Photo

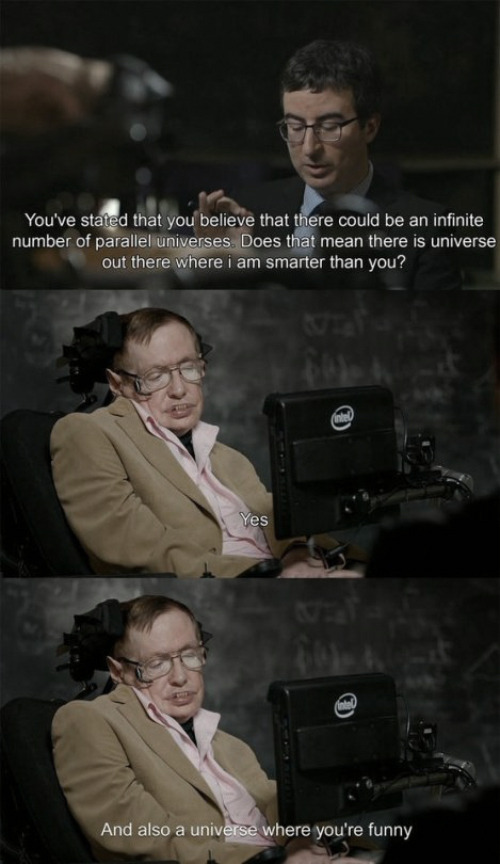

Stephen Hawking, January 8, 1942 - March 14, 2018

Born 300 years to the day after Galileo died

Died on Albert Einstein’s birthday

March 14: Annual Pi day (π)

“Life would be tragic if it weren’t funny” - S.H.

43K notes

·

View notes

Text

The Chronicle of Lean Management and Six Sigma Study - Part 3: The End

Note: Four weeks have gone by since Process Improvement Using Six Sigma (PIUSS) Module and hours have spent reading, thinking and debating with myself over the PMA. The study of Lean Management (LM) and Six Sigma (SS) is therefore divided to three parts; The Contemplation, The Discovery, and The End.

The end is an unravelling of a mystery. I started out intimidated by the question, worried if I got it wrong. But as I was encouraged by my tutor to explore the literature, I gain the sense of confidence and excitement that I can go on to yet another journey of discovering new unknowns. The results and findings of my study are as evident in my PMA. However, there is one distinct factor that I would like to highlight that makes this journey interesting - this blog. I find that it is easier for me to fall back to my PMA whenever I am done with writing this blog as it gives a sense of direction, from myself to myself. As Sherlock puts it, I was in my ‘mind palace’. Things are clearer, my writing is much better, and I get lesser ‘writer’s block dilemma’ when I was in the process of writing this PMA. My plan is to use this blog as my canvas and references for myself as I set out to new adventures.

1 note

·

View note

Text

The Chronicle of Lean Management and Six Sigma Study - Part 2: The Discovery

Note: Four weeks have gone by since Process Improvement Using Six Sigma (PIUSS) Module and hours have spent reading, thinking and debating with myself over the PMA. The study of Lean Management (LM) and Six Sigma (SS) is therefore divided to three parts; The Contemplation, The Discovery, and The End.

THE QUESTIONS. As mentioned in Part 1, I have questioned myself a lot to start any kind of studies and this one is not an exception. These questions are fundamental in understanding the basis of LM, SS as well as Lean Six Sigma (LSS). The questions are listed below:

How does Kaizen fit in LM? Is it an approach or a tool?

How did Taiichi Ohno start with the idea of LM and how it is evolved to “The Machine That Changed The World” by Womack et al. (1990)?

What is the focus of LM?

What is Business Process Improvement (BPI), is it different from Business Improvement?

Waste is associated with Kaizen but what is the impact on business improvement?

Failure of LM --> Failure to change leadership practices --> one of the gaps in BPI --> can this issue/gap be complemented by SS?

Compatibility of LM and SS as approaches are measured through its impact level to business improvement; initial assumption: the higher the impact level of business improvement, the better is compatibility of both LM and SS. Is it true?

Is there any significant point in the differing opinions of authors in Antony Jiju’s work?

Initial conclusion based on the study: THe context of compatibility of LM and SS in business improvement highly depends on the purpose of it being implemented. If it is to only serve for leadership purposes, then LSS is unsuccessful and thus not compatible. Is it true?

These are some of the questions that I had in mind during the study. Of course, there were more but the in-depth study started with the triggers mentioned above.

FINDINGS. Lean Management Focuses on customer’s value by reducing waste (Fliedner, 2016). The phases, components, and principles of LM are fundamental in making it a successful approach for companies such as Toyota. However, there are several point-of-views that argued LM is only applicable to Toyota because of the culture of the company and not as versatile as SS. SS, on the other hand, focuses on quality by eliminating variations leading to better decision making. The debate goes on and the conflicting views are summarised in the PMA. The guidebook by Graeme and presentations during seminars, particularly by Horton, really help throughout the discovery phase. By the end of the discovery phase, I was confident that I can conclude the PMA with concise proving in the analysis chapter (Chapter 3).

0 notes

Text

The Chronicle of Lean Management and Six Sigma Study - Part 1: The Contemplation

Note: Four weeks have gone by since Process Improvement Using Six Sigma (PIUSS) Module and hours have spent reading, thinking and debating with myself over the PMA. The study of Lean Management (LM) and Six Sigma (SS) is therefore divided to three parts; The Contemplation, The Discovery, and The End.

DETERMINED. Since the end of the Module, I was determined to answer Question 6 which revolves around Organisational Learning. The idea then was I could learn a lot from this topic and incorporate it into my dissertation. I have spent a whole week working on the study. However, three weeks have passed and I attended the last module for the term: Product Design and Development Management (PDDM). In this class, the materials that I learnt in PIUSS was refreshed and I have felt this strong interest in LM and SS, wanting to study them in great details. At that point then, I made new plans for my dissertation and PIUSS study, start everything all over again to answer Question 5: the study of LM and SS and their compatibility.

QUESTIONED. Since I have spent most of my time studying another topic and I have to start all over again, I was worried of the time that was left for me to be done with PIUSS PMA since I have another two PMAs to work on. It was easy to get distracted by the state that I was in but I persevere with my developed interest in studying LM and SS. Firstly, I questioned myself, secondly, I read and make mind maps and thirdly I reach out for my module tutor, Graeme.

BEGAN. This is when my discoveries began.

Continue to Part 2.

0 notes

Text

What is the big thing about Six Sigma?

"Have you went for the Six Sigma yet?” - the most frequent question that I heard whenever I took some break from work and poke around the HR department. At first, it did not make sense. Why does it sound like a system? It must be a system. Or is it an extension to R programming? Oh! it must be a new programming language! No, it is more like a software. Yes, it must be it. But the HR officers are asking ‘have you went’ so it must not be a software. It must be a certification! So, I googled it and there it is. The first thing that came out was circle with colours. I was sure at that point it was a certification, all good certifications have fancy circles and colours methodologies - at least that is what I thought as a young executive who just passed her foundation ITIL certification. But, as curious I was back then and today, why is it a huge thing? Why does it seems like a compulsory certification to all the bosses? WHAT IS IT?!

I am lucky to be able to study Six Sigma as a course during my masters degree and gets to take up the most anticipated certification - Six Sigma Yellow Belt Certification. Above all, I get to answer the question that I always wondered four years ago - what is it? So, the answer is, Six Sigma is certainly a certification, a best practice, a tool and in some ways, can be a treated like a programming language. Not to be used to program softwares, but to solve ever so complex organisational problems that are easily overlooked and/or underestimated. Today, I understand why most to all project managers across the organisation have to take up the certification - IT IS A COMMON LANGUAGE! It may not make sense now, but let me try by giving an example: Question 1: Why do we need programming language? Answer 1: Because we need a common language to interact with computers. Question 2: Why do we need to interact with computers? Answer 2: Because we need it to solve our complex problems and we wish to automate them. Question 3: Why do we need to automate problem solving? Answer 3: So that we can make better decision making in the future and make better prioritisation to what is more important. So, how does Six Sigma fits in to the Q&A? Project Managers are the programmers, Six Sigma is the computer, its tools and processes are the language. The objectives are to ensure better communication in problem solving and automate towards better decision making. As what all computer is, Six Sigma is quantitative by itself and requires other tools or methodologies to complement it - add ons, peripherals and what not. So, there you go. Another ‘What’ mission accomplished!

2 notes

·

View notes