Don't wanna be here? Send us removal request.

Text

Control Power Transformer (CPT) A Control Power Transformer (CPT) is a specialized transformer designed to supply power to control circuits or auxiliary equipment in electrical systems. It steps down the high voltage from the main supply to a lower, manageable voltage suitable for control devices like relays, contactors, and indicator lights. These transformers are built for high reliability, often featuring insulation and protection against voltage spikes to ensure smooth and safe operation. CPTs are commonly used in industrial control panels, motor starters, and automation systems to provide consistent power for control and monitoring functions.

c3controls has launched a new product, "CPT," which is ideal for industrial control panels, motor starters, and automation systems, providing consistent power for control and monitoring functions.

0 notes

Text

youtube

A VFD Bypass Panel is a crucial component for systems that rely on continuous motor operation, such as HVAC systems, industrial pumps, and machinery. It is designed to provide flexibility and reliability by allowing seamless switching between the Variable Frequency Drive (VFD) mode and bypass

In VFD mode, the panel enables energy-efficient motor control by regulating speed and torque. However, if the VFD fails, requires maintenance, or needs to be taken offline, the bypass mode ensures the motor continues operating by directly connecting it to the main power supply. This feature mini

The VFD Bypass Panel is typically equipped with safety interlocks, overload protection, and easy-to-use controls, ensuring safe and efficient operation. It is especially beneficial in critical applications where system failure or prolonged downtime is not an option.

0 notes

Text

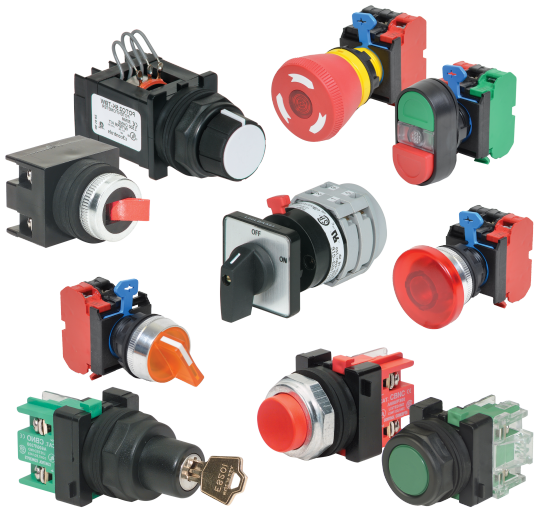

Installing 22mm IEC pilot devices may feel overwhelming, but with the right steps, it becomes a simple task. This video provides an easy-to-follow guide, starting with an overview of the necessary tools and components. Having everything ready beforehand ensures a smooth installation process. It sets the stage for mounting, wiring, and securing the devices, making it ideal for both beginners and experienced professionals.

#c3controls#electrical control products#Pilot Light#Light#automotive industry#industries#manufacturers#manufacturing

0 notes

Text

How Contactors Work and Their Role in Motor Control?

When we think about motor control, we often imagine large machines in industries or the electric motors that power everyday appliances. But behind these motors is a critical component that manages their operation, controls the power, and ensures safe handling of electrical currents: the contactor. In this blog, we will dive into what contactors are, how they work, and their vital role in motor control systems.

What is a Contactor?

A contactor is an electrically controlled switch designed to handle high currents. Unlike standard switches, which can only manage low currents, contactors are built to switch electrical circuits with much higher current loads. This makes them suitable for applications like motor control, lighting systems, and heating systems, where they protect equipment and ensure safe operation.

In simple terms, an electrical contactor works as an intermediary between the power source and the motor. It allows a small electrical signal to control a much larger power flow, making it ideal for automated control. By managing the connection between the motor and the power source, contactors enable machines and equipment to turn on or off safely, without manually handling large electrical currents.

Basic Structure of a Contactor

To understand how contactors work, let's break down their basic structure:

Electromagnetic Coil: The heart of the contactor is the electromagnetic coil. When powered, this coil creates a magnetic field that activates the switching mechanism within the contactor. The coil voltage can vary depending on the application and requirements.

Contacts: Contacts are the parts of the contactor that actually open and close the electrical circuit. There are three main types:

Power Contacts: These are the main contacts responsible for handling the high current load to power equipment.

Auxiliary Contacts: These smaller contacts handle additional functions, such as signaling or interlocking with other devices.

Arc Suppressors: Located around the contacts, these components help control and reduce electrical arcs when the contacts open, preventing damage and prolonging contactor life.

Enclosure or Housing: The contactor’s enclosure protects its internal components from dust, moisture, and other environmental factors. It also ensures safety, keeping the high-voltage parts away from accidental touch.

How Does a Contactor Work?

Now that we understand the contactor’s structure, let’s look at how it operates.

Activation of the Coil: When an electrical current flows through the electromagnetic coil, it generates a magnetic field. This magnetic field pulls a movable armature towards the coil, closing the main contacts. This allows the electrical current to flow through the contactor to the motor or load.

Current Flow to the Motor: With the contacts closed, the contactor enables current to flow through the motor circuit. The motor receives the necessary power to start and run.

Deactivation: When the control circuit interrupts the power to the coil, the magnetic field collapses. This causes the contacts to return to their original, open position, breaking the current flow. The motor stops as a result.

Arc Suppression: When the contacts open, an arc of electricity often forms between them. This arc can damage the contactor and motor if not controlled. Contactors are designed with arc suppressors and other features that minimize the impact of these arcs, making them safer and extending their life.

This process of opening and closing happens quickly and repeatedly, allowing the contactor to control the motor’s operation without exposing users to the high electrical currents involved.

Role of Contactors in Motor Control

In motor control, contactors are essential for several reasons. Let’s break down their role in more detail:

Starting and Stopping Motors Safely: One of the primary roles of a contactor is to start and stop motors safely. By controlling the connection between the motor and the power source, the contactor lets operators turn motors on and off without manually handling high-current connections.

Protection from Electrical Overloads: Contactors often work alongside other protective devices like overload relays. The contactor itself may not detect an overload, but it plays a role in the overall safety of the system. When an overload relay senses a current spike, it signals the contactor to open, disconnecting the motor and preventing damage.

Remote and Automated Control: Contactors allow for remote or automated motor control, making them ideal for industrial automation. For example, a control signal from a PLC (Programmable Logic Controller) can activate the contactor, starting the motor. This automation is essential in industries where machinery operates continuously and needs precise control.

Interlocking and Sequence Control: Contactors are frequently used in interlocking systems, where multiple devices must operate in a specific sequence. For example, in a conveyor belt system, one motor must start only after another completes its task. Contactors, with their auxiliary contacts, help create these interlocking arrangements.

Energy Efficiency and Safety: By controlling when and how long a motor runs, contactors help improve energy efficiency. They allow the motor to operate only when needed, saving electricity. Moreover, contactors reduce the risk of electrical shock or fire by isolating high currents within a secure enclosure, making the environment safer for operators.

Types of Contactors Used in Motor Control

There are various types of contactors, each suited for specific applications. In motor control, some of the most common include:

Electromagnetic Contactors: These are the standard type, using an electromagnetic coil to open and close the contacts. They’re versatile and can handle high currents, making them ideal for motor control applications.

Definite Purpose Contactors: These are specially designed for specific applications, such as HVAC systems, compressors, or pumps. They are reliable and more economical but have limited uses compared to general-purpose contactors.

Vacuum Contactors: These contactors use vacuum-sealed contacts to extinguish arcs, making them highly reliable in environments with high voltages or where arcs can be hazardous. They are commonly used in heavy-duty industrial motor control systems.

Solid-State Contactors: Instead of mechanical contacts, solid-state contactors use electronic components to control current. They are fast, quiet, and wear-resistant, making them useful in applications requiring precise control, although they’re often more expensive.

Contactors play a fundamental role in motor control by providing a reliable and safe way to start, stop, and manage motors. Their ability to control high currents through a relatively simple electromagnetic process makes them invaluable for various industries. Whether used in industrial automation, heating systems, or lighting applications, contactors bring safety, efficiency, and convenience to motor control.

Understanding how contactors work helps us appreciate their function within complex motor control systems. By managing high electrical currents efficiently, they ensure our equipment operates smoothly, securely, and with minimal risk. As industries continue to grow and automation becomes more common, the role of contactors in motor control will only increase, making them a cornerstone of modern electrical engineering.

0 notes

Text

What is Industrial Automation? A Beginner’s Guide

In today’s fast-paced world, industrial automation has become a critical part of modern manufacturing and production processes. Automation is not only improving the efficiency of factories but also reshaping how products are made.

If you’re new to the topic, this guide will help you understand the basics of industrial automation, its components, benefits, and how it’s transforming industries across the globe.

What is Industrial Automation?

Industrial automation refers to the use of technology, control systems, and information technology to operate machinery and processes without human intervention. In simple terms, it’s when machines and systems take over tasks that were once done manually. This can range from simple tasks like turning on a conveyor belt to complex processes like assembling cars on an automated production line.

Automation aims to enhance production speed, improve accuracy, and reduce human error. By automating repetitive tasks, companies can operate more efficiently, save costs, and produce goods with consistent quality.

Key Components of Industrial Automation

Industrial automation relies on several key components that work together to control machines and processes. Here’s a breakdown of some of the most important parts:

Sensors: Sensors detect changes in the environment, such as temperature, pressure, or motion. They provide feedback to the automation system to adjust machine operations. For example, a sensor might detect if a product is in the right position on a conveyor belt and trigger the next step in the process.

Controllers: Controllers are the “brains” of the automation system. The most common controller used in industrial automation is the Programmable Logic Controller (PLC). A PLC takes data from sensors, processes it, and sends instructions to machines to perform specific tasks. Think of it as a computer that controls industrial equipment.

Actuators: Actuators are mechanical devices that carry out the actions directed by the controllers. These include motors, pumps, and valves. For example, an actuator might open a valve to allow liquid to flow through a pipe or move a robotic arm to assemble a product.

Human-Machine Interface (HMI): While automation reduces the need for human intervention, there are still times when operators need to monitor or control machines. The HMI is a user interface that allows workers to interact with the automation system. It provides real-time data about the machine’s status and allows operators to make adjustments if needed.

Communication Systems: Automation systems rely on seamless communication between different components. Communication networks ensure that sensors, controllers, actuators, and HMIs can exchange data in real-time. This helps the entire system run smoothly and efficiently.

Types of Industrial Automation

Industrial automation can be categorized into different types based on the level of complexity and the nature of the processes involved:

Fixed or Hard Automation: In fixed automation, machines are designed to perform a specific task repeatedly. This type of automation is ideal for mass production of products that don’t change frequently. For example, an assembly line that makes the same part over and over is using fixed automation.

Programmable Automation: This type of automation allows machines to be programmed to perform different tasks. It’s ideal for manufacturing environments where products may change, but the process remains similar. In programmable automation, the system can be reprogrammed to handle variations in product design or production volume.

Flexible or Soft Automation: Flexible automation allows for greater adaptability. It enables machines to quickly switch between different tasks with minimal downtime. This is ideal for industries where product customization is common, like automotive manufacturing, where various car models can be assembled on the same production line with little interruption.

Integrated Automation: In integrated automation, all the processes in a factory are connected through a central control system. This allows for seamless coordination between different machines and processes. Integrated automation is the most advanced form, combining hardware, software, and control systems to manage every aspect of production.

Benefits of Industrial Automation

The widespread adoption of industrial automation is driven by its numerous benefits. Let’s take a closer look at how automation is transforming industries:

Increased Productivity: Automation allows machines to operate 24/7 without the need for breaks, boosting production capacity. This means companies can produce more goods in less time, meeting customer demands more effectively.

Improved Quality and Consistency: Machines operate with precision, ensuring that each product is made to the same standard. This eliminates the variability that comes with human labor, leading to higher quality and fewer defects in the final products.

Cost Savings: While setting up an automation system requires an initial investment, the long-term cost savings are significant. Automated systems reduce labor costs, minimize waste, and use resources more efficiently, leading to overall cost reductions.

Enhanced Safety: Automation reduces the need for human workers to perform dangerous or repetitive tasks. Machines can handle hazardous materials, heavy loads, and operate in environments that are unsafe for humans. This leads to fewer workplace accidents and improved worker safety.

Better Data and Analytics: Automated systems provide real-time data on machine performance, production rates, and potential issues. This data allows companies to optimize their processes, predict maintenance needs, and improve overall operational efficiency.

Flexibility and Adaptability: In industries where product designs or production requirements change frequently, automation provides the flexibility to adapt quickly. Programmable and flexible automation systems allow companies to modify their production lines with minimal disruption.

Applications of Industrial Automation

Industrial automation is used across a wide range of industries, including:

Manufacturing: Automation plays a vital role in manufacturing industries such as automotive, electronics, food and beverage, and pharmaceuticals. Machines assemble products, manage inventory, and perform quality control tasks.

Energy: Automation is used in power plants and energy systems to monitor and control the production and distribution of electricity. It helps maintain the stability of the power grid and reduces energy waste.

Mining and Oil & Gas: In the mining and oil & gas industries, automation is used to operate drilling equipment, monitor safety systems, and control the extraction of natural resources.

Transportation: Automated systems are used in logistics and transportation to manage shipping, track goods, and operate warehouse equipment like conveyor belts and robotic arms.

The Future of Industrial Automation

The future of industrial automation looks promising as advancements in technology continue to shape the industry. Emerging trends like the Industrial Internet of Things (IIoT), Artificial Intelligence (AI), and Robotics are expected to take automation to the next level.

IIoT enables machines to communicate and share data with each other in real-time, making factories more efficient and interconnected.

AI allows machines to learn from data and improve their performance over time, reducing the need for human oversight.

Robotics is becoming more advanced, with robots capable of performing increasingly complex tasks and working alongside human workers in collaborative environments.

These advancements will make automation even more powerful and essential for industries around the world.

Conclusion

Industrial automation is a game-changer for industries, helping companies increase productivity, improve quality, reduce costs, and enhance safety. With the growing use of automation technologies, the future of manufacturing and production is set to become even more efficient, intelligent, and interconnected. Whether you're involved in manufacturing, energy, or any other industry, understanding the basics of industrial automation is the first step toward embracing this transformative technology.

1 note

·

View note

Text

What is HDTB?

The HDTB setup, or High-Density Terminal Block setup, is a compact and organized system used to connect multiple electrical wires in a control panel or electrical system. It provides a neat and efficient way to manage wiring, ensuring that connections are secure and easy to identify. By using terminal blocks, the HDTB setup simplifies troubleshooting and maintenance, reduces wiring clutter, and improves the safety of electrical installations. This setup is commonly used in industrial and commercial applications where space is limited but multiple connections are needed.

In this video, we will learn how to install an HDTB (High-Density Terminal Block). For more information, check our website "www.c3controls.com".

#Terminal block#electrical control products#electrical products#industrial control product#c3controls

0 notes

Text

MCBs (Miniature Circuit Breakers) and MCCBs (Molded Case Circuit Breakers) are both used to protect electrical circuits, but they have different applications and features. MCBs are designed for low-voltage circuits and offer protection against overcurrent and short circuits, typically handling up to 100 amps. They are compact, cost-effective, and suitable for residential and small commercial use. MCCBs, on the other hand, are used for higher voltage and current applications, handling currents from 100 amps to several thousand amps.

They provide more robust protection and have adjustable settings for overcurrent protection, making them ideal for larger industrial or commercial systems. MCCBs also often include additional features like thermal and magnetic protection, which offer more flexibility and control compared to MCBs.

0 notes

Photo

What are disconnect switches (Safety Switches)? Types and Uses (on Wattpad)

https://www.wattpad.com/1344072289-what-are-disconnect-switches-safety-switches-types

0 notes

Text

Pilot Devices: The Importance of Disconnect Switches, Push Buttons, Selector Switches and More

Pilot devices are control components that are essential to the operation and safety of industrial machinery. These devices are used to control and monitor the flow of electrical power and signals within a system. Some common pilot devices include push buttons, selector switches, pilot lights, and audible alarms.

Push Buttons

Push buttons are another essential component of pilot devices. These buttons are used to start and stop machinery or to signal for attention. Push buttons come in a variety of styles and colors, making it easy to identify their function. For example, a red button is often used to signal an emergency stop, while a green button is used to start or resume operation.

In addition to standard push buttons, there are also illuminated push buttons that have built-in lights that indicate the status of the machinery. These buttons are particularly useful in low-light conditions or in situations where the operator needs to monitor the machine from a distance.

Selector Switches

Selector switches are used to choose between different operating modes or functions in a piece of machinery. These switches are often used to select between automatic or manual operation or to choose between different speed settings. Selector switches come in a range of styles, from two-position switches that allow for a simple on-off function, to four-position switches that allow for multiple operating modes.

Like push buttons, selector switches are typically color-coded to indicate their function. For example, a red switch might be used to indicate an emergency stop, while a blue switch might be used to select automatic operation.

Pilot Lights

Pilot lights are small, illuminated indicators that are used to signal the status of a piece of machinery. These indicator lights can be used to indicate a variety of conditions, such as when a machine is running or when it is in standby mode. Pilot lights can also be used to indicate a fault or an error condition, such as when a component has failed or when there is a problem with the machinery.

Pilot lights come in a variety of colors, including green, red, yellow, and blue. Each color is typically used to indicate a specific status or condition. For example, a green light might indicate that the machine is running, while a red light might indicate that there is a fault or an error condition.

Audible Alarms

Audible alarms are another important component of pilot devices. These alarms are designed to alert operators to a problem or a hazard. They are typically used in situations where a visual signal, such as a pilot light, might not be sufficient to alert the operator to the problem.

Audible alarms can be programmed to sound different tones or frequencies to indicate different conditions. For example, a continuous tone might indicate an emergency stop condition, while a pulsating tone might indicate a warning condition.

youtube

Conclusion

Pilot devices such as disconnect switches, push buttons, selector switches, pilot lights, and audible alarms are essential components of industrial machinery. These devices help to ensure the safe and efficient operation of machinery by allowing operators to control and monitor electrical

#pilotdevices#selectorswitches#disconnect switches#push buttons#indicator lights#pilot lights#electrical control products#Youtube

1 note

·

View note