#smartfactory

Explore tagged Tumblr posts

Text

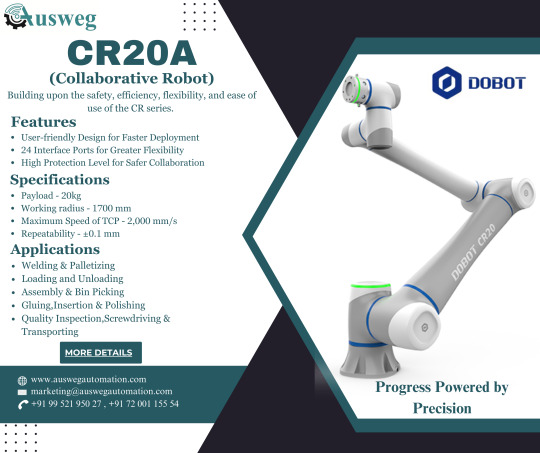

DOBOT CR20A Performance Unleashed With High Payload and Wide Radius

www.auswegautomation.com [email protected] +91 99 521 950 27, +91 72 001 155 54

#cobots#collabrativerobots#automation#industry40#robotics#manufacturing#ai#roboticstechno#digitaltransformation#innovation#techtrends#futureofwork#smartfactory#industrialautomation#productivity#workplacesafety#efficiency#humanrobotcollabration#roboticsindustry#advancedmanufacturing

2 notes

·

View notes

Text

Manufacturing Sector Trends & Innovations - BizzBuzz

Discover the latest in manufacturing including Industry 4.0 technologies, supply chain optimization, and global production trends. Our coverage spans automotive, electronics, pharmaceuticals, and consumer goods manufacturing. Learn about smart factories, sustainable production methods, and workforce development strategies. Essential reading for manufacturing executives, operations managers, and investors tracking the transformation of global production networks in the digital age.

0 notes

Text

Our latest infographic highlights how digital Permit to Work solutions can help reduce incidents and ensure safer operations. How does your organization currently handle high-risk work permits?

https://www.softdesigners.co.in/work-permit-system/

#workplacesafety#smartfactory#ehs#permit to work software#permit to work#permit to work system#ptw#ai in ehs#ehs management software

0 notes

Text

PROLIM at Hannover Messe 2025! We’re excited to announce that Prabhu Patil (Founder & CEO) and Srinath Koppa (Managing Director, India) will be representing PROLIM at Hannover Messe 2025! Meet us as we showcase PROMIS™ Digital Manufacturing, a game-changer in AI, IoT, and automation for the future of smart factories. 📍 Hannover, Germany 📅March 31 – April 4, 2025 Don’t miss out on this innovation-packed event! 🔗 Read More : https://lnkd.in/gMTR2W48

0 notes

Text

Pinakastra Computing Private Limited

Founded in 2021 in Bangalore, Karnataka, India, Pinakastra Computing specializes in Private cloud infrastructure and hyperconverged infrastructure (HCI), offering innovative cloud solutions for enterprises, academia, and research organizations. Our Pinaka ZTi™ cloud platform integrates advanced hardware and software to deliver scalable, efficient, and secure private cloud solutions. Pinakastra aims to fill the gap in India’s enterprise tech ecosystem by offering alternatives to global cloud providers. We focus on addressing the growing demand for VM & Container based AI/ML workloads with modular, cost-efficient, and scalable solutions, aspiring to become a global leader in cloud infrastructure.

https://pinakastra.com/

#PrivateCloud#CloudComputing#IoT#DataSecurity#HyperConvergedInfrastructure#HCI#SecureData#HealthcareIT#FinTech#EdTech#biotech#GovernmentIT#ManufacturingTech#RetailSolutions#smartfactory

1 note

·

View note

Text

The Evolution of Lean Manufacturing in the Digital Era

Lean Manufacturing is built on the foundation of continuous improvement, focusing on efficiency, waste reduction, and value creation. Over the years, its principles have evolved significantly, especially with the rise of Industry 4.0. The introduction of digital technologies has reshaped Lean methodologies, enabling manufacturers to make smarter, data-driven decisions.

Let’s explore how modern advancements like automation, real-time data, and AI have transformed Lean Manufacturing.

1. The Shift to Digital-Driven Lean Manufacturing Traditional Lean Manufacturing focused on streamlining workflows, reducing waste, and optimizing production. However, the rise of Industry 4.0 has introduced powerful tools like the Industrial Internet of Things (IIoT), Artificial Intelligence (AI), and data analytics, which allow manufacturers to move beyond conventional methods.

These technologies provide real-time insights, helping businesses make more precise decisions and continuously improve their operations. With real-time machine communication and AI-driven analysis, manufacturers can achieve levels of efficiency that were previously unattainable.

A key factor in this transformation is the ability to reduce changeover time, ensuring production lines switch between tasks seamlessly without unnecessary downtime.

Key Advancements: • Real-time data collection through IIoT and smart sensors. • AI-driven decision-making to improve accuracy and efficiency. • Optimized workflows that help reduce changeover time and increase uptime.

2. Automation and Smart Factories in Lean Manufacturing Automation is at the core of modern Lean Manufacturing. By integrating machine connectivity, predictive maintenance, and AI-powered optimization, smart factories can now self-adjust production speeds, minimize downtime, and reduce human error.

One of the most impactful benefits of automation is its ability to reduce changeover time between production runs. By automating setup processes and leveraging data-driven scheduling, manufacturers can ensure smoother transitions with minimal disruption.

Key Advancements: • Machines now communicate in real-time to optimize production. • Automated systems help reduce changeover time, eliminate errors, and improve efficiency.

3. Enhancing Efficiency with MOM Systems Manufacturing Operations Management (MOM) systems play a critical role in modern Lean environments. These systems connect every aspect of production, from scheduling and inventory tracking to quality control. With real-time visibility across operations, manufacturers can ensure smooth workflows and prevent bottlenecks.

By integrating MOM systems, manufacturers gain greater control, efficiency, and responsiveness—key factors in today’s fast-paced production environments. Additionally, MOM systems help reduce changeover time by optimizing production schedules and ensuring that materials and resources are available when needed.

Key Advancements: • Improved real-time visibility and control across production lines. • Seamless integration of scheduling, quality control, and workflow management. • Data-driven scheduling to reduce changeover time and enhance productivity.

4. The Role of OEE & Takt Time in Lean Optimization

Optimizing Overall Equipment Effectiveness (OEE) and Takt Time has become a priority for manufacturers looking to streamline production. With real-time monitoring and advanced analytics, factories can quickly identify inefficiencies and adjust their production schedules accordingly.

A major contributor to low OEE is excessive downtime during product switches. By focusing on strategies to reduce changeover time, manufacturers can improve machine utilization, increase throughput, and maintain consistent production flow.

Key Advancements: • AI and data-driven insights help optimize OEE and reduce waste. • Takt Time adjustments ensure a balanced production flow. • Faster setup and transition processes help reduce changeover time and minimize disruptions.

Final Thoughts

Lean Manufacturing is no longer just about eliminating waste—it’s about leveraging technology to drive smarter, more efficient production. The integration of automation, AI, IIoT, and MOM systems is revolutionizing the way manufacturers approach continuous improvement.

By focusing on strategies to reduce changeover time, manufacturers can enhance productivity, improve quality, and stay ahead in an increasingly competitive industry.

0 notes

Text

Top Smart Factory IoT Solution Vendors | Sterison Technology

Optimize your manufacturing process with Smart Factory IoT solutions vendors from Sterison Technology. As a leading IoT solution vendor in India, we offer cutting-edge industrial automation, real-time data monitoring, and AI-driven analytics to enhance productivity. Our smart factory solutions integrate IoT sensors, machine learning, and cloud computing for seamless automation and predictive maintenance. Upgrade your factory with Industry 4.0 technologies and drive operational excellence. Visit Sterison Technology to explore the best IoT solutions for smart factories.

0 notes

Text

Igus Articulated Robot | High-Performance Automation Solutions

Articulated Robots are revolutionizing automation with precision and flexibility. Igus, a pioneer in motion plastics, offers lightweight, cost-effective solutions perfect for industries like manufacturing, automotive, and packaging. Igus Articulated Robots are corrosion-resistant and energy-efficient, ensuring optimal performance. With easy integration and minimal maintenance, they are ideal for advanced automation needs. Learn how Igus combines innovation and practicality to redefine robotics for businesses worldwide.

#Igus#ArticulatedRobot#Automation#Robotics#IndustrialSolutions#FlexibleManufacturing#SmartFactory#Innovation

0 notes

Text

Explore how Blockchain and IoT together are game-changers for Industry 4.0 and how businesses can leverage this powerful combination to create a smarter, more connected future.

0 notes

Text

Smart Factory ( ThirdEye AI)

Contact for more- https://third-eye.ai

0 notes

Text

Top 5 Use Cases of IoT in Manufacturing

The introduction of IoT in the electronic manufacturing sector aims to further transform the sector's operating and managing practices by reevaluating the basic working process. Moreover, utilizing IoT in this sector will assist in overcoming the obstacles that the pandemic has brought about. IoT technology has changed how manufacturers interact with their customers, allowing them to quickly respond to customer needs and demands."- ResearchGate

According to a report by McKinsey & Company , IoT applications in manufacturing have the potential to create an economic impact of $1.2 to $3.7 trillion per year by 2025.

Read this blog on how impact of IoT in manufacturing extends far beyond the factory floor, reaching into every aspect of the value chain: https://nextgeninvent.com/.../iot-in-manufacturing.../

Bosch is developing smart factories utilizing IoT in manufacturing. Sensors in these facilities collect data on all parts of the manufacturing procedure, which includes everything from the chain of distribution to the assembly line.

NextGen Invent Corporation help you to make smart factories by utilizing IoT in manufacturing if you are looking for AI Based Software Development Services Company: https://nextgeninvent.com/ai-development-services

0 notes

Text

Discover the Future of Workplace Safety with Our EHS Software!

Watch our video to see how our advanced EHS software streamlines compliance, and enhances operational efficiency.

youtube

#EHSSoftware#WorkplaceSafety#Compliance#SafetyManagement#Innovation#OperationalExcellence#safetyfirst#artificialintelligence#smartfactory#digitaltransformation#ehs#Youtube

0 notes

Text

Transform Your Factory with AI: Boost Productivity and Efficiency!

Step into the future of manufacturing with AI-powered solutions from Applied Smart Factory. Our AI in smart factory technology is revolutionizing the industry, empowering businesses to enhance productivity and efficiency like never before.

With our AI productivity solutions, you can optimize every aspect of your manufacturing process, from production scheduling to quality control. Harness the power of artificial intelligence to predict maintenance needs, prevent downtime, and streamline operations for maximum efficiency.

Say goodbye to guesswork and hello to data-driven decision-making with our AI manufacturing solutions. By leveraging advanced analytics and machine learning algorithms, you'll gain valuable insights that drive continuous improvement and innovation.

Don't let your competitors outpace you—embrace the future of manufacturing with Applied Smart Factory's AI solutions. Transform your factory into a well-oiled machine that operates at peak performance, delivering high-quality products on time, every time. Unlock the full potential of your operations with AI today!

1 note

·

View note

Text

Elevate industrial automation with #PLC and #SCADA solutions! 🏭✨ Discover how our cutting-edge technologies enhance efficiency and control in manufacturing processes.

Reach Us: 8807148869

PLC SCADA

#PLC#SCADA#AutomationTech#ControlSystems#PLCProgramming#IndustrialAutomation#SCADASystems#SmartFactory#Industry40#ProcessControl#PLCSCADA#AutomationEngineer#IoTinIndustry#SmartManufacturing#FactoryAutomation#PLCTechnology#DigitalTransformation#SCADAControl#AutomationSolutions#TechInnovation

0 notes

Text

Industrial Control and Factory Automation Market Size 2024 Research Report by Global Growth Rate, Development Strategy, Recent Trends, and Regional Demand till 2030

The qualitative report published by Exactitude Consultancy research on the “Industrial Control and Factory Automation Market offers an in-depth examination of the current trends, latest expansions, conditions, market size, various drivers, limitations, and key players along with their profile details. The Industrial Control and Factory Automation market report offers the historical data for 2018 to 2023 and also makes available the forecast data from the year 2024 to 2030 which is based on revenue. With the help of all this information research report helps the Market contributors to expand their market positions. With the benefit of all these explanations, this market research report recommends a business strategy for present market participants to strengthen their role in the market. This report analyzes the impact of the Covid 19 pandemic on the Industrial Control and Factory Automation Market from a Global and Regional perspective.

The Industrial Control and Factory Automation Market Is Expected to Grow At 10.5% CAGR From 2022 To 2029. It Is Expected to Reach Above USD 297.51 Billion By 2029 From USD 129.1 Billion In 2023.

For The Full Report Click here:

https://exactitudeconsultancy.com/reports/24982/industrial-control-and-factory-automation-market/

#FactoryAutomation#ManufacturingAutomation#IndustrialAutomation#AutomationTechnology#ControlSystems#ProcessAutomation#SmartManufacturing#IndustrialIoT#Industry40#SmartFactory#DigitalFactory#AutomatedManufacturing#PLC#SCADA#RoboticsAutomation#IoTinManufacturing#ProductionControl#MachineAutomation#FactoryFloor

0 notes