"JWELL Machinery Co.,Ltd was established in 1997,Shanghai, China based on her mother company JINHAILUO which is China's first Screw and Barrel manufacturer.With over 24 years experience in the field of plastic extrusion, Jwell Company has become distinctive because of her deep understanding of plastic extrusion and outstanding performance of machine processing.For quite some time, we accumulate experience of production and machine adjustment, learning latest technology of plastic extrusion and guarantee high quality production under the standard of CE or UL certification, IS09001 and 2008 quality management system certification.JWELL could satisfy the demand of our customers and Jwell Company can be your reliable business partner.After all these years development, Jwell has become the leader of plastic extrusion industry. Jwell is also the largest plastic extrusion machinery producer in China with 6 large production factories located at Shanghai, Suzhou, Changzhou, Haining, Zhoushan, Dongguan.Mealwhile, Jwell first Overseas factory--Jwell Thailand factory is also under construction. Jwell always keep innovation and provides the best quality products and after-sale services for both home and abroad customers.JWELL is diversifying her extrusion lines to meet different marketing requests.Jwell products are as followingHDPE/PP/PVC/PPR/PEX/PERT pipe extrusion machinePVC/WPC/PP/PE/ABS profile extrusion machineABS/PP/PS/PET/PE/PC/PMMA/GPPS/PVC/PSP/XPS plate & sheet extrusion machinePolymer compouding extrusionHDPE/PP/PVC pipe shredder systemScrew barrel, T die, rollers, etc.Blow molding machinePP melt blown fabric machinesJwell is always looking forward to cooperating with you to build a high intelligent global extrusion eco-chain together!" https://www.jwellextrusions.com/

Don't wanna be here? Send us removal request.

Text

Plate Extrusion

https://www.jwellextrusions.com/products/plate-extrusion/

Plate extruder is one of the screw plastic extruders. The working mechanism of screw plastic extruder is to rely on the pressure and shear force generated by screw rotation, so that the materials can be fully plasticized and evenly mixed, and formed through die; Therefore, sometimes one extruder of plate extrusion line can complete a series of processes such as mixing, plasticization and molding at the same time, so as to carry out continuous production.

Jwell machinery company specializes in providing all kinds of extrusion plate, such as solid thick plate or hollow plate, usually PP, PC hollow grid plate, PP hollow building template, PP, PE thick plate, PVC thick plate, and other plate equipment. The products can be applied to environmental protection, chemical industry, packaging, construction, billboard, and other fields with mature technical level, stable equipment use, high output, low energy consumption Rapid after-sales, and other advantages.

Types of Plate Extrusion

Waterproof Sheet Extrusion LineWaterproof Sheet Extrusion Line

Jwell is suitable for the production of a variety of materials, including PVC, TPO, PE, and other waterproof coiled materials; Waterproof coiled materials suitable for various product structure forms, including Homogeneous coiled material (code h): waterproof coiled material without inner reinforcement material or backing material.

PP Hollow Sheet Extrusion LinePP Hollow Sheet Extrusion Line

PP hollow lattice board can be used in turnover box, packing box, and other packaging fields because of its light material, high strength, moisture-proof, good environmental protection performance, and secondary processing performance.

PE Sheet Extrusion LinePE Sheet Extrusion Line

PE thick plate production line, namely polyethylene (PE) plate, is widely used in chemical industry, electric power, and other industries. It can also replace the traditional steel plate to pave the road. HDPE board can also be used as engineering plastics in machinery, chemical, and other equipment, and is widely used in the manufacture of ice court wallboard.

PS Sheet Extrusion LinePS Sheet Extrusion Line

PP, PS blister sheet, and stationery decorative sheet production line: PP and PS sheets are widely used, and can be directly used for the packaging of food and electronic products after Blister molding; All kinds of transparent, two-color, frosted, and three-dimensional stationery pieces. The multi-layer co-extrusion production line can be customized according to customer requirements, and the output ranges from 100-1200kg/h.

Die PlatesDie Plates

Plastic sheet extrusion die belongs to a molding die, his discharge way is through the extrusion action to achieve. It is a tool used to shape things. This tool is made up of various parts. Different molds are made up of different parts. Mainly through the need to shape the physical state of the material to change the shape of the mold processing.

Advantages of Plate Extrusion

1.Some plate equipment adopts twin-screw extrusion structure

The building block parallel twin-screw extruder is used. One step process to reduce granulation links. The products can be used in the fields of electronics, luggage, automobile, building materials an...

2.Optimize the screw structure and greatly improve the production capacity

Jwell company after years of technical research, experiments, by changing the screw structure and other ways, greatly improve the equipment capacity of the sheet extrusion line, so that customers can ...

3.It can be customized according to your own needs

Jwell has been specialized in producing extrusion machines for more than 20 years. It has its own complete processing system. It has its own processing center for confidential components such as molds...

4.Timeliness and convenience of after-sales service

Jwell has many years of overseas service experience, factories in Thailand and offices in Turkey, Brazil, India and other countries. With fast service, rich experience and mature technology, jwell can...

Products

FAQ about Plate Extrusion

What is the use of breaker plate in extrusion process?

Prepare raw materials - raw materials into the feeding machine, through the feeding machine into the host hopper - extruder to eat material, through the screw mixing, pressing to plasticize - after the screw out of the plasticized material through the flow channel,Filter impurities or carry out secondary plasticization through metering pump -- after the flow channel, the plasticized and filtered material enters the mold for forming -- after the mold is formed, the raw material enters the three rollers or the shaping table for pressing.Adjust the thickness -- after pressing, it enters the cooling bracket for cooling and shaping -- then it is pulled back by the tractor once or twice -- finally, the finished product after complete cooling enters the cutting part and completes the final cut product according to the actual demand.

What are the applications of breaker plate?

Design Optimization of Jwell Plate Extrusion

Through the technical improvement of screw structure, machine cooling, forming, and other aspects, on the premise of ensuring that the finished products are qualified, the production capacity of the equipment is improved to the greatest extent, and the optimal production capacity is produced on the basis of the same energy consumption.

0 notes

Text

Plastic Profile Extrusion Line

https://www.jwellextrusions.com/products/plastic-profile-extrusion-line/

This plastic profile extrusion line consists of Single Screw Extruder, Vacuum Calibration Table, Haul-off Unit, Cutter and Stacker, the producing line features of good plasticization, high output capacity, low power consumption, and etc. The main plastic profile extruder speed controlled by imported AC inverter, and temperature control by Japanese RKC temperature meter, vacuum pump, and traction gear reducer of the down.

stream equipment are all good quality products, and also easy maintenance. Replace different parts, stably extrude various types of different shapes and structures, such as PP PC PE PVC profile extrusion ABS PS TPU TPE, etc.

Types of Plastic Profile Extrusion Line

WPC Profile Extrusion LineWPC Profile Extrusion Line

The line is mainly used in an extrusion molding of WPC (PE & PP) wood-plastic products such as indoor and outer floor, guardrail, pallet, pavilion, corridor.

PVC Profile Extrusion LinePVC Profile Extrusion Line

Adopting new technologies, optimizing the unit, has the advantages of uniform plasticization, small shear rate, high yield, long service life, suitable for processing various types of plastic profiles.

Trunking Extrusion LineTrunking Extrusion Line

The production line is mainly used for extrusion processing of various industrial cable grooves, civil cable slots, cable bridges, and other products, can achieve online punching, printing, stickers and protective film, high extrusion efficiency, simple operation.

PVC/TPU/TPV/TPE Sealing Profile Extrusion LinePVC/TPU/TPV/TPE Sealing Profile Extrusion Line

The machine is used for producing sealing strip of PVC, TPU, TPE, etc material, features high output, steady extrusion, low power consuption. Adapting famous inverter, SIEMENS PLC and screen, easy operation and maintenance.

3D Printing Extrusion Production Line3D Printing Extrusion Production Line

The production line of JWell independently design is used for processing 3D consumables, car tubes,trachea and other products.

PVC Door Panel Extrusion LinePVC Door Panel Extrusion Line

The production line can produce the PVC wood-plastic door of the width between 600 and 1200 .the device has SJZ92/188 conical twin screw extruder, calibration, hall-off unit, cutter

PVC Wall/Ceiling Panel Extrusion LinePVC Wall/Ceiling Panel Extrusion Line

The machine is used for producing WPC decoration product, which is widely used in house and public decoration field, . It can be high quality decoration material for ceiling, door frame, window frame,...

Applications of Plastic Profile Extrusion Line

1

The PE / PP wood-plastic line is mainly used in PE / PP floor extrusion, PE / PP floor is widely used in outdoor parks, outdoor pavilions, etc. The production line can use different specifications of ...

2

Mature applied to door and window profiles, plastic products such as fence and other plastic products. In various types of buildings, plastic windows, doors, floors, wall panels, ceiling have highligh...

3

Car seals are one of the important parts of the automobile, widely used in the door, window, body, skylight, engine box and backup (luggage) box, etc., with sound insulation, dust, anti-seepage and sh...

4

Jwell helps build a green ocean pasture! Traditional offshore box breeding is the main production information in wooden box, woody fishing and plastic foam. It will cause serious pollution to the sea ...

Products

FAQ about Plastic Profile Extrusion Line

Can JWEEL companies offer plastic formulas?

JWELL machinery china company has more than 200 professional equipment engineers, can provide customers with relevant technical services.

What are your standard lead times?

Plastic Profile Extrusion Line Materials

This series of plastic profile extrusion line includes single screw extruders, vacuum calibration tables, traction devices, tools and stacker.

Extruder uses Siemens, ABB, and other imported inverters, Japan Omron temperature control form, France Schneider contactor, relay, electrical control system. German imported oil seals, molars, and other mechanical transmission systems. It can provide different design screws according to the characteristics of customer products, to deal with the requirements of plasticization. The fixed station uses special to increase the swirl current cooling system for cooling, special horizontal tilt control unique three-dimensional adjustment control, making it easier to operate. The tractor adopts unique lift technology, up and down track back pressure control, smooth work, good reliability, large traction. The cutting machine can be automatically fixed and configure dust recovery unit. Jwell's 30-year experience in the industry, as well as the design of the entire product from the perspective of the operator, makes it easy to operate, easy to maintain.

0 notes

Text

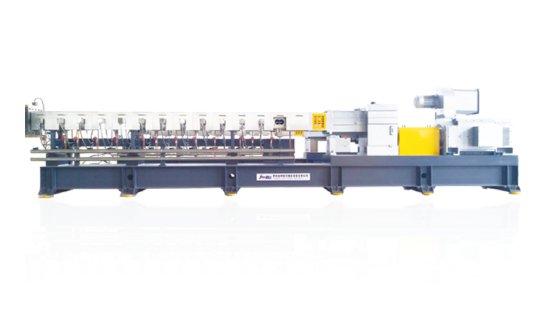

Plastic Compounding Machine

https://www.jwellextrusions.com/products/plastic-compounding-machine/

The twin-screw extruder is composed of a transmission device, a feeding device, a barrel, and a screw, and the functions of each component are similar to single-screw extruder. The difference from the single-screw extruder is that there are two parallel screws in the twin-screw extruder.

The complex flow pattern of the material in the twin screw compounding machine macroscopically shows the advantages that the single-screw extruder cannot match, for example, sufficient mixing, good heat transfer, large melting ability, strong exhaust ability and good temperature control of the material, etc.

Description About Plastic Compounding Machine

Item

Description

Place of origin

China

Brand name

JWELL

Model number

CJWH-85

Capacity

300-500kg/hr

Typical application

TPU

Packaging details

Wooden pallet packing

Delivery time

90days

Payment terms

TT. LC

Specifications of Plastic Compounding Machine

Model

Diameter

L/D

Screw speed

Motor Power

Torque per shaft

Specific torque

Capacity Range

mm

rpm/min

KW

N.m

T/A3

kg/hr

CJWH35

35.6

24~68

600

30

235

8.7

75~150

1000

45

8.7

110~220

CJWH40

41.1

24~68

600

45

357

8.7

110~220

1000

75

8.7

190~380

CJWH52

51.4

24~68

600

90

692

8.7

220~440

900

132

8.7

330~660

CJWH65

62.4

24~68

600

160

1224

8.7

400~800

900

220

8.7

550~1100

CJWH75

71

24~68

600

220

1880

8.7

550~1100

800

315

8.7

800~1600

CJWH85

81

24~68

600

315

2713

8.7

800~1600

800

450

8.7

1100~2200

CJWH95

93

24~68

600

500

4131

8.7

1250~2500

700

600

8.7

1500~3000

CJWH110

108

24~68

500

630

6346

8.7

1500~3000

600

800

8.7

2000~4000

CJWH120

120

24~68

500

900

8705

8.7

2250~4500

600

1000

8.7

2500~5000

CJWH135

132

24~68

400

900

11586

8.7

2250~4500

500

1000

8.7

3000~6000

Plastic Compounding Machine Application

Plastic Compounding Machine Application

Petrochemical Powder Pelletizing and Powder Compouding:

Petrochemical powder pelletization and powder modification are one of the most important applications for twin screw extrusion machine. Through continuous efforts, optimization, and improvement, the integration of industry resources has been widely recognized by the market.

Bio-degradable Plastic Compouding and Pelletizing Series:

Typical application as plastic alloy, starch filled compound, bio-mass filled compound or mineral power filled compound for bio degradable plastics as PLA, PBAT, PBS, PPC, PCL, TPS, and PHA, etc.

Plastic Compounding Machine Performance and Advantages

The screw and barrel adopt the "building block" structure, which has good interchangeability, and can be used in any combination according to the different material processing technology;

The cylinder body is made of nitrided steel and bimetal materials, which are wear-resistant and corrosion-resistant, and extend the service life; the threaded elements are made of nitrided steel and high-speed steel. Normal tooth surface clearance, and good self-cleaning;

The specially designed connection method and transmission device enhance the strength of the threaded element and the mandrel. The above measures achieve the purpose of uniform material dispersion, good mixing and plasticizing effect, short material retention time, and high conveying efficiency.

0 notes

Text

Pipe Extrusion Machine

https://www.jwellextrusions.com/products/pipe-extrusion-machine/

JWELL Machinery is designed and developed in a new idea, pipe and profile extrusion line produces PP pipe series, PVC pipeline series, ABS pipeline series, composite pipe series, etc., plastic pipe extrusion machine is high-yield, low energy consumption, good melt homogeneity, and long-term Running stability, modular design is a pipe extruder series, providing convenience, how to save raw materials, improve automation, ensure high output rate, high quality extrusion, and pipe extrusion machine price is very competitive for users, etc. aspects provide the perfect total solution

Types of Pipe Extrusion Machine

Corrugated Pipe MachineCorrugated Pipe Machine

HDPE/PP/PVC horizontal type Double Wall Corrugated pipe extrusion line、Special Use Single Wall and Double-wall Corrugated Pipe Extrusion Line produced by Jwell has many patents. Full automatic control, running stable, high capacity.

HDPE Pipe Extrusion MachineHDPE Pipe Extrusion Machine

This hdpe extrusion machine line adopts the most advanced technology of Europe, It is a new research achievement of energy-saving production line, The product line has a good appearance and high cost performance compared to the traditional equipment. The line is higher capacity and lower tons-consumption, more precise extrusion.

Twin Screw Pvc Pipe MachineTwin Screw Pvc Pipe Machine

This production line adopts special screw and mould design to make the material form easily with uniform plasticizing, high production speed, stable running, and easy operation. Suitable for pipe extrusion production such as PVC, CPVC, OPVC

PP Pipe Extrusion MachinePP Pipe Extrusion Machine

This Jwell self-manufactured production line adopts Europe's advanced technology with the feature of unique structure, leading configuration, high automation, and easy operation. The extruder screw adopts BM high-efficiency type with big output, good plasticizing, nice stability, and excellent reliability, Suitable for PP-R PO, PE-RT, PB, MPP, etc.

Highlights of Pipe Extrusion Machine

1

Founded in 1978 China's first screw JHL brandHigh extrusion efficiencyLow energy consumptionMelt temperatureExcellent melt uniformitySpecial screw design, fast heating, compared to other same type...

2

Advanced SIEMENS computer control system achieves integration and closed-loop control of the whole line, easy data analysis (energy consumption display and analysis), remote diagnosis (fast after-sale...

3

High torque precision reducer and AC frequency conversion or permanent magnet servo motor to ensure the stability and less energy consumption of long-term high extrusion production

4

Jwell make the pipe molds by herself. For HDPE pipes, with special material mold 40Cr. Beside, we can also provide a complete spare parts service for mold including die pin, die bush, and calibration ...

Products

FAQ about Pipe Extrusion Machine

Can JWELL currently produce how big size pipe extrusion lines?

Jwell plastic extrusion company PE pipe machine from extrusion line can stably extrud out a solid wall pipe of 3 meters, and the bellows can be highly squeezed out of the 1.2-meter diameter double-wall corrugated pipeline.

How to identify good or bad performance of PVC pipe?

Pipe Extrusion Machine Produce Process

1, mixed drying

The mixture of the mixed water is to obtain a well-known raw material with the color master material and mix, mix, mix, mix.

2, plasticizing extrusion

The raw material is hopped from the hopper to the extrusion line machine, transported, reduced, melted, homogenized, slowly turned from solid particles to high elastic, and then slowly became a viscous fluid (viscosity) And persistently squeeze.

3, mold forming

At a suitable temperature, the material extruded from the extruder is based on the filter plate by the rotational motion into a straight movement into the mold. After the spiral separation, the compaction is a tubular blank in the forming section and finally press the mouthoff.

4, refrigeration molding

From the mold extruded heat pipe blank in a negative pressure state, according to the type and refrigeration of the vacuum set of vacuum box, it will slowly refrigerate the pipe inside the pipe, and the overall cooling is formed.

5, cutting

Under the calculation of the wheel meter, the fixed length cutting of the pipe is completed according to the cutting machine.

6, stacked packaging

0 notes

Text

PET Sheet Extrusion Line

https://www.jwellextrusions.com/products/pet-sheet-extrusion-line/

Jwell PET sheet extrusion line: this line equipped with degassing system, The crystallization-free and drying-free exhaust PET sheet unit launched by Jwell has the advantages of low energy consumption and high efficiency. This model is the continuous improvement and upgrade of Jwell.

Pet sheet making machine of pet sheet extrusion line has made a major technical upgrade to the core all system, it uses PET special structure rollers Group so that the cooling efficiency is greatly improved, thereby increasing the output, and improving the toughness and transparency of the product. Jwell's independently programmed operating system ensures the user-friendly and easy-to-operate type of equipment.

Description About PET Sheet Extrusion Line

Place of Origin:

Changzhou

Brand Name:

JWELL

Model Number:

JWS75/85/95

Cerrification:

CE, ISO

Minimum Order Quantity:

1 set

Packaging Details:

wooden Pallet Packing

Delivery Time:

90days

Payment Terms:

TT, LC

Specifications of PET Sheet Extrusion Line

Model

Multi layer

single layer

Highly-efficient

Extruder model

SJz75&36/40-1000

SJz85/40-1000

SJz95&65/44-1500

Production thickness(mm)

0.15-1.5

0.15-1.5

0.15-1.5

Main moror power (kw)

132/15

200

315

Capacity (kg/h)

500

750

800-1000

PET Sheet Extrusion Line Application

PET Sheet Extrusion Line Application

PET/PLA extruded sheets are widely used in vacuum forming fields because of PLA and PET sheet extrusion line price: food packaging, toy boxes, stationery boxes, gift boxes and tools, fruit hardware, and other packaging; application in the field of antistatic: electronic parts packaging, permanent electrical conductivity Packaging of films, permanent antistatic films, permanent semi-conductive films, etc.; applications in daily life: blister, folding box, packaging, printing, card making, and other industries.

FAQ about PET Sheet Extrusion Line

Can Multi-layer Structured Sheets Be Produced?+

Jwell machine can produce single-layer, double-layer and multi-layer structure PET sheets.

How Long is the Delivery Date?+

How Long is the Warranty Period?+

PET Sheet Extrusion Line Performance and Advantages

Kingwell is the largest plastic extrusion machinery manufacturer in China. We have a complete quality management system, stable suppliers, and high-end suppliers, to provide us with the best quality products, such as motors, gearboxes, PLC... etc. For the most important parts, screws, barrels, core parts, etc., we manufacture ourselves. In addition, we have the best after-sales service. We have more than 300 after-sales service personnel, with offices all over the world, and can provide after-sales service to customers all over the world. We look forward to working with you!

0 notes

Text

PET Recycle Compounding Line

https://www.jwellextrusions.com/products/pet-recycle-compounding-line/

PET bottle flakes in the process of recycling has strict requirements to the viscosity of the granules, through years of hard search, steady accumulation, our company has developed two kinds of production according to the market for customer option, one is economical, using common way to water cooling strand pelletizing, the other is a high energy-saving, adopt advanced strand cutting in water, simple operation, convenient maintenance.

Description About PET Recycle Compounding Line

Item

Description

Place of origin

China

Brand name

JWELL

Model number

CJWH85

Application

PET falkes pelletizing

Packaging details

Wooden pallet packing

Delivery time

90days

Payment terms

TT. LC

Specifications of PET Recycle Compounding Line

Model

L/D

Speed

Capacity

CJWH75

40-48

300-500rpm

300-500kg/hr

CJWH85

40-48

300-500rpm

400-600kg/hr

CJWH95

40-48

300-500rpm

1000-1200kg/hr

PET Recycle Compounding Line Application

PET Recycle Compounding Line Application

The main market of PET recycle flakes is still sheet material, accounting for 38%; followed by blow molding equipment accounting for 26%; fiber accounting for 24%. The survey report concluded that a little more than 11% of the remaining is used for bandage and other applications.

PET bottle

PET stable fiber

PET POY yarn

PET sheet

PET Recycle Compounding Line Performance and Advantages

The output of PET extrusion line is 10-15% higher than the single screw, the mixing and dispersion are good.

No complicated pre-crystallization drying system is needed, ideal PET intrinsic viscosity control can be achieved, IV drop is very small, and chemical viscosity can be achieved online with the addition of appropriate additives.

0 notes

Text

PE Sheet Extrusion Line

https://www.jwellextrusions.com/products/pe-sheet-extrusion-line/

Jwell has the following products in the thick plate production line:

PP thick plate production line

Sheet from PP Thick Plate Extrusion Line can be widely used in chemical industry, food industry, anti-corrosion industry, purification industry, and environmental protection equipment production industry. The 2000mm wide PP thick plate production line is the most stable production line developed by jwell company, which is ahead of its peers. At present, jwell can achieve the super large production line of double machine coextrusion of 2000kg / h.

PE thick plate production line

Polyethylene (PE) sheet from PE foam sheet extrusion line and extruder is widely used in chemical industry, electric power, and other industries. HDPE board can also be used as engineering plastics in machinery, chemical, and other equipment, and is widely used in the manufacture of ice court wallboard. Jwell's latest research and development of PE paving board production line is widely used in Oilfield paving and other aspects.

PVC thick plate extrusion line

Hard PVC thick plate is widely used in chemical industry, petroleum, electroplating, water purification and treatment equipment, environmental protection equipment, mining, medicine and electronics, communication, anti-corrosion containers, equipment electrical shields, light boxes, advertising decoration, and other industries. PVC has a wide range of applications, preferential prices, and fast delivery time.

Description About PE Sheet Extrusion Line

Place of origin

China

Brand name

Jwell

Model number

JWS150, JWS180, SJZ80/156

Certification

CE ISO

Minimum order quantity

1 set

Packaging details

Wooden pallet packing

Delivery time

90days

Specifications of PE Sheet Extrusion Line

Species

PP, PE, ABSThick Plate Extrusion Line

PP, PE, ABS Thick Plate Extrusion Line

PVC Thick Plate Extrusion Line

Model

JW150-2000

JW180-2000

SJZ80/156-1500

Material

PP/PE/ABS

PP/PE/ABS

PVC

Production thickness(mm)

3-30MM

3-30MM

3-30MM

Products Width(mm)

1220-2000

1200-3000

1220

Output (kg/h)

500KG/H

800kg/h

450kg/h

PE Sheet Extrusion Line Application

PE Sheet Extrusion Line Application

The application range of plastic thick plates is very wide. The applications of thick plates of different materials are as follows:

PP thick plate can be widely used in chemical industry, food industry, anti-corrosion industry, purification industry, and environmental protection equipment production industry.

PE thick plate is widely used in chemical industry, electric power, and other industries. HDPE board can also be used as engineering plastics in machinery, chemical, and other equipment. It is widely used to manufacture ice court wallboard. It can also be used to replace metal paving board and pave roads.

ABS thick plate is widely used in home appliances, electronics, packaging, medical devices, and other fields.

PVC thick plate has the advantages of smooth and smooth surface, no water absorption, no deformation, and easy processing. It is an excellent thermoforming material and can replace some stainless steel and stainless steel Other corrosion-resistant synthetic materials are widely used in chemical industry, petroleum, electroplating, water purification and treatment equipment, environmental protection equipment, and other industries.

PE Sheet Extrusion Line Performance and Advantages

In the PP thick plate production line, jwell company has developed an extremely stable 2000mm wide PP thick plate production line ahead of its peers and a 2000kg / h double machine co-extrusion high-yield production line.

In the PE thick plate production line, jwell machinery china company has developed a deep textured PE paving plate production line, which can replace the traditional metal paving plate and be used for paving in oil fields and other places. Due to the unique toughness of plastics, it can be used repeatedly.

In the PVC thick plate, jwell company has the experience of leading its peers, and the price is preferential, the delivery time is fast, and the operation and after-sales are also very convenient.

0 notes

Text

Automatic Blow Molding Machine

https://www.jwellextrusions.com/products/automatic-blow-molding-machine/

1. In recent years, the electric blow molding machine has great advantages in the clean production and energy saving of blow molded products, and automatic blow molding machine's research and development progress are relatively fast.

For some blow molding production workshops that require a high degree of cleanliness, electric blow molding units will be one of the first choices.

2. Raw material plasticization, extrusion, mold shifting, mold closing, and blow molding are all driven by high-performance servo motors, completely replacing traditional hydraulic drive technology, energy-saving and environmentally friendly, and fully automatic blow molding equipment and auto deflashing blow moulding machine are excellent equipment for modern industrial production.

3. At present, the general electric hollow molding machine is mainly used in some high-end blow molding product industries and industries that require highly clean production. With the further reduction of automatic blowing machine and fully automatic blow moulding machine equipment manufacturing price and costs, it may be promoted to other blow molding product industries.

4. At present, large and medium-sized (high tonnage clamping force) electric hollow forming units are relatively rare. With the increasing requirements for the clean production of some large and medium-sized plastic barrels, the development of large and medium-sized electric hollow molding machines will likely be accelerated. To seize the development time is to seize the market.

Automatic Blow Molding Machine Application

JWELL machinery china is researching and developing a fully electric Blow molding machine to meet the Food, Medical, Health, and other industries' requirment for the machine and product clean. Compare with the traditional Hydraulic type blow molding machine, The fully electric blow molding machine adopts fully servo-driving motor, energy-saving about 30%.No oil-leakage. Fully automatic blow moulding machine has low noise and can keep the workshop.

Automatic Blow Molding Machine Performance and Advantages

Energy consumption

The use of servo motors and servo drives can effectively save energy, and the energy-saving efficiency is generally 50% to 70% (depending on the product).

Cleanliness and noise

All servo motors are used, and there is no noise caused by hydraulic pumps. The decibels are reduced by 10-15dB. There is no oil leakage problem. The workshop is very clean and easy to maintain.

Response

Faster response time, greater efficiency, and control range. Higher and wider, especially suitable for high-speed and large-volume extrusion blow molding machine.

Accuracy and repeatable positioning

fully closed-loop control, high-precision encoder, controllable within 0.02mm, suitable for the production of high-precision products, high repeat positioning accuracy.

Automatic Blow Molding Machine Packing & Shipping

1 note

·

View note