Text

Precision CNC Machining for Medical Devices

Get precision CNC machining services at RPWORLD. We specialize in CNC milling, CNC turning, and high-quality on-demand manufacturing solutions. Precision CNC Machining for Medical Devices

#CNC Services for Automotive#CNC Machined Parts Suppliers#How CNC Machining Works#CNC Machining Services Near Me#CNC Milling Services for Electronics#Custom CNC Parts for Prototyping#Rapid CNC Prototyping Services

0 notes

Text

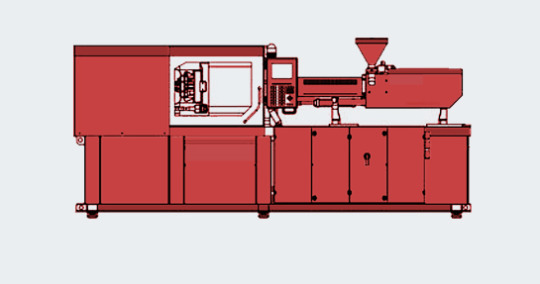

Custom Injection Molding Solutions

Get high-quality injection molding services at RPWORLD. We specialize in rapid injection molding and industrial solutions tailored to your manufacturing needs. https://www.rpworld.com/en/service/injection-molding/

#Injection Molding for Medical Devices#Custom Plastic Molded Parts for Electronics#Injection Molding#Plastic Molded Parts#Rapid Injection Molding

0 notes

Text

Custom Injection Molding Solutions

Get precision CNC machining services at RPWORLD. We specialize in CNC milling, CNC turning, and high-quality on-demand manufacturing solutions. https://www.rpworld.com/en/service/cnc-machining/

Contact Details:

Address: F1-3, Bldg. A1, Henghuifeng Industrial Zone, DaChong Town, Zhongshan, Guangdong Prov., 528476, P. R. China

Tel: +86 (0) 731 8983 2400 Fax: +86 10 8479 9500 Email: [email protected]

0 notes

Text

Precision CNC Machining for Medical Devices

Get precision CNC machining services at RPWORLD. We specialize in CNC milling, CNC turning, and high-quality on-demand manufacturing solutions.

0 notes

Text

Rapid Prototyping for Lab Equipment: The Role of RPWORLD in Accelerating Research and Development

Accelerating Research and Development with Rapid Prototyping

In the fast-paced world of laboratory equipment development, speed and precision are critical. RPWORLD plays a pivotal role in advancing research and development (R&D) through its innovative rapid prototyping solutions. As a leading machining manufacturer, RPWORLD specializes in on-demand manufacturing that meets the stringent demands of the laboratory equipment industry.

The Significance of Rapid Prototyping in Lab Equipment Development

Rapid prototyping revolutionizes the way laboratory equipment is designed and manufactured. This process allows researchers and engineers to quickly iterate on designs, test concepts, and refine functionalities before moving into production. RPWORLD’s expertise in rapid prototyping ensures that each prototype is meticulously crafted to exact specifications, enabling faster development cycles and superior product outcomes.

On-Demand Manufacturing for Flexibility and Efficiency

Flexibility is crucial in R&D environments where innovation drives progress. RPWORLD’s on-demand manufacturing capabilities empower laboratories to adapt swiftly to evolving research needs. By producing components as needed, laboratories can minimize inventory costs and reduce the time-to-market for new equipment. This approach not only enhances operational efficiency but also supports continuous innovation in scientific research.

RPWORLD: Your Partner in Machining and Prototyping Excellence

As a trusted machining manufacturer, RPWORLD combines cutting-edge technology with a commitment to quality and precision. From initial concept to final production, RPWORLD collaborates closely with laboratories to deliver bespoke solutions tailored to their unique requirements. Whether it’s creating intricate components for analytical instruments or developing specialized parts for biomedical devices, RPWORLD’s dedication to excellence ensures superior performance and reliability.

Case Study: Advancing Lab Equipment Development

A renowned research institute partnered with RPWORLD to develop a groundbreaking analytical device. Utilizing RPWORLD’s rapid prototyping capabilities, the institute was able to iterate rapidly on design concepts and validate functionalities early in the development process. This collaborative effort not only accelerated time-to-market but also enhanced the device’s precision and performance, setting new benchmarks in laboratory equipment innovation.

Expertise and Innovation in Action

RPWORLD’s team of skilled engineers and technicians brings a wealth of experience to every project. Their expertise in rapid prototyping and precision machining enables them to tackle complex challenges with confidence. By leveraging the latest advancements in manufacturing technology, RPWORLD continues to push the boundaries of what’s possible in laboratory equipment development.

Commitment to Quality and Sustainability

Quality and sustainability are integral to RPWORLD’s operations. They adhere to stringent quality control measures and prioritize sustainable manufacturing practices to minimize environmental impact. This commitment not only ensures compliance with industry regulations but also underscores RPWORLD’s dedication to delivering products of the highest standard.

Conclusion

RPWORLD’s leadership in rapid prototyping and on-demand manufacturing is reshaping the landscape of laboratory equipment development. By partnering with RPWORLD, laboratories gain access to cutting-edge solutions that accelerate R&D processes, enhance product innovation, and drive scientific discovery forward. Explore how RPWORLD can support your laboratory equipment initiatives by visiting RPWORLD today.

0 notes

Text

How to Solve Design Failures in the Automotive Industry?

The automotive industry constantly faces the challenge of balancing innovation with reliability. Design failures can be costly, impacting safety, performance, and customer satisfaction. Effective solutions to these failures are essential for maintaining quality and competitiveness. This article explores how leveraging advanced manufacturing techniques, such as plastic casting and plastic injection molding, can address design issues in automotive production, with a focus on the services provided by RPWORLD.

Identifying Common Design Failures

Design failures in the automotive industry often stem from material weaknesses, manufacturing inconsistencies, and design flaws. Common issues include:

Material Fatigue: Repeated stress can cause materials to weaken and fail over time.

Manufacturing Defects: Inconsistencies during production can lead to parts that don't meet design specifications.

Design Flaws: Poor design choices can result in parts that are not fit for purpose.

Solutions Using Advanced Manufacturing Techniques

Plastic Casting and Plastic Molding are pivotal in resolving many of these design failures. Here’s how:

Plastic Injection Molding

Plastic injection molding involves injecting molten plastic into a mold to create precise and consistent parts. It is especially beneficial for producing complex shapes and high-volume components. The advantages include:

Precision and Consistency: Injection molding ensures each part is produced to exact specifications, reducing the risk of manufacturing defects.

Material Versatility: This process can use various types of plastic, allowing manufacturers to select materials that best meet the performance requirements of each part.

Efficiency: High production rates and repeatability make plastic injection molding ideal for large-scale automotive manufacturing.

Plastic Casting

Plastic casting involves pouring liquid plastic into a mold where it solidifies into the desired shape. This method is useful for creating parts with complex geometries and for low to medium production volumes. Benefits include:

Complex Geometries: Plastic casting can produce parts with intricate details that might be challenging for other manufacturing methods.

Cost-Effective Tooling: Casting molds can be created more quickly and cost-effectively than some other types of molds, making it a good choice for prototyping and small production runs.

Flexibility: This process allows for the use of various plastic types, enabling customization based on specific application needs.

The Role of Plastic Molds in Design Success

Plastic molds are critical tools in both injection molding and casting processes. High-quality molds ensure that parts are consistently produced to meet stringent specifications. Key considerations for effective mold design include:

Durability: Molds must withstand the stresses of repeated use without degrading.

Precision: High precision in mold design ensures that every part matches the original design specifications.

Customization: Molds can be tailored to create parts with specific features, enhancing the functionality and performance of the final product.

RPWORLD: Your Partner in Automotive Manufacturing

RPWORLD specializes in providing advanced plastic casting and plastic injection molding services, ensuring that automotive parts meet the highest standards of quality and precision. Our expertise in mold design and manufacturing helps address and prevent design failures effectively.

Our Services Include:

Plastic Injection Molders: Expert molders who ensure each part is produced with precision and consistency.

Plastic Casting: Solutions for producing complex geometries and customized parts.

Plastic Molding: Comprehensive molding services that cater to various automotive needs.

Plastic Molds: High-quality, durable molds designed to produce accurate and reliable parts.

Conclusion

Addressing design failures in the automotive industry requires a combination of precise manufacturing techniques and high-quality materials. Plastic casting and plastic injection molding, supported by expertly designed plastic molds, offer robust solutions to these challenges. RPWORLD’s advanced manufacturing capabilities ensure that your automotive parts are produced with the highest levels of precision and quality. Explore our range of services and discover how we can help you overcome design failures at RPWORLD.

0 notes

Text

How to Choose the Right Manufacturing Processes for Electronic Enclosures?

In the realm of electronic enclosures, selecting the appropriate manufacturing processes is crucial to ensure the functionality, durability, and overall quality of the final product. With advancements in technology and manufacturing capabilities, there's a myriad of options available, making the decision-making process daunting. However, by understanding your requirements and considering factors such as CNC milling and on-demand manufacturing, you can streamline the selection process effectively.

CNC milling stands as one of the leading manufacturing processes for electronic enclosures, offering precision, versatility, and efficiency. RPWORLD, a pioneering name in manufacturing solutions, leverages CNC milling to produce high-quality enclosures tailored to specific needs. With CNC milling, intricate designs and precise specifications can be achieved with utmost accuracy, making it ideal for complex electronic enclosure designs.

One of the key advantages of CNC Milling is its ability to work with various materials, including metals and plastics, providing flexibility in material selection based on the application's requirements. Whether you need enclosures with robust metallic properties or lightweight yet durable plastic ones, CNC milling can cater to diverse material preferences.

Moreover, CNC milling facilitates rapid prototyping, allowing for quick iterations and modifications during the design phase. This iterative approach ensures that the final enclosure meets all functional and aesthetic criteria, minimizing design flaws and optimizing performance.

In addition to CNC milling, on-demand manufacturing emerges as a game-changer in the electronic enclosure industry. RPWORLD's on-demand manufacturing services offer unparalleled flexibility and scalability, catering to businesses of all sizes. Unlike traditional manufacturing methods that entail large batch productions, on-demand manufacturing allows for the production of enclosures in quantities as per the specific requirements, reducing excess inventory and minimizing costs.

The On-Demand Manufacturing model also accelerates the production timeline, enabling faster turnaround times from design to delivery. This agility is invaluable, especially in dynamic industries where speed-to-market is paramount. With RPWORLD's on-demand manufacturing, you can swiftly adapt to changing market demands and capitalize on emerging opportunities without being constrained by lengthy production cycles.

When selecting the right manufacturing processes for electronic enclosures, it's essential to consider factors such as design complexity, material compatibility, production volume, and lead times. By leveraging CNC milling and on-demand manufacturing offered by RPWORLD, you can address these considerations effectively while ensuring superior quality and cost-efficiency.

Furthermore, RPWORLD's expertise in CNC milling and on-demand manufacturing is backed by state-of-the-art facilities, cutting-edge technologies, and a team of experienced professionals dedicated to delivering excellence at every stage of the production process. Whether you're a startup venturing into the electronics industry or an established enterprise seeking innovative manufacturing solutions, RPWORLD offers tailored services to meet your specific needs and exceed your expectations.

In conclusion, choosing the right manufacturing processes for electronic enclosures is paramount for achieving optimal performance, durability, and cost-effectiveness. With CNC milling and on-demand manufacturing from RPWORLD, you can unlock endless possibilities in design, production, and scalability, empowering your business to thrive in a competitive landscape while staying ahead of the curve.

0 notes

Text

Driving Automotive Innovation Forward with Advanced Rapid Injection Molding Techniques

In the ever-evolving landscape of automotive manufacturing, staying ahead of the curve is paramount. With the demand for lightweight, durable, and cost-effective components, plastic injection molding has emerged as a cornerstone technology in the industry. As pioneers in the field, RPWORLD is leading the charge in driving automotive innovation forward through advanced rapid injection molding techniques.

Plastic Injection Molders play a pivotal role in the automotive supply chain, producing a diverse array of components ranging from interior trims to exterior panels. With the relentless pursuit of efficiency and precision, manufacturers are continually seeking ways to enhance their processes. This is where advanced rapid injection molding techniques come into play, revolutionizing the way automotive parts are produced.

At RPWORLD, we leverage cutting-edge technologies and extensive expertise to deliver unparalleled solutions to our clients. Our state-of-the-art facilities are equipped with advanced machinery and automated systems, allowing for high-speed production without compromising on quality. Through meticulous process optimization and stringent quality control measures, we ensure that each component meets the exacting standards of the automotive industry.

Plastic Molding is not just about producing parts; it's about pushing the boundaries of what's possible. With innovative materials and design concepts, we empower automotive manufacturers to unlock new possibilities in vehicle design and performance. From lightweight thermoplastics to high-strength composites, our comprehensive range of materials caters to diverse applications, providing the flexibility and versatility needed to realize ambitious design visions.

Innovation is at the heart of everything we do at RPWORLD. Our dedicated team of engineers and designers work closely with clients to develop customized solutions tailored to their specific requirements. Through collaborative partnerships and a relentless commitment to excellence, we strive to push the boundaries of what's possible in automotive manufacturing.

One of the key advantages of rapid injection molding is its ability to accelerate the product development cycle. With traditional manufacturing methods, prototyping and tooling can be time-consuming and cost-prohibitive. However, with rapid injection molding, we can quickly iterate designs and produce functional prototypes in a fraction of the time, enabling faster time-to-market and greater agility in response to changing market demands.

Furthermore, rapid injection molding offers cost efficiencies that are unparalleled in the industry. By streamlining the production process and minimizing material waste, we help automotive manufacturers optimize their manufacturing costs without compromising on quality or performance. This cost-effectiveness is particularly crucial in today's competitive market environment, where margins are constantly under pressure.

In conclusion, advanced rapid injection molding techniques are driving automotive innovation forward, empowering manufacturers to push the boundaries of design, performance, and efficiency. As a leading provider of plastic injection molding solutions, RPWORLD is committed to pushing the envelope of what's possible, helping our clients stay ahead of the curve in the fast-paced world of automotive manufacturing. With our cutting-edge technologies, unrivaled expertise, and unwavering dedication to excellence, we are shaping the future of mobility, one injection at a time.

#Plastic Injection Molders#Plastic Molding#Plastic Molds#Injection Molding Near Me#Injection Molding Spin Bar

0 notes

Text

Transforming Biotech Research Device Development with Customized CNC Machining

In the ever-evolving landscape of biotechnology research, innovation is key to staying ahead. As the demand for precision instruments and devices continues to soar, the need for efficient manufacturing processes becomes paramount. This is where machining manufacturers and rapid tooling solutions come into play, revolutionizing the biotech industry by offering customized CNC machining services.

Machining manufacturers play a pivotal role in transforming the conceptual designs of biotech research devices into tangible realities. By leveraging advanced technologies such as Computer Numerical Control (CNC) machining, these manufacturers can precisely fabricate intricate components with unmatched accuracy and consistency. This level of precision is essential in the development of biotech instruments where even the slightest deviation can affect performance.

At RPWORLD, we specialize in providing tailored CNC machining solutions to meet the unique requirements of biotech research device development. Our state-of-the-art facilities and team of skilled engineers enable us to deliver high-quality components with quick turnaround times. Whether it's prototyping a new device or mass-producing components for commercial use, our expertise in Rapid Tooling ensures that projects are completed efficiently without compromising on quality.

One of the primary advantages of CNC machining in biotech research device development is its ability to accommodate complex geometries and materials. Biotech instruments often feature intricate designs and require specific materials to meet performance criteria. With CNC machining, manufacturers can work with a wide range of materials, including metals, plastics, and composites, to produce components that meet the exact specifications of the application.

Furthermore, CNC machining offers unmatched repeatability, ensuring that each component produced adheres to the same precise dimensions. This level of consistency is crucial in the biotech industry, where reproducibility is essential for conducting reliable experiments and studies. By partnering with a Machining Manufacturer like RPWORLD, biotech companies can streamline their production processes and reduce the risk of errors or inconsistencies in their research devices.

In addition to precision and repeatability, CNC machining also offers flexibility in design iterations. Biotech research is a dynamic field where innovation and adaptation are constant. With CNC machining, manufacturers can quickly iterate on designs and make adjustments as needed, allowing for rapid prototyping and product development. This agility is invaluable in the fast-paced world of biotechnology, where time-to-market can make all the difference.

At RPWORLD, we understand the unique challenges faced by biotech companies in device development. That's why we offer comprehensive CNC machining services tailored to the specific needs of our clients. From initial concept design to final production, we work closely with biotech companies to ensure that their vision is brought to life with precision and efficiency.

In conclusion, CNC machining has revolutionized the way biotech research devices are developed and manufactured. Machining manufacturers like RPWORLD play a crucial role in this transformation by providing customized solutions that meet the stringent requirements of the biotech industry. With our expertise in rapid tooling and CNC machining, we empower biotech companies to innovate with confidence and drive advancements in medical research and healthcare.

0 notes

Text

Enhancing Robotics Development with Rapid Prototyping: A Look at Vacuum Casting and Overmolding

Introduction:

In the fast-evolving landscape of robotics development, staying ahead requires cutting-edge techniques that can expedite the design and manufacturing process. Rapid prototyping has emerged as a game-changer, allowing engineers and designers to quickly iterate and test their ideas. In this article, we will delve into the significance of rapid prototyping in robotics and explore two key methodologies - Vacuum Casting and Overmolding - that are revolutionizing the industry.

Rapid Prototyping: A Catalyst for Innovation

Rapid prototyping is a transformative approach that accelerates product development by enabling the swift creation of physical prototypes. Unlike traditional methods that are time-consuming and expensive, Rapid Prototyping empowers robotics engineers to bring their ideas to life in a matter of days. This iterative process not only enhances creativity but also facilitates the identification and resolution of potential issues early in the development cycle.

Vacuum Casting: Precision in Replication

Vacuum casting is a pivotal technique within the realm of rapid prototyping. It involves creating multiple copies of a prototype using silicone molds and polyurethane resins. This process is particularly advantageous for robotics development, where precision and consistency are paramount. Vacuum casting allows for the production of high-quality, detailed replicas that closely mimic the final product, providing engineers with the ability to conduct thorough testing and validation.

Key Benefits of Vacuum Casting in Robotics Development:

Cost-Effective Iterations: Vacuum casting significantly reduces the cost of producing multiple prototypes, enabling engineers to iterate and refine designs without breaking the bank.

Quick Turnaround: With vacuum casting, multiple copies can be produced in a matter of days, facilitating rapid design iterations and accelerating the overall development timeline.

Material Diversity: Engineers can choose from a variety of materials with different properties, allowing them to assess performance under various conditions and select the most suitable material for the final product.

Overmolding: Enhancing Functionality and Aesthetics

Overmolding is another innovative technique that adds a layer of complexity and functionality to robotics prototypes. It involves the process of molding a second material over the first to create a composite structure. This is particularly beneficial in robotics development, where the integration of sensors, grips, and other functional elements is crucial.

Key Advantages of Overmolding in Robotics Development:

Seamless Integration of Componentas: Overmolding enables the integration of multiple components into a single, cohesive structure, enhancing the overall functionality and reducing the need for additional assembly steps.

Improved Ergonomics: The addition of soft-touch or grip-enhancing materials through overmolding enhances the ergonomic aspects of robotics prototypes, making them more user-friendly and practical.

Enhanced Aesthetics: Overmolding allows for the incorporation of different colors and textures, contributing to the aesthetics of the final product and potentially improving user acceptance.

Conclusion:

In the dynamic world of robotics development, rapid prototyping, vacuum casting, and overmolding are becoming indispensable tools. By embracing these technologies, engineers can streamline the design and manufacturing processes, reduce time-to-market, and ultimately create more innovative and functional robotic solutions. As the industry continues to evolve, staying at the forefront of these advancements will be essential for those seeking to push the boundaries of what robotics can achieve.

Unlock innovation in robotics with RPWORLD. Explore rapid prototyping, vacuum casting, and overmolding at RPWORLD. Accelerate your development journey – turn ideas into reality today!

#Rapid Prototyping#Vacuum casting#Prototyping#On-Demand Manufacturing#Machining Manufacturer#Urethane Casting

0 notes

Text

The Role of CNC Machining in Customized Manufacturing of Medical Device Part

Introduction:

In the dynamic landscape of medical device manufacturing, precision and customization are paramount. As technology continues to evolve, CNC machining has emerged as a cornerstone in the production of customized medical device parts. In this article, we will delve into the pivotal role of CNC machining, particularly CNC manufacturing and CNC milling, in shaping the future of personalized medical devices.

CNC Manufacturing Unveiled:

CNC, or Computer Numerical Control, manufacturing involves the use of computerized systems to control and automate machining tools. This technology has revolutionized the manufacturing process by enhancing precision, efficiency, and the ability to produce intricate components. In the realm of medical devices, where precision is non-negotiable, CNC manufacturing shines as a versatile and reliable solution.

Precision at Its Core:

CNC manufacturing's prowess lies in its ability to execute highly complex and precise operations. The machinery, guided by computer-aided design (CAD) models, ensures unparalleled accuracy in shaping medical device components. This level of precision is crucial for the production of implants, prosthetics, and other intricate medical devices where even the slightest deviation can have significant consequences.

CNC Milling: Sculpting the Future of Medical Device Parts:

Within CNC manufacturing, CNC milling plays a pivotal role in the production of medical device parts. This subtractive manufacturing process involves removing material from a workpiece to achieve the desired shape. The precision and versatility of CNC milling make it an ideal choice for crafting intricate components, ranging from bone implants to specialized surgical tools.

Customization Beyond Limits:

One of the standout features of CNC machining, particularly CNC milling, is its ability to accommodate customization on a granular level. Medical devices often require tailored solutions to meet the unique needs of patients. CNC milling allows manufacturers to create intricate and personalized parts, ensuring a perfect fit and function for each individual case. This level of customization is a game-changer in the medical industry, where one size certainly does not fit all.

Efficiency and Time Savings:

CNC manufacturing, including CNC milling, significantly reduces production time compared to traditional manufacturing methods. The automated and precise nature of CNC machining minimizes errors, streamlines the production process, and accelerates time-to-market for critical medical devices. In an industry where timely delivery can be a matter of life and death, this efficiency is invaluable.

Quality Assurance and Compliance:

Medical device manufacturing demands adherence to stringent quality standards and regulatory requirements. CNC machining, with its automated processes and strict adherence to design specifications, ensures consistent quality and compliance with industry standards. This reliability is essential for meeting regulatory approvals and instilling confidence in healthcare practitioners and patients alike.

Conclusion:

In the realm of customized manufacturing for medical device parts, CNC machining stands as a technological beacon. The combination of CNC manufacturing and CNC milling not only guarantees precision and efficiency but also opens the door to a new era of personalized medical solutions. As technology continues to advance, the role of CNC machining in shaping the future of medical device manufacturing is poised to become even more significant, bringing us closer to a world where tailored medical solutions are the norm rather than the exception.

Experience this precision and customization with RPWORLD's cutting-edge CNC machining. Elevate your medical device production by contacting us today for unparalleled quality and innovation. Your vision, our precision, shaping the future of medical excellence.

0 notes

Text

Driving EV Innovation with Rapid Injection Molding

Introduction:

In the ever-evolving landscape of electric vehicle (EV) manufacturing, staying ahead of the curve is crucial for success. One key element that is revolutionizing the industry is the utilization of rapid injection molding, particularly in the realms of on-demand manufacturing and rapid tooling. In this article, we will explore how these innovative processes are driving EV innovation and reshaping the future of automotive manufacturing.

On-Demand Manufacturing:

On-demand manufacturing is a game-changer in the automotive industry, providing flexibility and efficiency that traditional manufacturing methods struggle to match. Rapid injection molding enables manufacturers to produce small to medium batches of parts with shorter lead times, allowing for quicker response to market demands. This is particularly beneficial in the fast-paced world of EVs, where technology and design advancements occur at a rapid pace.

By embracing On-Demand Manufacturing through rapid injection molding, EV manufacturers can reduce costs associated with large-scale production runs, minimize excess inventory, and adapt swiftly to design iterations. This agility not only accelerates the overall production process but also ensures that EVs incorporate the latest technological advancements, keeping them competitive in the market.

Rapid Tooling:

Rapid tooling is another critical aspect that contributes to the success of EV innovation. Traditional tooling methods can be time-consuming and expensive, making it challenging for manufacturers to keep up with the dynamic nature of the EV sector. Rapid injection molding addresses this challenge by significantly reducing the time and costs associated with tooling.

By leveraging Rapid Tooling techniques, EV manufacturers can accelerate the product development cycle. This is especially beneficial for prototyping and testing different design iterations before finalizing the production tooling. The ability to swiftly produce and modify molds allows for a more iterative and efficient approach, ultimately leading to a higher-quality end product.

Benefits of Rapid Injection Molding in EV Manufacturing:

Cost Efficiency: Rapid injection molding minimizes the expenses related to traditional manufacturing processes, allowing manufacturers to allocate resources more efficiently.

Reduced Time-to-Market: The quick turnaround times associated with on-demand manufacturing and rapid tooling enable EV manufacturers to bring their products to market faster than ever before.

Innovation and Customization: The flexibility offered by rapid injection molding empowers EV manufacturers to experiment with innovative designs and cater to the growing demand for customized electric vehicles.

Environmental Impact: As the automotive industry embraces sustainability, the reduced material waste and energy consumption associated with rapid injection molding contribute to a more environmentally friendly manufacturing process.

Conclusion:

In conclusion, the marriage of on-demand manufacturing and rapid tooling through rapid injection molding is propelling the electric vehicle industry into a new era of innovation. EV manufacturers adopting these techniques gain a competitive edge by reducing costs, accelerating production timelines, and fostering a culture of continuous improvement. As the demand for electric vehicles continues to surge, embracing these cutting-edge manufacturing methods is not just an option but a necessity for those striving to lead the charge in driving EV innovation.

Ready to revolutionize your EV manufacturing? Explore on-demand solutions with RPWORLD. Visit us today to discover cost-effective, cutting-edge technologies for accelerated time-to-market. Choose RPWORLD for a future-forward approach to electric vehicle production!Top of Form

0 notes

Text

On-Demand Manufacturing

RPWORLD provides the best CNC milling, turning and drilling servcies, and committed to your machined parts with tight tolernaces and short lead times. With 4-axis, 5-axis CNC machineds, you can get precision parts in as fast as 3 days.

0 notes

Text

How Customized Injection Molding Solutions Save Your Biotech Device Development by 80%

Introduction:

In the rapidly evolving landscape of biotechnology, the development of cutting-edge devices demands innovative solutions that not only meet stringent industry standards but also ensure efficiency and cost-effectiveness. One key aspect that plays a pivotal role in the biotech device development process is injection molding. This article delves into the significant impact of customized injection molding solutions on saving up to 80% of the development costs for biotech devices.

Precision Engineering for Complex Designs:

Customized injection molding allows for the precise replication of intricate and complex designs, a crucial requirement in the biotech industry where devices often have intricate geometries and tight tolerances. This level of precision ensures that the final product meets the specific needs of the biotech application, eliminating the need for costly revisions and adjustments in the later stages of development.

Material Selection for Enhanced Performance:

Biotech devices often require specialized materials to meet the stringent regulatory and performance criteria. Customized injection molding solutions enable the selection of materials that are not only compliant with industry standards but also enhance the overall performance of the device. This targeted material selection ensures durability, biocompatibility, and resistance to harsh environmental conditions, reducing the likelihood of failures and the need for redesigns.

Rapid Prototyping for Iterative Development:

The iterative nature of biotech device development demands quick turnaround times for prototypes and design modifications. Customized injection molding facilitates Rapid Prototyping, allowing developers to assess and refine their designs swiftly. This agility in the development process not only accelerates time-to-market but also significantly reduces costs associated with prolonged development cycles.

Cost-Efficient Production:

Traditional manufacturing methods often involve high tooling costs and lengthy lead times. Customized injection molding solutions, on the other hand, offer a more cost-efficient approach by minimizing

tooling expenses and allowing for large-scale production with shorter cycle times. This results in substantial cost savings, contributing to an overall reduction in the financial burden of biotech device development.

Streamlined Quality Control:

Ensuring the quality and consistency of biotech devices is paramount. Customized injection molding solutions enable the implementation of rigorous quality control measures throughout the manufacturing process. By maintaining tight control over key parameters, such as temperature, pressure, and material flow, manufacturers can produce high-quality components consistently, reducing the need for post-production inspections and rejections.

In conclusion, the utilization of customized injection molding solutions in biotech device development presents a transformative opportunity for companies to achieve substantial cost savings of up to 80%. From precision engineering and material selection to rapid Prototyping and cost-efficient production, these solutions empower developers to navigate the complexities of biotech innovation with greater flexibility and efficiency.

As you embark on your biotech device development journey, consider partnering with RPWORLD, a leading provider of customized injection molding solutions. With our expertise and commitment to excellence, we can help you realize significant cost savings while ensuring the precision and quality your project demands. Embracing customized injection molding is not just a strategic choice; it's a crucial step towards optimizing the development process and driving advancements in the biotech industry. Contact RPWORLD today and let's shape the future of biotechnology together.

0 notes

Text

RPWORLD’s Vacuum Casting Expertise: Accelerating Prototyping in the Robotics Industry

Introduction:

In the rapidly evolving field of robotics, innovation is key to staying ahead of the curve. Prototyping plays a pivotal role in the development cycle, enabling engineers and designers to iterate and refine their ideas before bringing them to market. RPWORLD, a leading player in the industry, has harnessed the power of Vacuum Casting to propel prototyping processes to new heights. This article explores how RPWORLD's Vacuum Casting expertise is accelerating prototyping in the robotics sector.

The Significance of Vacuum Casting in Prototyping:

Vacuum Casting, a versatile and cost-effective manufacturing process, has become a cornerstone in the realm of rapid prototyping. Its ability to produce high-quality, functional prototypes with intricate details makes it an ideal choice for the intricate designs often seen in robotics. RPWORLD has capitalized on this technique to offer robotics engineers and designers a streamlined and efficient prototyping solution.

Precision and Detail:

One of the standout features of Vacuum Casting is its unparalleled precision and ability to capture intricate details. In the robotics industry, where components often require complex geometries and fine details, RPWORLD's Vacuum Casting expertise ensures that prototypes faithfully represent the final product. This precision allows engineers to assess the functionality of their designs accurately and make informed decisions during the prototyping phase.

Speeding Up Development Cycles:

Time is of the essence in the fast-paced world of robotics development. RPWORLD's Vacuum Casting expertise significantly accelerates prototyping timelines, allowing for quicker design iterations and faster product development. With reduced lead times, robotics companies can stay agile, adapt to market changes swiftly, and bring innovative solutions to fruition in record time.

Cost-Effectiveness in Prototyping:

Cost considerations are always at the forefront of product development. RPWORLD's commitment to providing cost-effective solutions through Vacuum Casting ensures that robotics companies can prototype efficiently without compromising on quality. This cost-efficiency empowers organizations to allocate resources effectively and invest in refining their designs for optimal performance.

Customization and Material Options:

RPWORLD's Vacuum Casting expertise extends beyond precision and speed to offer a wide range of material options. Robotics engineers can choose from a variety of materials that closely mimic the final production materials, allowing for accurate performance assessments during Prototyping. Additionally, the flexibility in material selection enables customization to meet specific project requirements, ensuring that the prototypes are tailored to the unique needs of each robotics application.

Conclusion:

In conclusion, RPWORLD's Vacuum Casting expertise is undeniably a game-changer in the realm of robotics prototyping. By seamlessly integrating precision, speed, and cost-effectiveness, RPWORLD empowers robotics engineers and designers to drive innovation at an unprecedented pace. As the demand for cutting-edge robotics solutions continues to surge, there has never been a more crucial time to partner with RPWORLD for your prototyping needs.

Take the leap towards accelerated prototyping and unparalleled precision with RPWORLD. Contact us today to explore how our Vacuum Casting expertise can elevate your robotics projects, shorten development cycles, and ultimately bring your groundbreaking designs to market faster than ever before. Your journey to innovation starts here – let RPWORLD be your trusted partner in shaping the future of robotics.

0 notes

Text

Why Choose Vacuum Casting to Accelerate Your Medical Device Development?

In the dynamic landscape of medical device development, the quest for innovative and efficient manufacturing methods is constant. Vacuum casting has emerged as a prominent solution, offering numerous benefits for the rapid and cost-effective production of medical devices. In this article, we explore why vacuum casting stands out as a compelling choice for accelerating the medical device development process.

Precision and Reproducibility: Vacuum casting enables the creation of highly detailed and accurate prototypes, crucial for the intricate components in the medical field. Consistent reproduction of intricate details ensures the final product meets stringent standards.

Speedy Prototyping: Time efficiency is paramount in the medical device industry, and vacuum casting provides rapid Prototyping capabilities. Quick turnaround times facilitate efficient design iteration, expediting the overall product development timeline.

Material Variety: Medical devices require specific material properties, and vacuum casting supports a wide range of materials, including those with biocompatible and sterilization properties. This versatility allows manufacturers to choose materials tailored to the intended use of the medical device.

Cost-Effective Small-Batch Production: Ideal for small to medium batch production runs, Vacuum Casting offers cost-effective solutions. This is particularly advantageous in the medical device industry, where production volumes may be limited, especially during initial stages.

Complex Geometries and Overmolding: Vacuum casting excels in creating parts with intricate designs and multiple materials, crucial for medical devices with complex geometries and overmolding features.

Reduced Waste and Sustainability: Vacuum casting minimizes material wastage, as it uses only the necessary amount of material to create each mold. This not only contributes to cost savings but also aligns with the growing emphasis on sustainable manufacturing practices. For medical device developers committed to environmental responsibility, vacuum casting offers a greener alternative.

Quality Assurance and Testing: Vacuum casting facilitates the production of high-fidelity prototypes that closely resemble the final product. This allows for more accurate testing and validation processes, ensuring that the medical device meets regulatory requirements and performs as intended. The ability to conduct thorough testing during the development phase contributes to overall project success.

In conclusion, vacuum casting emerges as a compelling choice for medical device development, offering precision, speed, material variety, cost-effectiveness, and the ability to accommodate complex designs. Embracing this advanced manufacturing technique can significantly accelerate the product development cycle, allowing medical device manufacturers to bring innovative solutions to market efficiently and with confidence. As the industry continues to evolve, vacuum casting stands out as a key enabler for those seeking to stay at the forefront of medical device innovation.

For a seamless transition from prototype to production, consider leveraging the expertise and cutting-edge services offered by RPWORLD. Our commitment to excellence in vacuum casting ensures that your medical device development journey is not only efficient but also characterized by precision and reliability. Contact RPWORLD today to explore how our advanced manufacturing solutions can elevate your medical device projects to new heights. Accelerate your innovation with RPWORLD – your trusted partner in bringing ideas to life.

0 notes

Text

RPWORLD’s Vacuum Casting Expertise: Accelerating Prototyping in the Robotics Industry

Introduction:

In the rapidly evolving field of robotics, innovation is key to staying ahead of the curve. Prototyping plays a pivotal role in the development cycle, enabling engineers and designers to iterate and refine their ideas before bringing them to market. RPWORLD, a leading player in the industry, has harnessed the power of Vacuum Casting to propel prototyping processes to new heights. This article explores how RPWORLD's Vacuum Casting expertise is accelerating prototyping in the robotics sector.

The Significance of Vacuum Casting in Prototyping:

Vacuum Casting, a versatile and cost-effective manufacturing process, has become a cornerstone in the realm of rapid prototyping. Its ability to produce high-quality, functional prototypes with intricate details makes it an ideal choice for the intricate designs often seen in robotics. RPWORLD has capitalized on this technique to offer robotics engineers and designers a streamlined and efficient prototyping solution.

Precision and Detail:

One of the standout features of Vacuum Casting is its unparalleled precision and ability to capture intricate details. In the robotics industry, where components often require complex geometries and fine details, RPWORLD's Vacuum Casting expertise ensures that prototypes faithfully represent the final product. This precision allows engineers to assess the functionality of their designs accurately and make informed decisions during the prototyping phase.

Speeding Up Development Cycles:

Time is of the essence in the fast-paced world of robotics development. RPWORLD's Vacuum Casting expertise significantly accelerates prototyping timelines, allowing for quicker design iterations and faster product development. With reduced lead times, robotics companies can stay agile, adapt to market changes swiftly, and bring innovative solutions to fruition in record time.

Cost-Effectiveness in Prototyping:

Cost considerations are always at the forefront of product development. RPWORLD's commitment to providing cost-effective solutions through Vacuum Casting ensures that robotics companies can prototype efficiently without compromising on quality. This cost-efficiency empowers organizations to allocate resources effectively and invest in refining their designs for optimal performance.

Customization and Material Options:

RPWORLD's Vacuum Casting expertise extends beyond precision and speed to offer a wide range of material options. Robotics engineers can choose from a variety of materials that closely mimic the final production materials, allowing for accurate performance assessments during Prototyping. Additionally, the flexibility in material selection enables customization to meet specific project requirements, ensuring that the prototypes are tailored to the unique needs of each robotics application.

Conclusion:

In conclusion, RPWORLD's Vacuum Casting expertise is undeniably a game-changer in the realm of robotics prototyping. By seamlessly integrating precision, speed, and cost-effectiveness, RPWORLD empowers robotics engineers and designers to drive innovation at an unprecedented pace. As the demand for cutting-edge robotics solutions continues to surge, there has never been a more crucial time to partner with RPWORLD for your prototyping needs.

Take the leap towards accelerated prototyping and unparalleled precision with RPWORLD. Contact us today to explore how our Vacuum Casting expertise can elevate your robotics projects, shorten development cycles, and ultimately bring your groundbreaking designs to market faster than ever before. Your journey to innovation starts here – let RPWORLD be your trusted partner in shaping the future of robotics.

0 notes