#heat exchanger

Explore tagged Tumblr posts

Text

Self portrait

6 notes

·

View notes

Text

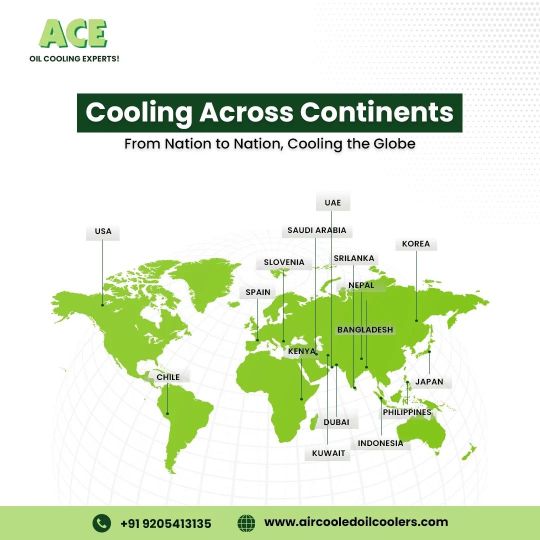

Ace Hydraulic Oil Cooler & Air Cooled Heat Exchanger Manufacturers in India.29+ years of Experience, Ex-Stock Delivery & Affordable Prices.

Hydraulic Oil Coolers & Air Cooled Heat Exchanger Manufacturers in India

2 notes

·

View notes

Text

Which is the best industrial chiller manufacturer in Delhi NCR?

If you are in need of a reliable Best industrial chiller Manufacture in Delhi NCR, then ARH Technologies is your trusted partner. We are an authorized channel partner of Werner Finley, a renowned name in the field of industrial chillers and panel air conditioners. Our focus is on providing energy-efficient, durable, and technologically advanced cooling solutions for a wide range of industries.

As a leading chiller dealer in Delhi NCR, we specialize in:

🔹 Air-Cooled Chillers 🔹 Water-Cooled Chillers 🔹 Brine Chillers & Low Temperature Chillers 🔹 Custom-Built Industrial Chillers 🔹 Werner Finley Panel ACs

We cater to various industrial segments including:

Pharmaceutical Manufacturing

Plastic Molding and Injection Plants

CNC & Laser Machines

Food and Beverage Industries

Chemical and Process Cooling Applications

Our industrial chillers are designed with a strong focus on energy efficiency, robust performance, and minimum downtime. Whether your requirement is a compact 2TR unit or a customized 100+ TR solution, we can assist with the most optimal chiller system for your plant.

#best chiller manufature#water cooled chillers#air cooled chillers#chiller manufacturer#chiller#hvac#industrial#pump#heat exchanger

0 notes

Text

Why You Should Sell Old Heat Exchangers Before They Break

Let’s be real: holding onto old equipment seems like a smart way to save money… until it’s not. If you’ve got aging heat exchangers in your factory, warehouse, or plant, you could actually be sitting on a problem waiting to happen. So, what should you do? Easy—sell used heat exchangers before they fail.

There are buyers out there looking for second-hand equipment. A used heat exchangers buyer might be exactly who you need to talk to right now.

The Hidden Danger of Old Heat Exchangers

Just because your heat exchanger seems to work doesn’t mean it’s doing its job well. Inside, things might be rusting, corroding, or barely holding together. It’s like driving a car with worn-out brakes—it might still move, but for how long? Instead of waiting for disaster, why not sell surplus heat exchangers while they still have some value?

Why You Shouldn’t Hold Onto Old Heat Exchangers

💸 Rising Energy Bills

Old heat exchangers get less efficient over time. They suck up more power just to do the basics. If your energy bills are creeping up, your heat exchanger could be the silent thief.

⚙️ Performance Drops

When your heat exchanger can’t keep up, your whole system slows down. Slow processing = lost time = lost money. If your equipment is always one step behind, you might want to sell it while it’s still working.

🚨 Unexpected Shutdowns

Old machines love to break down at the worst possible time. Emergency repairs are expensive. Even worse? Total system failure.

⚡ Safety First

Old heat exchangers aren’t just annoying—they can be dangerous. Corroded parts can leak, overheat, or even explode. Keeping your team safe is always priority number one. If your heat exchanger looks like it’s from the dinosaur age, it’s probably time to let it go.

Why Selling Your Surplus Heat Exchangers Makes Sense

If you’ve got extra units sitting around, don’t let them collect dust. When you sell surplus heat exchangers, you:

Get cash back 💰

Free up valuable space

Avoid future safety risks

Help someone else who’s looking for second-hand equipment

Keep useful machines in circulation instead of in a landfill ♻️

A used heat exchangers buyer can make this process super easy.

Final Thought: Don’t Wait for It to Break

Here’s the thing: you don’t have to keep equipment until it’s completely dead. Smart businesses sell early, recover some money, and upgrade to safer, better machines. When you sell surplus heat exchangers to a reliable used heat exchangers buyer, you save yourself from future headaches. Turn that old heat exchanger into cash before it turns into a problem.

0 notes

Text

How to Calculate Heat Transfer in Finned Tubes: Formula and Example

Finned tubes are widely used in heat exchangers to enhance heat transfer efficiency. By increasing the surface area, they allow for better heat exchange between fluids. But how exactly do you calculate the heat transfer rate in these systems?

Understanding the heat transfer formula is the first step:

Q = U × A × ΔT

Where:

Q is the rate of heat transfer (W)

U is the overall heat transfer coefficient (W/m²·K)

A is the effective surface area (m²)

ΔT is the temperature difference between the fluids (K)

To get accurate results, you need to factor in the fin efficiency, material conductivity, and design dimensions. A simple example can help put this into context, illustrating how changing the fin dimensions or material can significantly impact heat transfer performance.

For a step-by-step calculation and real-world example, check out the full guide:

Visit at: https://www.anandseamless.com/calculate-heat-transfer-in-finned-tubes-formula-example/

0 notes

Text

What Makes the Best Heat Exchangers in India?

Reliability and the Best Heat Exchanger Manufacturer in India When one is talking about high-performance heat transfer systems, especially the ones that are backed by reliability, then we have to make sure that the heat exchanger manufacturer is a dependable one. One such name that is in the lead everywhere is Sheheatexchange, which provides comprehensive solutions for heat exchangers designed for various industries.

Why Choose Sheheatexchange?

Among the established heat exchanger manufacturers in India, Sheheatexchange is notable for:

High-quality materials Precision engineering Quality control is very strict Specialised after-cooler design tailored to your requirements

From shell and tube heaters to plate and finned tube heat exchangers, Sheheatexchange offers products widely used in the following industries:

HVAC Chemical processing Oil & Gas Power generation Food & Beverage

Cutting-Edge Technology Plus Nationwide Coverage:

Situated in the heart of India’s industry, sheet exchange technologies are technology-protected and supported by regional sales and service. We are the absolute best at what we do, not because we have the fanciest website but because our people are well seasoned in manufacturing the right products. Our engineers are some of the brightest in the heat exchanger world, who use their specific domain knowledge to custom design all of our products. Superior thermal efficiency High corrosion resistance Long-term durability Whether you need a small unit or an industrial solution, heat exchange enables you to use your energy as efficiently as possible and with a minimum of maintenance.

Trusted by Customers From All Over India:

With its unwavering focus on innovation and service, Sheheatexchange continues to be a leading heat exchanger manufacturer in India. Their customer-focused emphasis ensures every product is designed to service the objectives of the company it serves.

#Heat Exchanger#Heat Exchanger manufacturesin india#Plate Heat Exchanger#Brazed Plate Heat Exchanger#Shell and Tube Heat Exchanger Manufactures in India#Air Cooled Heat Exchanger Manufacturers in India#Oil Cooler

0 notes

Text

Need a durable heat exchanger? Glasskem offers corrosion-resistant glass lined solutions for chemical and pharmaceutical industries.

0 notes

Text

Heat Exchanger Manufacturer in Pune, India

Heat exchangers are the product of well-known manufacturer Galaxy Industrial Equipments Pvt. Ltd., which is headquartered in Pune, India. As a dependable supplier of heat exchange systems in the area, we made a name for ourselves through a dedication to quality and innovation. In order to satisfy a variety of industrial purposes, we provide a broad range of heat exchanger products, such as finned tube heat exchangers, shell and tube heat exchangers, and plate heat exchangers. These heat exchangers are made to ensure maximum performance and energy efficiency while effectively transferring heat between two fluids.

In Pune, India, Galaxy Industrial Equipments Pvt. Ltd. is a well-known industrial equipment supplier that manufactures heat exchangers and is distinguished by its dedication to quality, innovation, and client satisfaction.

0 notes

Text

Cross flow heat exchanger, total heat exchanger, gas air heat exchanger, waste heat recovery of exhaust gas, rotary heat exchanger, steam coil, surface cooler, combined air conditioning unit, flue gas whitening

0 notes

Text

0 notes

Text

What are the benefits of plate heat exchangers?

Plate Heat Exchangers (PHEs) offer several advantages, making them an ideal choice for industries requiring efficient and compact heat transfer solutions. Here are the key benefits:

✅ 1. High Heat Transfer Efficiency

Plate heat exchangers use large surface area plates with corrugated patterns, ensuring turbulent flow and efficient heat transfer even with low temperature differences.

✅ 2. Compact Design

Compared to shell-and-tube exchangers, PHEs are much more compact and require less floor space—ideal for installations with space constraints.

✅ 3. Easy Maintenance & Cleaning

The plates can be easily removed for cleaning, inspection, or re-gasketing, reducing downtime and simplifying maintenance.

✅ 4. Energy & Cost Saving

Efficient heat exchange reduces energy consumption, leading to lower operating costs and improved process performance.

✅ 5. Flexibility & Expandability

The design is modular, allowing for easy expansion or capacity changes by simply adding or removing plates.

✅ 6. Close Temperature Approach

PHEs can achieve a temperature approach as low as 1°C, making them suitable for applications needing precise thermal control.

✅ 7. Low Fouling

High turbulence reduces the risk of fouling, which helps maintain performance over time and lowers maintenance frequency.

Industries We Serve: ARH Technologies supplies Tranter Plate Heat Exchangers to a wide range of industries including HVAC, pharmaceuticals, food & beverage, chemical processing, and water treatment.

0 notes

Text

Why Selecting Reliable Heat Exchanger Manufacturers Matters

Heat exchangers are indispensable in industries that require precise temperature control and energy efficiency. Collaborating with experienced heat exchanger manufacturers ensures that your facility benefits from advanced designs and long-lasting products tailored to your needs.

Features of a Good Manufacturer

Engineering Excellence: Manufacturers with strong technical expertise design heat exchangers that maximize heat transfer while reducing energy loss.

Range of Products: A diverse product portfolio, including shell-and-tube, plate, and air-cooled exchangers, ensures you can find equipment for any application.

Quality Standards: Reliable manufacturers adhere to global standards like ASME or ISO, guaranteeing safe and durable equipment.

After-Sales Service: From installation support to regular maintenance, dependable manufacturers provide comprehensive customer assistance.

Why Choose Advanced Heat Exchangers?

Modern heat exchangers are built to enhance energy efficiency, reduce environmental impact, and offer seamless integration with industrial systems. Manufacturers using innovative designs help businesses achieve operational excellence.

Conclusion

Selecting the right heat exchanger manufacturers is a strategic move that ensures efficiency and reliability in thermal processes. Choose manufacturers with proven expertise, quality products, and excellent customer support to optimize your industrial operations.

#Heat Exchanger Manufacturer in India#Heat Exchanger Supplier in India#Heat Exchanger Manufacturer#Heat Exchanger Supplier#Heat Exchanger

0 notes

Text

How Manufacturers Meet Zero-Leakage Demands in Heat Exchangers

Heat exchangers are essential components in industries ranging from power generation to oil & gas, chemical processing, and marine applications. As operational demands grow more stringent, the margin for error narrows—especially when it comes to leakage. For leading heat exchanger manufacturers in India, achieving zero leakage is no longer just a goal—it's a fundamental requirement. Here's how industry leaders are rising to meet this challenge.

The Zero-Leakage Imperative in Modern Industries

Leakage in a heat exchanger can lead to cross-contamination, corrosion, safety risks, environmental hazards, and costly downtime. In sensitive industries like pharmaceuticals, petrochemicals, or nuclear energy, even minimal leakage can compromise product purity or plant safety. That's why the demand for zero-leakage heat exchangers has surged, and manufacturers are redesigning their approach from the ground up.

Engineering Precision from the Ground Up

Zero leakage starts with meticulous engineering. From CAD design to final fabrication, every component is built with tight tolerances and high precision. Manufacturers are investing in advanced design software, simulation tools, and CNC machining to ensure that each part aligns perfectly during assembly.

The Crucial Role of High-Quality Heat Exchanger Tubes

At the heart of any shell and tube heat exchanger lie the tubes. Their strength, finish, and integrity play a pivotal role in determining the overall durability and leak resistance of the system. Manufacturers like Anand Seamless Tubes prioritize cold-drawn seamless tubes known for their superior wall uniformity, tight tolerances, and high pressure-withstanding capacity.

Joint Integrity: The Make-or-Break Factor

Even the strongest tubes are only as reliable as the joints that connect them. Whether it's tube-to-tubesheet joints, welds, or gasketed flanges, manufacturers pay close attention to joint design, welding processes, and post-weld heat treatments. Specialized welding techniques and automated orbital welders are now standard in achieving uniform, defect-free joints.

Testing Beyond Industry Standards

Zero-leakage isn’t just a design claim—it must be proven. That’s why manufacturers conduct rigorous testing well beyond standard regulatory requirements. Common procedures include hydrostatic testing, helium leak testing, pneumatic testing, dye penetrant inspections, and radiographic analysis. The aim is to simulate real-world operating conditions and identify any potential weak points before deployment.

The Material Science Edge

Selecting the right material is critical in preventing leakage caused by corrosion, temperature extremes, or fluid incompatibility. Today’s manufacturers utilize high-grade stainless steel, duplex alloys, Inconel, and other specialized metals, each selected based on the operating environment. Material traceability and certification are integral to ensuring long-term reliability.

Customisation for Industry-Specific Demands

Different industries have distinct requirements—be it ultra-high purity in pharmaceuticals or extreme pressure tolerance in offshore rigs. Customisation is key. Heat exchanger manufacturers work closely with clients to tailor designs for specific temperature, flow, and pressure conditions, ensuring optimal performance and zero leakage across diverse applications.

Collaboration Across the Supply Chain

Meeting zero-leakage demands is a collective effort. From tube manufacturers and metallurgists to assembly teams and quality inspectors, every stakeholder in the supply chain must align with the zero-defect mindset. Leading companies foster strong partnerships, transparent communication, and joint quality assurance protocols to maintain consistency and accountability.

Looking Ahead: Smart Monitoring and Predictive Maintenance

The future of zero-leakage lies in proactive monitoring. Smart sensors, IoT-enabled diagnostics, and predictive maintenance tools are being integrated into modern heat exchangers. These technologies can detect early signs of wear, fatigue, or minor leaks—allowing maintenance teams to act before failures occur.

Conclusion: Zero Leakage Is a Standard, Not a Luxury

Today, zero leakage isn’t an added feature—it’s an operational standard. Top heat exchanger manufacturers in India are continuously evolving their design, material, and testing practices to meet this expectation. The result: safer, more efficient, and longer-lasting equipment that industries can rely on.

Partner with the Leading Heat Exchanger Manufacturer in India

Looking for a trusted partner that delivers zero-leakage solutions tailored to your industry needs? Anand Seamless Limited offers premium-quality seamless tubes and heat exchangers engineered for maximum reliability and leak-free performance.

Visit us at: How Top Manufacturers Eliminate Leakage in Heat Exchangers

0 notes