Longhua Technology Group (Luoyang) Company Limited was established in 1995 and listed on the A-share market of the Shenzhen Stock Exchange in 2011 (stock code: 300263). Since then, Longhua has embarked on a development journey of innovation, expansion and integration. The Group currently has six wholly-owned subsidiaries or holding companies (branches), which have formed an industrial pattern of multilateral, collaborative and sustainable development, covering new electronic materials, polymer composite materials, new chemical materials, energy conservation and environmental protection sectors. The Group is steadily forging ahead to become a high-tech industrial group with leading technology, excellent management and combination between industry and finance. https://www.longhuatech.com/

Don't wanna be here? Send us removal request.

Text

ITO Target

ITO target is made up of a combination of indium oxide and tin oxide and serves as a crucial component in the production of ITO film. This film holds a significant position in the electronic information area and is used in a range of applications such as liquid crystal displays, organic light emitting diodes, touch screens and thin-film solar cells.

Operating Principle of ITO Target

An ITO target is a combination of indium oxide and tin oxide and serves as a crucial raw material in the field of electronic information, specifically in the production of ITO film. Due to its superior electrical conductivity, optical transparency, and high stability, ITO film is employed in different applications such as liquid crystal displays, organic light emitting diodes, touch screens, and thin-film solar cells.

Japan and South Korea have enjoyed a monopoly in the ITO target market for some time now, particularly in high-end TFT applications. However, our company has achieved independent innovation by acquiring core technology for mass-producing high-end ITO target, with multiple intellectual property rights and patent achievements. Presently, our production capacity for ITO targets is approximately 300 tons per year and we provide a steady supply to all TFT production lines ranging from G2.5 to G10.5. The quality of our targets ranks top in China, reaching world-class standards. Our growing market share is a testament to the satisfaction of our clients in the industry.

1 note

·

View note

Text

INDUSTRIAL EVAPORATIVE COOLING SYSTEM

Industrial evaporative cooling system is a cost-effective, energy-efficient approach to cooling large industrial spaces, production floors, and public areas. This evaporative cooling solutions use a natural process of evaporative cooling to reduce the temperature of the air. Water is pumped over evaporative pads, which helps to cool the air as it passes through and is circulated throughout the space using fans. As the air is cooled and circulated, it also provides ventilation, improving the indoor air quality. This system is particularly effective in hot and dry climates, providing reliable cooling at a fraction of the cost of traditional air conditioning units. Industrial evaporative cooling systems are becoming increasingly popular in many industries, including data centers, manufacturing plants, agriculture, and warehouses, due to their affordability and environmental benefits.

Industrial Evaporative Cooling System Benefits

Energy Efficiency: Industrial Evaporative Cooling Systems are significantly more energy-efficient than traditional air conditioning systems.

Cost Savings: By using minimal power to operate, industrial evaporative cooling systems can save companies a considerable amount of money on their energy bills.

Low Maintenance: Compared to traditional HVAC systems, that require frequent maintenance and repairs, evaporative coolers are relatively low maintenance and can last for many years with minimal upkeep.

Improved Air Quality: Unlike air conditioning systems, that tend to recirculate stale indoor air, evaporative coolers constantly bring in fresh outside air, improving the air quality within the facility.

Ecologically Friendly: Compared to traditional air conditioning systems, evaporative cooling systems use lesser energy and have a lower carbon footprint, making them environmentally sustainable.

High Durability: Industrial evaporative cooling systems are designed to withstand harsh industrial conditions and operate for extended periods under high stress.

Versatile: An industrial evaporative cooling system can be implemented in an array of industrial settings, from manufacturing plants to data centers, warehouses, and distribution centers, providing a reliable cooling solution across a broad range of industries and applications.

Comparison Between Industrial Evaporative Cooling Systems And Traditional AC Units

Operational Method: Traditional AC units work via a refrigeration cycle, which requires electricity to pump refrigerants to cool air. In contrast, Evaporative cooling uses a natural process of exchanging fresh air with the moisture present in it to reduce temperature.

Energy Efficiency: Evaporative cooling systems consume far less energy than traditional AC units, with an estimated energy savings of up to 75% for cooling the same area.

Maintenance Requirements: Evaporative cooling units require minimal maintenance when compared to traditional AC units, which require frequent maintenance and filter replacements.

0 notes

Text

ENERGY CONSERVATION AND ENVIRONMENTAL PROTECTION

Industrial Cooling System is a type of cooling system designed to regulate and maintain the temperature of industrial processes and equipment. Industrial cooling systems are used in a wide range of applications such as data centers, manufacturing facilities, and chemical processing plants. These cooling systems can utilize air or water as a cooling medium and are typically comprised of specialized equipment such as chillers, cooling towers, and heat exchangers. The effectiveness of industrial cooling systems is critical to the reliability, longevity, and efficiency of industrial equipment and processes.

Pressure Vessel

Pressure Vessel is a container designed to hold gases or liquids at a pressure different from the ambient pressure. These vessels are widely used in various industries such as chemical and petrochemical, oil and gas, energy, and food and beverage. They are designed to be safe and durable, and must be manufactured in accordance with strict standards and regulations to ensure the highest level of quality and safety.

Plate Heat Exchanger

Plate Heat Exchanger is a piece of equipment designed for efficient heat transfer between two liquids. It consists of a series of metal plates, which form a heat exchange surface and are placed in contact with the liquids. Plate Heat Exchangers are widely used in various industries such as refrigeration, chemical, and energy. They offer high heat transfer rates, are compact in size, and can be easily cleaned and maintained.

0 notes

Text

INDUSTRIAL AIR COOLING SYSTEM

Industrial Air Cooling System is a type of cooling system that uses air as a medium to regulate the temperature of industrial processes and equipment. Industrial air cooling systems are used in a wide range of applications such as data centers, manufacturing facilities, and automotive plants. Unlike water-based cooling systems, air cooling systems use fans to circulate air and remove heat from industrial equipment. These types of air cooling systems can be more energy-efficient and easier to maintain than water-based systems, making them a popular choice for many industrial applications.

Industrial Air Cooling System Advantages

Energy Efficiency: Industrial air cooling systems are designed to be more energy-efficient compared to other cooling systems. This is because they use less power to cool the air, and they have a lower energy consumption for running compressors and fans.

Reduced Environmental Impact: Industrial air cooling systems often use refrigerants that have lower global warming potential and reduced ozone depletion potential, which makes them a more environmentally friendly option.

Reduced Operating Costs: The lower energy consumption of industrial air cooling systems translates to lower operating costs compared to other cooling systems. They have low installation and maintenance costs, making them an affordable solution.

Improved System Reliability and Performance: Industrial air cooling systems are more reliable and high-performing compared to traditional cooling systems. They can maintain a consistent temperature that meets the requirements of industrial processes, which helps to avoid damage to equipment and improve overall efficiency.

Lower Maintenance Requirements: Industrial air cooling systems usually have fewer moving parts than other cooling systems, which reduces the maintenance costs and requirements. Regular maintenance is still essential, but it is easier and more cost-effective to carry out.

Industrial Air Cooling Systems Maintenance

Regular cleaning of air filters to ensure proper airflow and prevent clogging.

Inspection and cleaning of evaporator and condenser coils to remove any accumulated dust or debris.

Lubrication of fan bearings and motors to ensure smooth operation.

Inspection of electrical connections, wires, and controls for damage or wear and tear.

Checking of refrigerant levels and ensuring there are no leaks.

Regular inspection of refrigerant lines for any damage or corrosion.

Cleaning and inspection of drain pans to prevent the buildup of algae and bacteria.

Inspection of ductwork and insulation to ensure proper airflow and prevent leaks or damage.

Difference Between Industrial Air Cooling System And Other Cooling Systems

Industrial air cooling systems are designed to handle the cooling needs of large industrial spaces such as factories, warehouses, and manufacturing plants. With air cooling technology, they are typically more powerful and efficient than other cooling systems, as they must be able to cool large volumes of air in a short amount of time.

Other cooling systems, such as residential air conditioning units or portable fans, are designed for smaller spaces and are not as powerful as industrial air cooling systems. In addition, industrial air cooling systems often use water as a cooling agent, while other cooling systems typically use refrigerants or other synthetic coolants.

Industrial air cooling systems are also designed to be more durable and long-lasting than other cooling systems, as they must be able to withstand the wear and tear of an industrial environment. They also need to be able to operate continuously for long periods of time without breaking down or overheating.

Overall, the main difference between industrial air cooling systems and other cooling systems is their size, power, efficiency, and durability, which enable them to handle the unique cooling needs of large industrial spaces.

Industrial Air Cooling Systems Troubleshooting

Start by checking the thermostat settings to ensure it is correctly set to the desired temperature.

Check the air filter for clogging that can lead to restricted airflow.

Verify that the tube bundles are clean and free of any debris.

Check the medium to verify that it is within manufacturer specifications.

Inspect the ductwork and look for any leaks or damage.

Check the electrical connections, wires, and controls for any damage or wear and tear.

Check the fan for damage.

If the system is still not working correctly, it's recommended that a professional technician is called to perform a more in-depth diagnosis and repairs.

0 notes

Text

IGZO Target

IGZO target is a crucial material used in the manufacturing of transparent conductive oxide (TCO) thin-film transistors (TFTs). It is a composite material composed of indium oxide (In₂O₃), gallium oxide (Ga₂O₃), and zinc oxide (ZnO). IGZO TFTs offer superior performance, such as high electron mobility, transparency, and low power consumption. Therefore, IGZO targets are highly demanded in the electronics industry, specifically in the production of LCDs, OLEDs, and touchscreens.

Operating Principle of IGZO Target

IGZO (indium-gallium-zinc oxide) targets are used in sputter deposition processes to create thin films of transparent conductive oxides (TCOs) that exhibit excellent electrical and optical properties. During sputter deposition, positively charged ions, such as argon, are accelerated towards the negatively charged IGZO target. This bombardment of ions ejects atoms from the target surface, which then deposit onto a substrate to form a thin film.

The indium, gallium, and zinc oxide material properties of the IGZO target enable the formation of high-quality thin films with improved electronic performance. The presence of gallium in the IGZO target allows for higher electron mobility, while zinc aids in stabilizing the crystal structure and reducing lattice defects. These properties make IGZO targets a popular choice for creating thin-film transistors (TFTs), such as those found in LCD displays and touchscreens, due to their high electrical conductivity, transparency, and low power consumption.

Overall, the operating principle of IGZO targets involves the use of sputter deposition technology to create high-quality TCO thin films with exceptional electrical and optical properties, making them a valuable component in electronic devices.

Manufacturing Process of IGZO target

The manufacturing process of IGZO targets involves several steps, including the production of IGZO powder, target fabrication, and sintering.

The first step involves the production of IGZO powder using techniques such as solid-state reactions, spray pyrolysis, and pulsed laser deposition. These methods create a high-quality IGZO powder with controlled particle size and composition.

In the second step, the IGZO powder is pressed into a target shape using a hydraulic press with a pressure between 15-30 MPa. The powder is placed in a die and subjected to continuous pressure to ensure uniform density and shape.

Lastly, the sintering step involves heating the IGZO target at high temperatures, typically around 1500°C, in a vacuum or controlled atmosphere furnace. This process fuses the IGZO powder particles together to form a dense and uniform target material suitable for use in sputtering processes.

Overall, the manufacturing process of IGZO targets requires careful control of the particle size and composition of the IGZO powder, as well as precise target fabrication and sintering conditions. These variables can significantly impact the final quality and performance of the IGZO targets, making it important to ensure consistency and accuracy throughout the manufacturing process.

0 notes

Text

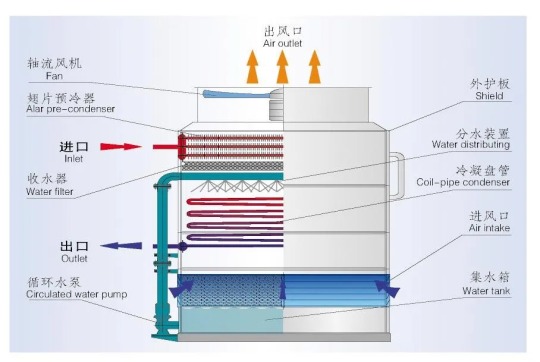

Hybrid Evaporative Cooler

A type of high-efficiency cooling device created and developed for the petrochemical sector by Longhua Technology Group (Luoyang) Company is the hybrid evaporative cooler. The high-efficiency cooler for the petrochemical industry has achieved an optimized combination of different cooling methods such as evaporative cooling, air cooling, and water cooling, thereby achieving a stable and reliable structure, extensive application scope, and obvious benefits such as energy saving, water saving, and environmental protection performance. This is based on the basic theories of latent heat exchange and sensible heat exchange.

Hybrid Evaporative Cooler Operating Principle

The hybrid evaporative cooler is similar to the three-stage series cooling system of "air cooler + water cooler + cooling water tower" combined into one set of intensive equipment, but compared with the traditional series cooling system, it has significant "three reuse processes and three differences":

1. "Three reuse processes" means that the wind and water are reused three times in the high-efficiency equipment. The first reuse of wind occurs from the lowest end of the evaporation tube to the liquid level of the water tank, in which the wind with the lowest temperature cools the circulating water falling continuously above to ensure that the water temperature in the water tank remains unchanged. The second reuse of wind occurs outside the water film of the evaporation tube, and the air with higher speed flows through the outside of the water film to form local negative pressure, which is beneficial to the evaporation of the water film and taking away the water vapor in time, thereby preventing the water vapor from forming pressure outside the water film. When the wind reaches the outside of the fin in the upward direction, the flow pattern changes from laminar flow to turbulent flow. In this state, the air heat transfer coefficient is high, the air temperature rises greatly (generally 10℃ - 15℃), and the high-temperature air is discharged from the induced-draft fan duct, thus completing the three-step cascade utilization of the air. The first cascade utilization of water also occurs at the bottom of the evaporation tube, in which water is in counter-current contact with the air inhaled from the outside for the first time. The water in torrential rain state has the function of washing, which can thoroughly flush the impurities in the air to the bottom of the water tank, ensure clean air passing through the tube bundle, and reduce scaling and blockage between the gaps of the tube bundle. The second reuse of water occurs outside the evaporation tube, and its main function is to evenly distribute the water film. It is necessary to ensure that each line of pipes and each row of pipes are evenly covered by the water film, without dry areas, and prevent scaling and corrosion under the scale. Most of the liquid water is intercepted by the water collector at the upper part of the spraying device. When saturated water vapor passes upward through the outside of the finned tube bundle, secondary interception occurs, in which saturated water vapor becomes unsaturated steam when passing through the superheated section of the fin and is discharged to the outside of the air duct, without the white mist phenomenon, and the air heat transfer coefficient outside the humidified fin is also be improved. In a series of cascade utilization, the water is reused three times, realizing "full use".

2. "Three differences" means that the equipment is quite different from the traditional air cooler, water cooler and cooling water tower. The difference between the fin section of the equipment and the fin section of the air cooler is the difference in anticorrosion. The traditional air cooler generally operates in dry air environment, so the outer side of its aluminum fins basically does not need anticorrosion, but the fin outer side of the hybrid evaporative cooler operates in humid air environment, so the fin tube bundle needs to be anticorrosive as a whole, and the overall hot dip galvanized zinc anticorrosion is generally adopted on the processed steel pipe and steel sheet. The evaporation tube section of the equipment is also very different from the tube bundle of the water cooler. The cold medium of the water cooler generally goes through inside the tube and hot medium goes through outside the tube, but the hybrid evaporative cooler is just the opposite: The hot medium goes through inside the tube, the wind and water go through outside the tube, so the outer side of the tube also needs hot dip galvanized zinc anticorrosion. Hybrid evaporative cooler is also very different from cooling water tower. Traditional cooling water tower generally has packing, but hybrid evaporative cooler has no packing in the countercurrent contact section of wind and water. Besides, cooling water tower is generally installed on the ground, while hybrid evaporative cooler is a kind of movable equipment, which can be conveniently installed on pipe gallery, platform or roof, conducive to utilizing used equipment.

0 notes

Text

Hybrid Cooler (Peak Load Cooling System)

The direct air cooling system has various issues, such as inadequate safety measures, restricted performance, high coal consumption for power generation during unpredictable cross winds in summers, and challenges with anti-freezing in winters. After more than a decade of R&D, manufacturing and application experience, Longhua Technology Group has developed a new high-efficiency condensing device - the hybrid cooler. This new device combines the optimized direct air cooling system with the evaporative condenser system to solve these problems. The hybrid cooler is primarily used for cooling and condensing the exhaust steam produced by steam turbines.

Product Structure of Hybrid Cooler (Peak Load Cooling System)

Inadequate safety measures, limited performance, high coal consumption for power generation during unpredictable cross winds in summers and issues with anti-freezing in winters present major problems with the direct air cooling system. Longhua Technology Group has worked on these issues for over a decade and has developed a solution to optimize the direct air cooling system and the evaporative condenser system. This optimized combination has resulted in the development of a new high-efficiency condensing device - the hybrid cooler.

Main components

The hybrid cooler is mainly based on air-cooled heat exchange, and evaporative heat exchange is an optimization measure to reduce back pressure. Exhaust steam of steam turbine enters direct air cooling tube bundle and evaporative condenser through the main exhaust tube, and condensed water is collected in exhaust device and is sent back into system for recycling through pipeline. Non-condensable gas is pumped out and discharged into the atmosphere by the vacuum-pumping system.

Features of Hybrid Cooler (Peak Load Cooling System)

01

High cooling efficiency: The hybrid cooler has an optimal design that provides high cooling efficiency and meets the needs of peak load cooling.

02

Energy savings: The hybrid cooler consumes less energy than traditional cooling systems, resulting in significant energy savings.

03

Environmental sustainability: This cooling system is environmentally friendly as it reduces carbon footprint and uses natural refrigerants instead of harmful chemicals.

04

Durable design: The hybrid cooler is made of high-quality materials that ensure durability and longevity, reducing maintenance costs in the long run.

05

Flexible operation: It operates with both water and dry air, making it adaptable to different weather conditions.

06

Easy to maintain: The hybrid cooler is easy to maintain as it has few components that require regular cleaning and maintenance.

07

Cost-effective: The hybrid cooler is cost-effective as it requires minimal maintenance and consumes less energy compared to traditional cooling systems.

08

Safe operation: It is designed with safety in mind, ensuring safe and reliable operation.

09

Improved indoor air quality: The hybrid cooling system improves indoor air quality by reducing the number of pollutants in the air and creating a more comfortable indoor environment.

1 note

·

View note