#CNC milling

Text

Never thought cnc milling machines have reached this level.. 😲

258 notes

·

View notes

Text

91 notes

·

View notes

Photo

A+M House, Santa Monica Canyon, Los Angeles, USA,

Eric Owen Moss Architect

#art#design#architecture#interiors#santa monica#los angeles#california#eric owen moss#sculpture#vertical#guitar#cnc milling#rhino 3d

142 notes

·

View notes

Text

How do you process carbon fiber brake discs?#carbonfiber #brakedisc #cncmachine #cncmachining #cnc #machine #cncmachinist #cncmillingmachine #cncrouter #cncporn #cncmill #cncmilling #cncplasma #cnclathe #cnccutting #cnclaser #cnctools #machinist #tools #cncprogramming #mold #components #machinetools #jinsucnc #5axis #cncoperator #factory #machining #fyp

#cnc milling#cncmachine#cncmachine tools#cncmachining#cncmill#cncrouter#cnctool#machine#cnc lathe#tool

5 notes

·

View notes

Text

How to Choose the Right Manufacturing Processes for Electronic Enclosures?

In the realm of electronic enclosures, selecting the appropriate manufacturing processes is crucial to ensure the functionality, durability, and overall quality of the final product. With advancements in technology and manufacturing capabilities, there's a myriad of options available, making the decision-making process daunting. However, by understanding your requirements and considering factors such as CNC milling and on-demand manufacturing, you can streamline the selection process effectively.

CNC milling stands as one of the leading manufacturing processes for electronic enclosures, offering precision, versatility, and efficiency. RPWORLD, a pioneering name in manufacturing solutions, leverages CNC milling to produce high-quality enclosures tailored to specific needs. With CNC milling, intricate designs and precise specifications can be achieved with utmost accuracy, making it ideal for complex electronic enclosure designs.

One of the key advantages of CNC Milling is its ability to work with various materials, including metals and plastics, providing flexibility in material selection based on the application's requirements. Whether you need enclosures with robust metallic properties or lightweight yet durable plastic ones, CNC milling can cater to diverse material preferences.

Moreover, CNC milling facilitates rapid prototyping, allowing for quick iterations and modifications during the design phase. This iterative approach ensures that the final enclosure meets all functional and aesthetic criteria, minimizing design flaws and optimizing performance.

In addition to CNC milling, on-demand manufacturing emerges as a game-changer in the electronic enclosure industry. RPWORLD's on-demand manufacturing services offer unparalleled flexibility and scalability, catering to businesses of all sizes. Unlike traditional manufacturing methods that entail large batch productions, on-demand manufacturing allows for the production of enclosures in quantities as per the specific requirements, reducing excess inventory and minimizing costs.

The On-Demand Manufacturing model also accelerates the production timeline, enabling faster turnaround times from design to delivery. This agility is invaluable, especially in dynamic industries where speed-to-market is paramount. With RPWORLD's on-demand manufacturing, you can swiftly adapt to changing market demands and capitalize on emerging opportunities without being constrained by lengthy production cycles.

When selecting the right manufacturing processes for electronic enclosures, it's essential to consider factors such as design complexity, material compatibility, production volume, and lead times. By leveraging CNC milling and on-demand manufacturing offered by RPWORLD, you can address these considerations effectively while ensuring superior quality and cost-efficiency.

Furthermore, RPWORLD's expertise in CNC milling and on-demand manufacturing is backed by state-of-the-art facilities, cutting-edge technologies, and a team of experienced professionals dedicated to delivering excellence at every stage of the production process. Whether you're a startup venturing into the electronics industry or an established enterprise seeking innovative manufacturing solutions, RPWORLD offers tailored services to meet your specific needs and exceed your expectations.

In conclusion, choosing the right manufacturing processes for electronic enclosures is paramount for achieving optimal performance, durability, and cost-effectiveness. With CNC milling and on-demand manufacturing from RPWORLD, you can unlock endless possibilities in design, production, and scalability, empowering your business to thrive in a competitive landscape while staying ahead of the curve.

0 notes

Text

Unveiling the Power of CNC Machines: Milling, Lathes, Plasma Cutting, and Beyond

Introduction

The world of manufacturing has been revolutionized by the advent of Computer Numerical Control (CNC) machines. These machines are essentially computer-controlled robots that can manipulate tools with incredible precision to fabricate a vast array of objects. This comprehensive guide dives deep into the fascinating realm of CNC machines, exploring different types like CNC milling…

View On WordPress

#3D printing#Additive Manufacturing#CNC Lathe#CNC Milling#CNC Plasma Cutting#Subtractive Manufacturing#Types of CNC Machines

0 notes

Text

0 notes

Text

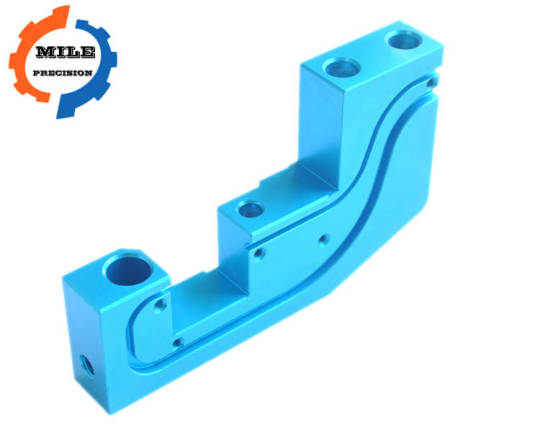

We are an experienced Custom precision machining services supplier, manufacturer in China

Our main industrial part products include turned parts, CNC machined parts, metal stamping parts and CNC milling.

Products include: hydraulic parts, pneumatic components, auto parts, medical equipment, photographic equipment, injection molding machine parts, etc.

OEM parts manufacturers,

Welcome to our website www.milemetal.com

Contact Us [email protected]

NINGBO MILE PRECISION MACHINERY CO.,LTD

#cnc milling#cnc machining#cnc turning#metal parts#oem parts#oem#stainless steel#stamping#casting#forging#auto parts

0 notes

Text

#machinist #cncmachine #cncmachinist #welder #metalwork #sillyhusband

2 notes

·

View notes

Text

The wonderful adventure of the Ruitai CNC milling machine

Once upon a time, in the bustling world of machining, there lived a great hero, his name was Ruitai CNC milling machine. With its precision and agility, this powerful machine is known across the country for its ability to shape metal into intricate, stunning creations.

In the kingdom of manufacturing, Ruitai CNC milling machines dominate. It possesses the ability to transform raw materials into beautiful parts, with every cut and contour carved with pinpoint accuracy. It spins firmly as its spindle moves deftly over the workpiece, bringing to life designs etched in digital blueprints.

From the grandest sculptures to the tiniest components, Ruitai CNC milling machines fearlessly meet every challenge. It can handle a variety of materials such as steel, aluminum, and even special alloys. With its versatile tooling options, it can skillfully shape, drill, and carve parts to create parts that are both functional and beautiful.

The Ruitai CNC mill takes it to distant lands, where it serves the noble Tob Company. Together they manufacture complex components for industries including aerospace, automotive, and medical. This dynamic duo brings ideas to life, pushing the boundaries of what is thought possible.

But the journey of Ruitai CNC milling machines does not end there. It's not just limited to milling as it has a secret power called CNC turning. With a simple change of tools, it can transform itself into a master of cylindrical and threaded wonders.

Stay tuned for the next chapter of the Ruitai CNC Mill, which will take you on an exciting journey into the world of CNC turning!

0 notes

Text

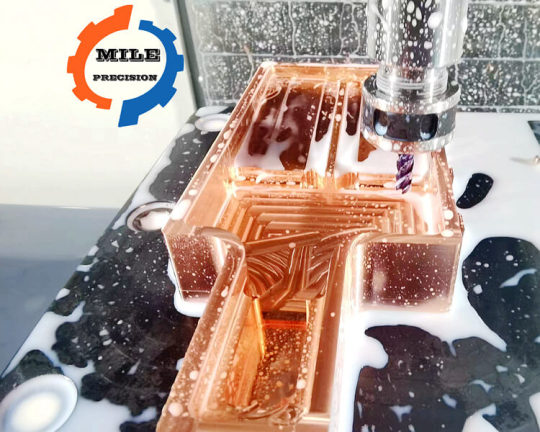

Copper mold sample test made by CNC milling machine. #copper #cncmachine #cncmachining #cnc #machine #cncmachinist #cncmillingmachine #cncrouter #cncporn #cncmill #cncmilling #cncplasma #cnclathe #cnccutting #cnctools #machinist #tools #cncprogramming #mold #components #machinetools #jinsucnc #5axis #cncoperator #factory #machining #aluminum #instagram #fyp

#cnc milling#cncmachine#cncmachine tools#cncmachining#cncmill#cncrouter#cnctool#machine#cnc lathe#tool

4 notes

·

View notes

Text

Precision CNC Machining Services | UAE-Based Manufacturer

We deliver high-tolerance CNC machined parts in the UAE. Our advanced CNC milling capabilities ensure exceptional quality and fast turnaround times for diverse industries. Get a free quote today!

0 notes

Text

Transforming Biotech Research Device Development with Customized CNC Machining

In the ever-evolving landscape of biotechnology research, innovation is key to staying ahead. As the demand for precision instruments and devices continues to soar, the need for efficient manufacturing processes becomes paramount. This is where machining manufacturers and rapid tooling solutions come into play, revolutionizing the biotech industry by offering customized CNC machining services.

Machining manufacturers play a pivotal role in transforming the conceptual designs of biotech research devices into tangible realities. By leveraging advanced technologies such as Computer Numerical Control (CNC) machining, these manufacturers can precisely fabricate intricate components with unmatched accuracy and consistency. This level of precision is essential in the development of biotech instruments where even the slightest deviation can affect performance.

At RPWORLD, we specialize in providing tailored CNC machining solutions to meet the unique requirements of biotech research device development. Our state-of-the-art facilities and team of skilled engineers enable us to deliver high-quality components with quick turnaround times. Whether it's prototyping a new device or mass-producing components for commercial use, our expertise in Rapid Tooling ensures that projects are completed efficiently without compromising on quality.

One of the primary advantages of CNC machining in biotech research device development is its ability to accommodate complex geometries and materials. Biotech instruments often feature intricate designs and require specific materials to meet performance criteria. With CNC machining, manufacturers can work with a wide range of materials, including metals, plastics, and composites, to produce components that meet the exact specifications of the application.

Furthermore, CNC machining offers unmatched repeatability, ensuring that each component produced adheres to the same precise dimensions. This level of consistency is crucial in the biotech industry, where reproducibility is essential for conducting reliable experiments and studies. By partnering with a Machining Manufacturer like RPWORLD, biotech companies can streamline their production processes and reduce the risk of errors or inconsistencies in their research devices.

In addition to precision and repeatability, CNC machining also offers flexibility in design iterations. Biotech research is a dynamic field where innovation and adaptation are constant. With CNC machining, manufacturers can quickly iterate on designs and make adjustments as needed, allowing for rapid prototyping and product development. This agility is invaluable in the fast-paced world of biotechnology, where time-to-market can make all the difference.

At RPWORLD, we understand the unique challenges faced by biotech companies in device development. That's why we offer comprehensive CNC machining services tailored to the specific needs of our clients. From initial concept design to final production, we work closely with biotech companies to ensure that their vision is brought to life with precision and efficiency.

In conclusion, CNC machining has revolutionized the way biotech research devices are developed and manufactured. Machining manufacturers like RPWORLD play a crucial role in this transformation by providing customized solutions that meet the stringent requirements of the biotech industry. With our expertise in rapid tooling and CNC machining, we empower biotech companies to innovate with confidence and drive advancements in medical research and healthcare.

0 notes

Text

https://necktech.net/

0 notes

Text

Benefits and Applications of CNC Milling in Manufacturing

0 notes