#freture techno

Text

Advancements in Smart Lined Valves: Integrating IoT for Enhanced Monitoring and Control

The integration of the Internet of Things (IoT) into industrial equipment is revolutionizing various sectors, including valve technology. Smart lined valves, equipped with sensors and connectivity features, represent a significant advancement in the field. These valves offer real-time monitoring, predictive maintenance, and remote control capabilities, enhancing efficiency and reliability in industrial processes. In this article, we will delve into the benefits of smart lined valves, their applications in different industries, and the future of this technology.

Benefits of Smart Lined Valves

Real-Time Monitoring: Smart lined valves come equipped with sensors that monitor various parameters such as pressure, temperature, and flow rate in real-time. This data is transmitted to a central monitoring system, allowing operators to have instant visibility into the performance of the valves. Real-time monitoring helps in early detection of anomalies, preventing potential failures and minimizing downtime.

Predictive Maintenance: Traditional maintenance strategies are often reactive, addressing issues only after they occur. Smart lined valves enable predictive maintenance by analyzing data trends and predicting when a valve might fail or require maintenance. This proactive approach reduces unplanned downtime, extends the lifespan of the valves, and optimizes maintenance schedules, thereby saving costs.

Remote Control and Automation: The ability to remotely control valves is a significant advantage, especially in industries with hazardous environments or difficult-to-access locations. Smart lined valves can be integrated into automated systems, allowing for remote adjustments and control. This feature enhances safety and operational efficiency by reducing the need for manual intervention.

Enhanced Data Analytics: The data collected from smart lined valves can be used for detailed analytics, providing insights into the overall system performance. These insights can help in optimizing processes, improving product quality, and reducing operational costs. Advanced analytics can also aid in compliance reporting, ensuring that all regulatory requirements are met.

Applications in Different Industries

Chemical Processing: In the chemical processing industry, the handling of corrosive and hazardous substances is common. Smart lined valves provide the necessary resistance to these chemicals while offering real-time monitoring and control. For instance, in a chemical plant dealing with highly corrosive acids, smart PTFE-lined valves can ensure safe and efficient handling of the substances, while predictive maintenance helps in avoiding unexpected downtimes.

Water Treatment: Water treatment facilities require precise control over the flow and composition of water. Smart lined valves, especially those lined with PVDF, are used to handle various chemicals involved in the treatment process. The real-time monitoring capabilities ensure that the water quality is consistently maintained, and any deviations can be promptly addressed.

Oil and Gas: The oil and gas industry operates in some of the harshest environments, where equipment reliability is crucial. Smart lined valves offer corrosion resistance essential for handling aggressive fluids and gases. Additionally, the integration of IoT allows for remote monitoring of offshore platforms, enhancing safety and reducing the need for on-site personnel.

Food and Beverage: In the food and beverage industry, maintaining hygiene and preventing contamination are critical. Smart lined valves help in achieving these goals by providing corrosion resistance and enabling real-time monitoring of the processes. For example, in a beverage production line, smart PFA-lined valves can ensure that the flow of ingredients is precisely controlled and monitored, maintaining product quality.

Future of Smart Lined Valves

The future of smart lined valves looks promising, with continuous advancements in IoT and sensor technology. Developments in artificial intelligence (AI) and machine learning (ML) are expected to further enhance the predictive maintenance capabilities, making these valves even more efficient and reliable.

Moreover, the integration of blockchain technology could provide secure and transparent data logging, ensuring compliance and traceability in industries with stringent regulatory requirements. This could be particularly beneficial in pharmaceuticals and food and beverage sectors, where product safety and traceability are paramount.

In addition, advancements in material science could lead to the development of new lining materials with even better performance characteristics. These materials could provide improved resistance to a wider range of chemicals and higher temperatures, expanding the applicability of lined valves in more demanding environments.

Conclusion

Lined valves play a crucial role in ensuring the safety, reliability, and efficiency of industrial processes across various sectors. In the pharmaceutical industry, they are indispensable for maintaining sterility and preventing contamination. The advent of smart lined valves, integrating IoT technology, marks a significant leap forward, offering enhanced monitoring, predictive maintenance, and remote control capabilities.

As industries continue to evolve, the adoption of advanced lined valve technologies will be essential for meeting the increasing demands for safety, efficiency, and regulatory compliance. Companies like Freture Techno Pvt. Ltd., a leading manufacturer of lined valves in Mumbai, India, are at the forefront of this technological revolution, providing high-quality solutions to meet the diverse needs of their clients.

0 notes

Text

Check Valve: Essential Component in Fluid Control Systems

A check valve, also known as a non-return valve, is a crucial component in fluid control systems. Its primary function is to allow fluid (liquid or gas) to flow through it in only one direction. This unidirectional flow is critical in various applications to prevent backflow, which could potentially damage equipment or cause system failures.

Types of Check Valves

There are several types of check valves, each suited for specific applications and operating environments:

Swing Check Valve: This type uses a swinging disc to allow or block flow. It's commonly used in water and wastewater treatment plants, as well as in fire protection systems.

Lift Check Valve: Featuring a disc that moves vertically, lift check valves are typically used in high-pressure applications. They are often found in steam and gas lines.

https://www.freture.com/site/assets/files/1238/lift-check-valve.png

Ball Check Valve: This valve uses a ball to block flow in the reverse direction. It's particularly effective in handling viscous fluids and is frequently used in pumping systems.

Diaphragm Check Valve: Utilizing a flexible diaphragm to control flow, these valves are ideal for applications where a tight seal is necessary, such as in chemical processing.

Wafer Check Valve: Compact and lightweight, wafer check valves are installed between two flanges. They are suitable for applications with limited space.

Advantages of Check Valves

Check valves offer several benefits that make them indispensable in many industries:

Prevention of Backflow: By ensuring unidirectional flow, check valves protect pumps, compressors, and other equipment from damage caused by reverse flow.

Minimal Maintenance: Most check valves are designed to operate automatically without the need for external control, reducing maintenance requirements.

Versatility: With various types and materials available, check valves can be used in a wide range of applications, from residential plumbing to industrial processing.

Cost-Effectiveness: Simple design and ease of installation make check valves an economical choice for controlling fluid flow.

Applications of Check Valves

Check valves are used in numerous applications across different industries, including:

Water Supply Systems: To prevent contamination of clean water by backflow from contaminated sources.

Oil and Gas Industry: For maintaining the integrity of pipelines and preventing reverse flow of hazardous materials.

Chemical Processing: To ensure safe and efficient operation by preventing cross-contamination.

HVAC Systems: To maintain the proper flow of refrigerants and air in heating, ventilation, and air conditioning systems.

Pharmaceuticals: For maintaining sterile conditions and preventing contamination.

Installation and Maintenance Tips

Proper installation and maintenance are crucial for the optimal performance of check valves. Here are some tips:

Correct Orientation: Ensure that the valve is installed in the correct direction of flow, as indicated by the arrow on the valve body.

Regular Inspection: Periodically inspect the valve for any signs of wear or damage, especially in high-pressure or corrosive environments.

Cleanliness: Keep the valve and the surrounding piping clean to prevent debris from obstructing the valve operation.

Freture Techno Pvt. Ltd.: Leading Manufacturer of Check Valves in Mumbai, India

Freture Techno Pvt. Ltd. is a leading company that manufactures high-quality check valves in Mumbai, India. With a commitment to innovation and excellence, Freture Techno Pvt. Ltd. offers a wide range of check valves designed to meet the diverse needs of various industries. Their products are known for their durability, reliability, and superior performance, making them a trusted choice for fluid control solutions. Whether you need check valves for industrial, commercial, or residential applications, Freture Techno Pvt. Ltd. provides the expertise and quality you can rely on.

#check valves#types of check valves#check valve applications#check valve manufacturers#freture techno

1 note

·

View note

Text

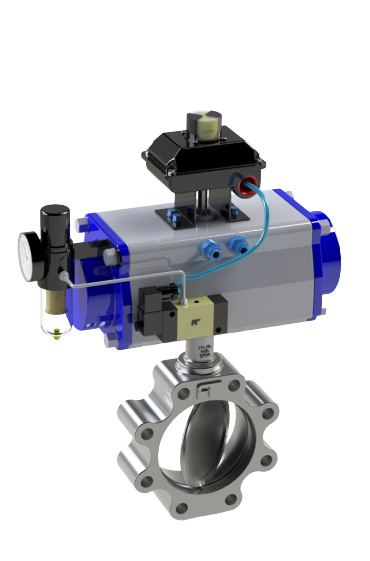

The Benefits of Using a Sanitary Butterfly Valve for Food Production

In the dynamic and meticulously regulated food production industry, maintaining high standards of hygiene, efficiency, and reliability is paramount. A critical component that significantly contributes to these standards is the sanitary butterfly valve. Designed specifically for hygienic applications, these valves offer numerous advantages over traditional valve types. Freture Techno Pvt. Ltd., a leading butterfly valve manufacturer based in Mumbai, India, excels in providing top-quality sanitary butterfly valves tailored to meet the stringent demands of the food industry.

Understanding Sanitary Butterfly Valves

Sanitary butterfly valves are a type of quarter-turn valve, designed with a disk that rotates to allow, regulate, or halt the flow of fluids. The “sanitary” aspect refers to their construction and materials, which ensure they meet the rigorous cleanliness standards required in food production. Typically made from stainless steel, these valves are designed to minimize crevices and cavities where contaminants could accumulate, making them easy to clean and maintain.

Key Benefits of Sanitary Butterfly Valves in Food Production

Hygiene and Cleanability

The primary advantage of sanitary butterfly valves is their superior hygiene. Made from high-grade stainless steel, these valves are resistant to corrosion and are designed with smooth surfaces that prevent the buildup of bacteria, mold, and other contaminants. The absence of internal pockets and crevices ensures thorough cleaning, reducing the risk of contamination in food products. This cleanability is essential for maintaining the safety and quality of food products, complying with food safety regulations, and achieving certifications such as HACCP (Hazard Analysis and Critical Control Points) and ISO 22000.

Ease of Maintenance

Sanitary butterfly valves are known for their simplicity in design, which translates to easier maintenance and lower downtime. The disk and seal design allows for quick disassembly, inspection, and cleaning without the need for specialized tools or extensive training. This ease of maintenance ensures that production lines can be quickly brought back online after routine checks or unexpected issues, maintaining consistent productivity and minimizing operational costs.

Efficient Flow Control

These valves offer precise flow control, essential for processes requiring exact dosing and mixing of ingredients. The ability to finely adjust the flow rate ensures consistent product quality and optimizes the use of raw materials. Sanitary butterfly valves provide a reliable seal in both the open and closed positions, reducing the risk of leaks and ensuring the integrity of the production process.

Durability and Longevity

Constructed from robust materials like stainless steel, sanitary butterfly valves are designed to withstand the demanding conditions of food production, including exposure to various temperatures, pressures, and cleaning agents. This durability translates to a longer lifespan, reducing the frequency of valve replacements and providing a better return on investment over time.

Cost-Effectiveness

Despite their high performance, sanitary butterfly valves are often more cost-effective than other types of valves. Their straightforward design and minimal moving parts mean they are less expensive to manufacture, purchase, and maintain. This cost-efficiency makes them an attractive option for food producers looking to optimize their budget without compromising on quality or performance.

Versatility

Sanitary butterfly valves are highly versatile and can be used in a wide range of applications within the food industry. Whether it's for the production of beverages, dairy products, or processed foods, these valves can handle various types of liquids and semi-liquids. Their adaptability to different production processes makes them an indispensable component in a modern food manufacturing facility.

Applications in Food Production

Sanitary butterfly valves are used across various stages of food production:

Ingredient Handling: Ensuring precise control over the addition of liquids and semi-liquids.

Mixing and Blending: Providing consistent flow rates for uniform mixing.

Pasteurization: Withstanding high temperatures and maintaining sterility.

Bottling and Packaging: Ensuring clean and efficient transfer of products into packaging.

Compliance with Industry Standards

Freture Techno Pvt. Ltd. manufactures sanitary butterfly valves that comply with international standards, including FDA, 3A, and EHEDG. This compliance ensures that their valves meet the highest quality and safety requirements, providing peace of mind to food producers.

Innovation and Customization

Freture Techno Pvt. Ltd. stands out not only for its adherence to quality standards but also for its innovative approach and customization capabilities. Recognizing that each food production facility may have unique requirements, the company offers customized solutions tailored to specific needs. This bespoke approach ensures that their sanitary butterfly valves integrate seamlessly into existing systems, enhancing efficiency and performance.

Sustainable Manufacturing

In addition to their functional benefits, sanitary butterfly valves from Freture Techno Pvt. Ltd. are manufactured with a focus on sustainability. The company employs eco-friendly manufacturing processes and materials, reflecting a commitment to environmental responsibility. By choosing these valves, food producers can align their operational practices with broader sustainability goals, appealing to eco-conscious consumers and stakeholders.

Real-World Success Stories

Numerous food production companies have experienced significant improvements in their operations after integrating sanitary butterfly valves from Freture Techno Pvt. Ltd. These success stories highlight reduced contamination risks, lower maintenance costs, and enhanced product quality. For instance, a dairy processing plant reported a 20% increase in productivity and a notable reduction in product recalls due to improved hygiene and reliability of the valves.

Conclusion

The role of sanitary butterfly valves in food production cannot be overstated. Their benefits, ranging from superior hygiene and ease of maintenance to precise flow control and cost-effectiveness, make them an indispensable component in the industry. Companies like Freture Techno Pvt. Ltd. are at the forefront of manufacturing these essential valves, providing high-quality, reliable solutions that meet the rigorous demands of modern food production.

As the food industry continues to evolve, the importance of maintaining stringent hygiene standards and operational efficiency remains paramount. Sanitary butterfly valves offer a robust solution to these challenges, ensuring that food products are safe, high-quality, and produced efficiently. By investing in these valves, food producers can not only enhance their production processes but also ensure compliance with international standards, ultimately leading to greater consumer trust and satisfaction.

Freture Techno Pvt. Ltd., with its expertise and commitment to quality, stands as a trusted partner for food producers seeking reliable and innovative sanitary butterfly valves. Based in Mumbai, India, the company continues to lead the way in delivering exceptional products that drive the success of food production facilities worldwide.

1 note

·

View note

Text

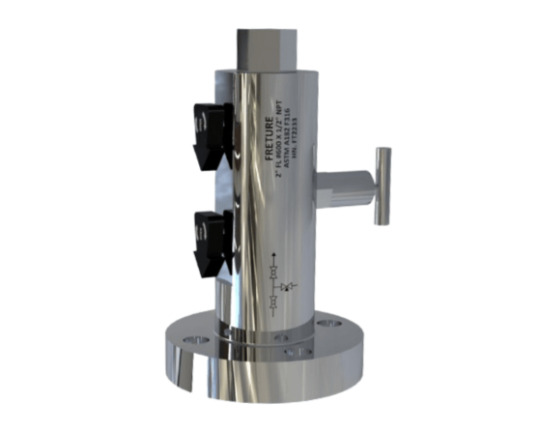

Double Block & Bleed Valves serve multifaceted roles, offering versatility across diverse applications. Whether for general utility or as a pivotal component in fuel service systems, these valves provide paramount control over fluid flow. With their unique design featuring dual isolation and bleed capabilities, they ensure heightened safety and efficiency, surpassing standard instrumentation ball valves. From regulating flow in industrial processes to safeguarding critical systems, Double Block & Bleed Valves from Feature Techno stand as the superior choice, empowering seamless operations and peace of mind.

0 notes

Text

🚭 Today marks No Smoking Day, a time to promote healthier habits and cleaner environments! At Freture Techno, we're proud to contribute to a smoke-free future not just in the air, but also in industrial operations. Our innovative valves ensure efficiency and safety while minimizing emissions, paving the way for a greener tomorrow. Let's breathe easier and work towards a world free of smoke and harmful emissions together!

#nosmokingday#nosmoking#helathylifestyle#emissionfreeprocess#inudstrialvalves#manufacturers#Freture techno#Mumbai#India

0 notes

Text

Celebrating National Science Day: A Tribute to C.V. Raman by Future Techno Pvt. Ltd.

National Science Day, commemorated every year on February 28th, serves as a testament to the remarkable strides humanity has made in the realm of science and technology. It is a day to honor the contributions of visionary scientists whose groundbreaking discoveries have reshaped our understanding of the world. One such luminary is Sir C.V. Raman, whose legacy continues to inspire and propel scientific innovation forward.

At Future Techno Pvt. Ltd., we recognize the invaluable impact of scientific research and discovery on society. On this National Science Day, we pay homage to the unparalleled genius of C.V. Raman and his monumental contributions to the field of physics. Raman's pioneering work, particularly his discovery of the Raman Effect in 1928, has left an indelible mark on scientific inquiry, paving the way for countless advancements in various disciplines.

The Raman Effect, which elucidates the scattering of light by molecules, revolutionized our understanding of light-matter interactions and earned Raman the Nobel Prize in Physics in 1930. His relentless pursuit of knowledge and unwavering commitment to excellence serve as guiding beacons for scientists and researchers worldwide. Raman's legacy transcends generations, inspiring curiosity, innovation, and a thirst for knowledge.

As we commemorate National Science Day, Future Techno Pvt. Ltd. reaffirms its dedication to fostering a culture of scientific inquiry and innovation. We recognize the importance of investing in research and development to address the challenges of today and unlock the possibilities of tomorrow. Through collaboration, curiosity-driven exploration, and a commitment to excellence, we can continue to build upon the foundation laid by pioneers like C.V. Raman.

In conclusion, National Science Day is a time to celebrate the transformative power of science and acknowledge the trailblazers who have shaped the course of human history. At Future Techno Pvt. Ltd., we honor the legacy of C.V. Raman and salute his enduring impact on scientific discovery. As we look to the future, let us draw inspiration from Raman's quest for knowledge and strive to push the boundaries of what is possible through innovation, curiosity, and dedication.

#nationalscienceday#cvraman#freture techno#ballvalves#bellowsealvalve#safetyvalve#butterflyvalve#control valve#instrumentation valve#instrumentation accessories

0 notes

Text

Taming the Beast: Selecting the Right Instrument Valve for High-Pressure Applications

In the complex world of high-pressure applications, the importance of selecting the right instrument valve cannot be overstated. Instrument valves play a crucial role in managing and controlling the flow of fluids in various industrial processes. From oil and gas to chemical and petrochemical industries, the challenges of high-pressure environments demand a careful and informed approach to valve selection. This article explores the key considerations, safety measures, material compatibility, testing procedures, and best practices essential for taming the beast that is high-pressure instrumentation.

Understanding the Challenges:

High-pressure environments bring forth a myriad of challenges, making the selection of instrument valves a critical aspect of any industrial operation. The stakes are high, with safety concerns at the forefront. A failure in valve performance can lead to catastrophic consequences, not only risking equipment integrity but also the safety of personnel. Therefore, it becomes imperative to delve into the specific challenges associated with high-pressure applications to make informed decisions when choosing instrument valves.

Safety Considerations:

Safety should always be the top priority when dealing with high-pressure systems. Selecting instrument valves that comply with industry standards and regulations is non-negotiable. Engineers and technicians must consider factors such as pressure ratings, temperature limitations, and the potential for corrosion or erosion. Additionally, the valve's design and construction must align with the specific demands of the application to ensure robust and reliable performance under extreme conditions.

Material Compatibility:

The compatibility of materials used in instrument valves with the fluids they will handle is a critical aspect often overlooked. Corrosion, erosion, and chemical reactions can compromise the integrity of the valve over time, leading to leaks or failures. Engineers must carefully evaluate the materials of construction, ensuring they can withstand the aggressive nature of high-pressure fluids. Stainless steel, alloy materials, and specialized coatings may be necessary to guarantee longevity and performance in corrosive environments.

Testing Procedures:

Rigorous testing procedures are essential to validate the reliability of instrument valves in high-pressure applications. Pressure testing, leak testing, and endurance testing are vital steps in the selection process. Only by subjecting the valves to conditions that mimic real-world scenarios can engineers ensure their capability to withstand the demands of high-pressure environments. Documentation of testing procedures and results should be meticulously maintained to comply with industry standards and provide a clear record of the valve's performance characteristics.

Best Practices for Long-Term Valve Performance:

To ensure long-term valve performance in high-pressure applications, it is crucial to adhere to best practices. Regular maintenance schedules, monitoring for signs of wear or damage, and implementing preventive measures are essential. Employing advanced technologies such as remote monitoring and diagnostics can enhance predictive maintenance strategies, allowing for proactive interventions before issues escalate.

Taming the beast of high-pressure applications requires a strategic and informed approach to instrument valve selection. By prioritizing safety considerations, addressing material compatibility, conducting rigorous testing, and implementing best practices for long-term performance, industries can navigate the challenges of high-pressure environments with confidence. In doing so, they not only protect their investments but also safeguard the well-being of personnel and the integrity of critical processes.

#instrumentation valve#instrumentation accessories#instrumentation fittings#instrumentation valve manufacturer#freture techno

0 notes

Text

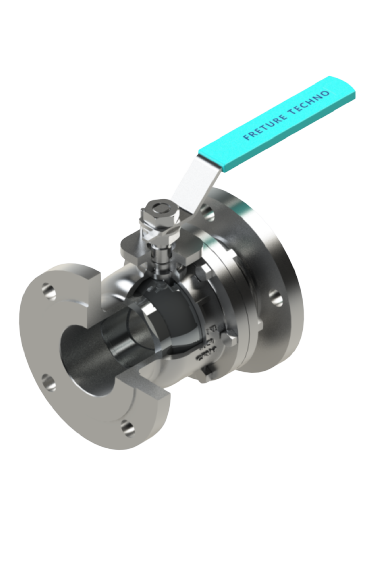

Have you ever wondered about the inner workings of ball valves? This article delves into the concept of ball valves and explores their various construction types.

Introduction to Ball Valves:

Valves are available in a myriad of types and sizes, serving as devices that can be opened or closed to control the flow of liquids or gases. A common household example is the kitchen faucet. In this article, we focus on a specific type – the ball valve.

What is a Ball Valve?

A ball valve is a quarter-turn valve employing a pivoting ball with a drilled-through hole to manage the flow. When aligned with the flow direction, it permits the passage of fluids or gases. Conversely, a 90-degree turn stops the flow completely. The valve's status is indicated by the handle: parallel means open, perpendicular means closed.

Key Features of Ball Valves:

Ball valves are robust and ideal for applications requiring a simple on/off action. They maintain durability and consistent performance over numerous cycles, offering reliability even after prolonged periods of disuse. Flow rate can be controlled by partially opening or closing the valve. Despite their advantages, ball valves lack the fine control for throttling applications that other valves provide.

#3 way ball valves#Ball Valve#Ball Valve advantages#Ball Valve Manufacturer#Ball Valve Selection Guide#Freture Techno

0 notes

Text

Maintaining Ball Valve Shut-Offs: A Guide to Longevity and Peak Performance

Ball valve shut-offs play a crucial role in controlling fluid flow in various industrial and residential applications. To ensure their longevity and optimal performance, regular maintenance is essential. In this guide, we will delve into the key steps and best practices for maintaining ball valve shut-offs, covering everything from routine inspections to proactive measures that can prevent potential issues.

Regular Inspections:

Regular inspections are the cornerstone of effective maintenance for ball valve shut-offs. Performing visual checks at regular intervals helps identify early signs of wear, corrosion, or leaks. Here are some steps to follow during inspections:

Visual Examination:

Inspect the exterior of the ball valve for any signs of corrosion, damage, or leaks.

Check the valve handles or actuators for smooth operation and signs of wear.

Operational Tests:

Open and close the valve to ensure smooth operation.

Listen for any unusual sounds that might indicate internal issues.

Confirm that the valve is sealing properly in the closed position.

Lubrication:

Proper lubrication is vital to the performance and longevity of ball valve shut-offs. Regular lubrication helps minimize friction, reduce wear, and maintain smooth operation. Follow these steps for effective lubrication:

Selecting the Right Lubricant:

Choose a high-quality, compatible lubricant based on the valve's material and application.

Apply lubricant to the stem, bearings, and other moving parts.

Frequency of Lubrication:

Establish a lubrication schedule based on the valve's usage and environmental conditions.

Ensure that lubrication is performed before signs of stiffness or resistance develop.

Troubleshooting Common Issues:

Identifying and addressing common issues promptly can prevent significant problems down the line. Here are some troubleshooting tips:

Leaks:

Inspect seals and gaskets for wear or damage and replace as needed.

Tighten any loose connections contributing to leaks.

Stiff Operation:

Check for debris or corrosion on the ball and seats.

Lubricate the valve as recommended by the manufacturer.

Proactive Measures:

Preventing issues before they arise is key to extending the lifespan of ball valve shut-offs. Consider these proactive measures:

Environmental Considerations:

Shield valves from extreme temperatures or corrosive environments when possible.

Install protective covers or coatings as needed.

Regular Training and Education:

Ensure that personnel responsible for valve operation and maintenance are trained regularly.

Stay informed about industry best practices and advancements in valve technology.

Conclusion:

By incorporating regular inspections, proper lubrication, effective troubleshooting, and proactive measures, you can significantly enhance the lifespan and performance of ball valve shut-offs. Investing time and effort in maintenance not only ensures the reliability of these essential components but also contributes to the overall efficiency and safety of fluid control systems in various applications.

0 notes

Text

In Control: Comparing Manual and Automated Ball Valve Actuation Systems

In the world of fluid control and regulation, ball valves stand out as essential components, facilitating the smooth operation of various industrial processes. What sets them apart is their actuation system, the mechanism responsible for opening and closing the valve. In this article, we delve into the fascinating realm of ball valve actuation, comparing the merits and nuances of manual and automated systems.

Manual Ball Valve Actuation:

Manual ball valve actuation has been the tried-and-true method for decades. It involves a simple, hand-operated lever or wheel that turns the valve stem, controlling the flow of fluids. This traditional approach offers a tactile and direct connection for operators, allowing them to respond quickly to changes in the system. It's cost-effective, straightforward, and reliable, making it a popular choice for applications where simplicity is paramount.

Advantages of Manual Actuation:

Cost-Effectiveness: Manual ball valves are generally more affordable than their automated counterparts, making them an attractive option for budget-conscious projects.

Reliability: With fewer components and less complexity, manual systems often boast higher reliability, requiring minimal maintenance.

Automated Ball Valve Actuation:

As industries evolve, the demand for increased efficiency and precision has given rise to automated ball valve actuation systems. These systems utilize electric, pneumatic, or hydraulic power to control valve movements. Automation introduces a new level of sophistication, allowing for remote operation, precise control, and integration with complex industrial processes.

Advantages of Automated Actuation:

Precision and Control: Automated systems provide precise control over the valve's position, flow rates, and timing, enhancing overall process efficiency.

Remote Operation: With automated systems, valves can be operated remotely, reducing the need for manual intervention in hazardous or hard-to-reach environments.

Integration with Control Systems: Automated ball valves seamlessly integrate with modern control systems, facilitating a more interconnected and responsive industrial setup.

Comparative Analysis:

Response Time: Manual systems offer quick response times, but automation excels in applications where rapid and precise adjustments are critical.

Complexity: While manual systems are simpler, automated systems add complexity. The choice depends on the specific requirements of the application.

Cost vs. Performance: Manual systems are cost-effective and reliable, but automated systems justify their higher cost through enhanced precision, remote operation, and integration capabilities.

Conclusion:

In the dynamic landscape of industrial processes, the choice between manual and automated ball valve actuation systems hinges on the specific needs of each application. Both systems have their merits, offering a spectrum of options for engineers and operators to tailor their choices based on factors such as cost, simplicity, precision, and the level of automation required. As industries continue to advance, the ball valve actuation landscape will undoubtedly see further innovations, providing even more choices for those seeking optimal fluid control solutions.

#ball valve manufacturer#ball valve suppliers#ball valve#manufacturers#freture techno#mumbai#india#valve automation

0 notes

Text

Innovation and Excellence in Fluid Control: A Deep Dive into Ball Valve Manufacturers, with a Spotlight on Freture Techno Pvt. Ltd., Mumbai, India

In the intricate web of industrial processes, one indispensable component is the ball valve. The efficiency of fluid control systems relies heavily on the quality and precision of these valves. This article delves into the world of ball valve manufacturers, focusing on the prowess of Freture Techno Pvt. Ltd., a Mumbai-based company that has etched its name as a beacon of innovation and excellence.

Understanding the Role of Ball Valves: Ball valves, with their simple yet effective design, play a pivotal role in regulating the flow of liquids or gases in various industries. From petrochemical plants to water treatment facilities, their versatility makes them indispensable. Choosing the right ball valve manufacturer is critical to ensuring the reliability and efficiency of these valves in diverse applications.

Key Considerations in Selecting a Ball Valve Manufacturer:

Quality Assurance:

The backbone of any reputable manufacturer lies in its commitment to quality. Freture Techno stands out in this regard, adhering to stringent quality control measures. Each ball valve undergoes rigorous testing to meet or exceed international standards, ensuring longevity and optimal performance.

Product Range and Versatility:

A manufacturer's ability to cater to diverse industries speaks volumes about its expertise. Freture Techno boasts a comprehensive product range, including ball valves tailored for specific applications. Whether in oil and gas, power generation, or chemical processing, their valves are designed to meet the unique demands of each sector.

State-of-the-Art Manufacturing Facilities:

The manufacturing process is the heart of quality production. Freture Techno's facility in Mumbai is equipped with cutting-edge technology, enabling precision engineering and innovation. The use of advanced machinery ensures that each ball valve meets the highest standards of craftsmanship.

Experience and Expertise:

With experience comes expertise, and Freture Techno's seasoned team brings both to the table. Years of navigating the complexities of fluid control have honed their skills, allowing them to deliver ball valves that align seamlessly with industry requirements.

Customization Options:

Industries are diverse, and so are their needs. Freture Techno understands the importance of providing tailored solutions. Their commitment to customization allows clients to specify requirements, ensuring that the ball valves integrate seamlessly into their unique processes.

Freture Techno Pvt. Ltd.: A Closer Look:

Precision and Quality Assurance:

Freture Techno's commitment to precision engineering ensures that each ball valve is a testament to quality. The company's adherence to international standards and meticulous testing processes guarantee products that withstand the test of time.

Extensive Product Range:

Freture Techno's product portfolio spans a wide spectrum, encompassing ball valves for various applications. From standard models to specialized valves designed for extreme conditions, their range caters to the diverse needs of industries worldwide.

Cutting-Edge Manufacturing Facility:

Nestled in the heart of Mumbai, Freture Techno's manufacturing facility is a hub of innovation. State-of-the-art machinery and a commitment to staying abreast of technological advancements position the company as a pioneer in the field.

Experienced and Skilled Team:

The success of Freture Techno is a result of its people. A team of skilled professionals, with years of industry experience, collaborates to bring forth ball valves that meet and exceed client expectations. Their collective expertise ensures that each valve is a testament to quality and reliability.

Customer-Centric Approach:

Freture Techno places customer satisfaction at the forefront. The company's commitment to understanding client needs and providing tailored solutions has earned them accolades. Positive testimonials from satisfied clients underscore their dedication to building lasting partnerships.

Conclusion: In the intricate dance of fluid control within industries, the role of ball valves is paramount. Selecting a manufacturer that combines quality, versatility, and innovation is pivotal to the success of any project. Freture Techno Pvt. Ltd., based in Mumbai, India, emerges as a frontrunner in this realm. Their unwavering commitment to precision engineering, extensive product range, cutting-edge manufacturing facilities, experienced team, and customer-centric approach position them as a reliable partner for industries seeking excellence in fluid control. As we navigate the complex landscape of industrial processes, Freture Techno stands as a testament to the marriage of innovation and reliability in the world of ball valve manufacturing.

#ball valve#ball valves#ball valves manufacturers#ball valve suppliers#ball valve exporters#freture techno

0 notes

Text

Embracing New Horizons: Freture Techno Pvt. Ltd Rings in 2024

As the calendar turns a new leaf and the world ushers in the promise of a fresh year, Freture Techno Pvt. Ltd stands poised at the threshold of 2024, brimming with excitement, gratitude, and an unwavering spirit of innovation.

The passing year has been a testament to resilience, unity, and the collective strength of our Freture family. Together, we've weathered storms, celebrated victories, and navigated challenges with an unwavering determination that defines us.

In the spirit of reflection, we cherish the milestones achieved and the lessons learned in 2023. Our journey has been marked by adaptability and growth, seizing opportunities amidst adversity and evolving to meet the dynamic demands of our industry.

As we extend our gratitude to every individual whose dedication has contributed to our success, we look ahead with a sense of purpose and ambition. Our vision for 2024 is guided by a commitment to continuous innovation and a drive to set new benchmarks in the realms of technology and business.

The heart of Freture Techno beats with a passion for excellence, collaboration, and the relentless pursuit of advancement. Our goals for the upcoming year are bold, rooted in our core values, and aimed at shaping a future that embraces transformation and creativity.

Our team, the heartbeat of our organization, embodies the ethos of Freture Techno. Your ingenuity, expertise, and unwavering dedication have been instrumental in our journey so far. As we embark on this new chapter, your commitment will continue to fuel our progress and inspire innovation.

To our esteemed partners and clients: your trust and collaboration have been the cornerstone of our achievements. We value the relationships we've cultivated and the opportunities to co-create solutions that redefine industry standards. In 2024, we remain steadfast in our commitment to delivering excellence and value.

Beyond our business pursuits, we recognize our responsibility to society. In the coming year, we reaffirm our dedication to corporate social responsibility, seeking meaningful ways to contribute positively to the communities we serve.

In unity and determination, let us embrace the canvas of 2024, painting it with the colors of resilience, creativity, and inclusivity. Together, let us scale new heights, celebrate milestones, and champion innovation that leaves a lasting impact.

To all who have been part of our journey—employees, partners, clients, and supporters—thank you for your unwavering support. Happy New Year 2024! May it be a year filled with boundless opportunities, growth, and shared success for Freture Techno Pvt. Ltd and everyone connected to us.

0 notes

Text

How does a ball valve work?

A ball valve, a fundamental component in fluid control systems, operates through a simple yet effective mechanism. Freture Techno, a reputable brand in valve manufacturing, also specializes in crafting these essential devices.

Functionality of Ball Valves

Design: A ball valve consists of a spherical closure unit, the "ball," with a hollow center. This ball contains a port or bore that aligns with the fluid flow path when open, and perpendicular to it when closed.

Operation: When the handle or actuator is turned, the ball inside the valve rotates, either allowing fluid to flow through the bore or blocking its path entirely.

Sealing: The mechanism employs a sealing element, often made of PTFE or other durable materials, which ensures a tight seal when the valve is closed, preventing leakage.

Freture Techno's Contribution

Freture Techno, known for precision engineering, incorporates advanced technology and quality materials into their ball valve designs. Their valves exhibit a seamless operation, ensuring efficient on/off control and reliable sealing to meet diverse industrial needs.

Advantages of Ball Valves by Freture Techno

Robust Construction: Freture Techno's ball valves are built with durability in mind, capable of withstanding harsh operating conditions.

Precision Engineering: Their valves offer smooth operation and precise control, ensuring optimal flow regulation.

Customization Options: The brand provides tailored solutions to suit specific industry requirements, ensuring compatibility and reliability in various applications.

Conclusion

Ball valves, including those crafted by Freture Techno, function through a straightforward yet efficient design. With a spherical closure unit that controls fluid flow, these valves ensure reliable on/off operation and play a critical role in various industrial applications. Freture Techno's commitment to quality and precision engineering further solidifies the reputation of their ball valves as reliable, durable, and adaptable components within fluid control systems.

0 notes

Text

Understanding Ball Valves and Water Pressure

Ball valves are fundamental components in plumbing systems, often used to regulate water flow. While they're primarily known for their on/off functionality, their impact on water pressure is a subject of interest.

Understanding Ball Valves and Water Pressure

1. Functionality: Ball valves work by using a spherical disc (the "ball") to control the flow of fluids. When fully open, they allow unrestricted flow; when closed, they stop the flow entirely.

2. Influence on Pressure: In theory, ball valves, when fully open, shouldn't reduce water pressure. They create minimal obstruction in the water flow path, allowing for efficient transfer of water without significant pressure drop.

3. Consideration for Pressure Reduction: Partially closing a ball valve might restrict water flow, potentially leading to reduced pressure downstream. This reduction occurs because the valve creates resistance as the flow area decreases.

4. Limitations in Pressure Regulation: Unlike some specialized valves designed for pressure regulation, standard ball valves are not primarily intended for pressure adjustment. They're more suitable for on/off control or full flow situations.

Factors Affecting Water Pressure in Plumbing Systems

1. System Design: The plumbing system's design, including the type and size of pipes, can affect water pressure. Properly sized pipes help maintain consistent pressure.

2. Valves and Fixtures: The number of valves, fixtures, and the type of valves used can influence pressure. Each component introduces some resistance to the flow.

3. Water Source and Elevation: The water source's pressure, elevation differences, and distance from the source can impact pressure levels throughout the system.

Conclusion

Ball valves, when fully open, typically do not significantly reduce water pressure as they allow for efficient flow. However, their impact on pressure can be noticeable if partially closed, introducing resistance and potentially reducing pressure downstream.

Understanding the role of ball valves in plumbing systems helps users make informed decisions about their application. While they're essential for controlling water flow, especially for shutting off or allowing full flow, for precise pressure regulation, considering specialized pressure-regulating valves might be more appropriate within plumbing systems.

0 notes

Text

The Ultimate Guide to Understanding Floating Ball Valves: A Comprehensive Overview

Floating ball valves are pivotal components in fluid control systems, playing a crucial role in regulating the flow of liquids in various industries. In this comprehensive guide, we will delve into the intricacies of floating ball valves, exploring their design, functionality, applications, and the advantages they offer in fluid handling systems.

Section 1: The Basics of Floating Ball Valves

To comprehend floating ball valves, it's essential to start with the basics. We'll explore the fundamental design principles that distinguish floating ball valves from other valve types. From the freely moving ball to the sealing mechanism, readers will gain a solid understanding of the internal workings of these valves.

Section 2: Advantages of Floating Ball Valves

Why choose floating ball valves over other valve types? This section will highlight the distinctive advantages, including low torque requirements, bidirectional sealing, and suitability for a wide range of pressures and temperatures. Real-world examples and case studies will illustrate the practical benefits in different industrial applications.

Section 3: Applications in Various Industries

Floating ball valves find applications in diverse industries, from oil and gas to chemical processing. We'll explore specific use cases, detailing how these valves contribute to efficient fluid control in different settings. Whether it's managing corrosive substances or handling high-pressure environments, floating ball valves prove their versatility.

Section 4: Comparing Floating Ball Valves with Trunnion-Mounted Ball Valves

Readers often encounter the dilemma of choosing between floating and trunnion-mounted ball valves. This section will provide a side-by-side comparison, outlining the distinct features and suitability of each type. By the end, readers will have a clear understanding of when to opt for floating ball valves and when trunnion-mounted valves may be more appropriate.

Section 5: Maintenance Best Practices

Ensuring the longevity and optimal performance of floating ball valves requires proper maintenance. We'll offer practical tips and guidelines, covering routine inspections, lubrication, and troubleshooting common issues. A well-maintained valve contributes to the reliability of the entire fluid control system.

Conclusion:

As we conclude this ultimate guide, readers will have gained a comprehensive understanding of floating ball valves. From their internal mechanisms to real-world applications, the versatility and advantages of these valves make them indispensable in various industries. Whether you're a seasoned engineer or someone new to fluid control systems, this guide equips you with the knowledge to navigate the world of floating ball valves with confidence.

#ball valve manufacturer#floating ball valves#ss floating ball valves#floating control ball valves#freture techno#india

0 notes