Don't wanna be here? Send us removal request.

Text

Compression Load Cell

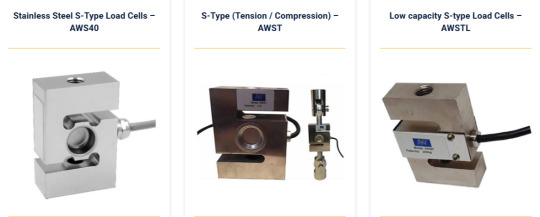

Explore high-quality industrial grade load cells at Load Sensors Australia. Our loadcells include shear beam, S-type, disc, weighbridge & single point load cells, designed for precision and durability in various industrial applications.

0 notes

Text

Compression Load Cell

Explore high-quality industrial grade load cells at Load Sensors Australia. Our loadcells include shear beam, S-type, disc, weighbridge & single point load cells, designed for precision and durability in various industrial applications.

1 note

·

View note

Text

The Ultimate Guide to Industrial Weighing Scales and Equipment

In industries ranging from agriculture to logistics, accurate weighing is critical. Industrial weighing scales and related equipment play an essential role in operations where precision, efficiency, and reliability are paramount. Whether you're looking for weighing scales for sale, truck weighbridges, or specialized load cells, understanding the types of equipment available can help you make an informed purchase. This article delves into the various types of weighing equipment and their applications.

Industrial Weighing Scales: What Are They?

Industrial weighing scales are specifically designed for use in harsh and demanding environments. Unlike household scales, these machines are engineered to handle high capacities and provide precise measurements, often under difficult conditions such as extreme temperatures or heavy usage. Load cells are central components of these scales, providing the means to accurately measure weight by converting force into an electrical signal.

Types of Weighing Scale Equipment

Load Cells and Load Sensors Load cells are crucial for the functionality of industrial weighing scales. These sensors detect weight by measuring the force exerted on them. Compression load cells and tension load cells are two common types. Compression load cells are designed for applications that apply force in compression, like tank and silo weighing, while tension load cells measure force in a pulling direction, ideal for applications like conveyor weighing or industrial hanging scales.

Weighing Bridges and Truck Weighbridges Truck weighing scales, also known as weighbridges, are large platforms designed to weigh entire vehicles, typically used in logistics and freight industries. They ensure that trucks are not overloaded, maintaining road safety and compliance with regulations. Portable weighbridges are also available, providing flexibility for temporary or mobile setups.

Hopper, Silo, and Tank Weighing Weighing systems for silos, hoppers, and tanks require high-precision tank weighing load cells that can measure heavy bulk materials or liquids stored in large containers. These systems help manage inventory and monitor production processes in industries like food processing, chemicals, and mining.

Pallet and Bench Scales Pallet scales are often used in warehouses and factories for weighing goods stored on pallets. These scales are essential in packaging and shipping operations. Bench weighing scales are smaller and often used for precise weighing in laboratories, retail, or general-purpose applications.

Livestock Weighing Scales Livestock weighing scales are designed for the agricultural sector. These scales ensure that livestock weights are accurately measured for purposes like breeding, health monitoring, and feed management.

Label Printing Scales For businesses in the retail sector, label printing scales allow users to print labels with weight and price information automatically. This is essential in environments like supermarkets and food markets.

Why Choose the Best Load Cell Distributors, Dealers, and Suppliers?

Choosing the right load cell manufacturers or load cell suppliers is critical to ensuring the quality and reliability of your weighing equipment. Opt for companies with a reputation for providing high-quality, accurate, and durable products. Whether you're buying load cells, digital weighing indicators, or price computing scales, sourcing from top distributors guarantees better service, support, and warranties.

Where to Buy Weighing Scales and Related Equipment?

If you're looking for reliable, high-quality weighing scales for sale, check out reputable suppliers like Load Sensors Australia. They offer a comprehensive range of products, including industrial hanging scales, truck weigh bridges, floor scales, and more. Weighing scale price varies depending on the application and capacity, so it's important to assess your needs before making a purchase.

Conclusion

From portable weighbridges to bench-top scales and digital weighing indicators, industrial weighing equipment serves diverse needs in multiple sectors. Whether you're in manufacturing, logistics, agriculture, or retail, having the right scale can enhance efficiency, accuracy, and compliance with regulations. Always work with trusted load cell distributors and weighing machine dealers to ensure your equipment meets your business’s requirements and standards.

For more information and to purchase high-quality weighing equipment, visit Load Sensors. https://loadsensors.com.au/products/load-cells/

0 notes

Text

Enhance Your Weighing Efficiency with Premium Weighing Accessories from Load Sensors Australia

When it comes to ensuring precise and reliable measurements, weighing accessories play a pivotal role in optimizing the performance of weighing systems. These accessories complement core weighing equipment, enabling users to achieve higher accuracy, efficiency, and consistency in their operations.

Weighing accessories include items like calibration weights, load cells, and junction boxes, which are essential for setting up and maintaining weighing systems. Calibration weights are vital for adjusting the scale to provide accurate readings, while load cells transmit the force applied to the weighing platform, allowing the measurement of weight. Junction boxes help in connecting multiple load cells, ensuring that the system works smoothly.

Quality weighing accessories not only enhance the functionality of scales but also contribute to their longevity. Regular maintenance, including periodic checks using these accessories, ensures optimal operation for a wide range of applications, from industrial weighing to commercial transactions.

Weight Indicators: The Heart of Weighing Systems

A weight indicator is an integral component of any weighing system. It acts as the interface between the load cell (or sensors) and the user, displaying the weight measurement on a digital screen. Weight indicators are designed to take readings from load cells and convert them into readable values. They can display weight in various units, such as kilograms, pounds, and tons, depending on the specific needs of the application.

In addition to their basic function of displaying weight, modern weight indicators come with a variety of advanced features. Some offer capabilities like connectivity with other devices for data logging or integration with automated systems. Others come with programmable settings for custom weight tolerances, making them highly versatile across industries such as logistics, agriculture, manufacturing, and retail.

The accuracy of a weight indicator depends on the quality of the load cells and sensors it interacts with. Therefore, choosing a reliable weight indicator can significantly impact the overall precision of the weighing process.

Weight Sensing Sensor: The Technology Behind Accurate Measurements

At the core of any weighing system lies the weight sensing sensor. These sensors are responsible for detecting the force applied to a weighing platform, converting it into an electrical signal that can be interpreted by the weight indicator. Weight sensing sensor work by using load cells, which are transducers that change electrical resistance in response to applied force. This change is then measured and converted into weight readings.

Load cells come in various types, including strain gauges, piezoelectric, and capacitive sensors, each offering different levels of sensitivity and accuracy. The selection of the right weight sensing sensor is crucial, as it directly influences the reliability and performance of the entire weighing system.

For industries requiring highly accurate measurements, choosing the best weight sensing sensor ensures precise data capture, reducing errors and improving operational efficiency.

Digital Weighing Indicator: The Future of Weight Measurement

The evolution of digital weighing indicator has transformed the weighing industry. Unlike traditional analog indicators, digital versions provide superior accuracy, enhanced functionality, and greater ease of use. These indicators feature digital displays, which offer clear and easy-to-read weight measurements.

Digital weighing indicators also often come equipped with advanced features like data logging, network connectivity, and automated tare functions, making them a preferred choice in many industries. Whether you're weighing large shipments or precise laboratory samples, a digital weighing indicator offers unmatched precision and flexibility.

Moreover, digital weighing indicators typically allow for easy calibration, ensuring that the equipment delivers reliable readings consistently over time. Their robust design ensures long-term performance, even in harsh industrial environments.

Weighing Scales: A Vital Tool for Accurate Weighing

In any industry that requires weight measurement, weighing scales are indispensable tools. Available in various types, including platform scales, bench scales, and pallet scales, weighing scales are designed to handle a wide range of weighing applications.

Industrial weighing scales are built to provide accurate measurements for heavy-duty loads, while digital weighing scales offer the advantage of electronic displays, improved accuracy, and easy data management. With a wide range of features such as adjustable units, high capacity, and durable construction, modern weighing scales ensure high performance across diverse operational needs.

Whether for retail use, warehouse management, or scientific analysis, weighing scales are integral to maintaining precision in weight-based tasks. Selecting the right weighing scale depends on factors such as the weight capacity required, the environment in which it will be used, and any special features necessary for the task.

Conclusion

The combination of weighing accessories, weighing indicators, and weighing scales creates a comprehensive weighing system that ensures high accuracy, efficiency, and reliability. By investing in quality components from trusted sources like Load Sensors, businesses can maintain a high level of performance in their operations, whether for product shipping, quality control, or inventory management. Precision in weight measurement is essential for achieving cost savings, maintaining regulatory compliance, and ensuring operational success. https://loadsensors.com.au/

0 notes

Text

Comprehensive Guide to Weighing Accessories, Indicators, and Scales for Accurate Measurements

When it comes to ensuring precise and reliable measurements, weighing accessories play a pivotal role in optimizing the performance of weighing systems. These accessories complement core weighing equipment, enabling users to achieve higher accuracy, efficiency, and consistency in their operations.

Weighing accessories include items like calibration weights, load cells, and junction boxes, which are essential for setting up and maintaining weighing systems. Calibration weights are vital for adjusting the scale to provide accurate readings, while load cells transmit the force applied to the weighing platform, allowing the measurement of weight. Junction boxes help in connecting multiple load cells, ensuring that the system works smoothly.

Quality weighing accessories not only enhance the functionality of scales but also contribute to their longevity. Regular maintenance, including periodic checks using these accessories, ensures optimal operation for a wide range of applications, from industrial weighing to commercial transactions.

Weight Indicators: The Heart of Weighing Systems

A weight indicator is an integral component of any weighing system. It acts as the interface between the load cell (or sensors) and the user, displaying the weight measurement on a digital screen. Weight indicators are designed to take readings from load cells and convert them into readable values. They can display weight in various units, such as kilograms, pounds, and tons, depending on the specific needs of the application.

In addition to their basic function of displaying weight, modern weight indicators come with a variety of advanced features. Some offer capabilities like connectivity with other devices for data logging or integration with automated systems. Others come with programmable settings for custom weight tolerances, making them highly versatile across industries such as logistics, agriculture, manufacturing, and retail.

The accuracy of a weight indicator depends on the quality of the load cells and sensors it interacts with. Therefore, choosing a reliable weight indicator can significantly impact the overall precision of the weighing process.

Weight Sensing Sensor: The Technology Behind Accurate Measurements

At the core of any weighing system lies the weight sensing sensor. These sensors are responsible for detecting the force applied to a weighing platform, converting it into an electrical signal that can be interpreted by the weight indicator. Weight sensing sensor work by using load cells, which are transducers that change electrical resistance in response to applied force. This change is then measured and converted into weight readings.

Load cells come in various types, including strain gauges, piezoelectric, and capacitive sensors, each offering different levels of sensitivity and accuracy. The selection of the right weight sensing sensor is crucial, as it directly influences the reliability and performance of the entire weighing system.

For industries requiring highly accurate measurements, choosing the best weight sensing sensor ensures precise data capture, reducing errors and improving operational efficiency.

Digital Weighing Indicator: The Future of Weight Measurement

The evolution of digital weighing indicator has transformed the weighing industry. Unlike traditional analog indicators, digital versions provide superior accuracy, enhanced functionality, and greater ease of use. These indicators feature digital displays, which offer clear and easy-to-read weight measurements.

Digital weighing indicators also often come equipped with advanced features like data logging, network connectivity, and automated tare functions, making them a preferred choice in many industries. Whether you're weighing large shipments or precise laboratory samples, a digital weighing indicator offers unmatched precision and flexibility.

Moreover, digital weighing indicators typically allow for easy calibration, ensuring that the equipment delivers reliable readings consistently over time. Their robust design ensures long-term performance, even in harsh industrial environments.

Weighing Scales: A Vital Tool for Accurate Weighing

In any industry that requires weight measurement, weighing scales are indispensable tools. Available in various types, including platform scales, bench scales, and pallet scales, weighing scales are designed to handle a wide range of weighing applications.

Industrial weighing scales are built to provide accurate measurements for heavy-duty loads, while digital weighing scales offer the advantage of electronic displays, improved accuracy, and easy data management. With a wide range of features such as adjustable units, high capacity, and durable construction, modern weighing scales ensure high performance across diverse operational needs.

Whether for retail use, warehouse management, or scientific analysis, weighing scales are integral to maintaining precision in weight-based tasks. Selecting the right weighing scale depends on factors such as the weight capacity required, the environment in which it will be used, and any special features necessary for the task.

Conclusion

The combination of weighing accessories, weighing indicators, and weighing scales creates a comprehensive weighing system that ensures high accuracy, efficiency, and reliability. By investing in quality components from trusted sources like Load Sensors, businesses can maintain a high level of performance in their operations, whether for product shipping, quality control, or inventory management. Precision in weight measurement is essential for achieving cost savings, maintaining regulatory compliance, and ensuring operational success. https://loadsensors.com.au/

0 notes

Text

Weighing Scale Equipment: Essential Tools for Accurate Measurement

In industries ranging from manufacturing to logistics, the need for precise weight measurement is crucial for ensuring quality control, operational efficiency, and compliance with regulations. Weighing scale equipment plays an indispensable role in these sectors, enabling businesses to accurately measure and monitor goods, materials, and products. From heavy-duty industrial models to precision weighing instruments, understanding the different types of weighing scales and their applications is key for choosing the right equipment.

Industrial Weighing Scale: Robust and Durable Solutions

Industrial environments often require weighing equipment that can handle large quantities and heavy loads. Industrial weighing scale are designed to provide high-capacity, accurate measurements in harsh environments. These scales are commonly used in manufacturing, warehousing, logistics, and agriculture. The rugged construction ensures that they can withstand the demands of continuous use while providing consistent and reliable results. Whether you are weighing raw materials or finished products, industrial scales offer essential durability, stability, and precision.

Buy Weighing Machine: How to Make an Informed Decision

Purchasing a weighing machine can be a significant investment, and it’s essential to ensure you choose the right one for your specific requirements. When you buy a weighing machine, factors like load capacity, material type, and environment conditions should be taken into account. Whether you need a high-capacity platform scale, a bench scale, or a portable model, it's important to select the right scale for your business needs. Opting for an accurate, durable model will not only enhance your operations but also provide a long-term solution for your weighing needs.

Industrial Hanging Scale: Versatile and Convenient

The industrial hanging scale is an indispensable tool in industries where goods need to be weighed in a suspended position, such as shipping, freight, and agriculture. These scales offer great versatility and are easy to use for both light and heavy loads. With a hook or load bar, the hanging scale can be used to weigh large items such as pallets, bulk containers, or livestock. Their compact design and portability make them ideal for environments where space is limited, and they can be easily transported between different locations or workstations.

Weighing Accessories: Enhancing Performance and Accuracy

To maintain optimal performance and extend the lifespan of your weighing equipment, it’s crucial to invest in the right weighing accessories. Accessories such as load cells, protective covers, calibration weights, and weighing platforms are designed to enhance the accuracy and reliability of your scales. Calibration is especially important to ensure your scale provides precise readings, especially in critical operations. Regular maintenance with the right accessories ensures that your equipment continues to operate at peak performance and meets industry standards.

Weight Indicators: Key for Precision Measurement

Weight indicators are essential components of modern weighing systems. These devices display the weight of the object being measured, and they can be integrated into various types of scales, including industrial, laboratory, and portable models. A high-quality weight indicator ensures that the measurement is displayed clearly and accurately, making it easier to monitor weights during production, shipping, or quality control processes. Many weight indicators offer additional features such as digital readouts, data storage, and connectivity with computers or printers for automated record-keeping.

Weight Sensing Sensor: The Heart of Accurate Measurement

The weight sensing sensor is the most critical part of any weighing scale. It detects the load applied to the scale and converts it into an electrical signal, which is then processed by the weight indicator. Without a high-quality weight sensing sensor, even the best weighing scales would fail to provide accurate readings. Load cells, which are often used as sensors in weighing equipment, are designed to handle various weight ranges and environmental conditions, ensuring consistent performance across a wide range of applications.

Weighing Indicator: Essential for Data Processing and Control

In more advanced weighing systems, the weighing indicator acts as the interface for controlling and processing data from the weight sensors. These indicators are often programmable, allowing businesses to set specific parameters, thresholds, and display units. In addition, modern weighing indicators are compatible with software that can automate processes, ensuring that your operations are efficient, accurate, and compliant with industry regulations.

Precision Weighing Balances: For High-Accuracy Measurements

For laboratory, pharmaceutical, and scientific applications, precision weighing balances are indispensable. These instruments are designed to measure small quantities with the utmost accuracy. Precision weighing balances can provide measurements down to milligrams or even micrograms, making them essential for research and development, quality control, and any application where minute weight differences are critical. When choosing a precision balance, it's essential to consider the level of accuracy, readability, and repeatability to ensure consistent and reliable results.

Weighing Machine Buy Online: Convenience and Variety

In today’s digital age, you can easily buy a weighing machine online from reputable suppliers. Online platforms provide a wide selection of weighing equipment, allowing you to compare models, prices, and features conveniently from the comfort of your home or office. Many suppliers, like Load Sensors, offer detailed product descriptions and expert support to help you select the right weighing equipment for your needs. Whether you're looking for industrial-grade scales, precision balances, or weighing accessories, purchasing online offers the convenience of doorstep delivery and sometimes even personalized installation and maintenance services.

Conclusion

Whether you're in need of an industrial weighing scale, a precision weighing balance, or any type of weighing accessory, selecting the right equipment is crucial for accurate, efficient operations. By choosing the right scale for your needs and investing in the best accessories and indicators, you can ensure that your weighing operations are seamless, accurate, and compliant. With the added convenience of being able to buy a weighing machine online, it's never been easier to access the equipment necessary for success in today's competitive industrial landscape. https://loadsensors.com.au/

0 notes

Text

Load Sensors Australia: Delivering Precision and Innovation in Load Cells and Industrial Weighing Solutions

Load Sensors Australia, a leading provider of advanced load cells and industrial weighing solutions, continues to set the standard for quality, precision, and innovation in the agricultural, industrial, and commercial sectors. Based in Australia, the company offers a diverse range of products designed to meet the ever-evolving demands of industries requiring accurate and reliable weighing systems.

Quality and Compliance at the Forefront

Load Sensors Australia prides itself on offering trade-approved products that comply with the strict standards of the National Measurement Institute (NMI). This commitment to quality ensures that every product delivers top-tier accuracy, making it ideal for commercial applications where precision is critical. Whether you need solutions for tanks, silos, hoppers, or other specialized applications, Load Sensors Australia guarantees reliable performance that meets industry regulations.

Innovation and Continuous Development

Innovation is the driving force behind Load Sensors Australia’s success. The company has invested heavily in research and development to stay ahead of emerging industry trends. This focus on cutting-edge technology enables the company to offer state-of-the-art solutions that enhance operational efficiency, improve productivity, and reduce downtime.

Customer-Centric Approach

At Load Sensors Australia, customer satisfaction is paramount. The company offers tailored solutions designed to meet the specific needs of each client. Whether it's for large-scale agricultural operations, industrial manufacturing, or commercial enterprises, the team at Load Sensors Australia works closely with clients to deliver personalized support, expert guidance, and high-quality products.

High Precision for Critical Applications

Load Sensors Australia offers a variety of load cells with high precision and quality, designed to suit applications in tanks, silos, hoppers, and more. These robust, reliable products are built to withstand the toughest environments, providing long-lasting performance even in challenging conditions. The company’s solutions help businesses optimize their operations, streamline processes, and enhance overall productivity.

Conclusion

As Load Sensors Australia continues to lead the way in industrial weighing solutions, its dedication to quality, innovation, and customer satisfaction ensures that businesses across Australia have access to the best products and services available. Whether you’re in agriculture, manufacturing, or any commercial industry that requires accurate, trade-approved weighing systems, Load Sensors Australia has the expertise and solutions you need.

For more information on Load Sensors Australia’s products and services, visit https://loadsensors.com.au/

0 notes

Text

Tank Weighing, Silo Weighing, and Hopper Weighing: Essential for Industrial Accuracy

In various industries, precise weight measurements are critical for efficiency, safety, and regulatory compliance. Tank weighing, silo weighing, and hopper weighing systems all play a significant role in maintaining accurate inventory control and operational efficiency.

Tank weighing systems are commonly used to monitor the weight of liquids or bulk materials stored in tanks. These systems use load cells to provide real-time weight data, which helps prevent overflow, ensures proper material management, and enhances the overall operational flow. Industries such as chemicals, food and beverage, and petroleum rely heavily on accurate tank weighing for optimal performance.

Similarly, silo weighing solutions are vital for monitoring materials like grains, powders, or pellets. By using load cells, businesses can accurately measure the amount of material in silos, ensuring there’s no overflow or underestimation. This is crucial in industries such as agriculture, mining, and cement manufacturing, where material quantities need to be precisely controlled.

Hopper weighing systems are typically used for monitoring the flow of bulk materials through hoppers. These systems ensure that the right amount of material is dispensed or transferred, contributing to the efficiency of production lines in industries like mining, food processing, and chemical manufacturing.

Tension Loadcells and Compression Loadcells: Accurate Force Measurement

When measuring force in different directions, tension loadcells and compression loadcells are essential tools in various applications. Tension loadcells are designed to measure forces applied in a pulling direction, such as in crane systems or monitoring cables under tension. These load cells are widely used in industries requiring precision monitoring of forces, including lifting, construction, and materials handling.

On the other hand, compression loadcells measure forces in a compressive or pushing direction. These load cells are ideal for applications such as monitoring the weight of compressed materials, including in storage containers, tanks, or vessels. They are frequently used in applications like concrete batching plants, construction, and manufacturing, ensuring accuracy and reliability.

Buy Load Cells with High Precision & Quality

If you’re looking to buy load cells with exceptional precision and quality in Australia, it’s crucial to select products that are designed to withstand harsh environments while providing highly accurate data. High-quality load cells are essential for industries such as logistics, transportation, manufacturing, and construction. Whether you require single point load cells, shear beam load cells, or tension and compression load cells, you can find top-tier products that meet your operational needs at Load Sensors Australia.

Shear Beam Load Cell Installation: Precision and Reliability

Shear beam load cells are commonly used in high-capacity applications and are ideal for systems such as platform scales and tank weighing. To ensure their optimal performance, proper shear beam load cell installation is critical. Correct alignment and load distribution are necessary to avoid inaccuracies and to maximize the durability of the system.

With careful installation and calibration, shear beam load cells provide consistent and accurate weight measurements, even in high-demand environments. This is crucial for industries such as industrial manufacturing, logistics, and agriculture, where high-precision weighing is essential for operational success.

Weighbridge Load Cells: Heavy-Duty Solutions for Vehicle Weighing

For operations involving heavy vehicles, weighbridge load cells offer an efficient and accurate solution for weighing trucks, trailers, and other large vehicles. Weighbridge load cells are typically used in systems designed to weigh vehicles as they drive over a platform. The load cells provide precise weight measurements, ensuring that vehicles comply with weight regulations and preventing overloading.

These weighbridge load cells are durable and reliable, designed to handle the heavy weight of trucks and other vehicles in industries such as logistics, transportation, and mining. The accurate data provided by these systems contributes to improved safety, efficiency, and regulatory compliance.

Single Point Load Cells: Compact and Versatile Solutions

Single point load cells are compact, high-accuracy load cells ideal for smaller scale applications. These load cells are commonly used in retail sales, small platform scales, and counting scales. Despite their small size, single point load cells offer excellent precision and are designed to handle light to moderate loads.

Their versatility makes them suitable for a wide range of industries, including food packaging, pharmaceutical, and laboratory applications, where accurate and reliable weight measurements are essential.

Weigh Bridge Load Cell: Optimizing Vehicle Weighing Systems

A weigh bridge load cell is designed to be part of a vehicle weighing system, typically found in weighbridge platforms. These load cells play a crucial role in accurately measuring the weight of trucks, containers, and other large vehicles. A weigh bridge load cell ensures that the weight of vehicles is measured accurately, which helps businesses comply with legal weight restrictions and ensures safety during transportation.

Universal Tension Loadcells: Flexibility Across Industries

Universal tension loadcells offer flexibility for measuring forces in various applications. These load cells are highly adaptable, suitable for measuring tension in cables, structural components, or equipment. Universal tension loadcells are commonly used in industries like construction, mining, and engineering, where monitoring the tension of materials or equipment is essential for safety and efficiency.

Tension and Compression Load Cell Australia: Precision Across Diverse Applications

In Australia, tension and compression load cells are essential components in industries that require accurate force measurements. These load cells are crucial for applications such as testing the weight of goods, measuring material forces, and monitoring structural integrity. From construction sites to agricultural operations, tension and compression load cells in Australia offer the precision and reliability needed for optimal performance.

For industries in need of high-precision measurement solutions, Load Sensors Australia provides a broad range of load cells that ensure accurate results for various applications. Explore top-quality products that meet your unique operational needs by visiting https://loadsensors.com.au/

0 notes

Text

Waterproof Weighing Scales

Waterproof Weighing Scales

Load Sensors Australia is a premier provider of advanced load cells and industrial weighing solutions, dedicated to delivering precision, durability, and innovation. Based in Australia, we specialize in a wide range of products designed to meet the demanding needs of agricultural, industrial, and commercial sectors.

We pride ourselves on offering trade-approved products that comply with the National Measurement Institute (NMI) standards, ensuring top-tier accuracy and reliability for all commercial applications.

At Load Sensors Australia, innovation is at our core. We continuously invest in research and development to stay ahead of industry trends, providing cutting-edge solutions that enhance operational efficiency and productivity. https://loadsensors.com.au/

1 note

·

View note