Don't wanna be here? Send us removal request.

Text

Maximizing Power Generation Efficiency with Cone Crusher Spare Parts and Small Jaw Crushers

Power generation is a critical component of modern society, providing us with the energy we need to power our homes, businesses, and industries.

In order to maintain a steady and reliable source of power, it is essential that power generation equipment is well-maintained and functioning optimally.

One key aspect is the crushing of large rocks into smaller pieces, and this is where cone crushers and small jaw crushers play a vital role.

Cone Crusher Spare Parts

Cone crushers are an integral part of power generation processes, as they are responsible for crushing large rocks into smaller, more manageable pieces.

The wear and tear of cone crusher parts over time can lead to the need for replacement, and this is where cone crusher spare parts come into play.

Cone crusher spare parts provide quick and easy replacement of worn-out parts, ensuring the continued optimal functioning of power generation equipment.

The foundry shop is a reliable and trustworthy provider of cone crusher spare parts, offering a wide range of high-quality products to suit all of your needs.

Whether you are looking for bearings, bushings, wear plates, or liners, the foundry shop has the expertise and resources to provide you with the cone crusher spare parts you need.

With a focus on providing durable and long-lasting products, the foundry shop is committed to maximizing the efficiency and reliability of your equipment.

Small Jaw Crushers for Sale in Australia

Small jaw crushers for sale in Australia are another crucial component of power generation processes.

These machines are designed to crush small rocks into smaller pieces which can then be processed and used in the production of power.

The compact and easy-to-operate design of small jaw crushers makes them ideal for use in remote and challenging locations, where larger, more complex power generation equipment may not be practical.

Additionally, small jaw crushers are cost-effective, making them an ideal choice for facilities with limited budgets.

Small jaw crushers for sale in Australia are available in a range of sizes and capacities, so you can choose the model that best suits your power generation needs.

Whether you are looking to crush small rocks for use in power generation or you need a machine that is capable of processing larger rocks, small jaw crushers are up to the task.

With their simple design, small jaw crushers are easy to operate and maintain, so you can be sure that they will continue to perform at their best for many years to come.

Benefits of Using Cone Crusher Spare Parts and Small Jaw Crushers

The use of cone crusher spare parts and small jaw crushers in power generation processes offers numerous benefits.

Firstly, they are reliable and efficient, ensuring that power generation equipment continues to function optimally.

This is essential for maintaining a steady and reliable source of power.

Secondly, they are cost-effective, helping facilities save money on replacement parts and maintenance costs.

This can be a critical factor for facilities with limited budgets.

Finally, they are easy to use and maintain, making them ideal for use in remote and challenging locations.

Environmental Benefits

The use of cone crusher spare parts and small jaw crushers in power generation processes also offers environmental benefits.

The smaller rock pieces produced by these machines can be used to produce renewable energy, reducing our reliance on non-renewable sources of energy and helping to reduce greenhouse gas emissions.

Additionally, small jaw crushers are designed to be energy-efficient, helping to reduce the carbon footprint of power generation facilities.

By choosing to invest in cone crusher spare parts and small jaw crushers, power generation facilities can play an active role in protecting our environment.

Customization and Support

Finally, the foundry shop also provides customization and support services to ensure that you get the best possible results from your cone crusher spare parts and small jaw crushers.

Our team of experts will work with you to understand your unique requirements and develop a customized solution that meets your specific needs.

Whether you need help with installation, maintenance, or troubleshooting, our team is here to support you every step of the way.

With our extensive experience and expertise in power generation, you can trust that we will provide you with the guidance and support you need to achieve maximum efficiency and reliability.

Conclusion

In conclusion, cone crusher spare parts and small jaw crushers for sale in Australia are an integral part of power generation processes.

These machines are designed to operate under extreme conditions and are subject to constant wear and tear.

With the right spare parts and maintenance, however, they can continue to function optimally for many years to come.

If you are looking for high-quality, reliable, and cost-effective power generation equipment, look no further than cone crusher spare parts and small jaw crushers.

The foundry shop

is your one-stop shop for all of your power generation needs, providing a wide range of durable and long-lasting products to suit all of your requirements.

So why wait? Invest in cone crusher spare parts and small jaw crushers today and experience the benefits of maximum power generation efficiency for yourself.

0 notes

Text

Unearthing the Hidden Gems: A Look into Australia's Small Jaw Crusher Market and Heat Treatment in Melbourne

Australia, known for its vast landscapes and rich mining industry, is home to some of the most innovative and advanced technologies in the field of mineral extraction.

One such technology is the small jaw crusher, a compact and efficient crushing machine that has revolutionized the mining and quarrying industry in Australia.

Small jaw crusher for sale in Australia is in high demand due to their versatility and compact size.

But why is the small jaw crusher for sale in Australia so popular among mining and quarrying companies?

The answer lies in its compact size and versatility. Unlike traditional jaw crushers, small jaw crushers for sale in Australia can easily fit into tight spaces and can be transported easily from one location to another.

This makes them ideal for use in small-scale mining and quarrying operations. Additionally, small jaw crushers are able to handle a wide range of materials, from soft to hard and abrasive, making them suitable for a variety of applications.

One of the best places to find small jaw crushers for sale in Australia is in Melbourne.

Melbourne is home to several reputable manufacturers and suppliers of small jaw crushers, making it easy for companies to find the right machine for their needs.

Furthermore, Melbourne is known for its advanced heat treatment facilities, which are essential for ensuring that the small jaw crushers are able to withstand the harsh conditions of the mining and quarrying industry.

Heat treatment in Melbourne is a crucial process for small jaw crushers to improve the strength, ductility, and toughness of metal components.

Another important aspect of Melbourne's mining industry is its foundry shop.

Foundries are responsible for creating and casting metal components for mining equipment, including small jaw crushers.

These foundries use advanced technologies and techniques to ensure that the components they produce are of the highest quality.

They also use strict quality control measures to ensure that the components are free of defects and meet the specified requirements.

A good foundry shop in Melbourne is essential to produce high-quality components for small jaw crushers for sale in Australia.

When it comes to purchasing a small jaw crusher for sale in Australia, it is essential to work with a reputable supplier or manufacturer who has a proven track record of providing high-quality equipment and excellent customer service.

Not only do they provide a wide range of small jaw crusher options, but they also offer custom solutions to meet the specific needs of the customer.

They can provide advice on the best small jaw crusher for your specific operation and also provide heat treatment in Melbourne to improve the durability of the machine.

Furthermore, a good supplier or manufacturer will also offer maintenance and repair services for your small jaw crusher, ensuring that it continues to operate effectively and efficiently over time.

In conclusion, small jaw crushers for sale in Australia are a valuable asset for mining and quarrying companies, and Melbourne is one of the best places to find them.

The city's advanced heat treatment facilities and foundry shops also play an important role in ensuring that the small jaw crushers are able to withstand the harsh conditions of the mining industry.

With the help of small jaw crushers, mining and quarrying companies can continue to extract valuable resources from the earth in an efficient and sustainable manner.

0 notes

Text

Top 4 Crucial Tips to Ensure Efficient Cone Crushing Operation

The cone crushing machine is a piece of important machinery suitable for crushing raw materials such as metal ores and medium-sized rocks. Compared to a jaw crusher or rock crusher, the cone crusher is an effective and widely used machine – it adopts innovative methods that ensure smooth crushing while saving time.

The innovative technology functioned the cone crusher can boost work efficiency. However, when crusher maintenance is neglected, it can damage internal parts, and constrainedly need to purchase Cone crusher spare parts to ensure great performance. Let's understand the key tips to maximize cone-crushing operation.

#1 Choose Automation to Extend Cone Crusher Parts life

Using automation greatly boosts cone crusher performance, but it shouldn't be complicated; rather, it is easy to use and control. One of the greatest things that automation offers is protecting the crusher parts from damage; it gives a warning system and alerts the operation before the parts become out of order.

Generally, when the crushing operation surpasses the pressure, it causes a bowl float or ring bounce, ultimately reducing the operation's efficiency.

#2 Operate at a regular "choke-fed" cavity level

When a crusher operates at different cavity levels during a shift – it will operate at inconsistent product shapes and production rates. A cone crusher operating at half the cavity level will produce a much rough product. Also, the low cavity level produces smaller and more elongated product particles.

It is important to ensure that the crusher operates at the correct choke-fed cavity level because this will result in a higher crusher throughput and a cubical-shaped product. This is especially important for the circuit's tertiary (short-head) crushers as they produce most of the aggregate operations' saleable products.

#3 Hydraulic Power Maintenance

Poor maintenance of the hydraulic power unit can damage the motor and pump assembly, which is important for the cone crusher to perform crushing operations. Using higher horsepower for performing hard operations can result in higher energy costs per ton of material (kW/hr/ton).

Thus, using higher horsepower result in shorter life cycles for hydraulic power unit ancillary parts, such as the pump, motor and coupling, starter, pressure switches, solenoid valve seals, packings, and pressure switches. So, to ensure larger efficiency, inspect the hydraulic power unit for filter condition, breather condition, and leaks.

#4 Avoid Excess Feed

To ensure smooth working of crusher parts, avoid trickle-feeding cone crushers. This practice can damage the parts in the long run, which results in low productivity and poor product shape. Also, overfeeding can affect the bearing alignment of the crusher and make you purchase Cone crusher spare parts.

A cone crusher's operational characteristics indicate that it shouldn't be utilised below 40 percent of its rated horsepower while crushing. Experts suggest that the crusher should run at 40 percent of its ideal horsepower. This practice will help obtain correct bearing alignment that ultimately maximizes productivity and allows for optimum load-bearing.

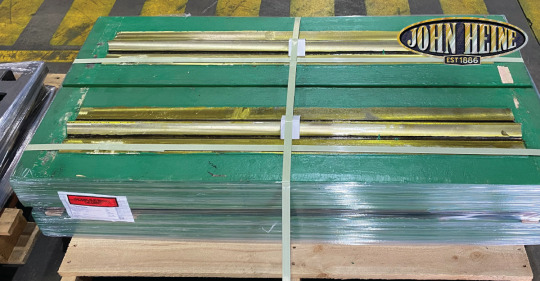

Partner with John Heine for Broad Range of Crushers

We are a renowned Machining shop and Mining pump casting manufacturers in Australia. Over the years, we have developed a high reputation of manufacturing highly precision products, mining tools, lathe machine, and many more. Our technical team is well trained and have experienced in supplying crushing equipment direct to mine sites of some of the largest coal, gold and iron ore companies in Australia and SE Asia.

Since 1886, John Heine and Sons under Heine hard brand has been catered several industries such as mining, quarrying, power generation, and general engineering sector. We are well known for supplying high quality, low volume ferrous casting for these industries.

We also supply cost efficient and durable jaws for BL-Pegson, Goodwin Barsby, Kemco, Parker, Kue Ken, Hadfield, Pioneer and Nordberg machines. So, to get durable Small Jaw Crusher for Sale in Australia, Look no further than John Heine.

Contact John Heine’s customer representative to get the best quality cone crusher parts at budget friendly rate.

SOURCE URL: https://medium.com/@seoo3digital/top-4-crucial-tips-to-ensure-efficient-cone-crushing-operation-b6f4d362193d

0 notes

Text

The Prime Advantage of Using Horizontal Boring Machine for Industries

A horizontal machining tool is efficient machinery used widely for performing different machining operations while using one machine. The prime work of a horizontal machine is to drill holes in the horizontal direction and perform milling, drilling and tedious operation simultaneously. One of the greatest perks of using boring machines is that it allows the large parts to be easily machined and enable end-user to reach small spaces.

Buying a Horizontal boring machine for sale is a great way to cost-efficiently perform boring operations in large components, irrespective of its size and shape. Here are the prime benefits of using the horizontal boring machine for industrial purposes.

Manufactures Large Format Elements

One of the greatest perks of using horizontal boring machines is the ability to produce extensive machined parts. These horizontal tools have the ability to produce large-format parts, especially for industries like the agricultural or engineering sectors.

High–Level Efficiency

These days, more and more industries are integrating boring machines, especially horizontal ones because they are efficient and generally ease the production process. These tools have the capability to improve efficiency in industrial projects. One of the great advantages of such machinery is that it reduces time and helps perform a large operation on time. Many industries across the board depend upon rely on horizontal machines since they streamline boring operations and get maximum work done in a short span of time.

Durable Parts

One such great advantage of boring milling machines is that they are durable and can be used for several years thanks to innovative horizontal boring machine design, sturdy manufacturing and effective post-sale servicing. A reliable provider like John Heine offers the best quality stainless steel casting components, general repairs, and full servicing. It provides a high – quality and valuable boring milling equipment.

Great Investment

Investing in boring machines is beneficial for any plant or production line. These horizontal machines offer a better option for long-term production than traditional boring techniques. Business leaders can find the best deal by comparing both used and new machines from well-respected manufacturers.

Rapid Technology

Horizontal mills can perform fast cuts simultaneously. They can be rotated to allow them to work from multiple edges rather than just the horizontal surface. The equipment structure speeds up the process without compromising precision.

Conclusion

In the end, all the mentioned advantages shows that horizontal boring machine is crucial and able to perform various operation under several industries as possible. When looking for a Horizontal boring machine for sale? Visit John Heine. It is one of the reputed and well-established manufacturer company that supplier high-quality and précised heavy-duty machines such as drilling machines, grinding machines, boring machines etc.

John Heine is well known for manufacturing ferrous equipment and produces an extensive varieties of general engineering products, mining equipment, Cone crusher spare parts and more. Its on-time product delivery record is greater than 95% and the customer service offer opportunity to build great customer- supplier relationship.

Contact the customer care team today if you need machined parts of any kind.

#heat treatment Australia#pump casing#horizontal boring machine for sale#foundry shop#power generation#heat treatment melbourne

0 notes

Text

The Ultimate Benefits of Heat-Treating Metals

Heat treatment is one of the critical methods performed in foundries to get desired characteristics of the metal. In this method, metal objects are heated first and then cooled at room temperature. Metals, including ferrous and non-ferrous, undergo a heat treatment process – it enhances or modifies the internal properties of materials to meet the requirements of intended applications.

Based on material type, desired material outcome heat treatment is selected. Some Heat treatment in Australia softens the metal, while some processes can decrease the stress of the material. Let's understand the importance and benefits of heat-treating metals.

Improve Workability and Machinability

The heat treatment of metals improves manufacturing by reducing the internal stress of material from previous fabrication processes such as cooling, heating, stamping and welding. For example, if a metal is hard enough to form a shape, annealing is the process that is performed to reduce its hardness. However, if the metal is heat-treated by flame or induction, it will soften only one part, and the rest will remain unchanged.

Boost Strength and Toughness

Heat treating of ferrous and non-ferrous metal can impact yield strength, tensile strength and fracture toughness. Heat treatment processes like case hardening in a machining shop in Sydney can significantly boost strength while decreasing brittleness. The amount of tempering performed on the metal can determine the material's ultimate strength. In order to make it more usable or ductile, it is annealed or re-tempered.

Improve Magnetic Property

One of the greatest perks of heat treatment on ferrous material is that it gains magnetism (measured as "magnetic permeability). It is possible when metals are work-hardened (machined, formed, stamped, bent etc.). However, the annealing process – a type of heat treatment Melbourne can reduce magnetic permeability. Sometimes, eliminating magnetic property becomes important because it will later be used in an electronic environment.

John Heine – trusted Foundry and Machining Shop in Australia.

We are one of the leading and premium foundry shop in Australia. Our team has several years of expertise in producing large and low volume ferrous casting and machined components for several industries. We have gained a high reputation of producing high precision mining, quarrying and engineering sector equipment.

Call our team today to customise high-class industrial equipment in our machining shop.

SOURCE URL: https://www.zupyak.com/p/3147155/t/the-ultimate-benefits-of-heat-treating-metals

0 notes

Text

John Heine is the best Machining shop center in sydney location

At John Heine, we are equipped to handle almost any precision heavy engineering including assembly. The Company specialises in machining wear parts in white iron, with the capability to machine up to 750 BHN.The company maintains an externally accredited quality system complying with AS/NZS ISO 9001 on casting and machining work. So for more details visit at website: https://www.johnheine.com.au/products/machining-shop/

#Small jaw crusher for sale australia#Machining shop in sydney#Stainless steel casting#Power Generation for mill liners#power generation#manganese wear plate#horizontal boring machine for sale

0 notes

Text

Cone crusher spare parts - Machining Shop in Sydney |John Heine

We are a leading premier CNC machining shop in Sydney, Australia, known for producing high precision engineering products, including Cone crusher spare parts, rail components, mining materials and many more. So for more details visit at website: https://www.evernote.com/shard/s525/sh/4fe93775-f8c3-ce49-6fad-54f6e4173843/5fe7c0eb7ece0ee0d124900258b94319

#machining shop in Sydney#horizontal boring machine for sale#heat treatment melbourne#power generation#foundry shop

0 notes

Text

Best services for Metal Casting in Sydney by John Heine website

John Heine & Sons, leading and established foundry shop for Metal Casting Sydney, has launched an upgraded version of cone crusher and parts for brands like Brown Lennox, Canica, Cedar Rapids, CVR, Hazemag, Kawasaki, SBM; it minimises the size reduction of hard materials such as rocks or stones. So for more details visit at website: https://sites.google.com/view/johnheine-power-generation/home?authuser=1

0 notes

Text

How To Decide the Ideal Crusher for Quarry Operation?

A Crusher machine is an essential piece of equipment that is used for crushing large stones in quarry and mining operations. However, based on material types, different operations need different types of crushers. Crushing operation efficiency is majorly dependent upon the right equipment as it helps maximise productivity while minimising maintenance.

When selecting quarry crusher tools, several critical factors must be considered. Therefore, read the below guide to choose the right Quarry crushing wear parts and equipment for crushing operation.

Types of Stone Crusher Equipment for Quarry Operations

There are two types of crushing equipment – compression and impact. So, by definition, a machine that crushes rocks by compression is called compression, whereas a machine that uses a rotor to hit rock aggressively is called an impact crusher.

Jaw Crusher

It is a primary crusher and most common compression crusher, used for crushing the hard material to a certain extent so that it can transfer to the next stage through a conveyor belt. This crusher performs excellently in moderate to very high compressive strength applications and ensures high-efficiency operation. It can easily destroy the stable structure of hard rock. Therefore, it is ideal for quarrying operations.

Gyratory Crusher

In industries, the gyratory crusher is majorly used in the primary crushing stage of a quarry operation. The hard stone is compressed continuously between the mantle on the swing shaft assembly and the bowl liner inside the cavity. One of the best things about a gyratory crusher is that it produces laminated crushing effects, which can reduce the wear and tear of equipment parts. Moreover, it is preferred for performing a larger job as it is having higher capacity than the jaw crusher.

Cone Crusher

This type of crusher operates the same as the gyratory crusher that aggregate, concrete, mining, natural gas extraction, and coal industries use. The hard material is pushed into the feed and crushed between the mantle and the bowl liner. But the only difference is that the cone crusher is used in secondary, tertiary and quaternary crushing stages for producing fine aggregates. In some cases, when the size of raw material is small enough, in that case, cone crusher machine is ideal for quarrying operations.

Horizontal Shaft Impact Crusher (HSI)

This crusher type is mainly used in the secondary and tertiary crushing stages. It is mainly used for crushing applications where the rock is softer, less dense and less abrasive. The rotating rotor within the equipment rotates at high-speed impacts the stone to break them, and then they later shift to the impact plate to further crush at a more consistent size.

Vertical Shaft Impact Crusher (VSI)

VSI is used in the final stage of aggregate processing, usually used to produce cube-shaped artificial sand. Its movement is quite similar to centrifugal pumps because VSI’s axis is vertical. In this crusher, the material is fed into the centre of the rotating rotor, which is rotating at high-speed. The high speed throws the material through the opening and hits back at the block, and due to mutual collision, the material is crushed.

Conclusion

To sum up, there are varieties of option for selecting a mobile crusher for quarrying operation. The prime goal is to make quality production at low cost and selecting the right crusher machine will make quarrying job smoother and more profitable. John Heine is the leading foundry shop in Australia, known for producing high wearing alloy and Metal casting in Sydney. It offers the high precision products for mining, quarrying, Power generation and general engineering industries.

SOURCEURL: https://www.reddit.com/user/johnheineservicesaus/comments/uek8w7/how_to_decide_the_ideal_crusher_for_quarry/

0 notes

Text

Best Tips or Ideas for Improving Horizontal Boring Machine Efficiency

The horizontal boring machine plays an important role in manufacturing large parts in the industry sector. These machines are highly dependable and durable, but it doesn’t mean that their efficiency will be the same over the period. There are certain ways that typically improve productivity, techniques, technology and delay hours. When a technician opts for such a technique, the machine will show quicker turnaround times.

Functioning horizontal boring mills may seem simple and easy, but technicians must ensure to optimize machine performance for the best results. We manufacture Pump casings, valve bodies etc. Below are the certain technologies dramatically help improve horizontal boring machine performance.

Correct Angular Setting: When executing boring and drilling operations, it is crucial to opt effective setting for achieving optimal results. The operation will become easier when the angle becomes more refined. However, correcting angular settings also lowers the risk of mishappening caused by an unexpected setting.

Use of Sharp Blades: It is a vital maintenance tip that can significantly help improve efficiency and reduce energy consumption. It is because sharper blades can drill and cut the rocks more easily, so the machine will run for a shorter period, and the operators will attain the best results with the cleanest finish possible.

Central Controlling: A high-speed CNC (Computerized Number Control) system will allow operators to achieve the best operational efficiency from the horizontal boring machine. CNC is the most advanced and widely used technology in the industry. It enables operators to optimize the manufacturing process and maximize productivity while maintaining precision and accuracy during production.

Tools For Improving Horizontal Boring Machine Efficiency

Automatic head changer: This equipment is controlled by CNC and is very common in today’s boring mills. The multiple heads, including universal heads, right-angle heads, and fully articulating heads, allow the boring machine to drill, ream, mill and create bores. With the advantage of multiple heads, changing quickly allows the operation to be done in a limited time.

Automatic Pallet Changer system (APC): Unloading a heavy and large workpiece can be difficult. Fortunately, an automatic pallet changer system takes only 100 seconds to change pallets. The shifting slide moves the existing pallet unloads it and loads the new one again. However, a few accessories are essential to increase the productivity and efficiency of the horizontal boring machine. Contact the manufacturers that provide the best and high-efficiency accessories.

Programming: In general, programming and machine operation go hand-in-hand. It is crucial to consider good programming because a slight change in programming can cause a big catastrophe. Therefore, it is essential to understand the programming for the manufacturing process so that anytime operator can do necessary changes.

Conclusion

As mentioned earlier, boring equipment plays an essential role in the progress of several industries. When it comes to attain greater results and business revenue, business will need a high-precision machine to begin with. John Heine, a leading foundry shop in Australia, offers the best accessories for horizontal boring machines for sale.

John Heine is a proud supplier of high-durable parts, it manufactures tools by performing Heat treatment in Australia . Under Heinhard brand, it has experienced sales team of engineers that manufactures a suitable spare part, including bearing housings, pump casing, valve bodies etc.

For more information on our popular products, get in touch.

SOURCE URL: https://johnheine1.wordpress.com/2022/04/18/best-tips-or-ideas-for-improving-horizontal-boring-machine-efficiency/

0 notes

Text

A Complete Overview of CNC Milling Machine

The computer numerical control (CNC) process is one of the most common processes used in the various manufacturing unit to produce complex parts. The prime goal of the CNC milling machine is to transform material casting into finished and useable parts. Moreover, CNC milling machines enable manufacturers to produce intricate machinery parts precisely while meeting high tolerance needs.

So, let’s take a deep dive into CNC milling and understand its various process aspects. It will also help you determine whether you should Buy CNC milling machine or go for another alternative.

What is the Importance of a CNC Milling Machine?

As mentioned, the CNC process is widely used in several industries because of its multi-dimensional work. This process can reshape various materials, including steel, plastics, glass or wood.

The CNC milling is operated by highly qualified technicians who can use quantitative and accurate specifications to produce custom-designed parts within minutes. Due to the excellent efficiency, modern manufacturing depends on CNC machines for the economical production of a large and varied number of products.

How Does CNC Milling Process Work?

We are going to look at the prime aspects of the CNC milling process, machinery. CNC machining is the mix up of two terms: milling and turning. Both perform distinct operations; machining refers to mechanical cutting technology which uses physical contact to remove materials from metals. On the other hand, turning bars are held in a chuck and rotated to remove unwanted material to form the desired shape.

However, the CNC milling process adopts subtractive fabrication to produce intricate parts and uses a computer numerical control system. Let’s understand the complete overflow of the milling process:

The first and foremost step in the milling process is designing the visual representation of the final product using CAD software.

The next step is to check the CAD software outcomes and translate them into machining code.

The further step is setting up the machinery for production operation.

The final step in the milling process is using the rotating tool used to cut off chips and get the desired shape.

Why Visit John Heine?

We are one of Australia's leading machining shops and Stainless-steel casting foundry. We have 135 years of experience serving various industries. Our technicians have expertise with all types of machinery, both conventional and CNC.

Under our Heine hard brand, our client can get specialised high precision components at an economical price. Those who would like to buy a Small jaw crusher for sale in Australia can visit our website https://www.johnheine.com.au/

Source URL: https://www.vingle.net/posts/4380167

0 notes

Text

Essential Factors to Consider When Purchasing Horizontal Boring Machine

Industrial projects are continuously rising in Australia, so it became necessary for industrialists to purchase equipment that caters to all manufacturing needs. Therefore, it only makes sense to look for equipment that can complete jobs faster, easier and cost-efficiently. It became possible by selecting the suitable machine with a prominent feature being versatility, which is inherited in the horizontal boring machine.

Below are the top tips to consider before purchasing a horizontal boring for an industry

Operational Cost

Usually, equipment for industrial are expensive, but it is good to purchase them at a competitive price if it is good to perform all the operation in industry projects. When it comes to purchasing the machine, look for reliable foundries shop in Australia as they offer Horizontal Boring Machines for Sale. However, it would be best to check all the necessary functions and prices of the boring machine before purchasing the equipment.

Fuel Consumption

Every machine operates on fuel. So, while choosing a horizontal boring machine, make sure it doesn’t consume the fuel at a fast rate. It is important to consider because the high fuel consumption can amplify the operation price in the long run.

Right Technology

Over the years, technology has reduced man work and became a friend of business person. Choose a horizontal boring machine designed with the latest technology and capable of completing tasks in less time. As mentioned earlier, the equipment can be costly, but companies will adopt machines that can overcome the cost factor because they are built with the right technology.

High Quality

In order to reduce unnecessary costly repairs, it is crucial to choose a boring machine that is of high quality. If a machine does not succeed in reaching its optimal threshold, it will quickly disintegrate under harsh conditions. Premature ageing also impacts the workability of operators and leads to a reduction in business profits. However, the horizontal boring machine is of high quality, and it boosts the safety of employees and work capability.

Right Supplier

When investing in a horizontal machine for industry, it is recommended to choose the manufacturing company with proven experience, expertise, knowledge, good reputation, and the best services. Manufacturing companies that have been in the industry for several years definitely provide the best quality, cost-efficient, right technology that a business can trust. Choosing the right supplier is also important because they can tackle the problem if anything goes with the machine in future.

Conclusion

Purchasing a new horizontal boring machine is beneficial in long run because it can operate for long time before the operator need to service it. However, it is good to follow all the precautionary steps to ensure longer operation.

If in need of good and highly precision horizontal boring machine for sale, Visit John Heine. It is a leading foundry shop that manufacture Stainless Steel Casting using heat treatment, Australia. It is known for providing the best quality casting for rail components, power generation, engineering parts and mining equipment. Contact the team of John Heine to explore world-class precision parts and equipment. SOURCE URL: https://wakelet.com/wake/NFZDB-iePgMrlkOJ9RtWU

0 notes

Text

Power Generation for wear resistant products - Stainless steel casting

The company has developed a number of specifications and heat treatment procedures that give superior wear life in different applications Our heat treatment facilities offer normalising, annealing, quench and tempering and stress relieving of cast irons, chrome irons, plain carbon steel, alloy steels, manganese Stainless steel casting.

#Quarry crushing wear parts

#Quarry Wear Parts

#Cone crusher spare parts

0 notes

Text

When it comes to finding the right kind of primary crushers in Australia, select the one that performs the best operation on the material to be crushed. Apart from the material, consider the feed size, the product size, and the desired capacity required.

0 notes

Text

A horizontal boring machine is an exceptional tool often used in industries for the production of low–volume parts. Several Industries likely opts for these machines because of their versatile features. Once deployed, such a machine will be able to perform different applications, including milling, shaping, drilling, boring, turning, tapping, forming, and threading.

0 notes

Text

When it comes to producing high-quality metal parts, it is essential to maximise the performance of the heat treatment process. Therefore, manufacturers are always searching for ways to produce high–quality heat-treated metal parts and achieve business objectives while lowering unnecessary material waste and reducing costs whenever possible.

0 notes

Text

5 Ways to Improve productivity for manufacturing Power Generation Equipment

Manufacturing high-dimension tools in a foundry require lots of effort and time investment. With time, many crucial pieces of equipment wear down, which will cost the manufacturers a huge loss. Even it costs loss in productivity and reduction in business ROI, so it is important for businesses to improve manufacturing efficiency.

When it comes to manufacturing power generation parts efficiently, opt for the below 5 tips – it will help cut costs, enhance throughput, and reduce the adverse impact on the environment.

#1 Improve Training Practices

You can’t deny employees play a huge role in running your industry. But the major reason behind the wear and tear of equipment is the absence of employees training. In order to augment productivity, you need to provide adequate training regarding handling tools health and safety practices to your workers so that they can manage tasks and work efficiently.

#2 Determine Breakdowns

While manufacturing ferrous casting parts, you will face several bottleneck situations. A little breakdown can cause a massive impact on your business reputation and eventually turn down your overall profits. Therefore, it is critical to identify the source of breakdowns and prevent them from reoccurring.

#3 Preventive Maintenance

As they say, “maintenance is better than cure” helps reduce premature wear and tear of the tool. Performing regular maintenance is necessary to keep your power generation tools optimal. It also helps improve mass production capability. Moreover, performing maintenance with expert manufacturers also eliminate the negative impact on the environment.

#4 Reduce Waste

In industry, reduction of waste is important to sail your business goals. Waste management can unknowingly help you improve fuel consumption, energy consumption which eventually boosts efficiency. Moreover, practising recycling material waste can also improve your production line.

#5 Usage of Right tools

Employees can perform their tasks efficiently and on time only if they have the right tools. Conversely, damaged tools and outdated gear are more harmful than anything. This applies to both the physical machinery as well as the software and hardware used to plan and track your physical processes.

How Can John Heine Help you in Manufacturing Parts?

We are a premier foundry shop in Australia known for manufacturing ferrous castings and machine components for Mining pump casting, power generation parts, and engineering parts through different heat treatment methods. Our team are determined to produce high precision, hard wearing parts under Heinehard Brand. Get in touch with our team to get a good quality ferrous casting material.

0 notes