Don't wanna be here? Send us removal request.

Text

Not All Abrasives Are Created Equal

“Not All Abrasives Are Created Equal” Plastic blasting media brings a unique balance of strength and softness. 🔹 Won’t warp or scratch sensitive substrates 🔹 Ideal for composite, aluminum, and plastic parts 🔹 Low heat generation avoids thermal damage 🔹 Recyclable and safer for enclosed environments When surface integrity is your top priority, plastic media makes all the difference. 💬 Looking for precision without the risk? Let’s find the right fit.

0 notes

Text

Smooth Finish Starts with Smart Media

“Smooth Finish Starts with Smart Media” When edge quality matters, nylon media makes the difference. 🛠️ Polyamide blasting improves surface performance by: 📌 Gently removing burrs without damaging delicate features 📌 Reducing post-processing like polishing or sanding 📌 Ensuring consistent edge finish across complex geometries 📌 Minimizing dust and static buildup for cleaner results From electronics housings to molded components, it’s the clean cut that sets the standard. 💬 Want better finishes with less rework? Nylon gets it done right.

2 notes

·

View notes

Text

Not Just Clean—Aerospace Clean

“Not Just Clean—Aerospace Clean” ✈️ Aerospace blasting demands: 📌 Consistent media, zero contamination 📌 Controlled pressure, certified process 📌 Precision that protects structural integrity In this industry, surface prep is safety. 💬 Need blasting that meets the highest standards? Let’s talk.

0 notes

Text

“Engineered to Endure: Power Meets Precision”

When surface integrity is non-negotiable, rely on media that delivers both strength and control. ⚙️ Zirconia Beads offer: 📌 Ultra-high hardness and density for maximum impact energy 📌 Near-perfect sphericity for uniform blasting results 📌 Outstanding recyclability, reducing media loss and downtime 📌 Trusted in aerospace, mold finishing, and high-precision metal parts These beads don’t just clean—they condition, refine, and extend component life. 💬 Need durability without compromise? We’ll help you find the right solution.

0 notes

Text

“Fine Details Matter: Finish with Precision”

In industries where even the smallest imperfections are unacceptable, your media must rise to the challenge. ✨ Ultrafine Aluminum Oxide is engineered for superior micro-finishing: 📌 Particle sizes as small as 5 microns for ultra-smooth surfaces. 📌 Ideal for polishing metals, ceramics, and glass without contamination. 📌 High-purity alumina ensures no unwanted chemical reactions. 📌 Creates a consistent matte finish, perfect for decorative or technical applications. Whether you're finishing medical implants or etching luxury components, this media delivers clarity, control, and cleanliness. 💬 Need a surface that speaks for your precision? Let’s make it happen.

1 note

·

View note

Text

How the Aerospace Industry Uses Ceramic Blasting to Enhance Component Performance

Ceramic bead blasting an aerospace component. This precision blasting process creates a smooth, clean surface on critical parts, improving their performance and longevity.

The aerospace sector demands exceptional quality and durability from every component. To meet these high standards, manufacturers increasingly use ceramic blasting – a specialized surface treatment using hard ceramic media – to improve parts’ surface finishing, fatigue life, and coating adhesion. By propelling fine ceramic beads at metal surfaces, aerospace engineers can achieve smoother finishes, introduce beneficial compressive stresses, and ensure coatings or bonds adhere securely. This article explores how ceramic blasting works, why it outperforms traditional media (like glass beads or aluminum oxide) in aerospace applications, real-world use cases such as turbine blades and structural alloys, and how to select the best ceramic blasting products for precision aerospace needs.

How Ceramic Blasting Works in Aerospace Manufacturing

Ceramic blasting (often performed as bead blasting or shot peening) is a process in which spherical ceramic particles are accelerated (via compressed air or turbine wheel) to impact a component’s surface. The ceramic media – typically made from zirconium-based or alumina-based ceramics – are extremely hard and durable. Upon impact, the beads micro-erode impurities and smooth the surface without significant material removal, or if applied with higher intensity (shot peening), they impart compressive stresses into the metal. This dual capability makes ceramic blasting versatile for both cleaning/finishing and strengthening operations.

Compared to conventional sand or grit blasting, ceramic bead blasting uses hard, spherical media that distribute impact evenly. The uniform shape avoids the uneven gouging that angular abrasives can cause. As a result, ceramic blasting preserves the integrity of the surface while still removing oxides, scale, or minor flaws. The ceramic beads are also chemically inert and leave no corrosive residue on the metal. Unlike glass beads that can impart alkali residues when they oxidize, ceramic media remain chemically stable and won’t contaminate aerospace alloys. This clean process is crucial for aircraft parts, which often must meet strict contamination and surface quality standards.

In practice, aerospace manufacturers choose ceramic media in various sizes and compositions depending on the task. Zirconia-based ceramic beads (about Mohs 7–8 hardness) are favored for precision work because they produce a controlled surface finish with minimal embedment or contamination of the substrate. Alumina-based ceramic beads (Mohs 8–9) offer even higher hardness and are used when more aggressive peening is required on very hard alloys. Operators can fine-tune the process by adjusting blast pressure, angle, distance, and media size to achieve the desired outcome. For example, using slightly larger ceramic beads at higher pressure will create a coarser texture ideal for coating adhesion, whereas smaller beads at lower pressure yield an ultra-smooth finish for precision parts. In all cases, the controlled impact energy of ceramic media allows achieving the target surface condition without excessive erosion. This makes ceramic blasting especially suited to aerospace components, which often have tight tolerances and need careful treatment.

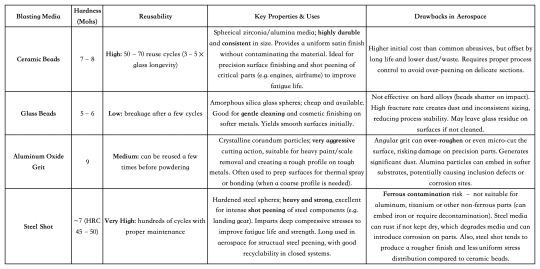

Comparing Ceramic Blasting Media with Other Options

In aerospace manufacturing, a variety of blasting media are used – glass beads, aluminum oxide grit, steel shot, etc. – each with its own characteristics. Ceramic media distinguish themselves by providing an optimal balance of hardness, durability, and gentleness on the substrate. The table below compares ceramic beads to some common alternatives, highlighting why ceramics often come out on top for critical aerospace applications:

Comparison of Blasting Media for Aerospace

Why ceramics outperform: In summary, ceramic blasting media combine many of the benefits of the above options without the major downsides. Ceramic beads are nearly as hard as aluminum oxide yet far tougher, so they don’t fragment rapidly – this yields lower dust and much longer usable life per particle. They are spherical like glass or steel shot, ensuring even coverage and no sharp scratching of the surface. Unlike steel, they contain no free iron, so there’s zero risk of rust or metallic contamination on titanium, aluminum, or composite workpieces. These qualities make ceramics a “best of both worlds” media for aerospace: capable of achieving the required surface conditions on high-strength alloys, while maintaining a clean and precise process.

Key Performance Benefits of Ceramic Blasting

Using ceramic blasting on aerospace components yields concrete performance improvements that directly translate to longer-lasting, higher-quality parts. Below are the main benefits and why they matter for aerospace manufacturing:

Superior Surface Finishing: Ceramic bead blasting produces a smooth, uniform surface finish on machined or cast parts. The hardness and round shape of the beads allow effective removal of oxides or machining marks without pitting or scratching the underlying metal. The result is a satin-like finish that not only looks polished but also reduces stress concentrations (tiny surface nicks that can initiate cracks). Additionally, ceramic media leave no embedded contaminants, so surfaces are chemically clean – an important factor before applying coatings or adhesives. Many aerospace shops use ceramic blasting as a final surface refinement step to ensure components meet strict roughness and cleanliness specs for service.

Increased Fatigue Resistance: One of the most valuable effects of ceramic blasting is its ability to boost fatigue life through shot peening. When ceramic beads strike the metal at controlled intensity, they introduce a layer of compressive residual stress in the surface. This counteracts tensile stresses and makes it much more difficult for fatigue cracks to initiate and propagate. For critical rotating parts like turbine blades or structural airframe parts, this can yield dramatic life extension. For example, Rolls-Royce applies ceramic shot peening to its aircraft turbine blades; this treatment has been shown to enhance blade fatigue and corrosion resistance and extend service life by 15–20%. By preventing micro-cracks and relieving tensile “pre-stress” in the material, ceramic blasting strengthens components to withstand the extreme cyclical loads and vibrations in aerospace service. The process is so reliable that it’s specified in aerospace standards (e.g. SAE AMS 2431/7 for ceramic shot peening media) as a proven method to improve fatigue performance.

Improved Coating and Bonding Adhesion: Proper surface preparation is the foundation for any coating or adhesive to bond well. Ceramic blasting excels at creating an optimal surface texture for coatings like thermal barrier sprays, anti-corrosion platings, or structural adhesive bonding. The process can be tuned to produce a fine micro-roughness that increases surface area and mechanical “tooth” for coatings, without overly eroding the part. In comparative tests on aerospace-grade titanium, ceramic bead blasting achieved higher coating adhesion (pull-off strength ~38 MPa) than traditional aluminum oxide blasting (~32 MPa) – all while maintaining a lower surface roughness profile. In other words, ceramic media provided better paint/coating adhesion than harsher grit but with less surface damage. This is particularly beneficial for precision parts that need coatings: the ceramic-blasted surface helps the coating stay firmly attached through thermal cycles and stress, yet the part’s dimensions and integrity remain intact. Aerospace manufacturers also use ceramic blasting to prep bonded surfaces on composites and metals, finding it yields strong adhesive bond performance without leaving residues that could interfere with the adhesive. Overall, ceramic blasting produces a clean, slightly etched surface that coatings and sealants can grip onto much more effectively.

Aerospace Applications and Use Cases for Ceramic Blasting

Ceramic blasting is used across a range of aerospace components to enhance performance and longevity. Some notable use cases include:

Turbine Blades and Engine Components: Aircraft engine parts (turbine blades, vanes, and discs in jet engines or gas turbines) see extreme temperatures and stresses. These parts are commonly ceramic shot peened to improve fatigue strength and damage tolerance. The process helps blades resist crack initiation at the roots or around cooling holes, and it mitigates creep and stress corrosion in high-temperature alloys. Additionally, before applying Thermal Barrier Coatings (TBCs) or oxidation-resistant coatings, manufacturers use ceramic bead blasting to perfectly clean and roughen the blade surface. This ensures excellent coating adhesion and uniform coverage. The combined effect is that coated and peened blades can run longer at high RPM without failure. Major engine OEMs have reported significant life extension from these techniques (as noted, Rolls-Royce saw ~15–20% blade life increase by adopting ceramic peening).

Airframe Structural Parts and Landing Gear: Beyond engines, ceramic blasting is applied to many structural aerospace alloys. On airframe assemblies (e.g. aluminum or titanium wing fittings, bulkheads, and fastener hole areas), a light ceramic bead peening can relieve machining stresses and improve fatigue resistance of the finished part. This is especially useful for extending the life of parts that experience cyclic pressurization or vibration. Landing gear and other suspension components (typically made of high-strength steel or titanium) also benefit – they are often shot peened to combat fatigue and stress-corrosion cracking, and ceramic media allows this without introducing foreign metal contamination on the surface. Because ceramic beads meet strict aerospace process standards, they are trusted for treating fuselage structures, wing spars, gears, and critical joints to bolster durability. Essentially, any aerospace part that needs high reliability and endurance is a candidate for ceramic blasting in its manufacturing or maintenance process.

Surface Preparation for Coatings and Bonding: Ceramic blasting is frequently employed as a pre-treatment step whenever a subsequent coating, plating, or bonding is involved. In aircraft manufacturing, for instance, composite-to-metal bonding areas may be blasted with fine ceramic media to slightly roughen and clean the metal surface for maximum adhesive grip. Similarly, before applying paint or specialty coatings to an aircraft component, a pass with ceramic beads ensures the surface is free of oxides and has the right texture profile. This technique is used on everything from preparing engine components for thermal spray coatings to improving sealant adhesion on fuel tank surfaces. The advantage of ceramic media here is that it creates the needed surface “bite” for coatings without contamination or excessive roughness, leading to stronger bonds and fewer coating defects. Aerospace coating suppliers often recommend a ceramic grit-blast as part of their process to meet strict adhesion and surface quality requirements. In summary, whenever a precise, high-quality surface prep is required in aerospace, ceramic blasting provides a reliable solution.

Selecting the Right Ceramic Blasting Products and Suppliers

For procurement managers and engineers looking to implement ceramic blasting, choosing high-quality media and equipment is critical. Not all ceramic beads are the same, and aerospace applications require media that meet rigorous specifications. Here are key factors and recommendations for selecting ceramic blasting products:

Aerospace-Grade Media Hardness: Ensure the ceramic beads have sufficient hardness (typically ~7+ Mohs, ~700+ HV) to tackle aerospace alloys. Harder media can effectively peen nickel superalloys or titanium, whereas softer media (below Mohs 6) would shatter on such materials. Most aerospace-grade ceramic beads are zirconia-based, which provides the needed hardness and toughness.

Spherical Shape & Size Consistency: High-quality ceramic media come in tightly controlled size ranges (e.g. 100–200 µm, etc.) with near-perfect sphericity. This consistency is vital for uniform coverage and repeatable results. Look for suppliers that guarantee a tight particle size distribution and inspect their media for roundness. Spherical beads ensure even impact distribution and flow smoothly through blasting equipment without clogging.

Recyclability and Durability: One reason ceramic media is cost-effective despite higher upfront cost is its ability to be reused many times. Premium ceramic beads have high fracture toughness, meaning they resist shattering and can be recycled through dozens of blast cycles before replacement. This longevity saves money and reduces downtime for media changes. When comparing products, check the expected reuse count or breakage rate – a quality ceramic bead may last 3–5× longer than glass beads under the same conditions. Also, efficient recyclability (with proper cleaning/sieving between uses) lowers overall media consumption and waste disposal costs.

Chemical Purity (No Contaminants): Use chemically inert, pure ceramic media with no free iron or other contaminants that could transfer to your parts. For example, zirconia-based beads typically contain ~60–70% ZrO₂ with SiO₂ and minor oxides, and they do not leave any corrosive residue on surfaces. Avoid inferior ceramic or mineral media that might include metallic inclusions. Purity is especially crucial if blasting sensitive materials like titanium or if the parts will undergo subsequent plating or bonding. The goal is a residue-free surface, and a reputable supplier will provide material composition specs to ensure this.

Compliance with Aerospace Standards: Select ceramic media that meet established aerospace shot peening and blasting standards. Media like Saint-Gobain’s Zirshot® ceramic beads, for instance, conform to SAE and AMS specifications for aerospace shot peening (AMS 2431/7 for ceramic shot). Using a certified product gives confidence that the media hardness, size, and performance are within the required limits. Many aerospace primes and OEMs maintain approved source lists for blasting media – it’s wise to choose a known brand that is already trusted in the industry. Ask suppliers for documentation like conformity to SAE AMS 2431/7, J1830 or other relevant specs.

Supplier Support and Equipment Compatibility: Finally, consider suppliers who offer technical support in dialing in the process for your specific needs. A good media supplier can advise on optimal bead size for, say, peening a turbine disk vs. blasting an aluminum panel. They may also offer test data or case studies in aerospace to back their product’s performance (for example, data on fatigue improvement or surface roughness achieved). Ensure the media is compatible with your blasting equipment (pressure or wheel blast machines) – most ceramic beads work in standard systems, but verifying the size/flow is important. Some suppliers provide sample quantities for trial. Additionally, check if the supplier offers related equipment or nozzles optimized for ceramic media use, as this can further improve efficiency and results.

By focusing on the above qualities, aerospace manufacturers can confidently choose a precision blasting media that delivers consistent, high-quality results. In the market, zirconia-based ceramic beads from established suppliers (e.g. Saint-Gobain ZirPro’s Zirshot® line) are known to provide excellent peening energy transfer and a smooth finish without surface damage. These beads also require no post-blast cleaning for non-ferrous parts since they leave virtually no embedded particles. Procuring such proven media and using it with proper parameters will translate into improved component performance and reliability.

In conclusion, ceramic blasting has become an indispensable process in aerospace manufacturing for achieving superior surface finishing and strengthening of components. Its unique combination of hardness, durability, and cleanliness outshines traditional blasting media, enabling critical aircraft parts to meet rigorous performance demands. From turbine engines to airframes, the use of ceramic blasting enhances fatigue resistance, ensures coating adherence, and prolongs service life – all key factors for safety and cost-efficiency in the aerospace industry. By selecting high-quality ceramic blasting products and following best practices, companies can leverage this technology to boost production quality and ultimately gain a competitive edge in delivering top-notch aerospace components.

1 note

·

View note

Text

Glass Beads vs Ceramic Beads: A Comparative Analysis of Sandblasting Results for Medical Device Manufacturers

In the manufacturing of medical devices, sandblasting plays a crucial role in achieving surface cleanliness, micro-roughness, and biocompatibility. Among the many variables, the choice of blasting media—particularly between glass beads and ceramic beads—has become a key concern for manufacturers and quality control managers.

I. Sandblasting in Medical Device Manufacturing

When producing high-precision products such as surgical tools, implants, orthopedic plates, and dental instruments, sandblasting is used to:

Remove surface burrs and contaminants

Increase surface roughness for better coating adhesion

Achieve uniform, sterile surface texture compliant with FDA and CE standards

Therefore, selecting the right blasting media is critical for ensuring product consistency and compliance.

II. Glass Bead Sandblasting: Performance Analysis

Advantages:

Softer material, suitable for delicate components requiring minimal surface damage

Produces a satin finish with a fine texture

Cost-effective, ideal for small-batch production or R&D phases

Limitations:

Lower durability, limited reuse

Less effective on hard materials for consistent roughness

Breakage may cause dust, increasing cleaning and environmental burdens

Case Study:

A dental tool manufacturer used glass bead blasting on stainless steel handles and observed good surface uniformity. However, coating adhesion tests revealed issues, leading them to switch to ceramic beads to improve surface texture and bonding strength.

III. Ceramic Bead Blasting: Key Advantages

Benefits:

High hardness and sphericity produce stable and uniform micro-roughness

Enables micro-etching, enhancing adhesion of PVD coatings, adhesives, etc.

Purity and low dust emissions meet ISO 13485 cleanliness standards

Long lifespan, suitable for mass production and automation

Case Study:

An orthopedic implant manufacturer used ceramic beads to treat titanium alloy screws. They successfully maintained a surface roughness (Ra) under 0.8μm and improved coating adhesion by 25%.

IV. Which to Choose: Glass or Ceramic Beads?

Application TypeRecommended MediaReasonR&D or soft materialsGlass beadsLow cost, gentle processTitanium, stainless steel, hard metalsCeramic beadsConsistent finish, enhanced bondingCleanroom environmentsCeramic beadsLow dust, safe and cleanPrecision components with controlled RaCeramic beadsHigh precision, excellent surface control

V. Conclusion & Conversion Prompt

For medical device manufacturers aiming for high cleanliness, superior adhesion, and process stability, ceramic bead blasting offers distinct advantages. In today’s tightly regulated environment, choosing the right blasting media is more than a technical decision—it reflects brand reliability and commitment to quality.

Looking for tailored ceramic bead blasting solutions? Visit our official website at hlh-js.com to request technical data and samples. Let’s partner in creating world-class medical products.

#MedicalDeviceSandblasting#GlassBeadBlasting#CeramicBeadBlasting#SurfaceTreatmentMedia#MedicalManufacturingQC

1 note

·

View note

Text

3D Printing Revolution: How Low-Temperature Deburring Technology is Reshaping Manufacturing Precision and Efficiency

In the rapid development of modern manufacturing, 3D printing technology is transforming traditional production modes with its exceptional flexibility and innovation. However, surface processing of printed parts has long been a critical challenge for engineers and procurement managers. This article will delve into low-temperature deburring technology, revealing its revolutionary applications and significant advantages in the 3D printing industry.

Low-Temperature Deburring: Definition and Principles

Low-temperature deburring is an advanced surface processing technology that removes burrs and excess materials from 3D printed parts in an extremely low-temperature environment. Compared to traditional mechanical deburring methods, this technology can significantly improve processing accuracy while minimizing mechanical stress and deformation of precision parts.

Key Technological Advantages

1. Exceptional Precision Control

Traditional deburring methods often cause slight geometric deformations of parts, whereas low-temperature deburring technology can control dimensional tolerances to the micron level, ensuring high-precision requirements.

2. Strong Material Adaptability

Whether for metal, polymer, or composite 3D printed parts, low-temperature deburring technology can provide precise and uniform surface treatment with a wide range of applications.

3. Energy Efficiency and Environmental Friendliness

Compared to chemical deburring and traditional mechanical deburring, low-temperature technology significantly reduces energy consumption and minimizes harmful emissions, aligning with modern green manufacturing concepts.

Typical Application Scenarios

Aerospace Industry

Complex structured turbine blades and precision mechanical parts require extremely high surface quality, making low-temperature deburring the ideal choice.

Medical Device Manufacturing

Implants and precision medical equipment have stringent requirements for surface smoothness and burr-free conditions, which low-temperature technology perfectly meets.

Automotive Industry

Surface processing precision of engine components and transmission system parts directly impacts equipment performance, and low-temperature deburring provides an excellent solution.

Frequently Asked Questions

Q1: Is the cost of low-temperature deburring higher than traditional methods? Although the initial investment is higher, by improving product yield rates and reducing subsequent processing steps, it is economically advantageous in the long term.

Q2: How is the technology's adaptability to different materials? It has been successfully applied to multiple 3D printing materials including metals, resins, and ceramics, demonstrating exceptional versatility.

Q3: What are the obvious advantages compared to traditional deburring methods?

Higher precision

Less deformation

More environmentally friendly

Broader applicable range

Future Outlook

With continuous innovation in 3D printing technology, low-temperature deburring technology is expected to achieve further optimization in material adaptability, processing efficiency, and cost control.

Conclusion

Low-temperature deburring technology is redefining surface processing standards in the 3D printing industry. For manufacturing professionals pursuing ultimate precision and efficiency, this is undoubtedly a cutting-edge technology worth in-depth research and application.

#3D Printing#Low-Temperature Deburring#Precision Manufacturing#Surface Treatment#Industrial Innovation

1 note

·

View note

Text

Ceramic Blasting Beads: A Key Technology for Enhancing Fatigue Resistance in Medical Device Metal Components

In the modern medical device industry, the reliability and durability of metal components directly impact patient safety and treatment efficacy. From implantable devices to surgical instruments, from diagnostic equipment to therapeutic devices, metal component fatigue failure remains a significant challenge for medical device manufacturers and quality control managers. Ceramic blasting beads, as an advanced surface treatment technology, are revolutionizing the fatigue resistance performance of medical device metal components. This article will explore in depth how ceramic blasting beads enhance the fatigue resistance of medical device metal components and the special value of this technology in the medical field.

Metal Fatigue Issues in Medical Devices

Severity of Fatigue Failure

In the medical device field, metal component fatigue failure can lead to catastrophic consequences:

Implant fractures may require emergency revision surgeries

Surgical instrument failures during use may endanger patients' lives

Diagnostic equipment malfunctions may lead to misdiagnosis or delayed treatment

Therapeutic device failures may interrupt treatment plans

FDA data indicates that approximately 25%-30% of medical device recall events are related to metal component fatigue failures, causing serious impacts on patient safety and healthcare institutions.

Unique Challenges Facing Medical Device Metal Components

Medical device metal components face unique challenges:

Biocompatibility requirements: Materials must be non-toxic, harmless, and not cause immune responses

Strict sterilization conditions: Must withstand high temperature, high pressure, radiation, and other sterilization methods

Complex physiological environments: Long-term exposure to corrosive body fluids

Cyclic loading conditions: Such as orthopedic implants bearing periodic physiological loads

Zero-tolerance requirements: Medical devices cannot allow any risk of failure

These challenges make medical device metal components face more severe fatigue issues than general industrial applications.

Technical Characteristics of Ceramic Blasting Beads and Advantages in Medical Applications

Ceramic blasting beads offer unique application advantages in the medical device field:

Good biocompatibility: Materials like zirconium oxide and aluminum oxide have passed ISO 10993 biocompatibility testing

No residual contamination: Will not leave particles on component surfaces that could cause infection

High surface cleanliness: Can thoroughly remove surface machining marks and contaminants

Controllable surface roughness: Can adjust surface topological structure according to different medical device requirements

Non-magnetic: Will not affect the use of magnetic-sensitive medical equipment such as MRI

Medical-grade ceramic blasting beads typically have the following technical parameters: Technical Parameter Typical Specification Significance in Medical Applications Sphericity >98% Ensures surface treatment uniformity Purity >99.9% Avoids chemical contamination Hardness Mohs 9 Suitable for treating hard materials such as titanium alloys Particle size range 20-150μm Can be used for precision medical devices Surface finish Ra 0.1-0.8μm Meets different interface contact requirements

Mechanisms by Which Ceramic Blasting Beads Enhance Medical Device Fatigue Resistance

1. Formation of Residual Compressive Stress Layer

When ceramic blasting beads impact the metal surface at high speed, they form a residual compressive stress layer on the surface. This mechanism is particularly important for medical devices because:

The compressive stress layer effectively prevents micro-crack initiation and propagation in fluid environments

It improves the resistance of medical-grade metals such as titanium alloys and stainless steel to corrosion fatigue

It is especially important for implants that bear alternating loads (such as orthopedic screws, bone plates, artificial joints)

Research shows that appropriate ceramic blasting treatment can form a compressive stress layer with a depth of 0.1-0.2mm on medical-grade titanium alloy surfaces, increasing fatigue life by 100%-200%.

2. Microstructure Optimization

In medical device applications, microstructure optimization has special significance:

Grain refinement improves the metal's yield strength, enhancing implant resistance to deformation

Increased dislocation density reduces stress concentration phenomena in physiological environments

Changed microstructure facilitates cell attachment and tissue integration (crucial for osseointegration)

Microstructure optimization can significantly improve the safety factor of medical devices, especially in the field of long-term implants.

3. Surface Topography Control

For medical devices, surface topography control has dual significance:

Mechanical aspect: Appropriate surface roughness reduces fatigue crack sources

Biological aspect: Optimized surface microstructure promotes cell attachment and biological integration

Different types of medical devices require different surface topographical structures: Medical Device Type Recommended Surface Roughness (Ra) Purpose Orthopedic implants 1.0-2.0μm Promote osseointegration Joint replacements 0.05-0.2μm Reduce friction and wear Cardiovascular stents 0.3-0.8μm Improve blood compatibility Dental implants 1.5-2.5μm Enhance tissue bonding Surgical instruments 0.1-0.4μm Improve corrosion resistance and cleanliness

4. Surface Bioactivity Regulation

Unique to medical applications, ceramic blasting can also regulate metal surface bioactivity:

Change surface energy and wettability, affecting protein adsorption and cell attachment

Adjust the chemical composition and structure of the surface oxide layer

Provide an ideal foundation for subsequent surface functionalization treatments (such as hydroxyapatite coating)

This bioactivity regulation both improves device biocompatibility and enhances metal fatigue resistance, forming a dual safeguard.

Ceramic Blasting Process Optimization in Medical Device Production

Medical devices have requirements for surface treatment far higher than general industrial applications, and ceramic blasting processes must be conducted under strictly controlled conditions:

Key Process Parameters

Process Parameter Medical-Grade Recommended Range Special Considerations Blasting pressure 0.3-0.5MPa Adjust according to device size and wall thickness Blasting distance 80-150mm Uniformity control Blasting time 20-90s Avoid excessive treatment causing precision loss Bead specification 20-150μm Determined by device precision and surface requirements Coverage requirement >98% Ensure no fatigue-weak zones

Special Process Control Points

Contamination-free process environment: Clean room grade blasting environment to prevent particle contamination

Batch quality control: 100% surface inspection to ensure zero defects

Parameter validation: Validate blasting parameters through fatigue testing

Sterilization compatibility: Ensure blasted surfaces can withstand subsequent sterilization processes

Traceability: Complete process recording, complying with medical device regulatory requirements

Medical Device Application Case Studies

Case 1: Titanium Alloy Spinal Fixation System

Challenge: Spinal fixators bear complex cyclic loads in the body, with fatigue failure being the main issue.

Solution: 45-75μm zirconium oxide ceramic blasting treatment of titanium alloy spinal screws and connecting rods.

Results:

Fatigue strength increased by 36%

Failure rate reduced from 2.3% to 0.4%

Patient revision surgery rate decreased by 75%

Product 5-year survival rate improved to 98.7%

Case 2: Stainless Steel Orthopedic Surgical Instruments

Challenge: Orthopedic surgical instruments require repeated use and sterilization, facing serious stress corrosion fatigue issues.

Solution: 50-100μm aluminum oxide ceramic blasting treatment, forming a uniform surface compressive stress layer.

Results:

Instrument service life extended 2.5 times

Sterilization cycle resistance improved by 40%

Surface corrosion resistance increased by 65%

Repair and replacement costs reduced by 58%

Case 3: Cobalt-Chrome Alloy Artificial Hip Joints

Challenge: Artificial hip joints require excellent fatigue strength and biocompatibility.

Solution: Two-stage ceramic blasting: coarse blasting (125μm) to form a compressive stress layer, fine blasting (45μm) to optimize surface topographical structure.

Results:

Fatigue strength improved by 43%

Friction coefficient reduced by 28%

Metal ion release decreased by 67%

Implant service life increased from 12 years to over 20 years

Case 4: Nitinol Cardiovascular Stents

Challenge: Cardiovascular stents work in a pulsating environment, requiring extremely high fatigue resistance and blood compatibility.

Solution: Ultra-fine (20-45μm) zirconium oxide blasting, optimizing surface morphology and oxide layer.

Results:

Stent fatigue life increased to over 400 million cycles

Thrombosis risk reduced by 32%

Restenosis rate decreased by 26%

Product safety incident reports reduced by 81%

Quality Control and Regulatory Compliance

For medical device manufacturers and quality control managers, ceramic blasting treatment is not just a technical means to improve product performance but also a key step in ensuring regulatory compliance:

FDA and NMPA Compliance Points

Process validation: Required according to FDA 21 CFR 820.75 and relevant NMPA regulations

Surface characteristic testing: Including ASTM F86 surface inspection and ISO 4287 surface roughness testing

Fatigue testing requirements: Compliance with standards such as ASTM F1801, ISO 14242

Biocompatibility assessment: Comprehensive biological evaluation according to ISO 10993-1

Risk management: Incorporating blasting treatment into ISO 14971 risk management system

Key Quality Control Testing Methods

Test Item Test Method Acceptance Criteria Surface roughness Surface profilometer Within design specifications ±10% Residual stress X-ray diffraction Surface compressive stress >200MPa Coverage Microscopic inspection >98% Surface defects Electron microscopy No cracks, peeling, or sharp edges Metal ion release ICP-MS Below ISO standard limits Accelerated fatigue testing According to ISO standards Achieves 5 times design life or more

Cost-Benefit Analysis: Medical Device Perspective

In the medical device field, the cost-benefit of ceramic blasting technology needs to be evaluated from multiple levels:

Direct Cost Benefits

Reduced product recall costs: Each medical device recall costs an average of $3-7 million; improving fatigue performance can significantly reduce recall risks

Decreased warranty claims: Fatigue-related failure claims reduced by 65%-80%

Extended product life: Implant service life extended by 50%-100%, reducing revision surgery rates

Enhanced market competitiveness: Product reliability becomes a key selling point, increasing brand value

Indirect Cost Benefits

Accelerated regulatory approval: Reliable fatigue data support speeds up registration and approval processes

Improved physician and patient satisfaction: Reduces medical disputes caused by device failures

Better insurance coverage: Higher reliability devices more easily obtain insurance coverage

Enhanced corporate reputation: Avoids negative publicity due to product fatigue failures

Return on investment analysis shows that in the high-end medical device field, investment in ceramic blasting technology typically pays back within 18-24 months, with long-term ROI exceeding 300%.

Frequently Asked Questions (FAQs)

Does ceramic blasting treatment affect the sterilization efficacy of medical devices?

No. On the contrary, appropriate ceramic blasting treatment can improve the surface microstructure, reducing microbial attachment points and enhancing sterilization effectiveness. Research shows that optimized ceramic blasting treatment can improve the Sterility Assurance Level (SAL) of medical device surfaces.

Do different types of medical-grade metals require different ceramic blasting materials?

Yes, different metals require different blasting materials and parameters:

Titanium alloys: Zirconium oxide beads recommended (matching hardness, avoiding embedding)

Stainless steel: Can use aluminum oxide or zirconium oxide beads

Cobalt-chrome alloys: Zirconium oxide beads recommended (reducing surface contamination)

Nitinol: Must use ultra-fine zirconium oxide beads (avoiding damage to superelastic properties)

What post-processing steps are required after ceramic blasting treatment?

Medical devices typically require the following post-processing steps:

Ultrasonic cleaning (removing all residual particles)

Passivation treatment (forming a stable oxide layer)

Electrochemical polishing (for certain applications)

Surface functionalization (if special biological characteristics are needed)

Sterilization packaging (preventing contamination)

How does ceramic blasting affect the service life of medical devices?

By increasing fatigue strength and reducing corrosion sensitivity, ceramic blasting can significantly extend medical device service life:

Implantable devices: Life extended by 50%-100%

Surgical instruments: Usage cycle count increased by 150%-200%

Diagnostic equipment: Metal component failure interval extended 3-5 times

How is the consistency and reliability of the ceramic blasting process validated?

The medical device industry uses the following methods to validate process consistency:

Process Validation Studies (PVS)

Statistical Process Control (SPC)

Failure Mode and Effects Analysis (FMEA)

Accelerated Life Testing (ALT)

Real-time stability monitoring and data trend analysis

Future Development Trends

Ceramic blasting technology in the medical device field is developing in the following directions:

Biofunctionalized blasting materials: Ceramic beads containing antibacterial elements or bioactive factors

Gradient blasting technology: Achieving different surface characteristics in different areas of the same component

Intelligent monitoring blasting systems: Real-time quality control based on machine vision and AI

Personalized parameter optimization: Adjusting implant surface characteristics according to specific patient needs

Hybrid processes combined with 3D printing: Providing optimal surface treatment for complex geometries

Conclusion

Ceramic blasting bead technology provides significant improvements in fatigue resistance for medical device metal components, which has special significance in the medical field. Through forming residual compressive stress layers, optimizing microstructures, controlling surface topography, and regulating bioactivity, ceramic blasting technology not only improves the safety and reliability of medical devices but also extends service life, reduces patient risk, and decreases healthcare costs.

For medical device manufacturers and quality control managers, understanding and correctly applying ceramic blasting technology is a key strategy for improving product quality, ensuring regulatory compliance, and enhancing market competitiveness. As medical devices develop toward smaller size, more functionality, and greater personalization, ceramic blasting technology will continue to play an irreplaceable role, providing more reliable safeguards for patient safety and treatment efficacy.

2 notes

·

View notes