Don't wanna be here? Send us removal request.

Photo

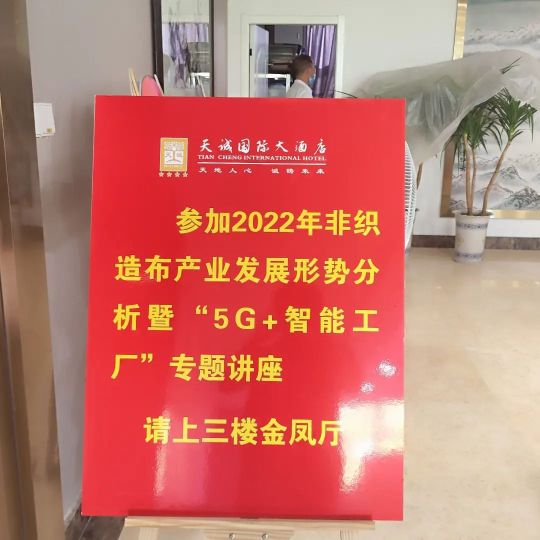

上海让雷智能科技参加“2022年非织造布产业发展形式分析暨‘ 5G+智能工厂 ’专题讲座” 上海让雷的智能工厂用工业物联网、大数据等前沿技术,同时建立通过生产、设备、能源、物流、人力等资源要素汇聚的大数据中心作为支持,已与国内多家大型无纺企业合作,帮助企业建立起绿色、安全、高效的智能工厂。 https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer(在 The Bund,shanghai) https://www.instagram.com/p/ChtWokkvWzH/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes

Photo

Digitization, visualization and transparency are important characteristics of intelligent factory. Data is the most important resource of intelligent factory and the basic ability to realize "intelligence". CFM, therefore, in the process of intelligent factory logistics planning, committed to the implementation of the end-to-end process data collection, analysis and presentation, make whole factory logistics operational process and visual order delivery process, and support enterprises to stock, efficiency, quality, cost, delivery process, risk and differences of the transparent management. https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer(在 The Bund,shanghai) https://www.instagram.com/p/CgyY0OdOBHP/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes

Photo

Traditional factories tend to focus on the linkage between production facilities, while intelligent factory logistics planning should emphasize the linkage of the whole system resources. CFM integrates these resources and subjects into the industrial Internet through the intelligent factory information platform, enabling networking communication between various resources and subjects and the interconnection of all elements of the intelligent factory. Only in this way can the basic conditions of self-perception, self-decision, self-adjustment and self-learning of the intelligent factory be achieved. https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer(在 The Bund,shanghai) https://www.instagram.com/p/Cgv19bwuudC/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes

Photo

Along with the upgrading process of manufacturing plant, its logistics planning should follow the iterative upgrading process of lean, digital and intelligent logistics paradigm. For CFM smart factory, not all links, materials, workshops, production lines or work stations are necessarily intelligent in logistics. Based on the necessity, flexibility and economy of intelligent logistics, the coexistence of three logistics paradigms is often reflected in the same smart factory. https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer(在 The Bund,shanghai) https://www.instagram.com/p/Cgl7VG8OuJX/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes

Photo

A factory with only automated production lines and industrial robots cannot be called an intelligent factory. CFM's smart factory not only achieves automation, transparency, visualization and lean production process, but also achieves closed-loop integration with production process in product inspection, quality inspection and analysis, production logistics and other links. Information sharing, on-time delivery and collaborative work can also be achieved between multiple workshops in a factory. https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer(在 The Bund,shanghai) https://www.instagram.com/p/Cglf1XHuOcY/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes

Photo

The 3rd China International Textile Raw Materials Expo in 2022 was successfully held. The China Textile Industry Internet Conference, the International Cotton and Cotton Yarn Forum, and the International New Fiber and Product Conference were held simultaneously. CFM won the 2022 Top Ten Most Popular Textile and Apparel Industry Internet Platform Award Xiongguan Mandao is like iron, and now it is starting from scratch. In 2022, textile people have endured the double torment of the epidemic and the geopolitical crisis. We are still full of confidence and hope in the future. Resolute and persistent textile people, let us work together to win the future! https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer(在 The Bund,shanghai) https://www.instagram.com/p/CgeKxryOkjA/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes

Photo

According to the experience of CFM smart factory service, the overall status assessment is the first step of smart factory planning, which should be as objective and real as possible. At the same time, the following points should be paid attention to in the assessment: summarize experience and problems; Identify the current state (prepare for the next step); The gap between benchmarking and benchmarking; Identify the direction of critical digital systems (obsolescence, retention or upgrading, etc.); Reach an agreement with business on the status quo. https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer(在 The Bund,shanghai) https://www.instagram.com/p/Cgd490JPivJ/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes

Photo

According to the experience of CFM smart factory service, the overall status assessment is the first step of smart factory planning, which should be as objective and real as possible. At the same time, the following points should be paid attention to in the assessment: summarize experience and problems; Identify the current state (prepare for the next step); The gap between benchmarking and benchmarking; Identify the direction of critical digital systems (obsolescence, retention or upgrading, etc.); Reach an agreement with business on the status quo. https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer (at The Bund,shanghai) https://www.instagram.com/p/CfdvzHCvzM7/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes

Photo

Driven by the boom of emerging technologies such as "new infrastructure, industrial Internet, artificial intelligence and big data", manufacturing enterprises in all industries are actively exploring the application of intelligent manufacturing and the construction of intelligent factories. In blessing cloth cloud business intelligence factory, with the aid of various production management tools, software, system and intelligent equipment, through the enterprise from the design, production, sales and maintenance of each link, to realize automatic simulation design, production scheduling, production process monitoring, information transmission, quality on-line monitoring, automatic material distribution of intelligent manufacturing. https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer https://www.instagram.com/p/CfYllWpvA6G/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes

Photo

With the improvement of information technology and the reduction of the cost of intelligent terminals, intelligent factory planning can popularize information terminals to every station, and operators can receive work instructions and production data at the terminals. CFM's intelligent factory can build a centralized production monitoring and command system, which presents key equipment status, production status, quality data, as well as various real-time analysis charts. Through kanban intuitive display, it can provide various types of content presentation to assist decision-making. https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer (at 魔都上海) https://www.instagram.com/p/CfWBJCkvMP_/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes

Photo

Data is the blood of smart factory construction and flows between application systems. CFM's smart factory is based on the big platform of the Internet to realize the interconnection of enterprise production information and collect data generated by people and machines to the cloud platform for analysis and processing. The physical system of information is composed of APP platform, intelligent factory, PLM, ERP and QMS based on semantics. In actual production, the client APP can check the turnover of materials and the whole process of production to realize information sharing. Customers do not need to consider the security of production data. All information, from material input to machine production and product output, is operated on the cloud platform to realize the authenticity and reliability of production data. https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer(在 The Bund,shanghai) https://www.instagram.com/p/CfThYKRPSE1/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes

Photo

Intelligent production line is the core of intelligent factory planning. Enterprises need to use value stream map and other methods to reasonably plan intelligent production line according to the product family, capacity and production tempo to be produced by the production line. The intelligent factory service provided by CFM in the design of intelligent production line, considering how to save space, how to reduce the movement of personnel, how to carry out automatic detection, so as to improve production efficiency and production quality, to help enterprises eventually achieve the goal of reducing costs, ensuring income, creating income and increasing income. https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer(在 The Bund,shanghai) https://www.instagram.com/p/CfJQh4hvIOZ/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes

Photo

Intelligent factory is the use of various kinds of up-to-date technology, factory production management and office automation, intelligent factory of CFM non-woven enterprise networked production equipment was achieved, and transparency of the process, data visualization, the unmanned, paperless production document, to strengthen and standardize enterprise management, improve the work efficiency and provide decision-making reference for safety production, The purpose of strengthening external contacts and broadening the international market. https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer(在 The Bund,shanghai) https://www.instagram.com/p/CfGnlDwv_eM/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes

Photo

CFM's smart factory is an "intelligent awareness" system based on the Internet and big data, which realizes the workshop data, mobile, real-time and visual management, and truly realizes the integrated smart factory management and control system. The industry-leading information control system is adopted to realize automatic collection of production data and automatic transmission of data between data acquisition and analysis system and manufacturing execution system. https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer(在 The Bund,shanghai) https://www.instagram.com/p/CfGRPlaP-g4/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes

Photo

CFM's intelligent factory provides professional services throughout the whole process for textile enterprises in each stage of project construction, system application and value creation, ensuring that information system solutions can take root in enterprise management and create value for enterprises. Professional services include requirements analysis, scheme design, modeling analysis, system development, operation verification, skills training, knowledge transfer, etc., with professional expert teams, professional industry knowledge base and standardized templates. https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer(在 The Bund,shanghai) https://www.instagram.com/p/CfEBbJoOP3A/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes

Photo

The intelligent transformation of CFM has run through the whole production process from raw silk processing, weaving to dyeing and finishing, bringing significant benefits. Through the central control room, managers have first-hand access to data and information. Be able to adjust personnel and equipment quickly and efficiently according to the data, especially when the process needs adjustment. Realize real-time and complete integration of supply chain, production, market, human resources and financial control. https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer(在 上海浦東陸家嘴) https://www.instagram.com/p/Ce5wxPlOB5_/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes

Photo

The overall objectives of CFM smart Factory construction are: Adopt mature digital, network and intelligent technologies, take key measures such as optimal control of key devices, integrated control of planning and dispatching operations, energy optimization and emission reduction, hierarchical control of security risks and dynamic evaluation of production performance, and strive to improve the perception and prediction ability of production control. Finally help non-textile enterprises to achieve efficient, green, safe and optimal management goals. https://www.chinafibermarketing.com/ #Smartfactory#Intelligentmanufacturing#Digitaltransformation#Nonwovenfabric#Nonwovenfabricmanufacturer(在 The Bund,shanghai) https://www.instagram.com/p/Ce5ejqjuZBb/?igshid=NGJjMDIxMWI=

#smartfactory#intelligentmanufacturing#digitaltransformation#nonwovenfabric#nonwovenfabricmanufacturer

0 notes