HHV Advanced Technologies excels at executing large, highly sophisticated custom thin film deposition equipment for a wide range of applications. It has been designing, developing, and manufacturing thin-film coatings and optics for the space, defense, and industrial sectors.For more information, Visit: https://hhvadvancedtech.com/

Don't wanna be here? Send us removal request.

Text

HHV Advanced Technology -Thin Film Equipment Division

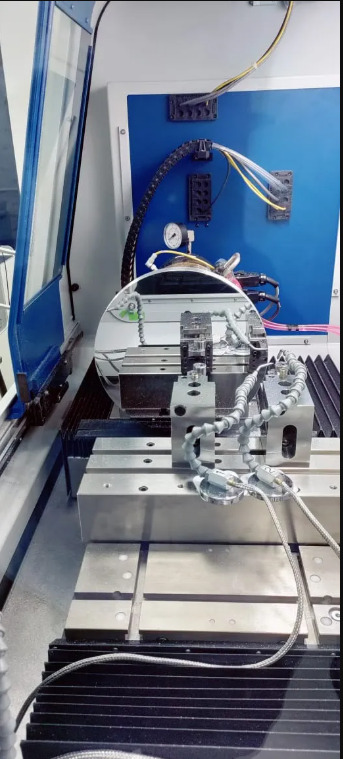

For over five decades, HHV Advanced Technologies has been designing, developing and manufacturing customized thin-film deposition systems to fulfill the needs of the scientific and industrial community. HHVAT's R&D team has been closely associated with world renowned scientists in thin film technology to develop challenging and advanced thin film deposition system products. These unique thin film deposition equipments have been successfully demonstrated for functional performance, product quality and repeatability. HHVAT constantly upgrades its manufacturing capabilities to keep in-line with the evolving demands of the thin-film coating and equipment market. HHVAT manufacturing processes include engineering design, process automation, precision machining and fabrication, electro polishing, TIG welding, vacuum brazing, global supply chain, electro-mechanical assembly and comprehensive product testing.

Learn more: https://hhvadvancedtech.com/thin-film-equipment#products Email: [email protected]

0 notes

Text

Atomic Layer Deposition

HHV Advanced Tech sets the standard with Atomic Layer Deposition for superior thin film performance. Achieve unparalleled control and breakthrough applications.

0 notes

Text

Thin Film Coating Manufacturers

As a trusted Optical Component Manufacturer, HHV Advanced Technologies specializes in Thin Film Technology, providing high-precision coatings and customized optical solutions.

For more Details, Visit: https://hhvadvancedtech.com/

0 notes

Text

Advanced Thin Film Coating

HHV Advanced Tech pioneers Thin Film Coating, defining excellence in optical and electronic applications. Experience precision and innovation like never before.

For more Details, Visit: https://hhvadvancedtech.com/thin-films-and-optics

0 notes

Text

Precision, Innovation, and Reliability: Inside HHV’s Thin Film Deposition Systems

As modern technology rapidly evolves, the demand for high-performance coatings across electronics, optics, defense, and renewable energy sectors has surged. At the heart of these innovations lies a foundational process: thin film deposition. To meet the industry's growing needs, HHV Advanced Technologies delivers advanced Thin Film Deposition Systems designed with precision, innovation, and long-term reliability in mind. As a pioneer in vacuum science and thin film solutions, HHV empowers research institutions, universities, and industries with systems that offer unmatched quality and consistency. The Role of Thin Film Deposition Systems in High-Tech Applications

Thin Film Deposition Systems are essential for creating layered materials at the micro- and nanoscale. These systems are used in a wide range of industries—semiconductors, aerospace, medical devices, and optical coatings—where performance and accuracy are non-negotiable. The process involves the application of thin material layers, typically measured in nanometers, onto a substrate to modify its electrical, optical, or mechanical properties.

HHV Advanced Technologies offers a comprehensive range of thin film solutions, including Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), and customized coating systems. Their equipment supports processes such as thermal evaporation, electron beam evaporation, and sputtering—each suited for specific materials and applications. These Thin Film Deposition Systems are developed with robust vacuum technology, precision control, and scalable configurations, ensuring they meet the dynamic needs of both research laboratories and full-scale manufacturing units.

From creating anti-reflective coatings for optics to developing advanced semiconductors and solar panels, HHVATs systems deliver consistent, high-quality films that stand up to demanding use cases.

What Sets HHVATs Thin Film Deposition Systems Apart

HHV Advanced Technologies distinguishes itself through a commitment to customer-focused design, quality engineering, and continual innovation. Every system they manufacture is backed by decades of experience in vacuum technology and material science. Their Thin Film Deposition Systems feature intuitive interfaces, advanced automation, and customizable configurations in power supply to chamber size, turbo pumps for better control on vacuum, HMI panels for interface to match specific project requirements.

HHV also places strong emphasis on research collaboration, offering tailored solutions for educational institutions and research centers. Their systems are designed to be modular, allowing for easy upgrades and adjustments as research goals evolve. Additionally, HHV’s global support team ensures seamless installation, training, and after-sales service, critical for maintaining uptime and performance in demanding lab or industrial settings.

What truly sets HHV apart is the integration of reliability into every step of the design and manufacturing process. From cleanroom compatibility to high-vacuum integrity, HHV’s systems are built to deliver long-term performance with minimal downtime. This makes them the trusted choice for clients who require dependable, repeatable, and scalable thin film processes.

Conclusion

Precision, innovation, and reliability are the cornerstones of HHV Advanced Technologies' approach to vacuum and coating technology. Their state-of-the-art Thin Film Deposition Systems are helping shape the future of materials science by enabling everything from solar cell development to advanced semiconductor fabrication. Whether you're a researcher exploring new frontiers or a manufacturer seeking consistent performance, HHV offers the technology and support to help you succeed.Top of Form

Contact Us

For more information, Visit:https://hhvadvancedtech.com/

Site No. 17, Phase 1, Peenya Industrial Area, Bengaluru – 560058, India

Phone: +91-80-66703700

Fax: +91-80-66703800

Email: [email protected]

0 notes

Text

Revolutionizing Thin Film Coating with Cutting-Edge Atomic Layer Deposition Equipment from HHV Advanced Technologies

Precision and consistency are the cornerstones of innovation in the ever-evolving world of nanotechnology and advanced materials. Thin film coatings are integral to various industries, including semiconductors, optics, aerospace, and renewable energy. Among the various coating techniques, Atomic Layer Deposition Equipment stands out as a game-changer, delivering atomically precise films with unmatched control. HHV Advanced Technologies, a leader in vacuum science and thin film technology, is at the forefront of this revolution. By offering cutting-edge Atomic Layer Deposition Equipment, HHV is enabling researchers and manufacturers to push the boundaries of what’s technologically possible.

Understanding the Power of Atomic Layer Deposition Equipment

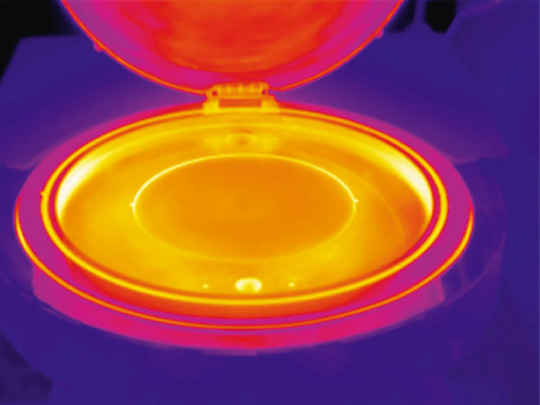

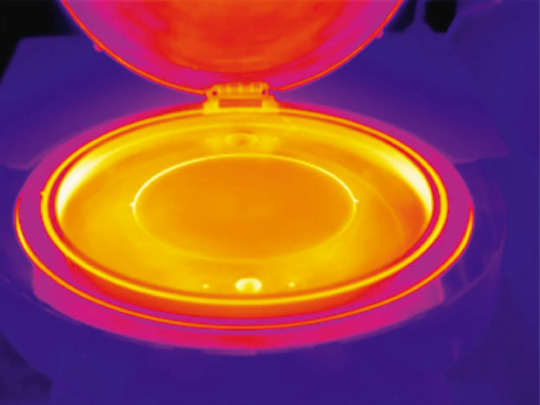

Atomic Layer Deposition (ALD) is a highly controlled technique that allows wafer deposition layer-by-layer at the atomic scale. This method offers unparalleled precision, which is essential for fabricating next-generation electronic devices, high-performance semiconductor wafers, and Anti Reflection ARC coatings. The true power of Atomic Layer Deposition Equipment lies in its ability to provide uniform coatings over complex surfaces, making it ideal for microelectronics, MEMS, and nanotechnology applications.

HHV Advanced Technologies has developed state-of-the-art Atomic Layer Deposition Equipment that meets the rigorous demands of both R&D and industrial environments for wafer size upto 8 Inches. Their systems are engineered to ensure consistent deposition, excellent repeatability, and process flexibility. Whether it’s for producing ultra-thin dielectric layers in semiconductor devices or creating multi layer high-quality coatings for solar cells, HHV’s ALD systems deliver dependable performance every time.

HHV’s Technological Edge in Thin Film Solutions

What sets HHV Advanced Technologies apart is its commitment to innovation, customization, and quality. Their Atomic Layer Deposition Equipment is designed to accommodate a wide range of materials, including oxides, nitrides, and metals, enabling researchers to explore diverse material combinations with confidence. HHV's in-house expertise and customer-centric approach allow them to tailor equipment to specific research or production requirements.

Moreover, HHV integrates cutting-edge automation and control features into its ALD systems, enhancing usability and process accuracy. This makes the systems powerful and user-friendly—ideal for academic institutions, government labs, and industrial R&D centers. With their robust design and long-term support, HHV’s ALD solutions empower users to scale from experimentation to production seamlessly.

Their comprehensive service offering, which includes installation, training, and technical support, ensures that customers are equipped with everything they need to succeed in thin film coating. As industries increasingly demand higher performance from smaller and more complex devices, HHV’s Atomic Layer Deposition Equipment is the trusted tool to meet those expectations.

Conclusion

Atomic Layer Deposition is not just a technique—it’s a cornerstone of next-generation material engineering. With HHV Advanced Technologies leading the charge, industries across the globe are experiencing a new era of precision, performance, and potential. Their cutting-edge Atomic Layer Deposition Equipment is empowering innovation across sectors by delivering reliable and advanced thin film solutions.

Top of FormFor more information, visit the website: https://hhvadvancedtech.com/

0 notes

Text

Thin Films and Optics Facility Tour- HHV Advanced Technologies

HHV Advanced Technologies' Thin Films and Optics division is a leading manufacturer of high precision optical components and thin film coatings. The manufacturing unit includes facilities for optical polishing, high end metrology, thin film coating and testing capabilities. The Thin Films and Optics Division has a wide range of technical coating and optics focused capabilities. HHVAT provides end to end services from customized design to supplying coated optical components.

youtube

0 notes

Text

Hybrid Micro Circuits

Explore HHV Advanced Tech's space-grade hybrid micro circuits, featuring superior thin film metallization through magnetron sputtering and electrical properties.

For more information visit our website: https://hhvadvancedtech.com/thin-films-and-optics/thin-films-and-optics/products/space/hybrid-micro-circuits

0 notes

Text

Antireflection Coatings Suppliers

Experience clarity and precision with HHV Advanced Tech, leading Antireflection Coatings Suppliers. Discover excellence in Thin Film Optical Coatings capabilities.

For more Details, Visit: https://hhvadvancedtech.com/thin-films-and-optics/thin-films-and-optics/capabilities/optical-coating

0 notes

Text

Empowering Aerospace & Defense: Optical Components Engineered by HHV Advanced Technologies

In today's rapidly evolving aerospace and defense sectors, precision and performance are non-negotiable. Optical components play a crucial role in enhancing the capabilities of systems used in surveillance, navigation, imaging, and communication. Meeting these high standards requires a combination of technological expertise, cutting-edge infrastructure, and industry foresight — all of which are hallmarks of HHV Advanced Technologies. As a leading optical component manufacturer, HHV Advanced Technologies has become synonymous with innovation and reliability in the aerospace and defense industries.

Pioneers in Thin Film and Optical Engineering

With over 61 years of experience, HHV Advanced Technologies stands at the forefront of thin film coating manufacturers in India and abroad. The company has consistently led advancements in high vacuum equipment, customized PVD and CVD coating systems, and high-precision optical components tailored for critical applications. Their legacy is deeply embedded in scientific excellence, with contributions to both research and industrial sectors across the globe.

The Thin Films and Optics division of HHV Advanced Technologies is a testament to this engineering excellence. This division focuses on designing and delivering top-tier optical components with superior surface quality, accurate dimensions, and highly specialized thin film coatings that meet the stringent requirements of the aerospace and defense sectors.

Customized Solutions for Aerospace and Defense

One of the key differentiators of HHV Advanced Technologies is its ability to develop customized thin-film deposition equipment and coated optical components for demanding environments. In aerospace and defense, where components must endure extreme conditions — from high altitudes to fluctuating temperatures — precision-engineered optics become mission-critical.

As a trusted optical component manufacturer, HHV offers end-to-end capabilities from design to manufacturing that include optical polishing, thin film deposition, high-end metrology, and quality testing. Their optical solutions are used in a variety of defense applications such as thermal imaging systems, laser targeting, avionics, and satellite communication — all requiring the highest level of precision and durability.

Moreover, HHV’s ability to deliver customized PVD and CVD systems for high-performance coatings ensures long-lasting and reliable performance of the optical elements, even in the most rigorous conditions.

Advanced R&D and Technological Leadership

Backed by a dedicated R&D team, HHV Advanced Technologies collaborates with globally recognized scientists to push the boundaries of what’s possible in thin film technology. The company was the first in India to build a thermal ALD system and has since expanded its offerings to include Plasma ALD, RIE and PECVD systems for electronic and optical applications.

Their state-of-the-art manufacturing unit houses advanced tools for deposition and testing, enabling the production of ultra-precise optical components. This not only makes them a preferred optical component manufacturer but also places them among the elite thin film coating manufacturers with the ability to deliver both standardized and tailor-made solutions.

Global Footprint and Industrial Impact

Ranked among global leaders in thin film technology, HHV Advanced Technologies has established a strong international market presence. Their optical and coating solutions serve industries beyond defense and aerospace, including automotive, scientific research, semiconductors, and renewable energy.

The company's contributions are particularly significant in India’s growing satellite space and defense programs, where homegrown technology and manufacturing capabilities are essential. HHVAT’s commitment to engineering excellence and innovation continues to empower mission-critical operations, reinforcing its position as a strategic partner in national and international defense and aerospace initiatives.

Conclusion

As aerospace and defense applications grow more complex, the need for advanced optical technologies becomes even more critical. HHV Advanced Technologies, with its rich heritage, robust infrastructure, and pioneering spirit, is ideally positioned to meet these challenges. As a top-tier optical component manufacturer and one of the most reliable thin film coating manufacturers, HHV is not just contributing to the future of aerospace and defense — it’s engineering it.

Contact Us

For more information, Visit: https://hhvadvancedtech.com/

Site No. 17, Phase 1, Peenya Industrial Area, Bengaluru – 560058, India

Phone: +91-80-66703700

Fax: +91-80-66703800

Email: [email protected]

0 notes

Text

Customized Coating Solutions for Periscope Prisms & Optical Assemblies

In the world of precision optics, the need for customized coating solutions has become critical for achieving superior performance, especially in components like periscope prisms and optical assemblies. These elements are essential in numerous high-tech applications, ranging from defense systems to space exploration, and demand high levels of clarity, durability, and reliability. HHV Advanced Technologies (HHVAT) has emerged as a pioneer in this domain, offering cutting-edge solutions through its specialized Thin Films and Optics division.

Delivering Precision with Customized Optical Coatings

Thin Film Optical coatings significantly influence the functionality of an optical assembly. By tailoring coatings for specific wavelengths, angles of incidence, and environmental conditions, manufacturers can enhance the performance of periscope prisms and other optical devices. HHVAT provides customized thin film deposition solutions that are engineered to meet the precise needs of each application. Whether it’s improving transmission, minimizing reflection, or enhancing durability under harsh conditions, for use in military, Submarine and defense applications these coatings play a pivotal role in Optics collections.

HHVAT’s facility is equipped with advanced capabilities for thin film coating, including high vacuum deposition, sputtering, and electron beam evaporation techniques. These methods allow for the creation of thin films optics with exceptional surface uniformity and accuracy, ensuring performance consistency across batches.

State-of-the-Art Infrastructure and Capabilities

HHVAT’s Thin Films and Optics division boasts a world-class manufacturing setup that includes optical polishing, high-end metrology, and comprehensive testing infrastructure. In house manufacturing enables the company to maintain tight control over every stage of production, ensuring unmatched quality for its coated optics. With a deep focus on research and development, HHVAT continuously innovates to develop novel coating solutions tailored to emerging industry demands.

A key strength of HHVAT lies in its ability to offer end-to-end solutions—from the customized design of coatings to the final delivery of finished optical components. The company’s expertise extends across a wide array of optics, including dichroic coated optics, laser filters, narrow band interference filters, hybrid microcircuits, periscope prisms, and thin films optics used in both industrial and defense sectors.

Specialized Solutions for Periscope Prisms

Periscope prisms are integral components in various optical systems, especially in defense, tankers and surveillance applications. They require coatings that provide excellent transmission above 90% in specific wavelength ranges while also resisting environmental stress. HHVAT delivers customized coating design and manufacturing technology, solutions that meet these complex requirements, ensuring high-performance operation in even the most demanding scenarios.

By applying high-precision thin film multi-layer metal coating like Silver and Copper, HHVAT enhances the optical properties of periscope prisms, such as reflectivity and spectral selectivity. These coatings are designed to function flawlessly under conditions involving high humidity, temperature variations, and mechanical vibrations, which are typical in military-grade optical devices.

Versatility in Applications

The benefits of HHVAT’s thin films optics extend beyond periscope prisms to a broad spectrum of optical assemblies used in space, medical imaging, automotive sensors, and laser systems. Each application demands unique coating properties, which HHVAT addresses through its vast technical expertise and customizable manufacturing processes.

In the realm of space technology, for example, HHVAT’s coatings are designed to withstand the vacuum of space, radiation exposure, and thermal extremes. In Defense applications, coatings are optimized for Wear resistance, chemical stability and electrical insulation opting for better spectral control. This adaptability showcases HHVAT’s capability to provide value-driven solutions across industries.

Partnering for Optical Excellence

Choosing HHVAT as a partner means gaining access to decades of experience in thin film coating and thin films optics manufacturing. Their commitment to quality, innovation, and customer-centric solutions makes them a trusted supplier for critical optical systems worldwide. From initial design consultation to the final delivery of coated periscope prisms and assemblies, HHVAT ensures every product meets the highest standards of optical performance.

In conclusion, HHV Advanced Technologies continues to lead the industry with its customized coating solutions for periscope prisms and optical assemblies. Through their specialized Thin Films and Optics division, they are pushing the boundaries of what’s possible in thin film coating technology—delivering performance, precision, and reliability in every component.

For more information, visit the website: https://hhvadvancedtech.com/

0 notes

Text

Advanced Thin Film Coating

HHV Advanced Tech pioneers Thin Film Coating, defining excellence in optical and electronic applications. Experience precision and innovation like never before.

For more Details, Visit: https://hhvadvancedtech.com/thin-films-and-optics

0 notes

Text

Ion Etching Process

HHV Advanced Tech sets the standard with Atomic Layer Deposition for superior thin film performance. Achieve unparalleled control and breakthrough applications.

0 notes

Text

Enhancing Optical Component Durability and Efficiency through Advanced Coating Techniques

In the field of precision optics, the deposition techniques of Thin Film Optical Coatings plays a crucial role in improving the durability, efficiency, and performance of optical components. These coatings may be designed for achieving Anti-Reflection, enhancing transmission, and protecting surfaces from environmental damage. With advancements in Thin Film Technology, manufacturers can now achieve superior optical performance while ensuring long-term stability and reliability.

Importance of Thin Film Optical Coatings

Optical components such as lenses, mirrors, and filters require specialized coatings to optimize their functionality. Thin Film Optical Coating Equipments are designed to control light reflection, transmission, and absorption, enabling high-performance applications in industries like aerospace, defense, medical imaging, and telecommunications. Vacuum Coating Techniques in Thin Film Deposition

HHV Advanced Technologies (HHVAT) has established itself as a leader in Thin Film Technology, offering cutting-edge coating solutions for various optical applications. The company’s Thin Film Optical Coatings are applied using multiple deposition techniques, ensuring precision and durability. HHVAT’s thin films production facility houses over twenty-five deposition systems, enabling the processing of substrates up to 600 mm for thermal evaporation and 1000 mm for sputtering deposition.

Major Physical Vapour deposition techniques include:

Thermal Evaporation: This process involves heating a source material in a vacuum chamber to create a vapor that condenses on the optical substrate. It is widely used for anti-reflective and high-reflective coatings.

Electron Beam Evaporation: Employs a focused beam of electrons to vaporize the material, allowing for higher purity and better control of the film's composition.

Ion-Assisted Deposition (IAD): This technique integrates ion bombardment during the coating process, improving film adhesion and reducing defects, leading to higher coating efficiency.

Sputtering Deposition: This method utilizes ionized gas to eject atoms from a target material, depositing a thin layer onto the optical component. Sputtering provides superior adhesion and density, enhancing the durability of the coating.

Dual Ion Beam Sputtering: a thin-film deposition technique that uses two ion sources: one for sputtering the target material and another for assisting in film growth, leading to improved film quality and control

Coating Metrology and Quality Assurance

To ensure the highest quality standards, Thin Film Optical coatings have to meet various standards of qualification which is specific to use cases. HHV Advanced Technologies employs advanced metrology instruments to evaluate the performance and durability of Thin Film Optical Coatings. These include:

Perkin Elmer Spectrophotometer for precise optical property measurement

Fourier Transform Infrared (FTIR) Spectrophotometer for infrared analysis

SEM with an EDX module for structural and compositional analysis

Environmental and Salt Spray Chambers to test durability under extreme conditions

These state-of-the-art metrology tools enable HHVAT to maintain consistency in coating performance while ensuring compliance with industry standards.

Advancements in Thin Film Technology

The demand for high-performance optical coatings continues to rise, prompting advancements in Thin Film Technology. Innovations in nanostructured coatings, plasma-enhanced deposition, and multilayer coatings are driving the next generation of optical enhancements. With these advancements, HHVAT remains at the forefront of the industry, providing customized Thin Film Optical Coatings for a wide range of applications.

Conclusion

As industries increasingly rely on precision optics, the need for durable and efficient optical coatings has never been greater. As use of optics grows with industrial applications the demand for precision is catching up too. For example, laser optics needs Laser Induced Damage Threshold certification (LIDT). Optical mirrors now seek 99.9% high Reflection for selected wavelengths in Visible Spectrum, 0.25% Ultra Low Reflection across UV-IR range. With its cutting-edge deposition techniques and rigorous quality control, HHVAT continues to lead the way in enhancing optical component durability and efficiency through superior Thin Film Optical Coatings.

Contact Us

For more information, Visit: https://hhvadvancedtech.com/

Site No. 17, Phase 1, Peenya Industrial Area, Bengaluru – 560058, India

Phone: +91-80-66703700

Fax: +91-80-66703800

Email: [email protected]

0 notes

Text

Custom Optical Filters: Meeting the Demands of Medical and Scientific Applications

In the evolving landscape of medical and scientific applications, custom optical filters play a critical role in enhancing precision, efficiency, and accuracy. These specialized filters are designed to manipulate light by transmitting, reflecting, or blocking specific wavelengths. Optical Filters Suppliers must meet the stringent demands of industries such as biomedical research, spectroscopy, and laser-based technologies.

The Role of Custom Optical Filters

Custom optical filters are used in various fields, including flame photometry, biomedical instrumentation, and industrial laser systems. These filters must exhibit high durability, optical clarity, and resistance to environmental stressors. HHV Advanced Technologies, a leading name in the industry, manufactures a broad range of optical filters tailored to meet the needs of medical and scientific applications.

Types of Optical Filters

HHV Advanced Technologies produces an array of filters to suit different applications. These include:

Flame Photometry Filters – Designed for precise detection of elements like sodium, potassium, calcium, lithium, and barium.

Neutral Density Filters – Used to attenuate light intensity without altering its spectral composition.

Short Pass Filters – Allow shorter wavelengths to pass while blocking longer wavelengths.

Long Pass Filters – Permit longer wavelengths to pass while blocking shorter ones.

Band Pass Filters – Transmit a specific range of wavelengths while blocking others.

Notch Filters – Block a narrow range of wavelengths while allowing others to pass.

Edge Filters – Used to separate spectral regions for fluorescence and Raman spectroscopy.

Coloured Glass Filters – Provide unique spectral characteristics for biomedical imaging and laser applications.

Key Features of Optical Filters

Substrates: BK7, Borofloat, UV Fused Silica, Quartz

Dimension: Diameter up to 1 inch

Durability: Compliant with MIL-C-675C standards

Additional: Flame photometry filters for elements like Sodium, Potassium, Calcium, Lithium, and Barium

Applications in Medical and Scientific Fields

Flame Photometry: Custom optical filters enable the precise analysis of metal ions in biological and chemical samples.

Biomedical Instrumentation: Filters play a vital role in imaging systems, fluorescence microscopy, and blood analysis.

Industrial Lasers: High-performance laser optics ensure precise beam delivery and wavelength control in laser cutting, welding, and medical laser treatments.

Advancements in Optical Filter Technology

The demand for high-precision Laser Optics and biomedical filters continues to grow. Advanced thin-film deposition techniques have revolutionized optical filters, allowing for superior durability, high transmission efficiency, and minimal signal interference. Innovations in coating technologies ensure filters can withstand extreme environments while maintaining optimal performance.

Choosing the Right Optical Filters Supplier

Selecting the right optical filters suppliers is crucial for achieving high-quality results in medical and scientific applications. With a commitment to excellence and innovation, HHV Advanced Technologies offers a diverse range of optical filters designed to meet industry-specific requirements. Their expertise in precision coatings and material selection ensures reliable performance in demanding environments.

In conclusion, custom optical filters are indispensable in medical diagnostics, scientific research, and industrial laser applications. As technology advances, the need for high-performance filters will continue to rise, making it essential to source them from reputable optical filters suppliers like HHV Advanced Technologies.

For more information, visit the website: https://hhvadvancedtech.com/

0 notes

Text

Single Point Diamond Turning

HHV Advanced Tech pioneers Single Point Diamond Turning, ensuring superior optics fabrication. Experience epitome of precision and innovation in thin film technology.

0 notes

Text

Antireflection Coatings Suppliers

Experience clarity and precision with HHV Advanced Tech, leading Antireflection Coatings Suppliers. Discover excellence in Thin Film Optical Coatings capabilities.

1 note

·

View note