Don't wanna be here? Send us removal request.

Link

For More Details:

Contact Person: Ritesh Tolia Website: https://www.lntindustries.in Phone: +91 9822210965 Email: [email protected]

0 notes

Link

For More Details:

Contact Person: Ritesh Tolia Website: https://www.lntindustries.in Phone: +91 9822210965 Email: [email protected]

0 notes

Link

For More Details:

Contact Person: Ritesh Tolia Website: https://www.lntindustries.in Phone: +91 9822210965 Email: [email protected]

0 notes

Link

For More Details:

Contact Person: Ritesh Tolia Website: https://www.lntindustries.in Phone: +91 9822210965 Email: [email protected]

0 notes

Link

For More Details:

Contact Person: Ritesh Tolia Website: https://www.lntindustries.in Phone: +91 9822210965 Email: [email protected]

0 notes

Link

For More Details:

Contact Person: Ritesh Tolia Website: https://www.lntindustries.in Phone: +91 9822210965 Email: [email protected]

0 notes

Link

For More Details:

Contact Person: Ritesh Tolia Website: https://www.lntindustries.in Phone: +91 9822210965 Email: [email protected]

0 notes

Link

For More Details:

Contact Person: Ritesh Tolia Website: https://www.lntindustries.in Phone: +91 9822210965 Email: [email protected]

0 notes

Photo

For More Details:

Contact Person: Ritesh Tolia Website: https://www.lntindustries.in Phone: +91 9822210965 Email: [email protected]

0 notes

Text

Bucket & Basket Strainers Manufacturer and Supplier by LNT Industrial Engineering Services

Manufactured in a cylindrical or basket shape primarily to be fitted in T-type or Y-type casings. Used in steam, water & petroleum lines for Separation of impurities. Manufactured with use of various materials like Stainless steel, Monel, Brass, etc.

Features:

Low Maintenance

Rust proof

Easy to operate

Basket or Bucket Strainers name is derived from type of Screen used in these Strainers. These Strainers are popular due to its moderate to large free flow area through screen, longer shut down time, lesser pressure drop & suitability for coarse & fine filtration upto 50 Microns. They are commonly installed at suction to prevent debris from entering Pumps, Compressors & Rotating Equipment& Vessels.

Construction of Basket Strainers

Most popular is Fabricated construction due to its economy & ease of manufacturing. Smaller sizes are also offered in cast constraction.

End Connection

Flange End connection is widely used. Smaller size Strainers have socket weld or threaded connection. For High Pressure explosive, hazardous & gaseous service sometimes Butt weld ends are also used.

Application Industries

Chemical, Petrochemical, Fertilizers, Process, Steam, Oil, Water, Gas, Air etc.

Advantages

Low Pressure drop across Screen.

Screen Size is moderate to high. Dirt holding capacity is better. Hence Shut down time is longer.

Easy to open Cover & cleaning of Screen.

#Demister pad#Filters#Strainers#Level Gauge#Agitators#Fabricated Valves#Oil Seperator#Heat Exchangers

0 notes

Text

Y Type Strainers Manufacturer and Supplier by LNT Industrial Engineering Services

Specification:

We offer Y-Strainers, which are often used for applications with water, steam, oil or fuel. However, these products are also suitable for higher viscosities and other media too. We design, manufacture and supply a simple and an effective product that guarantees to a general use construction. Our strainer is synonymous to quality and used where debris needs to be removed frequently. Y-Type Strainers are available in both fabricated and Cast Steel Materials.

Y type strainers can be used for both Horizontal and Vertical configurations. The Element is retained in its housing by a blowdown plug or a flange with a blowdown plug that can be removed for blow through cleaning. In either case, the Element itself is removable and so this type of strainer may also be used as a temporary strainer. Y Strainers are used to protect equipment such as pumps, water counters, and automatic check valves form foreign matters by being mounted on intake side of this equipment.

Features:

Robust construction

Excellent functionality

Low maintenance

Flat Seated Screen for Proper Sealing

Easy cleaning or replacing the element

Compact size and Low weight

With Drain Arrangement on request

Adequate strength of element and housing

Protect expensive Pumps. Meters, Heat Exchangers, Valve, Spray Nozzle, Regulators etc.

Remove foreign particles, lumps, debris, etc.

Interchangeability of component with another of the same type

Various perforations with or without Wiremesh from 2 mesh to 200 mesh ( upto 80 microns) for Strainer Element

Contact Person: Ritesh Tolia Website: https://www.lntindustries.in Phone: +91 9822210965 Email: [email protected]

#Demister pad#Filters#Strainers#Level Gauge#Agitators#Fabricated Valves#Oil Seperator#Heat Exchangers

0 notes

Text

Duplex Strainers Manufacturer and Supplier by LNT Industrial Engineering Services

Duplex strainer or twin basket strainer is a type of filter built into a fuel, oil or water piping system and it is used to remove large particles of dirt and debris. The duplex strainer system usually consists of two separate strainer baskets housings. The system also contains a valve handle placed between the two baskets to divert the flow of liquid to one strainer while the other is being cleaned. On some strainers, the valve will work automatically and the strainer will perform a self-cleaning operation.

Features:

Optimum finish

Best quality

Duplex Strainers are designed for applications where flow cannot be shut down to service the strainer screen. Change over is accomplished by use of butterfly valves.They are very economical because they are fabricated to your specific requirements and with your choice of valves.This arrangement provides a bubble-tight shut off between basket chambers, essential for use in negative head pump suction systems. They are very economical because they are fabricated to your specific requirements and with your choice of valves.

Contact Person: Ritesh Tolia Website: https://www.lntindustries.in Phone: +91 9822210965 Email: [email protected]

#Demister pad#Filters#Strainers#Level Gauge#Agitators#Fabricated Valves#Oil Seperator#Heat Exchangers

0 notes

Text

Fabricated Valves - LNT Industrial Engineering Services

Product Details :

Our company is involved in offering our customers with high-quality Fabricated Valves. Designed as per the defined industry standards, these are famous for their durable finish standards.

Features:

Dimensionally accurate

Rust resistant

Durable in nature

These valves are fabricated using qualitative factor input to provide optimum performance to our valuable clients. Our product range of these valves comprises Straight Line Valves and Right Angle Valves. Clients can avail these products at leading market prices.

Size Range : 1/2" To 30"

Pressure Ratings : Upto 2500 Class

Mgf. Standard : API 600

Testing Std. : API 598

Material : ASTM A216 Gr WCB/ASTM351CF8/ ASTM351CF8M/ASTM351CF3M/ Customize

Contact Person: Ritesh Tolia Website: https://www.lntindustries.in Phone: +91 9822210965 Email: [email protected]

0 notes

Text

Oil Separators - LNT Industrial Engineering Services

Product Details :

Leveraging on our business competency and vast experience in this field, we have offer a wide range of Oil Separators.

Features:

Efficient Separation of oil from required media

Easy Installation and Commissioning

Low maintenance

Operation

The oil separators' operating is based on the density difference between the elements present within the separator.Light liquids, density 0.85, rise to the surface while heavy materials, density 1, settle to the bottom of the unit.

Recommendations

The observation of a correlation between the effective volume of the compartment separator and purification performance highlights, in under 90 seconds dwell time, the phenomenon of re-release of hydrocarbons occurs.

Too much oil separators with sludge are bombs

In case of oil pollution, you could be held liable by the authorities if it is found that the pollution was caused by an undersized oil separator.

APPLICATIONS

Oil Separators are designed to receive, directly from plant equipment or floor drains, various kinds of oils, gasoline, kerosene, naphtha, benzene, other volatile liquid waste, and sludge. They retain this harmful waste matter and prevent its entry into the drainage system, providing triple advantages.

CONSTRUCTION

The separator is built of all-welded heavy-duty steel plate for maximum strength and durability. Both the interior and exterior are coated to resist acid corrosion. These units have removable covers for on-the-floor, partially recessed or flush-with-floor installation, suitable for pedestrian traffic or reinforced for heavy traffic. The cover is secured to the body with recessed stainless steel bolts and includes an extra-heavy leakproof gasket. Separating screens and a flow-regulator filter screen regulate flow and filter waste water, making outside flow control or retarder unnecessary. An extra-large inlet compartment has adjustable oil draw-off. The outlet is separated from the main body of the unit, meeting all plumbing code requirements of an outside visible trap seal. Independent internal vent connection on the inlet compartment dissipates excessive fumes and vapors from evaporating gases and volatile liquids. The outlet of the separator is vented to prevent siphoning of its contents into the drainage system. All units are available in double-wall construction with leak detection if specified.

Product List

Demister Pads

Filters

Strainers

Level Gauge

Agitators

Fabricated Valves

Oil Separators

Heat Exchangers

Contact Person: Ritesh Tolia Website: https://www.lntindustries.in Phone: +91 9822210965 Email: [email protected]

0 notes

Text

Heat Exchangers Supplier - LNT Industrial Engineering Services

Our product range includes a wide range of Heat Exchangers and Oil Coolers.

Product Details :

We offer premium range of Heat Exchangers to our customers in diverse specifications. This range is designed at our end.

Features:

High strength

Premium quality

A heat exchanger is a system used to transfer heat between two or more fluids. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

How to make a heat exchanger more efficient

Temperature differential - As discussed in point 3 (temperature cross-over) the difference between the hot fluid and coolant is very important when designing a heat exchanger. The coolant always needs to be at a lower temperature than the hot fluid. Lower coolant temperatures will take more heat out of the hot fluid than warmer coolant temperatures. If you had a glass of drinking water at room temperature for example, it is much more effective to cool it down using ice rather than just cool water, the same principle applies to heat exchangers.

Flow rate - Another important factor is the flows of the fluids in both the primary and the secondary side of the heat exchanger. A greater flow rate will increase the capability of the exchanger to transfer the heat, but a greater flow rate also means greater mass, which can make it more difficult for the energy to be removed as well as increasing velocity and pressure loss.

Installation - The heat exchanger should always be installed based on a manufacturers' guidelines. Generally speaking the most efficient way to install a heat exchanger is with the fluids flowing in a counter-current arrangement (so if the coolant is travelling left to right, the hot fluid travels right to left) and for shell and tube heat exchangers the coolant should enter at the lowest inlet position to ensure that the heat exchanger is always full of water. For air cooled heat exchangers it is important to consider the air flow when installing a cooler, any part of the core which is blocked will compromise cooling capacity.

Contact Person: Ritesh Tolia Website: https://www.lntindustries.in Phone: +91 9822210965 Email: [email protected]

0 notes

Photo

Strainers - Manufacturer and Supplier by LNT Industrial Engineering Services

The straining elements are generally made from a wire mesh type screen material or a perforation in sheet metal. In some cases, depending on size and pressure rating, a mesh unit may additionally include a perforation. Using a perforated material in conjunction with a mesh, may be best in providing greater strength and stability to the straining element.

Contact Person: Ritesh Tolia

Website: https://www.lntindustries.in/strainers.php

Phone: +91 9822210965

Email: [email protected]

0 notes

Photo

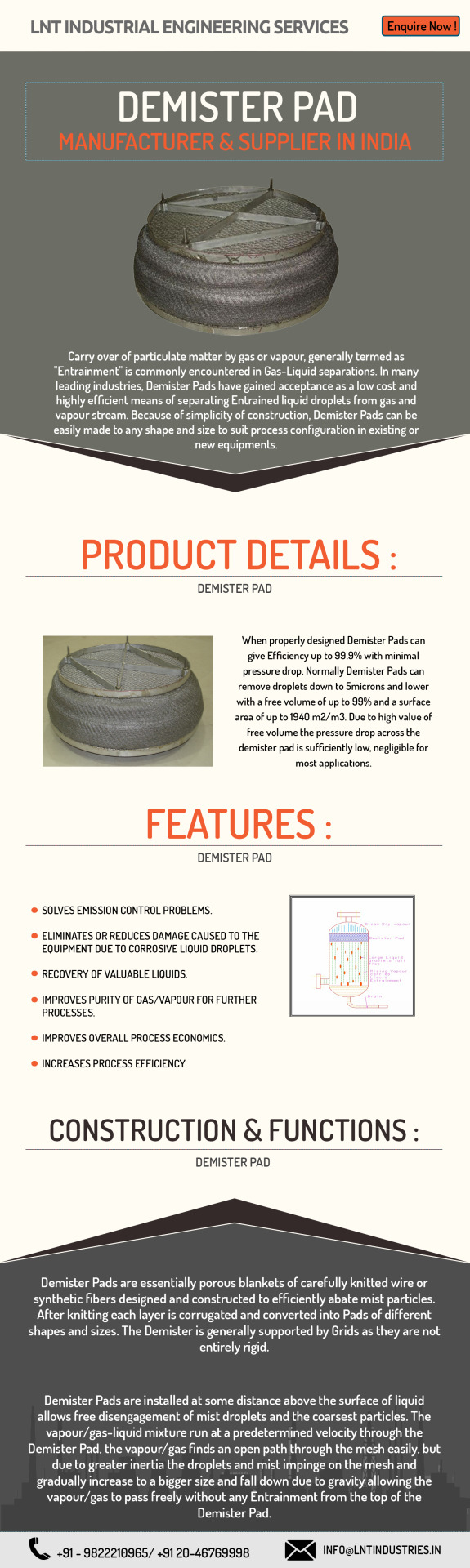

Demister Pad - Manufacturer and Supplier by LNT Industrial Engineering Services

Carry over of particulate matter by gas or vapour, generally termed as "Entrainment" is commonly encountered in Gas-Liquid separations. In many leading industries, Demister Pads have gained acceptance as a low cost and highly efficient means of separating Entrained liquid droplets from gas and vapour stream. Because of simplicity of construction, Demister Pads can be easily made to any shape and size to suit process configuration in existing or new equipments.

Contact Person: Ritesh Tolia Website: https://www.lntindustries.in/strainers.php Phone: +91 9822210965 Email: [email protected]

0 notes