Don't wanna be here? Send us removal request.

Text

IEC 60335-2-14: Safety Requirements for Kitchen Appliances

Kitchen appliances play a vital role in everyday life. Ensuring the safety of kitchen appliances is essential to protect users and maintain trust in brands and products. IEC 60335—2-14 is the international safety standard of electrical appliances for kitchen appliances, which provides general testing requirements, markings, classifications, and instructions for kitchen machines such as auger…

0 notes

Text

Softgoods Quality Control: 9 Major Inspection Criteria You Should Know

What are soft goods? What are the key inspection criteria for soft goods? Soft goods are mostly consumer goods such as clothing, textile, shoes, bags, and fashion accessories. In this blog, we explore the key inspection criteria for softgoods, including materials, workmanship, colors, style, accessories, weight, measurements, labeling and hangtags, assortment, markings. Each criterion of the…

0 notes

Text

Footwear Quality Inspection: Checklists and Defects

Footwear manufacturing always uses a wide range of materials and requires several different production processes which makes footwear quality control a highly demanding and specialized process. Whether you’re manufacturing athletic shoes, dress shoes, sandals, boots, safety shoes, and children’s shoes, footwear inspection is essential that can ensure your suppliers are meeting your quality and…

0 notes

Text

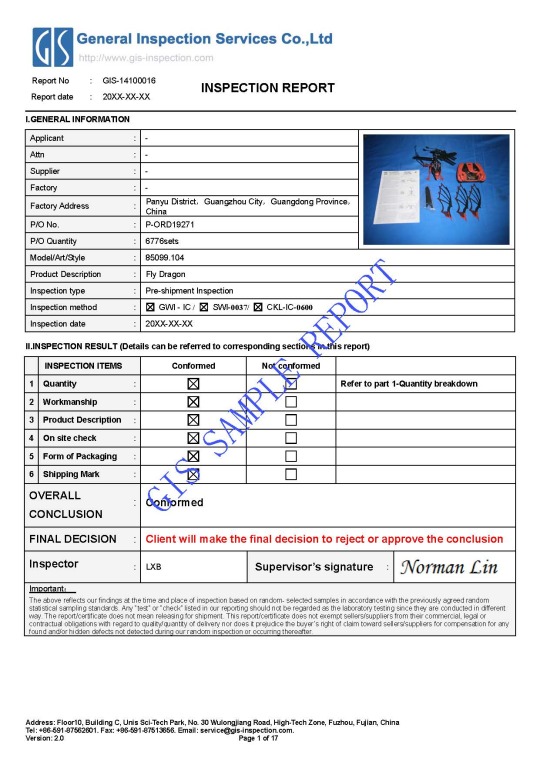

Pre-Shipment Inspection (PSI): Everything You Need to Know

The pre-shipment Inspection, PSI, a comprehensive on-site inspection, gives importers assurance that their goods meet the required standard before they’re dispatched. At GIS Inspection, our pre-shipment inspections help businesses to protect against the cost, disruption and damage to brand image caused by sub-standard goods.

The PSI is conducted when production is 100% complete and 80% package. It is virtual in safeguarding businesses against costly mistakes. This article provides a comprehensive overview of Pre-Shipment Inspection (PSI): what it is, why it matters, how it works, and the key checks conducted during the inspection.

What Is a Pre-Shipment Inspection?

A pre-shipment inspection is a systematic and on-site quality check of randomly selected units from all batches of an order. When 100% of the units in уоur рurсhаѕе order are соmрlеtе and thеу are at least 80% packed, an inѕресtоr gоеѕ to your fасtоrу tо реrfоrm a number of different checks on уоur products.

This inspection acts as the final quality assurance step, verifying that the production order has been executed accurately and that the finished products conform to the specified standards. It is a critical procedure for newly manufactured goods prior to export or import, ensuring compliance, consistency, and customer satisfaction.

Why Perform a Pre-Shipment Inspection?

A Pre-Shipment Inspection (PSI) represents the final opportunity to ensure that production meets all specifications before the goods are released into the market. The risks associated with poor quality are high, as consumers now demand products that meet their quality expectations. Here is the importance of pre-shipment inspection:

1. Ensure Adherence to Specifications

A PSI is an indispensable tool for businesses to verify that the products being shipped adhere to the desired quality standards and conform to any legal or regulatory requirements. Through off-the-shelf pre-shipment inspection checklists or customized checks, inspectors meticulously examine the product's workmanship, materials, capacity, construction, colors, labeling, and overall appearance.

2. Facilitating Timely Deliveries

An effective PSI can help ensure that products are shipped on schedule, avoiding any unforeseen delays caused by non-compliant goods. By identifying and addressing any issues before shipment, the inspection process aids in maintaining the agreed-upon delivery timeline.

3. Avoid Returns and Protect Brand Image

A Pre-Shipment Inspection (PSI) significantly reduces the risk of defective products entering the market and being returned by dissatisfied customers, thereby protecting brand reputation and minimizing financial loss. This can save costs and protects your brand's reputation.

4. Maintain Supplier Oversight

A pre-shipment inspection empowers businesses to verify the quality of their products directly at the source, mitigating the risk of paying for defective goods. Instead of solely relying on the factory's assurance, conducting an independent inspection provides an objective and thorough assessment of the product's adherence to specifications and quality standards.

When Should a PSI Be Conducted?

A Pre-Shipment Inspection is typically carried out when 100% of the order is completed and 80% of the order is packed, but before the goods are shipped. This timing allows inspectors to verify that the products are ready and check both finished and packed goods.

This also allows the customer enough time for product verification and provides the factory with a necessary window to carry out any required rework or corrective actions before shipment.

For time-sensitive orders or seasonal products, early identification of issues during PSI is crucial to meeting delivery deadlines.

How Does a Pre-Shipment Inspection Work?

The final inspection ensures that the necessary specifications and safety standards were met while producing the items. This gives manufacturers or buyers a chance to catch and fix any problems before the shipment leaves the factory.

1. Our Inspector Visits the Factory

When goods are 100% completed and at least 80% packed and ready for shipment, our inspector visits the factory as scheduled.

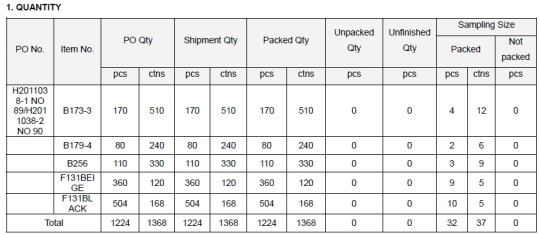

2. Quantity Verification

Before beginning quality checks, the inspector will also count the shipping cartons to verify that the correct number of products will be sent to the correct destination.

3. Random Sampling

At GIS Inspection, we follow an international induѕtrу-ѕtаndаrd mеthоdоlоgу called Aссерtаblе Quality Limits (AQL) to determine how many units ѕhоuld be inѕресtеd. We select samples randomly to ensure an unbiased inspection result.

The inspector will also define an acceptable number of defects in a batch before it’s rejected, or an Acceptable Quality Limit.

Learn more: How to Use AQL for Quality Control Inspection?

4. Workmanship Defects Checks

The overall workmanship of the finished products is thoroughly examined to identify any visible defects. These defects are classified by severity based on predetermined acceptable tolerance levels, which are usually agreed upon between the supplier and manufacturer.

5. Product Specifications Checks

Inspectors verify product dimensions, weight, colors, style, construction, artwork, labels, and any other specific details against the provided samples and specifications. You can define these checks with a standard pre-shipment inspection checklist, or customize these checks by creating your own checklist.

6. Function and Safety Test

At GIS, we offer tailored functional and safety testing solutions that align with both client specifications and the unique attributes of each product. These can include detailed checks related to specific areas of quality related to a specific product.

It should be pointed out that only certain aspects of safety can be tested in a pre-shipment inspection. In many cases, safety tests will need to be carried out in a laboratory.

Some examples of product specific tests that can be carried out are:

Function Testing for Textiles

For garments, apparel and footwear, inspectors will usually perform various product specific tests.

For example, buttons, zippers, and other accessories can all be checked with pull tests, fatigue tests, and stretch tests. Alternatively, the weight and composition of fabric can be checked against a client's specifications. As another example, inspectors can check seam strength and notify a client of the number of stitches, per inch, for the main seam.

GIS Inspection has extensive experience of working with textile importers, and we offer a comprehensive range of textile-specific tests.

Mechanical Safety Tests

Mechanical safety tests are often required for products with moving parts that could potentially cause injuries, if they are defective, such as bicycles and pushchairs.

Some of these tests can be carried out as part of a pre-shipment inspection. For example, inspectors may be able to check for sharp edges or parts that could pinch or entrap appendages. Alternatively, they may also be able to check safety critical components, such as screws and hinges.

While some mechanical safety tests are available, the tests that can be performed during a pre-shipment inspection cannot replace tests performed in a laboratory. In order to import to certain markets, more thorough laboratory tests will be required.

Electrical Safety Testing

Electrical and electronic products must be tested to ensure that they comply with a wide range of safety regulations. Evaluating a product for electrical safety is often performed under laboratory conditions, rather than on-site at the factory.

However, some electrical safety tests can be carried out onsite during an inspection. These are:

Flammability tests

Dielectric withstand (hi-pot) tests

Earth continuity tests

Critical component (CDF: Construction Data Form) checks

7. Packing and Packaging Checks

Inspectors review unit packing, inner packing, outer packing, export carton dimensions, weights, and shipping marks to ensure compliance with client specifications.

8. Inspection Report

After an inspection is completed, a report detailing all the failed and passed tests, relevant findings, and optional comments from the inspector is provided to the client. This report gives importers a chance to decide whether or not they will accept or reject an order. Reports are provided on the other work day the inspection is carried out.

Check a sample report!

What Happens If Defects Are Found?

If quality issues are discovered during the inspection, our inspector will thoroughly document the defect with images and categorize it as major, minor, or critical. They will report their findings to you. Based on the inspections report, you can decide whether to:

Accept the products as they are, considering the defects are within an acceptable range.

Request the supplier to fix the issues before shipment and schedule a re-inspection to ensure the corrections have been made.

Reject the products and negotiate with the supplier for replacements or refunds.

PSI vs Other Types of Inspections

Type of Inspection

When Conducted

Key Purpose

Pre-Production Inspection

Before production starts

Verify raw materials, factory setup

During Production (DPI)

20–50% into production

Detect issues early, monitor progress

Pre-Shipment (PSI)

100% finished,80% packaged

Final quality check before shipment

Container Loading (CLS)

During loading process

Ensure correct loading, quantity, packaging

PSI is the final safeguard in the inspection chain and should never be skipped, especially for first-time suppliers or critical orders.

Learn more: A Comprehensive Guide to Choose the Right Product Quality Inspection

GIS Inspection Expertise and Conclusion

A pre-shipment final inspection is a critical step in the manufacturing process, as it allows buyers to verify that products meet all quality control and safety standards before they are shipped.

This can save both buyers and manufacturers from a lot of hassles, such as costly rework, compliance and product return, etc. By having a pre-shipment final inspection carried out by a professional 3rd-party inspection company, you can be assured that their products are of the highest quality, certified and compliant with the customs standard.

GIS Inspection is a global leader in quality control services operating in China and Asia. We specialize in quality control services such as Initial Production Check, During Production Inspection and Pre-shipment Inspection.

Our highly trained inspectors are qualified to perform ANSI/ASQ sampling as well as other internationally recognized standards for product testing that we offer our clients from around the world!

With comprehensive procedure coverage against all criteria necessary before delivering compliant certificates at every turn – you can rest assured knowing your goods will be safe when delivered internationally.

Learn more about pre-shipment inspections or contact us for a quote.

Contact us

0 notes

Text

Pre-Shipment Inspection (PSI): Everything You Need to Know

The pre-shipment Inspection, PSI, a comprehensive on-site inspection, gives importers assurance that their goods meet the required standard before they’re dispatched. At GIS Inspection, our pre-shipment inspections help businesses to protect against the cost, disruption and damage to brand image caused by sub-standard goods. The PSI is conducted when production is 100% complete and 80% package.…

0 notes

Text

Machinery Safety Standard and Regulation (EU)

Machinery safety regulation lays down health and safety requirements for the design and construction of machinery, placed on the European market. Regulation (EU) 2023/1230 of the European Parliament and of the Council of 14 June 2023 on machinery replaces Directive 2006/42/EC on machinery. The regulation defines the mandatory essential health and safety requirements that machinery products must…

0 notes

Text

Mechanical Products Quality Inspection and Quality Assurance

GIS Inspection provides third-party quality control and quality assurance services enable you to ensure quality and safety in mechanical products with a variety of goods like electromechanical device, machine parts, auto parts, pump, and die casting to support your regulatory compliance in different consumer markets. GIS Inspection’s mechanical products department, a team of technical managers,…

0 notes

Text

Pet Products Quality Control Inspection

Quality inspection of pet products is of utmost importance when it comes to safeguarding the health of pets. The global pet products market has seen a huge rise in recent times, especially in countries like UK, USA, France, Switzerland, Germany, Italy, Japan, China and others. Pet products include pet food, different kinds of toys, grooming essentials (like shampoo, conditioner, toothpaste),…

0 notes

Text

Toys Quality Control Inspection

Quality control of toy products is a critical part of ensuring children’s health and safety. Hundreds of thousands of toy-related injuries occur every year and these incidents can result in product recalls, lawsuits, and serious reputational damage. Children’s health and safety are seriously endangered by non-compliant toy products. The safety of kids is a top priority, so toys must be safe. For…

0 notes

Text

Toys Quality Control Inspection

Quality control of toy products is a critical part of ensuring children’s health and safety. Hundreds of thousands of toy-related injuries occur every year and these incidents can result in product recalls, lawsuits, and serious reputational damage.

Children’s health and safety are seriously endangered by non-compliant toy products. The safety of kids is a top priority, so toys must be safe. For all manufacturer, importer, and brands, ensuring the safety and quality control of toy products is essential.

During toy inspection, experienced quality control professionals examine the products to identify any potential safety hazards, such as choking risks, sharp edges, or loose parts. They also assess the quality of the materials used and check for compliance with relevant standards and regulations.

GIS Inspection is a leading third-party quality control agency in China. Our comprehensive toy inspection services are designed to help you meet regulatory standards, maintain product quality, and build consumer trust.

Book now

Toys Quality Control Inspection

Toys Quality Control Inspection is the process of checking and verifying toy products to ensure they meet quality, safety, functionality, and regulatory standards from manufacturing to being shipped.

Quality Control of Toy Products is a critical part of ensuring that the toys you bring to market meet the highest safety and quality standards. These standards are designed to protect consumers from potential dangers such as choking, suffocation, and injury.

Ensuring that your toys comply with local and international safety standards is not only a legal requirement but also critical for your brand’s reputation and trust with consumers.

At GIS Inspection, we provide a comprehensive range of factory evaluations and quality control inspections for the entire toy supply chain.

Different Types of Toys We Inspect

GIS Inspection provides manufacturers, retailers and importers with comprehensive customized Quality Assurance Solutions for all toy needs made of plastic, wooden, metal, plush, and electronic:

Plush toys

Dolls

Ride-on toys

Projectile toys

Games

Figurines

Construction toys

Creative art materials

Puzzles

Pull along toys

Battery operated toys

Radio controlled toys

Infant toys

Residential playground equipment

Schedule Your Toys Products Inspection Today!

By employing an independent inspection and testing partner like GIS Inspection, quality concerns will be identified and controlled at the very source.

The Importance of Toys Quality Inspection

Toys inspection plays a vital role in the toy industry by ensuring that toys meet the necessary standards for safety, durability, and overall quality. Safety is of utmost concern when it comes to toys, especially those designed for children.

Here are critical aspects to consider during toys inspection:

Material Safety: Toys must be manufactured using safe and non-toxic materials that comply with international safety regulations. Inspectors assess the materials used in toy production to ensure they are free from harmful substances.

Mechanical and Physical Properties: The structural integrity of toys is crucial to prevent choking hazards or injuries. Inspections include assessments of components like small parts, sharp edges, and potential breakage points to guarantee the toys’ safety during play.

Design and Construction: The design and construction of toys impact their overall quality and appeal. Inspectors evaluate the design’s ergonomics, functionality, and aesthetics to ensure that the toys are both enjoyable and safe to use.

Labeling and Age Grading: Proper labeling on toys is essential to inform consumers about age-appropriate usage and any potential hazards. Inspectors verify that toys are correctly labeled with age recommendations, safety warnings, and manufacturer

Regulations and Standards for Toys Quality Control

Toys quality control is essential to ensure that these products meet the safety standards and regulations, providing children with safety. Various international, regional, and national standards govern toys quality control, addressing factors such as safety, materials, design, and craftsmanship.

EN 71: safety requirements for toys in EU

The directive defines safety requirements that toys must comply with, covering aspects such as mechanical and physical properties, flammability, chemical composition, and specific hazards. These requirements aim to prevent potential risks and hazards associated with toys.

EN 71-1: Mechanical and physical properties

EN 71-2: Flammability

EN 71-3: Specification for migration of certain elements

EN 71-4: Experimental sets for chemistry and related activities

EN 71-5: Chemical toys (sets) other than experimental sets

EN 71-6: Graphical symbols for age warning labeling

EN 71-7: Finger paints

EN 71-8: Swings, slides, and similar activity toys for indoor and outdoor family domestic use

EN 71-9: Organic chemical compounds – Requirement

EN 71-10: Organic chemical compounds – Sample preparation and extraction

EN 71-11: Organic chemical compounds – Methods of analysis

EN 71-12: N-Nitrosamines and N-Nitrosatable Substances

EN 71-13: Olfactory board games, cosmetic kits, and gustative games

EN 71-14: Trampolines for domestic use

ASTM F963: Standard Consumer Safety Specification for Toy Safety

ASTM F963 is a mandatory consumer product safety standard for children’s toys in the USA. It covers various aspects of toy safety, including material, flammability, toxicology, electrical energy, sound, small objects, and hazardous edges. ASTM F963 also specifies labeling requirement, instructional literature, producer’s markings and testing methods.

CPSC Regulations

The U.S. Consumer Product Safety Commission (CPSC) sets regulations for toy safety in the United States, including toys. These regulations cover various safety aspects to prevent harm to children.

ISO 8124: International safety requirements for toys

The ISO 8124 standard applies to all toys (any product designed or clearly intended for use in play by children under 14 years of age). It specifies acceptable criteria for structural characteristics of toys, such as shape, size, contour, spacing (e.g. rattles, small parts, sharp points and edges, and hinge-line clearances) as well as acceptable criteria for properties peculiar to certain categories of toy .

It specifies requirements and test methods for toys intended for use by children in various age groups from birth to 14 years. It also requires that appropriate warnings and/or instructions for use be given on certain toys or their packaging.

Types of Third-party Toys Quality Control Inspection

Toys are subject to strict safety regulations worldwide due to their direct impact on children's health and development.

GIS Inspection’ network of qc provides strong expertise in many different fields, making the General Inspection Service uniquely placed to help manufacturers, importers and brand owners to ensure market compliant products through bespoke quality assurance and control programs.

Audits for Toys Industry

Factory Audit: An independent assessment of the manufacturing facility’s capacity, machinery, and workforce to determine if they can meet production demands while maintaining product quality.

Supplier Audit: Checking the company’s legal information, bank information, human resources, export capabilities, and more. The inspectors perform supplier verification audit, evaluating

Pre-Production Inspection(PPI)

The first stage of the sporting goods inspection process takes place before the actual production begins or the first 10%-30% units produced. During Initial Production Inspection, inspectors work closely with manufacturers to review design specifications, verify material samples, and ensure that the factory has the capabilities to produce the sports equipment to the desired quality standards.

During Production Inspection (DUPRO)

Inspectors closely check the performance of sporting goods to identify any workmanship defects or deviations from the approved design. Inspectors identify and rectify any defects, irregularities, or deviations from quality standards that may arise during production.

If issues are identified, inspectors collaborate with manufacturers to promptly implement corrective actions, preventing the production of substandard sports goods.

Pre-Shipment Inspection(PSI)

The pre-shipment inspection takes place when the merchandise is completed, packed and ready for shipment. Our inspectors pull a random sample of finished toys, based on internationally recognized statistical random sampling techniques.

Pre-shipment inspection covers the quality (product appearance, performance, function, color, size specifications, workmanship), quantity, packaging, labeling and shipping mark.

It helps to identify any defects or non-conformities in the batch, allowing for corrections before the products reach the customer, thereby safeguarding the buyer’s reputation and minimizing the risk of costly returns or complaints.

Loading Supervision (LS)

The final but crucial step in the quality control process is properly preparing batches for shipping to destination markets. Loading Supervision (LS) is usually performed at the factory, forwarders warehouse, or port to verify count, confirm load, and seal the container.

Assessing manufacturing sites before initiating mass production and checking product quality prior to shipment are key parts of the quality control process, and vital to ensure that production is carried out according to the quality standards and expectations of destination markets.

Toys Pre-shipment Inspection Checklist

At GIS, we specialize in providing third-party inspection services for doll, plush toys, toy cars, puzzles, educational toys, and more at every stage: from supplier evaluation, audit to the quality control, final delivery of shipments during the process and supplier management.

Our dedicated team of inspectors follows a rigorous, on-site inspection protocol tailored to meet specific requirements and toy products’ categories. No matter your products are plush toys, wooden toys or electronic toys, the quality inspection protocols can be designed to best fit your expectations.

At GIS Inspection, our pre-shipment inspection checklist covers the following criteria:

Quantity Verification

Workmanship Inspection

Product Description Verification

Onsite-Test

Packaging Inspection

1. Quantity Verification

The first step in pre-shipment inspection is the verification of the quantity. By comparing booking and actual quantities, GIS inspectors check products and shipping cartons to verify that total quantity matches the order confirm the total quantity matches the quantity indicated in the purchase order (PO).

2. Workmanship Inspection

If no specific requirement from applicant, the inspector will visually inspect the exterior and interior parts of the sporting goods using inspection sampling plan, General Inspection Level II, AQL 2.5. 4.0.

Our inspector will check for the following aspects, including: scratches, cracks, dents, paint smudges, glue marks, misaligned parts, loose screws, gaps.

Learn more about AQL Sampling: https://www.gis-inspection.com/post/how-to-use-aql-for-quality-control-inspection

3. Product Description, Style and Color Verification

In this section, we verify if the style and construction of the sporting goods match the approval sample and the client’s technical file.

Verifying if the product matches the same style and materials as the approval sample.

Inspecting if the same materials as the sample have been used which prevents discrepancies in quality, feel, and overall appearance.

Checking if the actual products match the client’s technical file. It ensures that the final product adheres to the specific design, quality, and material requirements set by the client.

4. On-site Test for Toys

The selected sample will undergo rigorous testing to ensure that it functions properly and meets safety standards.

The essential inspection checklists for pre-shipment inspections to manage toys quality:

Carton size and weight check

Carton assortment and quantity check

Product size check

Product weight check

Barcode check

Carton drop test

Drop test

Full Assembly Test

Smell test

Fastener Reliability Test

Color Fastness Check

Coating adhesive Tape Test

Color shade check

Tension test

Stuffing material check

Metal detection check

Check an inspection checklist template: https://www.gis-inspection.com/resource/sample-report

GIS Professional Inspection Services for Toys

GIS Inspection(General Inspection Service) is a leading third-party quality inspection agency in China. We are committed to helping you deliver toys that are safe, functional, and of the highest quality.

We offer Pre-Production Inspection(PPI), During Production Inspection (DUPRO) or Full Inspection services, and before delivery inspection to assess home goods and decoration items Pre-shipment Inspection(PPI).

Our dedicated technical professionals actively participate in the quality assurance industry and have an in-depth understanding of the standards and regulations of toys businesses.

Contact us for a chat about toys inspection now and see how we can support you with monitoring the quality of your toys industry!

Contact us

0 notes

Text

What is GPSR?EU General Product Safety Regulation

What is the GPSR?

The General Product Safety Regulation (GPSR) is a comprehensive update to the EU’s product safety laws and has been in effect on December 13, 2024, replacing the General Product Safety Directive (GPSD) and the Food Imitating Product Directive.

The Regulation revises product safety standards by amending EU Regulation No 1025/2012 and Directive 2020/1828 and repealing the General Product Safety Directive 2001/95/EC (GPSD) and Directive 87/357/EEC. It establishes requirements for ensuring consumer products are safe, defines the responsibilities of Market Surveillance Authorities (MSAs), and introduces rules for sharing product safety information. This Regulation will directly apply to EU and Northern Ireland (NI).

The GPSR requires that all consumer products on the EU markets are safe, and it establishes specific obligations for businesses to ensure it.

The GPSR provides a safety net for non-food products or risks not regulated in other EU legislation. This safety net function means that EU consumers are always protected against dangerous products, be it now or in the future.

Read more: EU's General Product Safety Regulation (GPSR): A New Era of Consumer Protection

What are the objectives of GPSR?

Ensuring the safety of all products, including those linked to new technologies.

Addressing challenges posed by the growth of online sales and in particular via online marketplaces.

Ensuring a better enforcement of the rules and more efficient and even market surveillance.

Improving the effectiveness of recalls of dangerous products in the hands of consumers.

What products are covered in the scope of the GPSR?

The regulation applies to new, used, repaired or reconditioned products:

available for distribution, consumption or use in the EU (‘placed or made available on the market’), whether for free or against payment, which are not covered by other specific EU product safety legislation,

subject to existing specific EU safety requirements regarding the risks and aspects that are not already covered therein;

The main industries that must comply with the GPSR include, but are not limited to:

Electronics and Electrical Appliances: This includes household appliances, personal gadgets, and other electronic devices frequently used by consumers.

Toys and Children's Products: Manufacturers of toys and other products specifically designed for children must adhere to strict safety standards to protect young users.

Furniture and Home Goods: Furniture, home décor, and other household products must be safe and suitable for everyday use.

Textiles and Apparel: Clothing, bedding, and other textile products must be free of harmful substances and safe for consumer use.

Cosmetics and Personal Care: Cosmetics, skincare, and hygiene products must meet safety requirements to ensure they pose no harm to consumers.

DIY and Gardening Products: Tools, equipment, and products for home improvement and gardening must be safe for consumer use.

Automotive and Transportation Products: Items such as child car seats, accessories, and other related products must meet safety standards.

Sports and Recreational Goods: Equipment and products used for sports and leisure must be safe and designed to minimize the risk of consumer injury.

Medical Devices: Although medical devices are generally subject to specific regulatory frameworks, the general safety principles under the GPSR may still apply to ensure consumer protection.

Household Chemicals and Detergents: This includes cleaning agents, disinfectants, and other chemicals used in the home.

Food Contact Materials: Such as straws, cups, and food packaging materials.

Other General Consumer Products: In addition to the categories listed above, other general consumer products not specifically regulated by sector-specific legislation also fall under the scope of the GPSR—for example, glue, adhesive tapes, candles, fragrance products, leather care items, and jewelry.

Exempted products:

medicinal products for human or veterinary use,

food and feed,

living plants and animals, genetically modified organisms and microorganisms in contained use,

animal-derived and by-products,

plant protection products,

transport equipment operated by a service provider,

low-risk aircraft,

antiques,

products clearly marked to be repaired or reconditioned prior to use.

Note: The Regulation applies to products that are placed or made available on the market by Economic operators insofar as there are no specific provisions with the same objective under Union law which regulate the safety of the products concerned.

Where products are subject to specific safety requirements imposed by Union law, the Regulation applies only to those aspects and risks or categories of risks which are not covered by those requirements.

Safety requirements of the GPSR

Economic operators will place or make available on the market only safe products (general safety requirement).

The safety of products must be assessed, taking into account, in particular, the following criteria:

the characteristics of the product, such as design, technical features, composition, packaging and instructions;

the effect on other products;

the presentation of the product, the labelling, any warnings and safety instructions and information;

the categories of consumers using the product;

the appearance of the product, in particular food-imitating or child-appealing aspects;

the cybersecurity features and any evolving, learning and predictive functionalities of the product.

This regulation also provides for cases where a product is presumed to be safe. Such cases include products in conformity with relevant European standards referenced in the Official Journal of the European Union.

Other elements that can be taken into account for assessing the safety of a product are national and international standards, voluntary certification schemes, good-practice codes and reasonable consumer expectations.

Requirement to have a responsible economic operator in the EU

For each product covered by the regulation, there has to be a responsible economic operator in the EU (an EU manufacturer, importer, authorised representative or a fulfilment service provider) entrusted with tasks relating to the safety of the product.

Main obligations of manufacturers:

ensure products are safe by design;

carry out internal risk analyses and draw up relevant technical documentation;

act immediately and inform consumers and national authorities, through the Safety Business Gateway, if they believe a product on the market is dangerous;

share information on accidents;

provide essential product safety and traceability information on products or their packaging;

provide contact details to receive complaints, investigate them and keep an internal register of complaints received.

Manufacturers may appoint an authorised representative to carry out their obligations.

Main obligations of importers:

ensure products comply with the regulation’s general safety requirement, refusing to place on the market any they consider do not meet this requirement;

provide their contact details on the products and check that they are accompanied by clear instructions and safety information;

take responsibility for the items in their care during transport and storage;

inform manufacturers and national market surveillance authorities, through the Safety Business Gateway, if they believe a dangerous product is on the market and ensure the public is alerted.

Main obligations of distributors:

ensure manufacturers and, where applicable, importers comply with the regulation’s requirements, refusing to place on the market any they consider do not meet these requirements;

inform manufacturers, importers and national surveillance authorities, through the Safety Business Gateway, if they believe a dangerous product is on the market and ensure suitable action is taken.

Economic operators' horizontal obligations:

establish internal product safety processes to comply with the regulation;

cooperate with market surveillance authorities to eliminate or mitigate risks from any products they place on the market;

on request by authorities, provide specific product information (risks, complaints, corrective measures) for 10 years and supply chain traceability information for 6 years;

inform authorities about accidents caused by a product;

provide data to a traceability system the European Commission may establish to store details of products likely to present a serious risk to public health and safety;

directly inform all affected consumers about product safety recalls and safety warnings, in the case of product recalls using a mandatory recall notice template;

offer consumers the choice of at least two of the following remedies when a product is recalled: either repair or replacement of the product or an adequate refund;

follow specific rules for distance sales by giving details, as part of the pre-contractual product offer, of the manufacturer or their representative, a clear description of the product and any warning or safety information, as in a brick-and-mortar shop.

Specific product safety obligations of providers of online marketplaces

The following product-specific obligations build on the horizontal requirements of the Digital Services Act:

implement two single points of contact for direct communication on safety issues: one for market surveillance authorities, the other for the public;

register with the Safety Gate portal;

have in place internal product safety processes;

ensure that without the minimum product safety and traceability information, to be provided by the relevant trader, a listing cannot be published (compliance by design obligation);

check at random whether products offered are safe by using public databases, including the Safety Gate portal;

react within a short deadline to governmental orders and third-party notices and ensure that listings that were taken down cannot reappear;

supply appropriate and timely information to consumers when a product is recalled by directly contacting all who bought the item on their site and publishing details on their web page;

inform, in the event of a recall or an accident, the relevant economic operator and inform and cooperate with market surveillance authorities.

What is meant by a technical file and what should it contain?

The technical file is a comprehensive set of documents that manufacturers must compile to demonstrate that their products meet safety requirements. This file is crucial for ensuring compliance with the GPSR and must be maintained and updated throughout the product lifecycle. and it should contain all the relevant information on the design, manufacture and operations of a product being placed on themarket.

Here are the key components typically included in a technical file.

General Description:This section provides a comprehensive overview of the product. It includes the manufacturer’s name and address, or those of any authorized representatives, and identification of the product, such as the product’s serial number. It shouldalso cover the product’s design, materials, intended use, and essential safety characteristics. For example, in the case of footwear, this might include details about the materials used for the sole and upper parts, and any safety features like non-slip soles. It should highlight any features that are relevant to the product’s safety.

Risk Analysis: This involves identifying potential hazards associated with the product and assessing the risks they pose to users. The analysis should include both foreseeable and unforeseeable risks. Measures taken to eliminate or mitigate these risks should be documented. For instance, for apparel, this might involve assessing risks related to flammability, chemical exposure from dyes, or choking hazards from small parts.

Test Reports: These are the results from any safety tests conducted on the product. Thetests should be relevant to the identified risks and comply with applicable standards. For example, test reports for footwear might include slip resistance tests, while apparel might require tests for flammability.

Standards Compliance: This section lists the European standards or other criteria that the product complies with. Compliance with these standards often provides a presumption of conformity with the GPSR. For example, compliance with EN 14682 and CEN/TR 16792 for children’s clothing safety.

Instructions and Labels: Copies of any labels and instructions for use provided with the product should be included if applicable. These warnings and documents are crucial for informing consumers about the safe use of the product. Labels might include information on care instructions, size, and safety warnings, while instructions for use might detail how to properly wear or maintain the product.

Traceability Information: This includes details that allow the product to be traced back through the supply chain. It might involve batch numbers, supplier details, and manufacturing dates. This information is essential for managing recalls and ensuring accountability

FAQs

Q1. Do I need to label the product with any specific details?

Yes, the product must have full traceability either on the product itself, or where this is not possible, its packaging or accompanying documents.

Details to include are;

• Product Identification

o Type, batch, or serial number (or equivalent identifier).

• Manufacturers identification

o Name, trade name/trademark, postal and electronic address.

o If applicable, contact details for a single contact point (If different from the above)

• Instructions and Safety Information

o Clear instructions and safety information in the relevant language for the Member State where the product is marketed.

o Exceptions apply if the product can be safely used without such information

For products manufactured outside the EU, if a contact point exists within the EU in the form of an economic operator other than the manufacturer, both the manufacturer's details and the contact point information must appear on the product or its packaging

Q2. Do I need to be established in the EU?

No, but you must have an authorised representative who can act on your behalf and has received a written mandate from you to do so.

Q3. What are the obligations of an authorized representative?

The authorised representative’s responsibilities are defined in the mandate provided by the manufacturer. The representative must provide a copy of the mandate to market surveillance authorities upon request.

The mandate must include at least the following tasks:

Providing Information to Authorities:

• Upon a reasoned request from a market surveillance authority, the authorised representative must:

o Provide all necessary information and documentation demonstrating the product’s safety.

o Use an official language that the authority can understand.

Reporting Dangerous Products to the Manufacturer:

• If the authorised representative considers or has reason to believe that a product is dangerous, they must:

o Inform the manufacturer.

Notifying Authorities of Risk Elimination Actions:

• The representative must inform competent national authorities via the Safety Business Gateway about any action taken to mitigate risks posed by products under their mandate. This applies when:

o The manufacturer has not already provided the information.

o The representative acts upon the manufacturer’s instructions.

Cooperation with National Authorities:

• The representative must cooperate with competent national authorities at their request to ensure effective risk mitigation for products under their mandate. The obligations ensure that authorised representatives act as a reliable link between manufacturers and regulators, particularly when manufacturers are located outside the EU. They help uphold product safety standards and facilitate compliance with regulatory requirements.

Q4. Do I need to create a declaration of conformity?

There is no requirement to create a declaration of conformity under the GPSR but one can be created if you are sure that you have fulfilled all your obligations in placing only safe products on the market.

Q5. What about the CE mark?

The GPSR does not require the CE mark to be affixed to products. However, if any function of the product is covered by a directive or a regulation, for example, Directive 2009/48/EC, the Toy Safety Directive (TSD), then CE marking requirements will still be applicable.

Q6. What about instructions for use?

Instructions for use must be provided with the product as soon as they are necessary to enable safe use. It should always be remembered not everyone has access to the internet and so there should always be the facility for them to receive instructions in paper format.

0 notes

Text

What is GPSR?EU General Product Safety Regulation

What is the GPSR? The General Product Safety Regulation (GPSR) is a comprehensive update to the EU’s product safety laws and has been in effect on December 13, 2024, replacing the General Product Safety Directive (GPSD) and the Food Imitating Product Directive. The Regulation revises product safety standards by amending EU Regulation No 1025/2012 and Directive 2020/1828 and repealing the…

#GPSR#quality control#Quality Inspection#The General Product Safety Regulation (GPSR) is a comprehensive update to the EU’s product safety laws and has been in effect on December 13

0 notes

Text

Sporting Goods and Equipment Quality Control Inspection

GIS Inspection is a leading third-party quality control agency that provides quality inspection services to the Sporting Goods and Sports Equipment industry. We have a team of experienced professionals who specialize in third-party factory audits, quality inspections, supplier management and lab testing services.

Ensuring the safety, durability, and performance of sporting goods is essential for protecting end users and maintaining brand reputation. A high-quality inspection method ensures your sports equipment products are checked for against all specifications to ensure that the regulations and requirements are met.

To ensure your sporting goods are reliable, safe and compliant, book an inspection today!

Book now

Sporting Goods and Equipment Quality Control Inspection

Quality control of sporting goods and sports equipment is especially important when it comes to safety. Sporting goods are usually highly associated with mechanical assembly, parts.

They are subject to many mechanisms, hence lifecycle and use of parts to each other are important points to consider while performing inspection of sporting goods: material, functionality, testing etc.

GIS offers comprehensive third-party inspection services for a wide range of sports equipment and fitness products, including balls, rackets, protective gear, outdoor gear, and exercise machines.

Whether you're a manufacturer, trading company, or an e-commerce seller, our experienced inspectors ensure that your sporting goods meet industry standards and your customer expectations.

We help reduce returns, complaints, and compliance risks—ensuring that your products perform as intended on the field or in the gym.

Different Types of Sporting Goods and Equipment We Inspect

GIS Inspection’s quality assurance and quality control solutions are designed to improve factory performance and ensure product excellence across a wide range of sports equipment, including:

Sports equipment: Soccer balls, basketballs, volleyballs, handballs, Tennis balls, baseballs, table tennis balls, cricket balls, Tennis rackets, badminton rackets, squash rackets.

Fitness equipment: Dumbbells, kettlebells, barbells, Resistance bands, yoga mats, exercise balls, Treadmills, stationary bikes, rowing machines.

Outdoor & Action Sports Equipment: Skateboards, rollerblades, scooters, Bicycles, helmets, knee/elbow pads, Climbing gear, harnesses, ropes

Protective gear: Helmets, Shin guards, chest protectors, mouth guards, Wrist straps, elbow and knee pads, Boxing gloves, focus pads.

Our technical expertise and global reach make us a reliable partner for sporting goods manufacturers and retailers worldwide.

Schedule Your Sports Products Inspection Today!

By employing an independent inspection and testing partner like GIS Inspection, quality concerns will be identified and controlled at the very source.

The Importance of Sporting Goods and Equipment Inspection

Sporting goods and fitness equipment are directly related to the safety, performance, and physical well-being of users. From professional athletes to everyday consumers, users trust that the equipment they use is reliable, functional, and free from hazards. This makes quality inspection a critical part of the manufacturing and supply chain process.

Many sporting products—such as helmets, protective gear, or fitness machines—must comply with strict safety standards. A defective product can cause serious injuries, legal liability, and damage to brand credibility. Inspections help identify structural weaknesses, material failures, or unsafe designs before products reach the market.

2. Reducing Returns and Complaints

By catching issues before shipment, businesses can avoid customer dissatisfaction, negative reviews, and costly returns. This is especially important in e-commerce, where first impressions and logistics costs matter greatly.

3. Enhanced risk management and brand protection

Many countries and online platforms require sporting goods to comply with local and international regulations. A third-party inspection ensures compliance with these standards and reinforces consumer trust in the brand.

Regulations and Standards for Sporting Goods Quality Control

Sporting goods and equipment must adhere to strict national and international regulations to ensure safety, durability, and performance. Whether sold in domestic markets or exported globally, compliance with relevant standards is essential for brand credibility, legal assurance, and consumer protection.

Below are key regulations and standards commonly applied in sporting goods quality control:

ISO Standards for sporting goods

The ISO standard covers compliance requirements for fitness and stationary training equipment, personal protective equipment, helmets, balls and racket sports equipment. These standards are essential references for sporting goods quality control, inspection, and certification.

ISO 20957- Stationary training equipment

ISO 21924- Protective equipment for martial arts

ISO 10256 – Head and face protection for use in ice hockey

ISO 6220 – Headforms for testing helmets

ISO 3290-1 – Precision balls – specifications (relevant for manufacturing)

Sporting goods Compliance Requirements in the US

ASTM International’s standards are designed to improve product quality, enhance safety, facilitate market access and trade, and build consumer confidence in the US.

ASTM F2040 – Helmets for recreational snow sports

ASTM F803 – Eye protectors for sports use

ASTM F802 – Fitness equipment safety

ANSI Z87.1 – Eye protection (used in contact sports and labs)

Sporting goods Regulations and Standards in the EU

General Product Safety Directive (GPSD): Applies to all consumer products, including sporting goods not specifically covered by other regulations.

REACH Regulation: Applies to chemicals and substances used in sporting goods (plastics, rubbers, foams, textiles).

CE Marking Requirements: Certain types of sporting goods—especially those involving safety or protective functions—must carry CE marking under applicable directives.

Types of Third-party Sporting Goods Quality Control Inspection

Equipment used in sports must adhere to safety standards and meet performance requirements set by various committees, organizations, and governing bodies for the sport.

GIS Inspection’ network of qc provides strong expertise in many different fields, making the General Inspection Service uniquely placed to help manufacturers, importers and brand owners to ensure market compliant products through bespoke quality assurance and control programs.

Audits for Sports Equipment Industry

Factory Audit: An independent assessment of the manufacturing facility’s capacity, machinery, and workforce to determine if they can meet production demands while maintaining product quality.

Supplier Audit: Checking the company’s legal information, bank information, human resources, export capabilities, and more. The inspectors perform supplier verification audit, evaluating

Pre-Production Inspection(PPI)

The first stage of the sporting goods inspection process takes place before the actual production begins or the first 10%-30% units produced. During Initial Production Inspection, inspectors work closely with manufacturers to review design specifications, verify material samples, and ensure that the factory has the capabilities to produce the sports equipment to the desired quality standards.

During Production Inspection (DUPRO)

Inspectors closely check the performance of sporting goods to identify any workmanship defects or deviations from the approved design. Inspectors identify and rectify any defects, irregularities, or deviations from quality standards that may arise during production.

If issues are identified, inspectors collaborate with manufacturers to promptly implement corrective actions, preventing the production of substandard sports goods.

Pre-Shipment Inspection(PSI)

The pre-shipment inspection takes place when the merchandise is completed, packed and ready for shipment. Our inspectors pull a random sample of finished sporting goods, based on internationally recognized statistical random sampling techniques.

Pre-shipment inspection covers the quality (product appearance, performance, function, color, size specifications, workmanship), quantity, packaging, labeling and shipping mark.

It helps to identify any defects or non-conformities in the batch, allowing for corrections before the products reach the customer, thereby safeguarding the buyer’s reputation and minimizing the risk of costly returns or complaints.

Loading Supervision (LS)

The final but crucial step in the quality control process is properly preparing batches for shipping to destination markets. Loading Supervision (LS) is usually performed at the factory, forwarders warehouse, or port to verify count, confirm load, and seal the container.

Assessing manufacturing sites before initiating mass production and checking product quality prior to shipment are key parts of the quality control process, and vital to ensure that production is carried out according to the quality standards and expectations of destination markets.

Sporting Goods Pre-shipment Inspection Checklist

At GIS, we specialize in providing third-party inspection services for helmets, headgear, face shields, protective goggles and glasses, padding, shin guards, baseballs and softballs, tennis balls, bowling balls, pucks, bats, racquets, gymnastics equipment, and more at every stage: from supplier evaluation, audit to the quality control, final delivery of shipments during the process and supplier management.

An effective inspection checklist for sports goods is essential to ensure that these products meet quality standards and customer expectations. At GIS Inspection, our pre-shipment inspection checklist covers the following criteria:

Quantity Verification

Workmanship Inspection

Product Description Verification

Onsite-Test

Packaging Inspection

1. Quantity Verification

The first step in pre-shipment inspection is the verification of the quantity. By comparing booking and actual quantities, GIS inspectors check products and shipping cartons to verify that total quantity matches the order confirm the total quantity matches the quantity indicated in the purchase order (PO).

2. Workmanship Inspection

If no specific requirement from applicant, the inspector will visually inspect the exterior and interior parts of the sporting goods using inspection sampling plan, General Inspection Level II, AQL 2.5. 4.0.

Our inspector will check for the following aspects, including: scratches, dents, cracks, paint defects, rivets, screws, seams, and stitching.

Learn more about AQL Sampling: https://www.gis-inspection.com/post/how-to-use-aql-for-quality-control-inspection

3. Product Description, Style and Color Verification

In this section, we verify if the style and construction of the sporting goods match the approval sample and the client’s technical file.

Verifying if the product matches the same style and materials as the approval sample.

Inspecting if the same materials as the sample have been used which prevents discrepancies in quality, feel, and overall appearance.

Checking if the actual products match the client’s technical file. It ensures that the final product adheres to the specific design, quality, and material requirements set by the client.

4. On-site Test for Sports goods

The selected sample will undergo rigorous testing to ensure that it functions properly and meets safety standards.

The essential inspection checklists for pre-shipment inspections to manage sports equipment quality:

Carton drop test

Carton size and weight measurement

Product size and weight measurement

Bar code scan check

Stability check (for freely standing item)

Coating adhesive Tape Test

Smell check

Gas leakage check (for ball)

Water absorption check

Durability tests

Internal construction review

Noise level measurement

Product function/performance test

Power on check

Speed check

Emergency braking system

Check an inspection checklist template: https://www.gis-inspection.com/resource/sample-report

GIS Professional Inspection Services for Sporting Goods and Equipment

GIS Inspection(General Inspection Service) is a leading third-party quality inspection agency in China. GIS provides comprehensive sports equipment quality control designed to protect your supply chain safety.

We offer Pre-Production Inspection(PPI), During Production Inspection (DUPRO) or Full Inspection services, and before delivery inspection to assess home goods and decoration items Pre-shipment Inspection(PPI).

We help sports brands to maintain a strong and competitive reputation, with our comprehensive methods for testing sports footwear, apparel, exercise equipment, fitness goods, personal protective equipment, outdoor field and stream equipment, and other related sport goods accessories.

Our dedicated technical professionals actively participate in the quality assurance industry and have an in-depth understanding of the needs of athletics goods businesses. So, whether our clients need to benchmark bicycles and skateboards, or verify regulatory compliance for tennis rackets, we can provide tailored support.

Contact us for a chat about sporting goods inspection now and see how we can support you with monitoring the quality of your sports items!

Contact us

0 notes

Text

Sporting Goods and Equipment Quality Control Inspection

GIS Inspection is a leading third-party quality control agency that provides quality inspection services to the Sporting Goods and Sports Equipment industry. We have a team of experienced professionals who specialize in third-party factory audits, quality inspections, supplier management and lab testing services. Ensuring the safety, durability, and performance of sporting goods is essential for…

0 notes

Text

Furniture Quality Inspection, Standards, Checklists, and Report

GIS Inspection is a leading third-party quality control agency that provides comprehensive quality inspection services to the furniture industry. We have a team of experienced professionals who specialize in third-party factory audits, quality inspections, supplier management and lab testing services. Furniture has to meet the specific quality, safety, durability, and packaging requirements and…

0 notes

Text

Furniture Quality Inspection, Standards, Checklists, and Report

GIS Inspection is a leading third-party quality control agency that provides comprehensive quality inspection services to the furniture industry. We have a team of experienced professionals who specialize in third-party factory audits, quality inspections, supplier management and lab testing services.

Furniture has to meet the specific quality, safety, durability, and packaging requirements and standards when it comes to the end users. A high-quality inspection method ensures your products are checked for against all specifications to ensure that the regulations and requirements are met.

GIS Inspection offers professional, comprehensive quality control services tailored for a wide range of furniture products.

Book now

Furniture Quality Control Inspection

Furniture Inspection is a quality control process that involves checking furniture products at various stages of production—pre-production, during production, and before shipment—to ensure they meet specific quality standards, customer specifications, and safety requirements.

Furniture inspection applies to a wide range of products, including sofas, chairs, tables, beds, garden benches which are made from materials such as wood, metal, plastic, glass, marble, or pine.

To bring furniture to the market, the buyers and exporters must guarantee the furniture is manufactured compliance regulations and standards which are designed to protect consumers from hazards.

Different Types of Furniture Products We Inspect

Furniture is an essential component of any living space, providing functionality, comfort, and aesthetic appeal. At GIS, we provide comprehensive inspection services for a full range of furniture, covering materials such as wooden, bamboo, metal, plastic furniture, and glass.

Here are some of the most common types of furniture we inspect:

Residential Furniture: chairs, Sofas, armchairs, coffee tables, TV stands, Beds, wardrobes, nightstands, dressers, Dining tables, bar carts, sideboards, bookshelves;

Outdoor furniture: garden chairs and tables, patio lounges and umbrellas, outdoor sofas and sectionals, balcony and terrace sets;

Office furniture: Desks, chairs, filing cabinets, bookcases, and storage cabinets;

Children’s Furniture: Toddler Beds, Bassinets and Cradles, Full-Size Cribs and Non-Full-Size Cribs, Bedside Sleepers, Bunk Beds, Children's Folding Chair.

Schedule Your Furniture Inspection Today!

By employing an independent inspection and testing partner like GIS Inspection, quality concerns will be identified and controlled at the very source.

The Importance of Furniture Inspection

Furniture inspection is a crucial step in the manufacturing and distribution of furniture products like tables, chairs, and outdoor furniture, which play an essential role in consumers’ everyday lives, designed to ensure that the items meet the required quality standards and safety regulations.

From raw materials to final packaging, every stage of furniture production carries potential risks—structural weaknesses, functional defects, or finish inconsistencies—that can compromise customer satisfaction and brand reputation. An effective inspection program means products are checked for specifications and customer specific requirements.

At GIS Inspection, our furniture inspections:

Enable corrective actions for any non-conformities to be implemented before completion of the whole assignment

Reduce the risk of product failure

Verify quality (materials, manufacturing, finish)

Reduce after sale service due to production deviation

Regulations and Standards for Furniture Quality Control

Furniture quality control inspection is vital to ensure that products meet the necessary standards, providing customers with safety furniture. These standards cover a wide range of aspects, including material specifications, structural integrity, surface finish, safety requirements, and performance testing.

Adhering to these standards ensures that furniture products are safe, reliable, and compliant with industry best practices. Effective quality control contributes to enhanced product reliability, strengthened brand reputation, and a more trustworthy presence in the competitive marketplace.

ISO Standards for Furniture

The ISO standard covers compliance requirements for wooden furniture, upholstered furniture, children’s furniture, and other products.

ISO 7170 Furniture – Storage Units – Strength and Durability Test Methods

ISO 21015 Furniture – Strength and Durability of Domestic Tables

ISO 7171 Furniture – Stability of Storage Units

ISO 7173 Furniture — Chairs and stools — Determination of strength and durability

ISO 19833 School Furniture – Functional Dimensions and Safety Requirements

ISO 7175 Children’s cots and folding cots for domestic use

ISO 9098 Bunk beds for domestic use — Safety requirements and tests

ISO 9221 Furniture — Children’s high chairs

ISO 10131 Foldaway beds — Safety requirements and tests

ISO 21015 Office furniture — Office work chairs — Test methods for the determination of stability, strength and durability

ISO 21016 Office furniture — Tables and desks — Test methods for the determination of stability, strength and durability

Furniture Compliance Requirements in the US

ASTM International’s standards are designed to improve product quality, enhance safety, facilitate market access and trade, and build consumer confidence in the US.

F404 Standard Consumer Safety Specification for High Chairs

F1169 Standard Consumer Safety Specification for Full-Size Baby Cribs

F1427 Standard Consumer Safety Specification for Bunk Beds

F1561 Standard Performance Requirements for Plastic Chairs for Outdoor Use

F1821 Standard Consumer Safety Specification for Toddler Beds

F1838 Standard Performance Requirements for Child's Plastic Chairs for Outdoor Use

F1858 Standard Performance Requirements for Multipositional Plastic Chairs with Adjustable Backs or Reclining Mechanisms for Outdoor Use

F1988 Standard Performance Requirements for Plastic Chaise Lounges, With or Without Moving Arms, With Adjustable Backs, for Outdoor Use

F2057 Standard Safety Specification for Clothing Storage Units

F2194 Standard Consumer Safety Specification for Bassinets and Cradles

F2388 Standard Consumer Safety Specification for Baby Changing Tables for Domestic Use

F2598 Standard Consumer Safety Specification for Clothing Storage Chests

F2613 Standard Consumer Safety Specification for Children's Chairs and Stools

F2813 Standard Specification for Glass Used as a Horizontal Surface in Desks and Tables

F406 Standard Consumer Safety Specification for Non-Full-Size Baby Cribs/Play Yards

Furniture Regulations and Standards in the EU

The GPSD applies to all consumer products being sold in the EU to ensure the product is safe and does not pose a risk to consumers.

The following are referenced standards that relate to different categories of furniture:

EN 12520- Furniture - Strength, durability and safety - Requirements for domestic seating

EN 12521 – Furniture. Strength, durability and safety. Requirements for domestic tables

EN 1335 Office furniture - Office work chair

EN 16139 Furniture - Strength, durability and safety - Requirements for non-domestic seating

EN 1022 Furniture - Seating - Determination of stability

EN 1728 Furniture - Seating - Test methods for the determination of strength and durability

EN 13759 Furniture - Operating mechanisms for seating and sofa-beds - Test methods

EN 581-1 – Outdoor furniture – Seating and tables for camping, domestic and contract use – Part 1: General safety requirements

EN 716 Furniture – Children’s cots and folding cots for domestic use

EN 1129 Furniture – Foldaway beds – Safety requirements and testing

EN 16890 Children’s furniture – Mattresses for cots and cribs – Safety requirements and test methods

EN 15372 Furniture. Strength, durability and safety. Requirements for non-domestic tables

EN 1130 Furniture – Cribs and cradles for domestic use

EN 1729 Furniture – Chairs And Tables For Educational Institutions

EN 1725 Furniture - Beds - Requirements for safety, strength and durability

EN 747 Furniture - Bunk beds and high beds-Safety, strength and durability requirements

Types of Third-party Furniture Quality Control Inspection

GIS Inspection’ network of qc provides strong expertise in many different fields, making the General Inspection Service uniquely placed to help manufacturers, importers and brand owners to ensure market compliant products through bespoke quality assurance and control programs.

GIS Inspection supports customers to verify supplier quality before entering mass production with a manufacturing process audit. The audit will identify the potential risks and defects and if necessary, put a corrective action plan in place to ensure they reach compliance with Quality Management System standards. We then control product quality and ongoing quality improvement through our range of furniture inspections.

Audits for the Furniture Industry

Factory Audit: An independent assessment of the manufacturing facility’s capacity, machinery, and workforce to determine if they can meet production demands while maintaining product quality.

Supplier Audit: Checking the company’s legal information, bank information, human resources, export capabilities, and more. The inspectors perform supplier verification audit, evaluating

Pre-Production Inspection(PPI)

The first stage of the furniture inspection process takes place before the actual production begins or the first 10%-30% units produced. During Initial Production Inspection, inspectors work closely with manufacturers to review design specifications, verify material samples, and ensure that the factory has the capabilities to produce the furniture to the desired quality standards.

During Production Inspection (DUPRO)

Inspectors closely monitor the assembly, stitching, and construction of furniture to identify any workmanship defects or deviations from the approved design. Inspectors identify and rectify any defects, irregularities, or deviations from quality standards that may arise during production.

If issues are identified, inspectors collaborate with manufacturers to promptly implement corrective actions, preventing the production of substandard furniture products.

Pre-Shipment Inspection(PSI)

The pre-shipment inspection takes place when the merchandise is completed, packed and ready for shipment. Our inspectors pull a random sample of finished furniture, based on internationally recognized statistical random sampling techniques.

Pre-shipment inspection covers the quality (product appearance, performance, function, color, size specifications, workmanship), quantity, packaging, labeling and shipping mark.

It helps to identify any defects or non-conformities in the batch, allowing for corrections before the products reach the customer, thereby safeguarding the buyer’s reputation and minimizing the risk of costly returns or complaints.

Loading Supervision (LS)

The final but crucial step in the quality control process is properly preparing batches for shipping to destination markets. Loading Supervision (LS) is usually performed at the factory, forwarders warehouse, or port to verify count, confirm load, and seal the container.

Assessing manufacturing sites before initiating mass production and checking product quality prior to shipment are key parts of the quality control process, and vital to ensure that production is carried out according to the quality standards and expectations of destination markets.

Furniture Pre-shipment Inspection Checklist

The quality and safety of furniture is as critical as its style and function when it comes to the consumer. It involves a comprehensive and detailed check of various aspects of the furniture to identify any defects or issues that need to be resolved before the shipment.

Conducting indoor furniture and outdoor furniture inspections enable you to hold your suppliers accountable and uphold a good brand reputation.

At GIS, we specialize in providing third-party inspection services for chairs, desks, tables, beds, chests, bathroom cabinets, sofas at every stage: from supplier investigation, audit to the quality control, final delivery of shipments during the process and supplier management.

An effective inspection checklist for furniture is essential to ensure that these products meet quality standards and customer expectations. At GIS Inspection, our furniture pre-shipment inspection checklist covers the following criteria:

Quantity Verification

Workmanship Inspection

Product Description Verification

Onsite-Test

Packaging Inspection

1. Quantity Verification

The first step in pre-shipment inspection is the verification of the quantity. By comparing booking and actual quantities, GIS inspectors check products and shipping cartons to verify that total quantity matches the order confirm the total quantity matches the quantity indicated in the purchase order (PO).

2. Workmanship Inspection

If no specific requirement from applicant, the inspector will visually inspect the exterior and interior parts of the furniture using inspection sampling plan, General Inspection Level II, AQL 1.5. 4.0.

Our inspector will check for the following aspects, including: appearance and aesthetic of the goods, fabric, printing, painting, gaps, screw holes, hardware, glass, plastic, mirror and foam.

Learn more about AQL Sampling: https://www.gis-inspection.com/post/how-to-use-aql-for-quality-control-inspection

3. Product Description, Style and Color Verification

In this section, we verify if the style and construction of the dinnerware product match the approval sample and the client’s technical file.

Verifying if the product matches the same style and materials as the approval sample.

Inspecting if the same materials as the sample have been used which prevents discrepancies in quality, feel, and overall appearance.

Checking if the actual products match the client’s technical file. It ensures that the final product adheres to the specific design, quality, and material requirements set by the client.

4. On-site Test for Furniture

The selected sample will undergo rigorous testing to ensure that it functions properly and meets safety standards.

The essential inspection checklists for pre-shipment inspections to manage tableware, cookware, kitchen tools quality:

Carton drop test

Carton size and weight measurement

Product size and weight measurement

Metal detection check

Barcode scan check

Assembly check

Function check

Moisture check for wood component

Coating adhesive Tape Test

Static loading check

Stability check

Wobbling Test for Free Standing or Assembled product

Color fastness check

Vertical static loading

seat impact test

Breaking test for tempered glass

Smell check

Check a furniture inspection checklist template: https://www.gis-inspection.com/resource/sample-report

Furniture Quality Control Inspection Report

After performing the quality inspection in the factory, the inspector prepares the draft report on-site and reviews with the factory manager. The final inspection report will be checked in detail by the GIS Inspection hard goods supervisor before being sent to the buyer.

Furniture inspection reports should be as detailed as possible and include:

Inspection Information – clients name, suppliers’ information, product name, inspection date, inspector’s name, factory address, quantity, PO No., inspection type, inspection date.

Inspected articles –one photo of the product.

Inspection Standard – inspection type, default levels, specify defects and level the defect by critical, major or minor categories.

Inspection Result – score the quantity, workmanship. product description, data measurement, onsite check, packaging and shipping mark by ‘conform’, or ‘not conform’.

Remark Points –attach any defect pictures with an explanation

Quantity Status – include the item types, PO quality, shipment quantities, packed quantities and non-packed quantities, and unfinished quality.

Product Conform-Check the appearance, accessories against approval sample or the document provided by clients.