacturers have established strong partnerships with international clients, exporting to markets in Europe, the Middle East, and North America.

Leading Indian Check Valve Manufacturers

Several Indian companies are now recognized globally for their expertise in manufacturing non-return valves and industrial check valves. Their ability to produce customized solutions while maintaining affordability gives them a competitive edge in the global market.

For businesses seeking high-performance, cost-effective solutions, partnering with a top check valve company in India ensures optimal results for industrial applications.

#check valve manufacturer#swing check valve#lift check valve#ptfe lined checked valve#NVR Valve#freture techno#India

0 notes

Text

PTFE Lined Gate Valves vs. Conventional Gate Valves: Which One is Right for Your Industry?

Selecting the right valve for industrial applications is critical to ensuring safety, reliability, and efficiency. PTFE (Polytetrafluoroethylene) lined gate valves and conventional metal-seated gate valves are two widely used options, each with its own set of advantages and limitations. PTFE lined gate valves are preferred in industries dealing with highly corrosive fluids, while conventional gate valves remain dominant in high-pressure and high-temperature applications.

This article provides a comprehensive comparison between PTFE lined gate valves and conventional gate valves, discussing their design, performance, maintenance requirements, cost-effectiveness, and suitability for different industries.

Design and Material Composition

PTFE Lined Gate Valves

Designed with an internal PTFE lining that protects the valve’s metallic body from corrosive fluids.

Typically constructed with materials like cast iron, ductile iron, or stainless steel to ensure structural integrity while benefiting from PTFE’s corrosion resistance.

The non-stick and low-friction properties of PTFE provide smooth valve operation and prevent buildup of deposits.

Conventional Gate Valves

Made entirely of metal, including stainless steel, carbon steel, or bronze.

Available in different designs such as wedge gate, slab gate, and parallel slide gate valves.

Require additional coatings or internal linings (like epoxy or rubber) for corrosion protection, which may degrade over time.

Performance & Durability

Corrosion Resistance

PTFE Lined Gate Valves: Offer excellent chemical resistance to acids, alkalis, and solvents, making them ideal for highly aggressive environments.

Conventional Gate Valves: More susceptible to corrosion, requiring special coatings or higher-grade alloys for resistance, which increases cost.

Temperature and Pressure Handling

PTFE Lined Gate Valves: Typically designed for moderate pressure applications (ANSI Class 150-300) and temperatures between -50°C to 200°C.

Conventional Gate Valves: Can withstand extreme high-pressure (ANSI Class 600-2500) and high-temperature conditions (up to 600°C), making them suitable for steam and power plants.

Sealing Efficiency

PTFE Lined Gate Valves: Provide superior zero-leakage sealing, ensuring tight shutoff and preventing fluid loss.

Conventional Gate Valves: Offer effective sealing but may experience wear over time, leading to potential leakage if not maintained properly.

Cost & Maintenance Considerations

Initial Investment

PTFE Lined Gate Valves: Higher upfront cost due to PTFE lining and specialized construction.

Conventional Gate Valves: Lower initial cost, but potential expenses arise due to frequent maintenance in corrosive applications.

Maintenance and Service Life

PTFE Lined Gate Valves: Require minimal maintenance since PTFE lining prevents scaling, deposits, and corrosion.

Conventional Gate Valves: More prone to corrosion, erosion, and mechanical wear, requiring frequent servicing and part replacements.

Industry Suitability

PTFE Lined Gate Valves: Best for Corrosive Environments

Chemical Processing: Handles strong acids and corrosive fluids safely.

Pharmaceutical Industry: Maintains sterility and prevents contamination.

Water & Wastewater Treatment: Resistant to scaling and harsh treatment chemicals.

Food & Beverage: Hygienic and resistant to cleaning agents.

Conventional Gate Valves: Best for High-Pressure and High-Temperature Applications

Oil & Gas Industry: Withstands extreme pressure in refineries and pipelines.

Power Plants: Handles steam at high temperatures and pressures.

Mining & Metallurgy: Robust design for handling abrasive slurries and solids.

Long-Term Cost Analysis

Although PTFE lined gate valves have a higher initial investment, their low maintenance costs and extended lifespan make them more cost-effective in corrosive industries. Conventional gate valves, while more affordable upfront, may lead to higher operational costs due to frequent repairs and material degradation in chemical environments.

Final Verdict: Which One Should You Choose?

Choose PTFE Lined Gate Valves if: You require excellent corrosion resistance, low maintenance, and contamination-free operation in industries like chemical processing and pharmaceuticals.

Choose Conventional Gate Valves if: You need to handle high-pressure and high-temperature conditions in power plants, steam applications, or the oil & gas industry.

Both PTFE lined gate valves and conventional gate valves serve critical roles in industrial applications. The choice depends on operational conditions, fluid compatibility, and long-term maintenance considerations. Investing in the right valve ensures safety, efficiency, and cost savings, making it essential to evaluate your industry’s specific requirements before making a selection.

0 notes

Text

The Role of Double Block and Bleed Valves in Chemical Processing: A Comprehensive Guide

Chemical processing facilities demand the highest standards of safety and operational efficiency due to the handling of reactive and potentially dangerous substances. One critical component that supports these standards is the Double Block and Bleed Valve. In this comprehensive guide, we examine the role of these valves in chemical processing, discussing their design, operational benefits, and the specific challenges they help overcome in maintaining a safe and efficient production environment.

What Are Double Block and Bleed Valves? At their core, Double Block and Bleed Valves are designed with two independent sealing mechanisms and an intervening bleed port. This configuration creates a redundant barrier that is crucial for isolating process lines, especially in scenarios where any leakage could have severe consequences. In chemical processing, where the purity and containment of chemicals are critical, these valves play an indispensable role.

Key Features and Operational Principles

Dual Sealing Mechanism: The valve employs two seals—an upstream and a downstream seal—to ensure that even if one seal fails, the other will maintain isolation.

Bleed Port Functionality: The bleed port, located between the two seals, allows for the controlled release of pressure and provides a means to test the integrity of the seals. This is especially important during routine maintenance or emergency shutdowns.

Material and Construction: Chemical processing environments can be extremely harsh. Therefore, these valves are often made from high-grade stainless steel, carbon steel, or specialized alloys to resist corrosion, high temperatures, and aggressive chemicals.

Advantages in Chemical Processing The deployment of Double Block and Bleed Valves in chemical processing offers several advantages:

Improved Safety: With dual seals, the risk of inadvertent chemical releases is greatly reduced, ensuring the safety of both personnel and equipment.

Enhanced Process Control: The ability to depressurize and monitor the interspace between seals allows operators to verify complete isolation before undertaking maintenance tasks.

Operational Flexibility: These valves enable selective isolation of process segments. This means that routine servicing or emergency interventions can be carried out without halting the entire production line.

Regulatory Compliance: Chemical processing plants are subject to strict safety and environmental regulations. The use of Double Block and Bleed Valves helps ensure compliance with industry standards, such as those set by API, ASME, and ISO.

Industry Applications and Use Cases Double Block and Bleed Valves are utilized in various chemical processing applications:

Batch Processing Systems: Where precise control over chemical reactions is required, these valves help isolate specific sections of the process, ensuring that reactions proceed safely.

Continuous Processing Plants: In continuous flow operations, they allow for the safe diversion of process streams during routine maintenance or emergency shutdowns.

Storage and Transfer Operations: When chemicals are transferred between storage tanks or processing units, these valves ensure that accidental mixing or contamination does not occur.

Installation and Maintenance Best Practices Ensuring the long-term reliability of Double Block and Bleed Valves in a chemical processing environment involves:

Professional Installation: Correct installation by trained technicians is essential. Proper alignment and secure connections are critical for maintaining the integrity of the dual seals.

Routine Inspections: Regular maintenance checks should be performed to assess seal wear, verify the functionality of the bleed port, and confirm overall valve performance.

Documentation and Compliance: Keeping detailed maintenance records and ensuring adherence to industry standards not only enhances safety but also facilitates regulatory compliance and audits.

Emerging Trends in Valve Technology The field of valve technology is rapidly evolving. Innovations such as the integration of digital monitoring systems and advanced materials are enhancing the performance of Double Block and Bleed Valves. These trends are particularly significant in chemical processing, where the ability to predict and prevent failures can lead to improved safety and operational efficiency. Smart sensors now offer real-time insights into valve performance, enabling predictive maintenance and reducing the likelihood of unexpected downtime.

Conclusion Double Block and Bleed Valves have become an essential component in chemical processing facilities, providing unmatched safety and operational benefits. Their robust design, featuring dual seals and a functional bleed port, ensures reliable isolation of process lines and helps maintain the integrity of sensitive chemical processes. As the Chemical industry continues to advance, the adoption of cutting-edge valve technologies will further improve safety standards, operational efficiency, and regulatory compliance. For chemical processing plants, investing in these advanced valves is not just a matter of regulatory necessity—it is a strategic move towards ensuring long-term process safety and operational excellence.

#Double Block and Bleed Valve#DBB Valve#Chemical and Fertilzer Industry#Isolation valves#Manufacturers#suppliers#freture techno#Mumbai#India

1 note

·

View note

Text

Comprehensive Guide to Valves in the Food & Pharma Industry

Valves are critical components in the food and pharmaceutical industries, playing an essential role in controlling the flow of liquids, gases, and semi-solid substances throughout processing. These industries adhere to strict hygiene, safety, and efficiency standards, making the selection of the right valve crucial for product integrity, compliance, and operational reliability. As global demand for high-quality food and pharmaceutical products increases, the need for robust, contamination-free, and precision-engineered valves has never been more significant. Indian manufacturers are at the forefront of supplying high-performance valves that meet international quality standards.

The Role of Valves in Food & Pharmaceutical Processing

Valves facilitate efficient and contamination-free processing in various stages, including ingredient mixing, sterilization, packaging, and distribution. They regulate pressure, temperature, and flow rates, ensuring smooth and controlled operations. In the pharmaceutical industry, valves play an essential role in sterile production processes, ensuring aseptic conditions that prevent microbial contamination. In food production, valves maintain hygiene by preventing bacterial growth and ensuring smooth operation in beverage, dairy, and processed food industries.

Types of Valves Used in Food & Pharma Industry

Butterfly Valves – These lightweight and compact valves are widely used due to their ease of cleaning and ability to facilitate quick shut-off and flow control. Their streamlined design minimizes dead space, reducing the risk of contamination and bacterial growth, making them ideal for hygienic applications.

Diaphragm Valves – Engineered to ensure sterility, diaphragm valves feature minimal dead space and a smooth flow path. These qualities make them particularly suitable for aseptic processes in pharmaceutical and food production, where strict contamination control is essential.

Ball Valves – Offering a robust sealing mechanism, ball valves provide excellent shut-off capabilities, preventing leaks and contamination. Their durability and ease of operation make them a preferred choice in high-pressure and high-purity applications.

Globe Valves – Designed for precision flow control, globe valves play a vital role in pharmaceutical processing, where accurate fluid regulation is required. Their ability to regulate flow rates efficiently makes them indispensable in processes that demand precision.

Control Valves – Automated control valves enhance processing consistency by regulating fluid flow with high accuracy. These valves integrate seamlessly with digital monitoring and control systems, ensuring optimal performance and process efficiency.

Key Features & Standards of Industrial Valves

Hygienic Design – Valves in food and pharmaceutical applications are designed with smooth, crevice-free surfaces that prevent bacterial buildup and allow for easy cleaning.

FDA & USP Class VI Compliance – Regulatory standards require materials used in valve manufacturing to be safe for food and pharma contact. Compliance ensures product integrity and consumer safety.

CIP/SIP Compatibility – Clean-in-Place (CIP) and Steam-in-Place (SIP) technologies allow automated cleaning and sterilization of valve systems without disassembly, ensuring consistent hygiene and reducing downtime.

How to Choose the Right Valve for Food & Pharma Applications

Material Selection – Stainless steel 316L and PTFE-lined surfaces offer excellent resistance to corrosion and chemical reactions, ensuring product purity and extended valve life.

Sealing Technology – Aseptic seals, minimal dead space designs, and leak-proof construction prevent bacterial growth and contamination.

Pressure & Temperature Ratings – Valves must withstand rigorous operating conditions, including high-pressure steam sterilization and extreme temperature fluctuations.

Ease of Maintenance – CIP/SIP-compatible valves reduce downtime and enhance process efficiency.

Automation & Control – Smart valve technology enables digital integration for precise fluid control, monitoring, and predictive maintenance.

Why Choose Freture Techno Valve Manufacturers?

We are leading Food and Pharmacutical valves manufacturers are recognized globally for producing high-quality valves that meet strict international regulatory standards, including ASME BPE, GMP, and EHEDG certifications. The advantages of sourcing valves from India include:

Cost-Effective Solutions – Competitive pricing without compromising on quality.

Customization – Tailored valve designs to meet specific industry needs.

Adherence to International Standards – Indian manufacturers comply with global safety and hygiene certifications.

Technological Advancements in Valve Manufacturing

The food and pharmaceutical industries are rapidly adopting advanced valve technologies, including:

Smart Valves – IoT-enabled valves provide real-time monitoring, predictive maintenance, and automated process adjustments.

Zero Dead-Leg Designs – Prevent product residue buildup, ensuring complete sterility and reducing contamination risks.

Self-Cleaning Mechanisms – Automated cleaning processes enhance operational efficiency and reduce downtime.

Applications of Valves in Food & Pharma Industry

Dairy Processing – Used in milk, yogurt, and cheese production to maintain product safety and quality.

Beverage Industry – Ensures contamination-free handling of soft drinks, juices, and alcohol.

Pharmaceutical Formulations – Used in sterile fluid processing, IV fluids, and vaccine production.

Fermentation & Bioprocessing – Helps regulate the flow of bioactive substances in drug manufacturing.

Cleanroom Operations – Supports high-purity environments by ensuring contamination-free operations.

Investing in high-quality pharmacutical and Food industrial valves is critical for food and pharmaceutical manufacturers to maintain efficiency, hygiene, and compliance with industry regulations. Indian manufacturers offer cutting-edge solutions tailored to global market demands, making them a preferred choice for businesses looking for reliability and innovation in industrial valve technology. Choosing the right valve ensures product integrity, operational efficiency, and regulatory compliance, making it a key factor in successful food and pharmaceutical production.

0 notes

Text

High-Pressure Valves in Oil and Gas: Ensuring Safety and Efficiency

High-pressure valves play a critical role in the oil and gas industry by regulating, controlling, and isolating the flow of liquids and gases under extreme conditions. These valves are designed to withstand intense pressure and temperature fluctuations, ensuring operational safety, system integrity, and process efficiency. Without high-pressure valves, oil rigs, refineries, and pipeline systems would be at significant risk of leaks, pressure surges, and catastrophic failures.

The selection of the right high-pressure valve is crucial for ensuring durability, compliance with industry standards (such as API and ASME), and seamless integration into complex industrial systems. Let’s explore their working principle, types, materials, challenges, and applications in the oil and gas sector.

Working Principle of High-Pressure Valves

High-pressure valves function by controlling fluid flow through a pressurized system, either by opening, closing, or regulating the passage of oil, gas, or steam. These valves are specifically designed to:

Withstand extreme pressures (up to 10,000+ PSI)

Prevent leaks with precision sealing mechanisms

Regulate flow rate to avoid pressure surges

Operate in high-temperature environments, often exceeding 400°C

The internal components, including valve seats, stems, and seals, are reinforced with high-strength alloys and corrosion-resistant coatings to ensure longevity. Advanced sealing technologies, such as metal-to-metal or polymer seals, further enhance their leak-proof performance.

Types of High-Pressure Valves

Different types of high-pressure valves are used in oil and gas operations, depending on their function and application:

1. Ball Valves

Ball valves use a rotating ball with a bore to control fluid flow. They provide tight sealing, quick operation, and are commonly used in high-pressure Ball Valve gas pipelines and offshore platforms.

2. Gate Valves

Gate valves feature a sliding gate mechanism that moves up and down to control flow. They are ideal for applications requiring full shut-off capability and minimal pressure drop.

3. Globe Valves

Globe valves regulate precise flow control and pressure modulation. Their spherical body design ensures excellent throttling capabilities in refining and processing units.

4. Check Valves

High Pressure Check valves in Oil and Gas Industry allow one-way flow to prevent backflow and potential contamination of pipelines. They are critical in oil transportation and offshore drilling applications.

5. Needle Valves

Needle valves provide fine flow control with a tapered needle-like stem. They are commonly used in high-pressure instrumentation and hydraulic systems.

Material Selection & Design Considerations

Given the harsh conditions of oil and gas extraction, refining, and distribution, high-pressure valves must be constructed using robust materials:

Stainless Steel (316, 304) – Corrosion-resistant, ideal for offshore applications

Alloy Steel (Inconel, Hastelloy) – High-temperature tolerance, excellent mechanical strength

Duplex & Super Duplex Steel – Superior strength and resistance to stress corrosion cracking

Tungsten Carbide Coatings – Enhances wear resistance and extends valve life

Design considerations such as pressure ratings (ANSI Class 1500–4500), end connections (flanged, threaded, or welded), and actuation methods (manual, electric, or pneumatic) also influence valve selection.

Challenges & Solutions in High-Pressure Environments

High-pressure valves in oil and gas Industry operations face several challenges, including:

Corrosion & Erosion – Exposure to saline environments, hydrocarbons, and chemicals leads to material degradation. Solution: Use corrosion-resistant alloys and coatings.

Pressure Surges & Water Hammer – Sudden pressure changes can damage pipelines and equipment. Solution: Install surge relief valves and use gradual valve actuation.

Seal Leakage & Valve Failure – Continuous exposure to high temperatures and pressures can degrade gaskets and seals. Solution: Implement advanced sealing technologies like graphite packing or polymer-based seals.

Applications of High-Pressure Valves in Oil & Gas Industry

High-pressure valves are indispensable in various oil and gas industry applications, including:

Drilling Operations – Controlling mud flow, well pressure, and blowout preventers (BOPs)

Refining & Processing – Regulating crude oil refining, gas separation, and chemical injections

Offshore Platforms – Ensuring seawater injection systems, safety shut-off, and subsea control valves

Pipeline Transportation – Preventing leaks and pressure drops in long-distance oil & gas pipelines

Storage & Distribution – Enhancing tank farm safety and LNG terminal operations

Future Trends & Technological Advancements

The oil and gas industry is evolving with technological innovations, leading to advancements in high-pressure valve design:

Smart Valves & IoT Integration – Remote monitoring, predictive maintenance, and automation for improved efficiency

Zero-Emission Valves – Reducing fugitive emissions to comply with environmental regulations

Advanced Materials – Development of self-lubricating polymers and composite materials for extended valve lifespan

With increasing emphasis on safety, reliability, and efficiency, high-pressure valve manufacturers continue to invest in cutting-edge technology to meet the industry’s growing demands.

Conclusion

High-pressure valves are the backbone of oil and gas operations, ensuring fluid control, system integrity, and operational safety. Their ability to withstand extreme conditions makes them indispensable in drilling, refining, offshore platforms, and pipeline systems.

Selecting the right high-pressure valve requires careful consideration of material compatibility, pressure ratings, sealing mechanisms, and compliance with API and ASME standards. With ongoing innovations like smart valve technology and zero-emission solutions, the future of high-pressure valves in the oil and gas sector is poised for significant advancements.

For businesses in the oil and gas industry, investing in high-quality, API-certified high-pressure valves is key to enhancing safety, efficiency, and long-term reliability.

#Oil and Gas Industry Valves Manufacturers#High pressure Check Vavles#High Pressure Ball Valve#High Pressure Needle Valve#freture techno#india

0 notes

Text

Choosing the Right Industrial Valve Manufacturer in India

Selecting the right industrial valve manufacturer in India is crucial for ensuring long-term reliability, safety, and efficiency in industrial applications. Whether in oil & gas, pharmaceuticals, water treatment, or power plants, choosing a certified, experienced manufacturer can significantly impact operational success.

One such leading name in the industry is Freture Techno Pvt. Ltd., based in Mumbai, India. With a commitment to quality, precision, and innovation, they offer a wide range of API-certified, high-performance industrial valves.

Key Factors to Consider When Choosing a Valve Manufacturer

When selecting an industrial valve supplier in India, consider the following critical aspects:

✅ Certifications & Quality Standards A reputable manufacturer should comply with international and national standards, including:

ISO 9001 – Quality management certification.

API 6D & API 600 – Compliance with oil & gas industry requirements.

ASME B16.34 – Pressure-temperature ratings for industrial valves.

IBR Certification – Necessary for steam and boiler applications.

✅ Material Selection & Durability The valve material must be compatible with temperature, pressure, and media composition. Look for manufacturers offering:

Stainless Steel (SS 304, SS 316, Duplex Steel) – High durability and corrosion resistance.

Hastelloy & Inconel – Ideal for extreme temperature and pressure applications.

PTFE/PFA-lined Valves – Chemical-resistant solutions for pharmaceutical and chemical processing industries.

✅ Customization Capabilities Industries often require customized solutions based on specific process needs. Leading manufacturers should provide:

Size variations (1/2" to 48")

Pressure ratings (ANSI 150–2500, PN10–PN420)

Actuated valve options (pneumatic, electric, and hydraulic actuators)

✅ Testing & Quality Assurance Ensure the manufacturer conducts rigorous testing to guarantee performance and safety. Tests should include:

Hydrostatic and Pneumatic Testing – Ensuring leak-proof operations.

Fire-safe Testing (API 607, API 6FA) – Required for oil & gas applications.

Fugitive Emission Testing – To minimize environmental impact.

Freture Techno Pvt. Ltd. – A Trusted Name in Industrial Valves

Freture Techno Pvt. Ltd., Mumbai, is a leading industrial valve manufacturer in India, known for:

✔ ISO and API-certified valves, meeting global quality standards. ✔ A wide product range, including Ball Valves, Gate Valves, Globe Valves, Check Valves, Butterfly Valves, and Control Valves. ✔ Industry-specific solutions, tailored for oil & gas, pharmaceuticals, power plants, and water treatment facilities. ✔ Advanced manufacturing technology ensuring high precision, durability, and safety. ✔ Customization and on-time delivery, meeting unique project requirements.

Comparison: Freture Techno Pvt. Ltd. vs. Other Manufacturers

FeatureFreture Techno Pvt. Ltd.Other ManufacturersCertificationsISO 9001, API 6D, ASME, IBRVariesMaterial OptionsSS 316, Duplex Steel, Hastelloy, PTFE-linedLimited OptionsProduct RangeFull range of industrial valvesMay be specialized in a few typesCustomizationFully customized solutionsStandard offeringsTesting StandardsHydrostatic, Pneumatic, Fire-Safe, Fugitive EmissionBasic Testing

Final Thoughts

Choosing the right industrial valve manufacturer in India is a crucial decision that impacts efficiency, safety, and cost-effectiveness. With its certified, high-performance valves and industry expertise, Freture Techno Pvt. Ltd. stands out as a trusted supplier for industrial needs across multiple sectors.

📌 Looking for high-quality industrial valves? Contact Freture Techno Pvt. Ltd. for customized, reliable, and globally certified valve solutions

1 note

·

View note

Text

Revolutionizing Fluid Control The Versatility of Pneumatic Diaphragm Control Valves

In today's fast-paced industrial landscape, reliable and precise control of fluid systems is essential for maintaining operational efficiency. Pneumatic diaphragm control valves are at the forefront of this need, offering exceptional performance across a wide range of industries. These valves are not only known for their ability to manage flow and pressure but also for their adaptability to various environmental conditions and demanding applications.

This article explores the unique features, operational mechanisms, and wide-ranging applications of pneumatic diaphragm control valves, demonstrating how they contribute to seamless industrial processes.

The Unique Features of Pneumatic Diaphragm Control Valves

Pneumatic diaphragm control valves are engineered to deliver superior functionality and durability. Their defining features include:

1. Flexible Diaphragm Actuation

The flexible diaphragm serves as the heart of these valves, allowing precise control over the flow of fluids. The pneumatic actuator ensures quick and responsive movements, ideal for processes requiring high accuracy.

2. Compatibility with Aggressive Media

These valves are constructed from robust materials such as stainless steel, PTFE, and elastomers, enabling them to withstand corrosive and abrasive fluids. This makes them suitable for chemical and wastewater applications.

3. Hygienic Design

In industries like pharmaceuticals and food processing, maintaining a sterile environment is crucial. Pneumatic diaphragm control valves feature smooth internal surfaces and crevice-free designs to prevent contamination.

4. Low Operational Noise

The pneumatic mechanism eliminates the noise often associated with electrically actuated valves, making these valves suitable for environments where minimal noise is a priority.

5. Versatile Configurations

Available in various sizes and configurations, these valves cater to specific application needs. Options like globe, angle, and three-way designs enhance their versatility.

How Pneumatic Diaphragm Control Valves Operate

At the core of these valves is the diaphragm, which is actuated by compressed air supplied through the pneumatic actuator. The actuator's force pushes the diaphragm to open, close, or modulate the valve, controlling the flow of fluids.

This straightforward mechanism eliminates the need for complex components, making pneumatic diaphragm valves reliable and cost-effective solutions. The absence of electrical components also enhances their suitability for hazardous environments.

Applications of Pneumatic Diaphragm Control Valves

Pneumatic diaphragm control valves are integral to a variety of industries, owing to their versatility and dependability.

1. Pharmaceutical Manufacturing

These valves play a pivotal role in ensuring precision and sterility in pharmaceutical processes. They are used to control pure water, solvents, and other critical fluids while adhering to stringent regulatory standards.

2. Chemical Processing

In chemical plants, these valves manage the flow of aggressive chemicals, including acids and alkalis, with exceptional durability and control.

3. Wastewater Treatment

Pneumatic diaphragm control valves are used to regulate the flow of wastewater and treatment chemicals, ensuring efficient operations in municipal and industrial water treatment facilities.

4. Oil and Gas Operations

The oil and gas sector employs these valves to manage high-pressure fluids and gases in pipelines, separators, and refineries. Their rugged construction and reliability are indispensable in harsh operating conditions.

5. Food and Beverage Production

The hygienic design of these valves ensures compliance with strict food safety standards while managing fluids like syrups, oils, and cleaning solutions.

Advantages of Pneumatic Diaphragm Control Valves in Industrial Use

1. Enhanced Safety

The absence of electrical components makes these valves inherently safe for explosive and flammable environments.

2. Simplified Maintenance

With fewer moving parts, these valves are easy to maintain and have a lower risk of mechanical failure.

3. Cost Efficiency

The use of compressed air instead of electricity reduces energy costs, making these valves a sustainable choice for long-term operations.

4. Scalability

Their ability to adapt to varying flow rates and pressures ensures seamless integration into systems of different scales.

Selecting the Right Pneumatic Diaphragm Control Valve

To maximize the benefits of these valves, selecting the right model and specifications for the application is crucial. Key considerations include:

Fluid Type: Compatibility with the fluid's chemical and physical properties is essential.

Pressure and Temperature Requirements: Ensure the valve can handle the operating conditions.

Valve Size and Flow Capacity: Proper sizing ensures optimal performance and minimizes pressure losses.

Regulatory Compliance: In industries like pharmaceuticals, valves must meet specific standards for safety and hygiene.

Challenges in Using Pneumatic Diaphragm Control Valves

Despite their advantages, certain challenges may arise in using these valves:

1. Compressed Air Dependency

An uninterrupted supply of compressed air is vital for their operation. Ensuring proper air filtration and pressure regulation is critical to avoid system inefficiencies.

2. Diaphragm Wear

Over time, diaphragms may wear out due to repeated cycles or exposure to aggressive fluids. Regular inspections and timely replacements are necessary.

3. Limited Flow Range

In some cases, these valves may not be ideal for extremely high flow rates. Selecting the appropriate valve type or configuration can address this limitation.

Future Trends in Pneumatic Diaphragm Control Valves

The integration of smart technologies is set to redefine the functionality of pneumatic diaphragm control valves. Features like real-time monitoring, remote control, and predictive maintenance are being incorporated into valve systems, enhancing efficiency and reducing downtime.

Additionally, advancements in material science are leading to the development of diaphragms with improved chemical resistance and longer lifespans, further expanding the applications of these valves.

Conclusion

Diaphragm Control valves have emerged as reliable and versatile solutions for fluid control across diverse industries. Their unique features, from precise flow regulation to compatibility with challenging fluids, make them indispensable for optimizing industrial processes.

Understanding their functionality, applications, and advantages ensures informed decision-making when selecting these valves for specific needs. Regular maintenance and the adoption of modern technologies can further enhance their performance and reliability.

For industries seeking premium pneumatic diaphragm control valves, Freture Techno Pvt. Ltd. stands out as a leading manufacturer in India, offering high-quality solutions tailored to meet diverse industrial requirements.

0 notes

Text

Bellow Sealed Globe Valves A Reliable Solution for Industrial Applications

Bellow Sealed Globe Valves are specially designed to prevent leakage in critical industrial applications. Unlike conventional globe valves, they feature a bellows mechanism that provides a hermetic seal, ensuring zero emissions and enhanced operational safety. These valves are widely used in industries requiring precise flow control and absolute leakage prevention, such as pharmaceuticals, chemical processing, oil and gas, and power plants.

Working Principle

The primary function of a Bellow Sealed Globe Valve is to regulate fluid flow with minimal leakage. The valve consists of a flexible metallic bellows welded to both the bonnet and the stem, creating a secure, leak-proof seal. When the valve is operated, the bellows expand or contract, allowing fluid to pass while preventing leakage. The secondary packing further enhances the sealing integrity, ensuring a double-layered protection system against fugitive emissions.

Key Features & Advantages

Zero Leakage: The bellows mechanism ensures a completely leak-proof operation, making these valves ideal for handling hazardous fluids.

Enhanced Safety: By preventing external leakage, these valves reduce the risk of contamination and environmental hazards.

Extended Lifespan: The robust design and high-quality materials enhance durability, reducing maintenance requirements and operational downtime.

High Performance in Extreme Conditions: Capable of withstanding high temperatures and pressures, making them suitable for demanding industrial applications.

Double Sealing Mechanism: The combination of bellows and secondary packing ensures long-term reliability and safety.

Reduced Emissions: Complies with environmental regulations by preventing volatile emissions and fluid leakage.

Applications

Bellow Sealed Globe Valves are extensively used in various industries due to their superior sealing properties:

Oil & Gas Industry: Used in pipeline systems where leakage prevention is crucial.

Chemical Processing: Ideal for handling toxic and corrosive chemicals.

Pharmaceutical Industry: Ensures sterile and contamination-free fluid flow.

Power Plants: Employed in high-temperature steam and water applications to enhance system efficiency.

Food & Beverage Industry: Ensures hygiene and compliance with industry standards.

Material & Design Specifications

These valves are manufactured using high-grade materials to withstand extreme industrial conditions:

Body Materials: Stainless Steel (SS304, SS316), Carbon Steel, and Alloy Steel.

Bellows Material: Multi-ply stainless steel bellows for flexibility and durability.

End Connections: Flanged, Socket Weld, and Threaded as per industry standards.

Pressure Rating: Ranges from Class 150 to Class 600, ensuring suitability for high-pressure environments.

Temperature Range: Designed to operate effectively in temperatures ranging from -196°C to 600°C.

Compliance Standards: Conforms to API, ASME, and DIN standards for quality assurance.

Why Choose Bellow Sealed Globe Valves?

Compared to conventional globe valves, Bellow Sealed Globe Valves offer superior performance and safety. Traditional globe valves rely on gland packing to prevent leakage, which can deteriorate over time, leading to emissions and safety hazards. In contrast, Bellow Sealed Globe Valves provide a maintenance-free, long-lasting solution with an added layer of sealing protection. They are the preferred choice for industries where leak prevention and operational efficiency are top priorities.

Conclusion

Bellow Sealed Globe Valves are a vital component in industrial applications requiring high-performance, leak-proof solutions. Their ability to prevent fugitive emissions and ensure operational safety makes them an excellent choice for industries handling hazardous and high-value fluids. Freture Techno Pvt. Ltd., a leading manufacturer in Mumbai, India, offers high-quality Bellow Sealed Globe Valves designed to meet stringent industry standards. For reliable and efficient valve solutions, trust Freture Techno Pvt. Ltd. to deliver the best in class.

#bellow valves#bellow sealed valves#bellow sealed globe valves#freture techno#manufactuers#mumbai#india

0 notes

Text

0 notes

Text

0 notes

Text

High Pressure Sealed Globe Valves Enabling Efficiency in Critical Applications

High Pressure Sealed Globe Valves are integral to industrial processes that demand precision, safety, and reliability. With their robust design and pressure-sealing capabilities, these valves are critical for industries handling high-pressure and high-temperature environments. This article highlights their functionality, advantages, and the specific industries where these valves play a crucial role.

Engineering Excellence in High Pressure Sealed Globe Valves

These valves are meticulously crafted for controlling and regulating fluid flow in challenging operational conditions. Key engineering attributes include:

Pressure-Seal Technology: The sealing becomes tighter with increasing internal pressure, ensuring leak-free operation.

Throttling Precision: Aided by a disc-and-seat arrangement, they provide accurate control over fluid flow.

Material Durability: Available in stainless steel, carbon steel, and other alloys to resist corrosion and extreme temperatures.

Compact Design: Suitable for space-constrained installations without compromising performance.

Why Choose High Pressure Sealed Globe Valves?

Superior Sealing Performance The pressure-seal bonnet ensures a fail-proof barrier against leaks, enhancing safety in critical systems.

Operational Longevity Built with durable materials and advanced sealing mechanisms, these valves reduce maintenance frequency and associated costs.

Compliance-Driven Design Manufactured in accordance with standards like ASME B16.34, ensuring quality and safety compliance.

Versatile Functionality High compatibility with various pipeline systems due to multiple end connection options such as flanged, welded, and threaded.

Industries Driving Demand for High Pressure Sealed Globe Valves

1. Oil and Gas Sector

The oil and gas industry operates under extreme pressures and temperatures, making these valves indispensable.

Applications:

Managing crude oil transport systems.

Controlling gas injection for enhanced oil recovery.

Regulating steam and fluid flow in refineries.

Industry Impact: Their ability to prevent leaks ensures operational safety and compliance with environmental standards.

2. Power Generation Facilities

Efficient handling of steam and feedwater systems in thermal and nuclear power plants requires precision-engineered valves.

Applications:

Steam regulation in turbine operations.

Managing boiler feedwater pressure.

Cooling water flow control.

Industry Impact: These valves contribute to maximizing energy efficiency and system reliability.

3. Chemical Processing Plants

In chemical industries, handling corrosive and hazardous fluids demands valves with superior material and performance capabilities.

Applications:

Controlling fluid flow in high-pressure reactors.

Managing critical feed lines for chemical processes.

Industry Impact: Their robust design minimizes risks of leaks and contamination, ensuring process safety.

4. Pharmaceuticals and Biotech Manufacturing

High purity standards and precise flow control are vital in pharmaceutical and biotechnology production facilities.

Applications:

Managing purified water systems.

Regulating sterilization and high-temperature processes.

Industry Impact: High Pressure Sealed Globe Valves ensure consistent quality while adhering to regulatory standards.

5. Aerospace and Defense

These valves are a staple in aerospace and defense applications where space constraints and reliability are critical.

Applications:

Hydraulic systems in aerospace machinery.

Fuel management in high-pressure military equipment.

Industry Impact: Their compact yet high-performance design supports precision and safety in demanding applications.

6. Desalination and Water Treatment

Water treatment facilities rely on these valves for high-pressure operations, especially in reverse osmosis and desalination systems.

Applications:

Managing flow in high-pressure filtration systems.

Controlling dosing chemicals for water purification.

Industry Impact: By ensuring leak-proof performance, these valves support sustainable water management practices.

Selecting the Right High Pressure Sealed Globe Valve

For optimized performance, consider the following factors when choosing a valve:

Pressure and Temperature Ratings: Verify compatibility with your system’s operating conditions.

Material Specifications: Select corrosion-resistant materials for aggressive or corrosive media.

Connection Type: Choose the appropriate end connection (flanged, butt-weld, or socket-weld) for easy integration.

Maintenance Requirements: Look for designs that simplify maintenance and minimize downtime.

Future Trends in High Pressure Sealed Globe Valve Technology

Innovations in materials and sealing technologies are driving the evolution of High Pressure Sealed Globe Valves. New advancements, such as zero-emission designs and enhanced corrosion resistance, are meeting the growing demand for environmentally sustainable and efficient fluid control solutions.

Industries are also benefiting from automation-ready valves, enabling remote operation and real-time monitoring, thereby enhancing overall system efficiency.

Conclusion

High Pressure Sealed Globe Valves are a cornerstone of operational efficiency and safety in industries ranging from oil and gas to pharmaceuticals. Their advanced engineering ensures precision, durability, and reliability in high-pressure environments, making them a critical investment for businesses worldwide.

For high-quality High Pressure Sealed Globe Valves tailored to your industry needs, Freture Techno Pvt. Ltd. is a trusted name in India. As a leading manufacturer, Freture Techno Pvt. Ltd. delivers cutting-edge valve solutions designed for superior performance and durability.

0 notes