Text

Why Is It Easy to Produce Gas or Jet Marks at the Gate of Injection Molding Products?

The reason why the gate of injection molding products is easy to produce gas marks or jet marks may be caused by the following aspects:

1. Uneven plastic flow: The gate is the first place where plastic is injected into the mold, when the plastic flows into the mold, the flow speed, pressure and temperature will change, if these factors are not uniform, it will lead to uneven plastic flow at the gate, forming pores or jet marks.

2. Unreasonable mold design: Mold design is also one of the factors affecting the gas or jet pattern at the gate. If the design of the mold is not reasonable, such as the improper location of the gate, or the mold cavity design is not reasonable, it will cause the plastic flow at the gate to be uneven, resulting in gas or jet marks.

3. Plastic material is not suitable: Different plastic materials have different mobility and shrinkage rates, if the selected plastic material has poor mobility or high shrinkage rate, it is easy to produce gas or jet marks at the gate.

4. Improper processing process: Injection molding is a complex process, if the operation is improper, such as the injection temperature, pressure and speed are set improperly, or the injection cycle is too long, it is easy to lead to uneven plastic flow at the gate, resulting in gas or jet marks.

In view of the above reasons, the problem of gas or jet marks at the gate can be avoided or solved from the following aspects:

1. Adjust injection molding parameters: By adjusting injection molding parameters, such as injection molding temperature, pressure and speed, you can make the plastic flow more uniform and reduce the possibility of gas or jet marks at the gate.

2. Increase the number of gates: In the mold design process, the number of gates can be increased so that the plastic can flow more evenly into the mold, reducing the pressure and temperature difference at the gate, thereby reducing the generation of gas or jet marks.

3. Strengthen mold cooling: In the injection molding process, the temperature of the mold has a great impact on the flow and contraction of the plastic, so strengthening the cooling of the mold can make the plastic flow more uniform, reduce the pressure and temperature difference at the gate, thereby reducing the production of gas or jet marks.

4. Increase the wall thickness of the injection molded parts: Increasing the wall thickness of the injection molded parts can make the plastic subjected to greater resistance during the flow process, thereby reducing the pressure and temperature difference at the gate and reducing the generation of gas or jet marks.

0 notes

Text

What Are the Reasons Why Injection Molding Products Are Easy to Produce Bubbles?

1. The problem of plastic raw materials. If the plastic raw materials used contain water or other volatile substances, during the injection molding process, these water or volatile substances will be heated by high temperature and high pressure, evaporate into gas, and form bubbles.

2. Injection molding machine problems. If the operation parameters of the injection molding machine are set improperly, such as the injection temperature is too high or the injection speed is too fast, it will lead to the generation of bubbles. In addition, if the pressure of the injection molding machine is unstable or insufficient, it will also cause the air to be unable to discharge the mold and form bubbles.

3. Mold problems. If there are burrs, grooves and other defects on the inner surface of the mold, or the mold opening is not tightly sealed, bubbles will be generated during the injection molding process.

4. Problems with the injection molding process. During the injection process, the injection speed is unstable or the injection cycle is too short, which will make it difficult for the gas to be discharged from the mold and form bubbles. In addition, if the material is discharged immediately after injection molding, it is also easy to produce bubbles.

5. Properties of plastics. Different kinds of plastics have different physical and chemical properties, and some plastics are easier to produce bubbles during injection molding.

6. Environmental factors. Environmental factors such as temperature and humidity at the injection molding site will also affect the generation of bubbles.

7. Operator problems. When the operator is operating, there may be improper operation, such as opening the door of the injection molding machine during the injection molding process or rapid discharge, which can easily lead to the generation of bubbles.

In order to avoid the formation of bubbles, the following measures can be taken:

1. Optimize the ratio of raw materials and choose plastic raw materials with stable quality as far as possible.

2. Adjust the operation parameters of the injection molding machine, including injection temperature, injection speed, pressure, etc., so that it meets the requirements of injection molding products.

3. Optimize the mold design to ensure that the inside surface of the mold is smooth, without burrs and grooves, and the mold opening is tightly sealed.

4. Strictly control the injection molding process, and control the injection speed and injection cycle during injection molding to ensure that the gas can be smoothly discharged.

5. Carry out proper maintenance and maintenance to keep the injection molding machine and mold in good condition.

6. Strengthen the training of operators to ensure that they understand the principles and operation skills of injection molding processing, and can correctly operate the injection molding machine and mold to avoid bubbles.

7. By changing the injection molding environment, such as adjusting temperature, humidity and other factors, to reduce the generation of bubbles.

8. Adopt the gas discharge strategy during the injection molding process, such as setting the air valve in the mold, so that the air can be smoothly discharged from the mold.

9. Use injection molding simulation software to simulate injection molding process, analyze and optimize injection molding parameters, and avoid bubbles.

To sum up, the causes of bubbles in injection molding products are more complex, and a variety of factors need to be considered comprehensively. For different reasons, different measures need to be taken to solve the problem to ensure the quality and stability of injection molding products.

0 notes

Text

What Are the Molding Process Conditions of Injection Molding Products?

Injection molding process conditions of injection molding products mainly include the following aspects:

1. Temperature conditions: Injection molding needs to heat plastic particles to a melting state, and generally the injection molding machine will set the heater of the heating cylinder, the cylinder and the mold to provide heating conditions. Different plastic materials require different heating temperatures, and usually need to be tested before production to determine the appropriate temperature conditions.

2. Pressure conditions: Injection molding needs to apply a certain pressure in the mold, so that the plastic can fully fill the cavity of the mold, and can maintain a certain pressure time to prevent the production of shrinkage holes, bubbles and other defects. The size of the pressure should be set reasonably according to the pressure range of the injection molding machine and the shape and size of the product.

3. Injection speed condition: Injection speed refers to the speed at which the plastic enters the mold. Generally speaking, too fast injection speed will lead to bubbles, flow marks, poor welding and other defects, while too slow injection speed will lead to rough surface of the product and shorten the injection cycle. Therefore, the size of the injection speed needs to be adjusted during the mold test.

4. Cooling time conditions: Cooling time refers to the plastic products formed in the mold need to be cooled in the mold for a certain time before they can be taken out to avoid deformation, shrinkage and other defects. The length of the cooling time needs to be set according to the size and thickness of the product and adjusted during the production process.

5. Injection molding material conditions: Injection molding needs to choose the right plastic material, and adjust the temperature, pressure, injection speed and other conditions according to the characteristics of the material. Different plastic materials have different melting points and fluidity, so different process parameters need to be adjusted.

6. Mold conditions: Mold is the key to injection molding, it needs to meet the requirements of the product, such as the shape of the product, size, surface quality and so on. At the same time, the material and production process of the mold also need to be considered to ensure its wear resistance, corrosion resistance and precision requirements.

In conclusion, the injection molding process conditions of injection molding products include temperature, pressure, injection speed, cooling time, injection materials and molds. In the production process, these conditions need to be scientifically adjusted and controlled to ensure product quality and production efficiency.

0 notes

Text

How to Ensure the Accuracy of Injection Molding Products?

In today’s modern industrial production, plastic injection molding technology has become extremely important. Injection molding plays an irreplaceable role in the fields of home appliance shell, auto parts, medical equipment, and household necessities. However, many companies often face a problem in the production process: how to ensure the accuracy of injection molding products? Today, we will discuss the factors that affect the accuracy of injection molding products, and share the secrets of improving accuracy for you.

1. Design molds and make molds

Mold is one of the key components of injection molding, and its design and manufacturing quality directly affect the accuracy of the final product. Scientific and reasonable mold design can ensure the uniform flow of plastics in the mold, reducing the possibility of defects and deformation. The key to ensure the service life of the mold and the accuracy of the product is the high-precision mold processing and heat treatment process.

2. Choose the right plastic raw materials

The characteristics of plastics have a great impact on the quality of injection molded products. The fluidity, shrinkage and thermal stability of various plastic materials are different. The selection of plastic materials that meet the needs of the product can effectively reduce the deformation and shrinkage during the molding process, thereby improving the quality requirements of the product.

3. Control the molding process

Molding parameters are the key link of plastic injection molding. Controlling the appropriate process parameters, such as temperature, pressure and time, directly affects the molding quality and appearance accuracy of the product. Scientific and reasonable parameter setting can ensure that the plastic is fully filled in the mold, reduce bubbles, shrinkage and other defects, and improve the quality of the product.

4. Improve the post-processing technology

The treatment of the late process of the product is also one of the factors that affect the quality of the product, such as heat treatment, cooling and removal of burrs after the product is moulded. It is necessary to eliminate the internal stress in the molding process by appropriate treatment methods, reduce deformation, and thus improve the quality of the product.

5. Establish a quality control system

Ensuring the accuracy of injection molding products is a key aspect of establishing a sound quality control system. From the entry of raw materials into the warehouse to the shipment of products, every step needs to implement strict quality inspection management. Through regular inspection and evaluation, timely detection and resolution of problems to ensure that product quality remains stable and accurate.

Only by continuously improving and perfecting these steps can we ensure the high quality requirements of injection molding products. If you have any questions related to injection molding technology or need more help, please feel free to contact us and we will do our best to answer your questions.

0 notes

Text

The Influence of Plastic Mold Quality on Injection Molding Production

The purpose of mold design and manufacturing is for the mass production of injection parts with high efficiency and high quality, to produce high-quality plastic parts, the first mold is good, a good set of plastic molds is not just a good look, want to do a set of high-quality, high level, high precision plastic molds, from the following aspects.

1. The smoothness of the injection mold surface

The polishing of the mold surface is very important, which is one of the most important links to determine the success or failure of mold manufacturing. The surface of the mold is not smooth enough, its surface is uneven, and the surface of the plastic parts injected will have skin lines and sand grains. Generally, the polishing surface into a mirror is good, in addition to the choice of mold steel, grinding personnel, time, technology will have an impact on the polishing mirror effect, requiring a professional mold polishing master, experience to be particularly rich in order to accurately grasp the polishing time, to ensure the effect of mold mirror polishing.

2. Accuracy of mold

The precision of the mold determines the dimensional accuracy of the plastic parts, mold manufacturing must first have the conditions of high-precision measurement, such as quadratic detector, three-dimensional detector and other detection instruments, using the object imaging principle to accurately calculate the size and spatial position of the object, can detect the difference of 0.02mm, accurate measurement of product size and injection volume.

3. Fit degree of mold production

Although the mold industry has certain operating standards, the mold and injection molding of different mold manufacturers will have small differences, such as mold opening and injection molding are not the same manufacturer, due to the different mechanical equipment and production methods of various manufacturers, there will be risks in production, affecting product quality and production efficiency, in order to reduce this risk, generally choose to open mold and injection molding in the same manufacturer is better. From mold opening to injection molding manufacturers can control themselves, and problems can be solved in time.

0 notes

Text

How to deal with the surface of plastic injection molding mold appears gloss defect?

Plastic injection molding mold will appear a lot of difficulties, injection molding mold is composed of two parts of the moving mold and the fixed mold, the production of plastic products need to use the mold injection molding, is through the injection molding machine will plastic raw materials into the injection mold cavity, after cooling and curing to form the injection molding parts. In the mold manufacturing process, how to deal with the surface of plastic injection molding mold appears gloss defect?

The following is the causes and solutions of the surface gloss defect of plastic injection molding mold and. Hope to help you.

1. The mold finish is poor, the cavity surface has rust, etc., the mold exhaust is poor.

2. The mold gating system has defects, should increase the cold well, increase the flow channel, polishing main channel, diverter and gate.

3. The material temperature and mold temperature are low, if necessary, the local heating method can be used at the gate.

4. The processing pressure is too low, the speed is too slow, the injection time is insufficient, the back pressure is insufficient, resulting in poor compactness and the surface is dark.

5. The plastic should be fully plasticized, but to prevent the degradation of the material, the heat should be stable, the cooling should be sufficient, especially the thick wall.

6. Prevent cold material into the parts, if necessary, use self-locking spring or reduce the nozzle temperature.

7. The use of recycled material is too much, the quality of plastic or coloring agent is poor, mixed with water vapor or other impurities, the quality of the lubricant used is poor.

8. Clamping force to be enough.

0 notes

Text

How to deal with the plastic injection molding raw material is not filled?

Electric injection molding machine in the production of injection mold will encounter the situation of injection molding is not filled, there is a lack of glue at the bone position right Angle and fuse connection, here to share some experience.

Analysis of glue injection is not filled:

1. The trapped air in the bone position makes the injection molding machine fill up.

2. The filling of the injection molding machine caused by the glue welding line is not filled.

Reason analysis of glue injection is not filled:

When the injection molding machine is working, the mold gluing method is two-point gluing, and the injection speed is too fast, which is easy to cause the gas trapped at the right Angle of the bone position and cause the filling dissatisfaction; If the injection speed is too slow, it is easy to fill the fuse at the end of the flow.

The solution:

Multistage injection molding and position switching.

In the first stage, the medium speed filling channel was used to pass through the glue inlet and switch the position; then, the second stage was used to quickly fill the vicinity of the bone site and switch the position; the third stage was used to slowly fill the bone site to discharge the gas; finally, the speed filling was used to switch the pressure holding position and the pressure holding time was extended appropriately.

0 notes

Text

Control of Injection Molding Parts Processing Temperature

There are many kinds of plastic, many plastic materials melting time are different, because the plastic does not have a specific melting point, the so-called melting point is a melting state of the temperature segment, the structure and composition of the plastic molecular chain is different, so the impact on its fluidity is also different, then in the production of injection parts manufacturers in the injection parts processing temperature control is also very important.

1. Mold temperature

Some plastic materials due to high crystallization temperature, slow crystallization speed, need higher mold temperature, some due to control size and deformation, or the need for demoulding, to higher temperature or lower temperature, such as PC generally requires more than 60 degrees, and PPS in order to achieve a better appearance and improve fluidity, mold temperature sometimes needs more than 160 degrees, Therefore, the mold temperature has an inestimable effect on improving the appearance, deformation, size and mold of the product.

2. Injection pressure

Melt to overcome the resistance required to advance, directly affect the size of the product, weight and deformation, different plastic products need different injection pressure, for materials such as PA, PP, increase the pressure will make its fluidity significantly improved, injection pressure size determines the density of the product, that is, the appearance of luster. It has no fixed value, and the more difficult it is to fill the mold, the pressure of the injection part increases.

3. Barrel temperature

The melt temperature is very important, and the injection cylinder temperature used is only a guide. The melt temperature can be measured at the nozzle or by air injection. The temperature setting of the injection cylinder depends on the melt temperature, screw speed, back pressure, injection volume and injection part cycle. If you do not have experience working with a particular grade of plastic, start with the lowest setting.

For ease of control, the cylinders are divided into zones, but not all are set to the same temperature. If operating for a long time or at high temperatures, set the temperature in Zone 1 to a lower value, which will prevent premature melting and diverting of plastics. Ensure that the hydraulic oil, hopper sealer, mold and injection cylinder are at the correct temperature before the injection parts begin.

4. Melting temperature

Melt temperature plays a major role in the flow performance of the melt, because the plastic does not have a specific melting point, the so-called melting point is a melting state of the temperature segment, the structure and composition of the plastic molecular chain is different, so the impact on its fluidity is different, rigid molecular chains are affected by temperature more obvious, such as PC, PPS, etc., and flexible molecular chains such as: PA, PP, PE and other fluidity by changing the temperature is not obvious, so should be adjusted according to different materials to reasonable injection molding parts temperature.

0 notes

Text

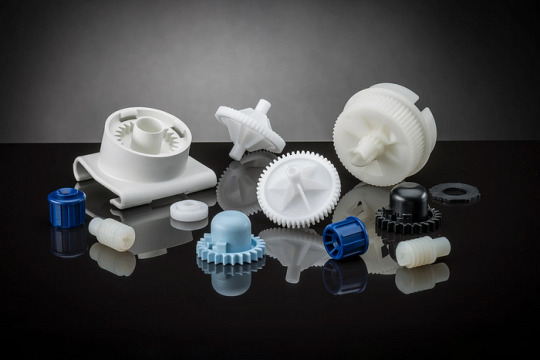

Common Injection Molding Processes

Injection molding is a plastic processing technology widely used in the manufacturing industry, and common types of injection molding include the following:

Conventional injection molding: Conventional injection molding refers to the heating and melting of plastic materials into the mold, cooling to obtain a variety of different shapes of plastic products. Conventional injection molding is suitable for the production of various specifications, shapes and materials of plastic products, such as plastic tableware, home appliance shell and so on.

Two-color injection molding: Two-color injection molding refers to the injection molding of two different colors or materials of plastic materials in the same mold, so as to form different colors or materials on the same product. Two-color injection molding is suitable for the production of complex plastic products requiring multi-color or multi-material combinations, such as automotive interiors.

High-speed injection molding: High-speed injection molding refers to the use of high-speed injection, high-pressure injection and other technologies in the injection process, so as to achieve rapid production of plastic products. High-speed injection molding is suitable for the production of large volume, simple structure of plastic products, such as bottle caps.

Precision injection molding: Precision injection molding refers to the use of high-precision molds and high-precision injection machines in the injection process, so as to achieve high-precision, high-quality plastic products production. Precision injection molding is suitable for the production of precision, complex, high-quality plastic products, such as mobile phone shells, optical lenses, etc.

Pneumatic injection molding: Pneumatic injection molding refers to the use of air pressure to drive plastic materials into the mold during the injection process, so as to achieve efficient and high-quality plastic product production. Pneumatic injection molding is suitable for the production of high-volume, thin-wall, high-transparency plastic products, such as plastic cups, plastic glass and so on.

Large injection molding: Large injection molding refers to the production of large size, large weight and large volume plastic products through large injection molding machines and large molds, such as auto parts and engineering plastic products.

Thin-wall injection molding: Thin-wall injection molding refers to the production of thin-wall plastic products with wall thickness below 0.5mm through high-speed injection molding and high-precision molds, such as plastic containers, boxes, etc.

Micro-injection molding: Micro-injection molding refers to the production of micro-size plastic products through micro-injection molding machines and micro-molds, such as micro-parts, micro-devices, etc.

Composite injection molding: Composite injection molding refers to the injection of plastic materials of different materials into the same mold, thereby forming plastic products of composite materials, such as plastic metal composite products, plastic rubber composite products, etc.

Hot runner injection molding: Hot runner injection molding refers to the setting of heating elements in the mold, by controlling the temperature and position of the heating elements, to achieve the precise control of plastic materials into the mold, so as to produce high-quality, high-precision plastic products.

Injection molding is a very flexible and efficient plastic processing technology that is suitable for the production of a wide variety of plastic products. With the continuous progress of technology and the constant change of market demand, injection molding technology is also constantly developing and innovating, and the types and application fields of injection molding are also constantly expanding and deepening.

0 notes

Text

The Working Principle of Plastic Injection Mold

Plastic injection mold is an important plastic processing tool, through which plastic raw materials are transformed into products of various shapes and specifications. The principle of injection mold can be summarized as the following steps:

1. Plasticizing and injection

First of all, plastic raw materials undergo a series of processing treatments, such as drying, screening, mixing, etc., to become plasticized materials suitable for injection molding. In the heating barrel of the injection machine, the plastic begins to melt and plasticize under the action of heat, forming a uniform molten state. Subsequently, the plasticized plastic is pushed into the nozzle of the injection machine through the pushing action of the plunger or screw. When the plastic in the nozzle accumulates to a certain amount, the driving force of the injection machine stops, and the nozzle of the injection machine injects plastic into the pouring system of the mold. At this point, the pouring system introduces the plastic into the mold cavity.

2. Mold filling

Under the pressure of the injection machine, the plastic flows in the mold cavity and fills the entire cavity. In this process, the plastic is subjected to pressure and temperature, and continues to plasticize and melt. At the same time, the cooling system of the mold begins to work, and the heat inside the mold is taken away by the cooling channel or the cooling medium, so that the plastic is quickly cooled and shaped in the cavity.

3. Mold opening and release

When the plastic is cooled and hardened in the mold cavity, the mold is opened and the molded plastic product is pushed out of the mold cavity or removed from the mold. This process is called opening and stripping. When the mold is opened, the parting surface of the mold is opened, and the product is pushed out or taken out of the mold. The mold is then closed and ready for the next round of injection molding.

4. Other auxiliary actions

In the process of injection molding, some other auxiliary actions are also involved, such as the exhaust of the mold, the adjustment of the ejector mechanism, and the control of the mold temperature. These actions are essential to ensure the quality of the product and the stability of the production.

In summary, the principle of plastic injection mold mainly involves plasticizing, injection, filling, cooling, mold opening and mold release steps. These steps are coordinated to complete the injection molding process of plastic products. With the continuous progress of science and technology, plastic injection molding technology is also developing, and new injection machines, molds and processes continue to emerge, providing more choices and possibilities for the production of plastic products.

0 notes

Text

Several Categories of Plastic Molds

1. Injection mold

It is mainly used in the production of thermoplastic parts of a common molding mold, injection mold corresponding processing equipment is injection molding machine, plastic first in the bottom of the injection molding machine heating cylinder heat melt, and then in the injection molding machine screw or plunger push, through the injection molding machine nozzle and mold pouring system into the mold cavity, plastic cooling hardening molding, release products.

2. Extrusion mold

A kind of mold used to form and produce continuous shape plastic products, also called extrusion molding head, widely used in pipe, bar, monofilament, sheet, film, wire and cable coating, profile processing.

3. High foaming polystyrene molding mold

It is a kind of mold for molding foam packaging materials of various desired shapes with the application of flexible polystyrene (beaded material composed of polystyrene and blowing agent) raw materials. The principle is that the polystyrene can be steam formed in the mold, including two types of simple manual operation mold and hydraulic press straight-through foam mold, mainly used to produce industrial packaging products. The materials for making this mold are cast aluminum, stainless steel, bronze and so on.

4. Blister mold

A kind of mold for some relatively simple plastic products formed with plastic plates and sheets as raw materials, the principle is to use vacuum blooming method or compressed air forming method to make the plastic plates and sheets fixed on the concave die or punch, deformed and stuck on the mold cavity under heating and softening to get the required molding products. Blister mold mainly used in the production of some daily necessities, food and toy packaging products.

0 notes

Text

Injection Mold Factory Processing Mold Application Field

Injection mold is an important process equipment for the production of various industrial products. With the rapid development of the plastics industry, the promotion and application of plastic products in aviation, aerospace, electronics, machinery, ships and automobiles and other industrial fields, the market requirements for molds are also getting higher and higher. Nowadays, the mold design method of traditional injection mold manufacturers is increasingly unable to meet people’s requirements. Compared with traditional mold design, computer-aided engineering techniques can increase productivity, ensure product quality, and reduce costs and labor. In terms of strength, Injection mold has a big advantage.

For mold parts with higher hardness, some injection mold manufacturers cannot be processed by mechanical processing methods, and they most use electric discharge machining. In addition, wire EDM can also be used for sharp corners, deep cavity parts and narrow grooves of mold cavities. CNC lathes are mainly used to process the standard parts of die rods, as well as the mold cavities or cores of rotary bodies, such as injection molds for bottles and POTS, and forging molds for shaft and disc parts. In the injection mold processing, the application of CNC drilling machine can also play a role in improving the processing accuracy and shortening the processing cycle.

By increasing the investment in technology research and development, most production enterprises are optimizing the structural design of the mold system and the CAD/CAE/CAM of the forming part, making it more intelligent, improving the molding process of the forming part and the standardization level of the mold, and improving the accuracy and quality of the mold manufacturing.

Research and apply special materials with high performance and easy cutting for various types of mold parts can improve the performance of molds. In order to adapt to the diversification of the market and the trial production of new products, rapid prototyping technology is applied to the rapid manufacturing of forming molds, injection molds or die casting molds.

0 notes

Text

The Importance of IGBT Module Heat Dissipation for New Energy Vehicles

IGBT Module for Electric Vehicle

IGBT module is an important component of new energy vehicles. In new energy vehicles, the core component of the motor drive part is the IGBT module, the IGBT module occupies about half of the cost of the motor drive system, and the motor drive system accounts for 15–20% of the cost of the vehicle, which means that the IGBT accounts for 7–10% of the cost of the vehicle. And IGBT module is the second highest cost component in addition to the battery, it also determines the energy efficiency of the vehicle.

IGBT module is a high-power semiconductor component, its loss of power makes it heat more but it should not work at a high temperature for a long time. So the manufacturers must pay attention to the heat dissipation of IGBT module. It is particularly important for IGBT module to select high-performance aluminum electronic heat sink and choose efficient heat dissipation program.

The combined profile heat sink is suitable for IGBT modules, new energy industry, etc.

Lori has long been committed to the research and development and production of various high-power heat sinks such as IGBT heat sinks. We provide customers with efficient and professional new energy heat sinks. For more information about our products and services, please contact us directly.

0 notes

Text

Which Industries Are CNC Machining Suitable for?

CNC machining is a process that uses computer numerical control (CNC) machine tools to manufacture and process parts and products. The CNC machining process involves the use of computer programs to control the movement of the machine tool, making precise machining adjustments to the workpiece by automatically removing excess parts of the material.

CNC machining is suitable for many industries due to its local efficiency, precision and flexibility. Here are some of the main application industries:

Automotive and parts manufacturing :CNC machining plays an important role in automotive manufacturing and can process components such as engines, chassis, body, interior, etc., ensuring high precision and quality.

Aerospace :CNC machining technology is essential for the manufacture of high-precision and complex shaped parts, such as aero engines, turbines, blades, etc., meeting the aerospace industry’s requirements for high quality and reliability.

Mold manufacturing :CNC machining has a wide range of applications in the field of mold manufacturing. It can process molds, fixtures, fixtures, etc., to improve the accuracy and efficiency of mold manufacturing.

Communication industry :CNC machining occupies an important position in the manufacturing of communication equipment, which is used to process precision components in communication equipment to ensure the performance and stability of the equipment.

Medical devices :CNC machining technology can process high-precision parts in medical devices to meet the high requirements for accuracy and reliability of medical devices.

Home appliance industry :CNC machining is also used in the manufacturing of home appliance products, which can process parts in home appliance products to improve product quality and performance.

3C industry :CNC machining plays a key role in the manufacturing of electronic products such as mobile phones, computers and tablets, and it is used to process various parts and components to ensure the accuracy and reliability of products.

In addition, CNC machining is also suitable for a variety of quenching, forging, casting, heat treatment and other hot processing processes. It can adapt to a variety of complex shape parts processing, improve the production efficiency, reduce the production costs and improve the product quality.

0 notes

Text

What Should Pay Attention to in the Operation of High-Speed 5-Axis Machining Center?

High-speed 5-axis machining center is an advanced processing equipment, with high precision, sound speed and high efficiency characteristics. It is usually used for processing complex and difficult parts, such as aerospace, medical equipment, automotive parts, etc. When operating a high-speed 5-axis machining center, special attention needs to be paid to the following points:

1. Familiar with the structure and principle of the equipment: the operator needs to be familiar with the structure and working principle of the high-speed 5-axis machining center, understand the name of each axis, the range of motion and restrictions, and master the control system and programming method of the machining center. Only with a deep understanding of the structure and principle of the equipment can we correctly operate and use the high-speed 5-axis machining center for processing.

2. Strictly follow the operating procedures: the operator should strictly follow the operating procedures, including wearing personal protective equipment, avoid body parts close to the moving parts, avoid strong light exposure, etc. In addition, safety devices such as safety doors, warning lights and emergency stop buttons need to be checked regularly to ensure that they are in good working condition.

3. Equipment inspection and maintenance: before use, it is necessary to maintain and check the equipment. First, check whether the tool is worn, and if it is worn, it needs to be replaced. Secondly, check whether the fixture is stable and firm. Clean the equipment to prevent dust and foreign matter from entering the equipment. At the same time, it is also necessary to carry out real-time monitoring of the equipment during the processing process to discover and deal with problems in time.

4. Material preparation and processing: before 5-axis processing, it is necessary to prepare the required materials and ensure the quality and accuracy of the materials. At the same time, in order to avoid temperature changes affecting the processing, the material should be placed in a constant temperature environment. After the processing is completed, it is also necessary to process the workpiece, including cleaning, inspection and maintenance.

5. Safety control: the operator needs to strictly control the safety risks in the processing process, such as the cutting and cutting methods, the length and diameter of the cutting county, and the setting of cutting parameters. In the processing process, it is also necessary to pay attention to observe the processing situation, adjust the cutting parameters and tool status in time, and avoid collision or over-cutting errors.

6. Programming and setting: the operator needs to be familiar with the programming language and programming method of the high-speed 5-axis machining center, and can perform the correct programming and setting according to the processing needs. In the programming process, it is necessary to pay attention to the planning of the tool path, the setting of cutting parameters, the distribution of machining allowance and other issues to ensure the stability and accuracy of the machining process.

7. Training and experience accumulation: operators need to go through professional training and practice, practice the accumulation of experience, and constantly improve their skill level and operational experience. Through continuous learning and practice, operators can better master the operation skills and maintenance methods of high-speed 5-axis machining centers, and improve the utilization rate and service life of equipment.

0 notes

Text

The Working Principle of Plastic Injection Mold

Plastic injection mold is an important plastic processing tool. Plastic injection molds transform the plastic raw materials into products of various shapes and sizes. The principle of injection mold can be summarized as the following steps:

1. Plasticizing and injection

First of all, plastic raw materials undergo a series of processing treatments, such as drying, screening, mixing, etc., to become plasticized materials suitable for injection molding. In the heating barrel of the injection machine, the plastic begins to melt and plasticize under the action of heat and forms a uniform molten state. Subsequently, the plasticized plastic is pushed into the nozzle of the injection machine through the pushing action of the plunger or screw. When the plastic in the nozzle accumulates to a certain amount, the driving force of the injection machine stops, and the nozzle of the injection machine injects plastic into the pouring system of the mold. At this point, the pouring system introduces the plastic into the mold cavity.

2. Mold filling

Under the pressure of the injection machine, the plastic flows in the mold cavity and fills the entire cavity. In this process, the plastic is subjected to pressure and temperature, and continues to plasticize and melt. At the same time, the cooling system of the mold begins to work, and the heat inside the mold is taken away by the cooling channel or the cooling medium, so that the plastic is quickly cooled and shaped in the cavity.

3. Mold opening and stripping

When the plastic is cooled and hardened in the mold cavity, the mold is opened and the molded plastic product is pushed out of the mold cavity or removed from the mold. This process is called mold opening and stripping. When the mold is opened, the parting surface of the mold is opened, and the product is pushed out or taken out of the mold. Then, the mold is closed and ready for the next round of injection molding.

4. Other auxiliary actions

In the process of injection molding, some other auxiliary actions are also involved, such as the exhaust of the mold, the adjustment of the ejector mechanism, and the control of the mold temperature. These actions are essential to ensure the quality of the product and the stability of the production.

In conclusion, the principle of plastic injection mold mainly involves plasticizing and injection, mold filling, mold opening and mold stripping. These steps are coordinated to complete the injection molding process of plastic products. With the continuous progress of science and technology, plastic injection molding technology is also developing, and new injection machines, molds and processes continue to emerge, which provide more choices and possibilities for the production of plastic products.

0 notes

Text

What Are the Advantages of Laser Cutting?

The process of precision sheet metal processing mainly includes parts drawing analysis, materials procurement, sheet metal cutting, sheet metal welding, surface treatments, detection and other links. Among them, sheet metal cutting is one of the most critical links in the entire processing process.

There are many kinds of sheet metal cutting technology in sheet metal processing, such as tungsten wire EDM cutting, laser cutting and so on. Laser cutting technology because of its high quality, high efficiency, high precision and cutting stability, it has become the preferred choice of more and more sheet metal processing manufacturers and customers. Compared with other cutting technologies, laser cutting has the following obvious advantages:

1. High precision

The cutting accuracy of the laser cutting machine can reach the millimeter level, the accuracy is highly controllable, and the probability of failure is low. It can effectively achieve high-precision cutting, which can0 ensure the quality of the parts.

2. High efficiency

Laser cutting technology can complete high-speed, efficient automated processing. Compared with traditional manual sheet metal processing, laser cutting technology can greatly improve production efficiency and work efficiency.

3. A variety of materials can be cut

Laser cutting technology can cut a variety of different types of materials, such as steel, stainless steel, aluminum, copper, alloys, etc., so that you can provide cutting services for parts with different requirements.

4. Low cost

Because laser cutting technology uses advanced automated processing technology, and its short cycle makes the cost of laser processing lower than other sheet metal processing technology.

In conclusion, the continuous development of precision sheet metal processing technology can not only provide high-quality, high-precision sheet metal processing services, but also bring more possibilities and prospects for the development of related fields. With the advancement of science and technology and the application of big data technology, in order to meet the needs of all walks of life, precision sheet metal processing technology and services will continue to upgrade and improve.

0 notes