#Wire Edm

Explore tagged Tumblr posts

Text

Enhancing Manufacturing with Sinker EDM Solutions from Phillips Corporation Middle East

In the ever-evolving manufacturing world, precision and efficiency are key to staying competitive. Electrical Discharge Machining (EDM) is one of the most transformative technologies that provide manufacturers with the capability to create parts with high accuracy and intricate detail. Among the different types of EDM, Sinker EDM stands out as one of the most efficient and versatile solutions for producing complex shapes and components with high precision. Phillips Corporation Middle East offers top-tier Sinker EDM machines that are designed to meet the needs of industries such as aerospace, automotive, and medical device manufacturing. This blog will explore the advantages of Sinker EDM and how Phillips Corporation Middle East is helping businesses in the region enhance their manufacturing processes.

What is Sinker EDM?

Sinker EDM, also known as cavity-type EDM, is a specialized form of electrical discharge machining where an electrode is used to create a cavity or shape within a workpiece. The process works by generating electrical sparks between the electrode and the material being machined. These sparks cause the material to melt and evaporate, which then creates precise cavities or contours in the workpiece. Unlike traditional machining methods, Sinker EDM can produce intricate and complex shapes with high precision, making it ideal for applications that require detailed geometries and fine tolerances.

Key Benefits of Sinker EDM Solutions

Exceptional Precision and Accuracy One of the main advantages of Sinker EDM is its ability to produce parts with exceptional precision and accuracy. By using an electrode to erode material in a controlled manner, Sinker EDM machines can achieve extremely tight tolerances. This is particularly important for industries such as aerospace, medical devices, and automotive, where even the smallest deviation can lead to significant issues. With Sinker EDM, manufacturers can ensure that their parts meet the highest standards of quality and performance, reducing the risk of defects and ensuring customer satisfaction.

Ability to Create Complex Geometries Sinker EDM excels at creating intricate and complex shapes that are difficult or impossible to achieve with traditional machining methods. Whether it’s creating molds with undercuts, producing complex cavities, or shaping hard-to-machine materials, Sinker EDM provides the flexibility and capability needed to tackle the most challenging tasks. Its ability to produce detailed contours and fine details makes it a perfect choice for manufacturers who need to create parts with unusual or highly specialized designs.

Efficient for Hard-to-Machine Materials Sinker EDM is particularly effective for working with hard materials that are difficult to machine using traditional methods. Materials such as titanium, tungsten, and Inconel, commonly used in industries like aerospace and medical devices, can be easily machined using Sinker EDM. These materials are challenging to process with conventional machining tools due to their hardness and strength, but Sinker EDM overcomes these challenges by using electrical discharges rather than mechanical force. This opens up new possibilities for manufacturers looking to work with advanced materials.

Reduced Tool Wear and Maintenance Unlike traditional cutting tools that experience wear over time, Sinker EDM uses an electrode that gradually erodes during the process. This minimizes tool wear and reduces the need for frequent tool changes, which can be time-consuming and costly. The result is a more efficient and cost-effective process with less downtime for maintenance. Sinker EDM machines from Phillips Corporation Middle East are designed for durability and long-term performance, making them a reliable investment for manufacturers in the region.

Minimal Material Waste Material waste is a significant concern for manufacturers, especially when working with expensive materials. Sinker EDM is a non-contact process, meaning that the electrode never physically touches the material. This reduces the chances of tool deflection or unnecessary material removal, leading to less waste and better utilization of raw materials. By improving material efficiency, manufacturers can save on production costs and increase profitability.

Sinker EDM Applications in the Middle East

The Middle East is home to several key industries that rely on high-precision manufacturing, including aerospace, automotive, oil and gas, and medical devices. Sinker EDM solutions are an essential tool for these industries, allowing manufacturers to produce complex parts and components that meet the stringent quality standards of the region. Whether it’s producing intricate molds, cutting precision components, or creating advanced tooling, Sinker EDM plays a critical role in the success of many businesses in the region.

For example, in the aerospace industry, where components must meet exacting specifications, Sinker EDM is used to create detailed parts such as turbine blades, airfoils, and other components that require high precision. Similarly, in the medical device industry, where parts such as implants and surgical instruments must meet strict regulatory standards, Sinker EDM is used to create components that are both accurate and reliable.

Phillips Corporation Middle East: Your Partner in Sinker EDM Solutions

Phillips Corporation Middle East is a trusted provider of high-precision Sinker EDM machines that help businesses in the region stay ahead of the competition. With a commitment to quality, innovation, and customer satisfaction, Phillips Corporation Middle East offers a range of Sinker EDM solutions that cater to the unique needs of local industries. Their machines are equipped with the latest technology to ensure maximum precision, efficiency, and reliability. From installation and training to ongoing technical support, Phillips Corporation Middle East is dedicated to helping businesses optimize their investment in Sinker EDM technology.

With their extensive experience in the EDM industry, Phillips Corporation Middle East works closely with clients to understand their specific requirements and provide customized solutions that meet their production goals. Their expert team is always available to offer guidance and support, ensuring that manufacturers can make the most of their Sinker EDM machines and achieve the best possible results.

Conclusion

Sinker EDM is a powerful and versatile technology that is revolutionizing the manufacturing process in the Middle East. Its ability to create intricate shapes, work with hard-to-machine materials, and produce parts with exceptional accuracy makes it an essential tool for industries such as aerospace, automotive, and medical devices. Phillips Corporation Middle East is at the forefront of providing high-quality Sinker EDM solutions that enable manufacturers to achieve their goals and stay competitive in an increasingly globalized market. By investing in Sinker EDM technology, businesses in the Middle East can enhance their manufacturing capabilities, reduce production costs, and improve overall efficiency.

0 notes

Text

Unlock Precision Engineering with Wire EDM Machines

Discover the world of wire EDM (Electrical Discharge Machining) technology, where precision meets efficiency. Wire EDM machines utilize a thin, electrically charged wire to cut intricate shapes and designs with exceptional accuracy. Ideal for industries requiring high precision, such as aerospace, automotive, and medical manufacturing, these machines ensure superior finish and minimal waste. Explore how wire EDM can enhance your manufacturing processes and elevate your production capabilities today!

0 notes

Text

Injection Mold Factory Processing Mold Application Field

Injection mold is an important process equipment for the production of various industrial products. With the rapid development of the plastics industry, the promotion and application of plastic products in aviation, aerospace, electronics, machinery, ships and automobiles and other industrial fields, the market requirements for molds are also getting higher and higher. Nowadays, the mold design method of traditional injection mold manufacturers is increasingly unable to meet people’s requirements. Compared with traditional mold design, computer-aided engineering techniques can increase productivity, ensure product quality, and reduce costs and labor. In terms of strength, Injection mold has a big advantage.

For mold parts with higher hardness, some injection mold manufacturers cannot be processed by mechanical processing methods, and they most use electric discharge machining. In addition, wire EDM can also be used for sharp corners, deep cavity parts and narrow grooves of mold cavities. CNC lathes are mainly used to process the standard parts of die rods, as well as the mold cavities or cores of rotary bodies, such as injection molds for bottles and POTS, and forging molds for shaft and disc parts. In the injection mold processing, the application of CNC drilling machine can also play a role in improving the processing accuracy and shortening the processing cycle.

By increasing the investment in technology research and development, most production enterprises are optimizing the structural design of the mold system and the CAD/CAE/CAM of the forming part, making it more intelligent, improving the molding process of the forming part and the standardization level of the mold, and improving the accuracy and quality of the mold manufacturing.

Research and apply special materials with high performance and easy cutting for various types of mold parts can improve the performance of molds. In order to adapt to the diversification of the market and the trial production of new products, rapid prototyping technology is applied to the rapid manufacturing of forming molds, injection molds or die casting molds.

0 notes

Text

"Zero tolerance machining" NO!!!!! I am going to kill you. This doesn't exist. It's a stupid phrase. For advertising or whatever. If you genuinely think you've achieved "Zero tolerance" you have a #metrology #skillissue. I'm going to kill you. What's next, huh? When your machines advance even more? Negative tolerance? Short-sighted marketing. Just say the tolerance, that should be impressive enough. Regular people think "5 thou" is crazy, you will be ok. You don't need to lie about the world.

#Yes this is about the wire edm parts that are being reblogged and sexualized#ALSO!!! I'm pretty confident that each part is made of MULTIPLE pieces of metal#YES you can get really good tolerances with an EDM which is how those parts are possible BUT there has to be space for the wire to go#Two pieces are cleanly put together and then probably finished on a different machine so they look like one piece#If one piece was being machined into two pieces and then put back together there would be a larger gap. The end result wouldn't be as cool#Correct me if I'm wrong though I don't have a ton of experience with EDM in general#Machining#○

77 notes

·

View notes

Text

#TOMBOY#LOVE#alternative#EDM#electronic#alternative music#electronic music#experimental#experimental music#anime#Cyberia#Lain#Lain Iwakura#Iwakura Lain#Serial Experiments Lain#love#trance#wired#Bandcamp#let's all love lain

9 notes

·

View notes

Text

C̷̨̨̢̢̳̭̱̩̲̉͌̎̑͊̏͝͝͝A̴̘̘͍̳̥̾̈́̋̈́̕̚L̵̨̧̡͚̙̦̘̗͐͐̓͛̕L̴̢͈̩͚͚̱̫̹͔̈́̇̾͑͂̇I̵̡̞̮͈͗̓̿̈N̴̡̬̥̯͙̜̖̄̊̎͋̇̍G̴͓̰̊̿͆̽̅ ̵͇͇̠̭̩̹͌Ä̷̧̠͈̥̪̖̟̗̙̹́Ļ̶̯͎̠̮̼̙̲͉̍̀̕L̴̳̀̆̑͋́̎̀̓ ̶̢͖̩͉̫̖̟͔̲̟̎͋̾C̷̼͔͓̺͓̠̤̾͂Y̴̛̟̟̎̏͒̃͗̍̿̓̿B̵̫̤̈́͗͆́̈́͆Ȩ̸̭̬͚̞̫̯̼̏͋̒̄̃̿ͅŖ̶̹͕̣̼̖̗̜̗̖͗̽Ḁ̵̂̽̄̌̕͘N̴͆̀͛́͜Ğ̸̖̮͉̜̿̍͠Ë̸̛̙͎͎̻̝̮̂̈́̆̋̊̌̑̕Ĺ̸͕͕̥̟͎͐̓̉̅͘̕̕̚͜Ş̵͙̞̘͐́̈̑̊͘

oopsie lemme just

𝘾𝘼𝙇𝙇𝙄𝙉𝙂 𝘼𝙇𝙇 𝘾𝙔𝘽𝙀𝙍𝘼𝙉𝙂𝙀𝙇𝙎

Do you want to join forces? Unite across the wire? Yes?!!!!?!?!?

Then I implore you to collaborate with me and other angels on this here playlist.

the goal is to create the most ethereal reflection of cyberspace in musical form :D

(/srs am I too into character pls tell me u can tell im being slightly ironic...lowkey feeling like a millennial tho)

#cyber angel#cyberpunk#grimes#grimezsz#edm#music#playlist#yeule#halsey#serial experiments lain#laincore#cyberspace#the wire#join us#internet angel#Spotify

4 notes

·

View notes

Text

niche (not really) music artists to help you be more performative

another semester has passed and i no longer foresee any english classes. they stress me out too much and i'm afraid of getting accused of ai cause i LOVE using semicolons and em dashes and random big words in the middle of my sentences. i've been trying to mitigate that and become a better writer by writing on here but it does NOT help...

i should preface this by saying that there are many different forms of male manipulators & today i will be focusing on the kind that is always on fashion tiktok and using wired headphones and most definitely has pierced ears with specifically silver hoop earrings. hope this guide helps you outperform them.

1. the deep

the deep's music totally reflects early 2010s ish "indie sleaze" type pop music (e.g. far east movement or kesha) but i think most people have probably heard angel tattoo by her—honestly i didn't really fw it that much at first but it's grown on me.

2. kimj

kimj (along with sebii) did produce that track by the deep. though i think kimj is still a bit more niche than sebii. he's worked with a lot of western artists in the past (i think recently nate sib) but his own music is also reminiscent of 2010s edm music. i really liked this track on korean.

3. the bird

two artists whose names start with the... interesting. anyways this specific track i'm gonna post had ren g in conjunction (on vocals i think) but a lot of the bird's music uses the same sample that lady gaga does.

4. YT

he's actually really popular but i'm not sure if that is outside of england. i've never heard anyone from here talk about him but i really like his production. i don't really know the term for what this kind of track is called but i like it and i think everyone should listen to it.

5. enhyphen

i actually just couldn't think of another artist but to be fair like if i was a male manipulator i'd def have some sort of kpop group in my playlist. i think newjeans is too easy and predictable so i'm gonna go with enhyphen (and i like lowkey fw their music...)

5. tonser

i just thought of another artist. i think i posted about him on here once before because i remember he was a lot less popular until 2hollis blew up with gold and now this evil hyperpop edm blend is really popular i think people should hop on tonser. his music is kind of joyous like a carol i think.

i wish you all well in your journeys fighting off evil men. more posts coming soon. thanks for coming to my ted talk.

#male manipulator#evil men#music#hyperpop#kimj#the deep#the bird#tonser#enhyphen#kpop#rap#yt#british rap#music review#music recs#songs#sweet tunes#tunes#playlist#playlist recs#song recs#performance#performatism#wired headphones#pop#edm#2010s nostalgia#2010s music#indie pop#underground

5 notes

·

View notes

Text

A Single Source To Your Filtration Needs – Wire EDM Filter Supplier

With more than a decade’s experience as wire EDM filter supplier, Ankok specialises in the sale of filters for wire electrical discharge machines (WEDM).

Wire EDM filters specialising in wire cut EDM processing mainly consists of filter paper and metal mesh. The quality of filter paper determines the filtration accuracy and service life.

Do you know that EDM filters keep your technology clean and in good working order, even after long periods? By lubricating the system and removing waste and harmful residues, filters save energy, cut costs, and increase productivity and efficiency.

However, it is important to regularly change your wire EDM machine filters because they are continuously put through their paces and, over time, the waste and dirt that build up can compromise their effectiveness.

Ankok brand wire EDM filters adopts great quality filter paper with fibre for different processing condition and cutting materials.

In the EDM world, the variety of materials machined has increased. Three micron, five micron, and ten micron filtration requirements have emerged. We have developed most type of OEM filter media to answer to the challenges of EDM process on specific materials with new styles of Sodick EDM Filters, Mitsubishi EDM filters, Fanuc EDM filters, and Charmilles EDM filters.

Looking for EDM advice and sales you can count on? Ankok Wire EDM filter supplier is a trusted source for all things EDM. Our superior service and customer care is what truly sets us apart. Our mission is to always provide unparalleled customer care and service in a one-stop-shop for EDM filter supplies and accessories.

The EDM consumables market is larger than just filters of course. But Ankok has stay focused on the filtration requirements of wire EDMs. We continue to design, manufacture and supply lower cost EDM filters that provide exceptional deionized water cleanliness and service life equivalent to the best original equipment filters.

We supply a large variety of EDM wear parts and consumables for most EDM machines including the following brands:

HITACHI, JAPAX, MITSUBISHI, AGIE CHARMILLES, ONA, SEIBU, FANUC, MAKINO, CHMER, BROTHER, SODICK, OKI, MANN HUMMEL.

Contact us for a quote and include the product code of the filter you are interested in for more information. We are here to answer any questions or meet any special requests you may have.

#EDM Filter Suppliers#EDM Filter Manufacturers#Wire EDM Filter Suppliers#Wire EDM Filter Manufacturers#EDM Machine Parts Suppliers#Charmilles Edm Filters#Sodick Edm Filters#Sodick Wire Edm Filters#Mitsubishi Wire Edm Filters#Mitsubishi Edm Filters

2 notes

·

View notes

Text

Whos ready for barbed wire????

#edm#silent hill#midtempo#music artwork#music#electronic music#complextro#electro house#trip hop#barbed wire#rust and blood#horror

2 notes

·

View notes

Text

5 Recommendations For EDM Filter Maintenance By EDM Filter Manufacturer

High-performance EDM machines perform precision work in tool and mould making. Wear and machine downtimes cost manufacturers time and money. Contact us for a quote and include the product code of the filter you are interested in for more information. As a EDM filter manufacturer we are here to answer any questions or meet any special requests you may have. Visit: https://ankok.com/5-recommendations-for-edm-filter-maintenance-by-edm-filter-manufacturer/

#EDM Filter#Wire EDM Filter#EDM Filter Suppliers#EDM Filter Manufacturers#Wire EDM Filter Suppliers#Wire EDM Filter Manufacturers#EDM Parts Suppliers#Mitsubishi EDM Parts#EDM Machine Parts Suppliers#Wire EDM Consumables Suppliers

2 notes

·

View notes

Text

I WANT MY DAMN WIRES BACK

i swear idk what happened to them i was in class and i tugged a little too hard NOW THEY DONT WORRKKKKKKKKKKKKK NOT EVEN AN ANGLE IS SAVING MEEEEEEEWWW

#angel#spotify#grunge#angelic#2hollis#girl blogger#landmine girl#this is girlhood#the hellp#wired headphones#wired#headphones#electronic music#edm#alternative

0 notes

Text

Wire EDM Machines Market Expected to Reach $651.4 Million by 2035

The Wire EDM (Electrical Discharge Machining) Machines market is projected to grow significantly, with industry revenue estimated to reach $651.4 million by 2035, up from $329.2 million in 2024. This growth reflects an annual revenue increase of 6.4% from 2024 to 2035. Wire EDM Machines are essential in several key applications, including precision manufacturing, tool and die making, medical device manufacturing, and prototype development. This report delves into the opportunities for growth and revenue expansion in the Wire EDM Machines market, focusing on technology types, applications, power input, automation levels, and customer types.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/wire-edm-machines-market-research-report

Market Dynamics and Growth Drivers

The market for Wire EDM Machines is expected to see substantial growth, driven by increasing demand for precision engineering and technological advancements in automation. As industries seek to meet higher standards of accuracy and efficiency, Wire EDM Machines play a pivotal role. This growth is further supported by the expansion of the electronic devices market, which continues to drive the need for advanced machining technologies.

Industry Leadership and Competitive Landscape

The Wire EDM Machines market is highly competitive, with numerous leading players shaping the industry landscape. Key companies in the market include Makino Inc., Sodick Inc., Mitsubishi Electric Corporation, Fanuc Corporation, GF Machining Solutions Management SA, Seibu Electric & Machinery Co. Ltd., Makino Milling Machine Co. Ltd., ONA Electroerosion SA, Chmer EDM, Knuth Machine Tools USA Inc., AccuteX Technologies Co. Ltd., and Suzhou Baoma Numerical Control Equipment Co. Ltd. These companies are expected to lead the market by leveraging technological innovations and forming strategic partnerships to meet the growing demand for precision engineering solutions.

Regional Shifts and Supply Chain Evolution

North America and Europe are the leading regions in the Wire EDM Machines market. However, challenges such as the high cost of machines and the complexity of maintenance continue to influence market dynamics. As the supply chain evolves—from raw material suppliers to component manufacturers and machine assemblers—market players are expected to adapt by targeting emerging markets for expansion. Key regions like Vietnam, Indonesia, and Poland present significant opportunities for revenue diversification and expansion of the Total Addressable Market (TAM).

Opportunities for Expansion

The Wire EDM Machines market presents several opportunities for growth, including exploring untapped markets, advancing technology, and forming strategic partnerships. The increasing need for high-precision machining, particularly in sectors such as electronics and medical devices, offers key avenues for expansion. Additionally, the growing demand in emerging economies is expected to fuel market growth, particularly in regions like the U.S., Germany, Japan, China, and South Korea.

About DataString Consulting

DataString Consulting provides a comprehensive range of market research and business intelligence solutions for both B2C and B2B sectors. With more than 30 years of combined experience in market research and strategic advisory, DataString Consulting offers tailored insights to help businesses achieve their specific strategic goals. The company’s team of industry experts continuously monitors high-growth sectors across more than 15 industries, ensuring clients receive timely, actionable market intelligence that helps them stay ahead of emerging trends and capitalize on new opportunities.

0 notes

Text

Leading Wire EDM Automation Providers in Minnesota

Looking for wire EDM automation services in Minnesota? Our advanced wire EDM technology provides high-precision cutting for various industries. Improve your manufacturing process with efficient, automated solutions that reduce downtime and boost productivity. Trust our experts for reliable wire EDM automation services in Minnesota to meet your precise manufacturing needs.

0 notes

Text

Wire EDM Machines: Precision Cutting Technology for Modern Manufacturing

Explore the power of Wire EDM (Electrical Discharge Machining) technology, a high-precision solution for cutting complex shapes in hard materials. Learn how a Wire EDM machine provides accuracy, flexibility, and efficiency, making it essential in industries like aerospace, automotive, and medical device manufacturing. Discover the benefits and applications of wire EDM in modern manufacturing.

0 notes

Text

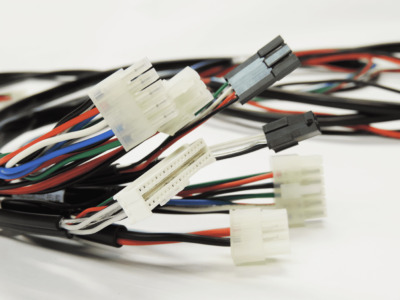

Cable/Wire Harness Assembly

In today’s technologically advanced world, the demand for reliable and efficient cable assemblies and wire harnesses spans across numerous industries. From automotive to aerospace, consumer electronics to industrial machinery, these components are vital for the functionality and reliability of countless devices and systems. At inYantra, we specialize in providing top-tier cable and wire harness assembly services that meet the specific needs of our customers across a wide range of industries.

Our Commitment to Excellence

At inYantra, we adhere to the highest standards of quality and workmanship. Our cable and wire harness assemblies are manufactured following the IPC/WHMA-A-620 workmanship standards, ensuring that every product we deliver is built to perform reliably under various conditions. We understand that every application has unique requirements, and our facility is equipped to manufacture both power and signal cable assemblies to your exact specifications.

Comprehensive Cable & Wire Harness Assembly Services

Our cable and wire harness assembly services are designed to cater to diverse industry needs. We offer a wide range of services that ensure precision, quality, and reliability in every assembly we produce.

Single Core Wires and Multi-Core Cables

Whether your project requires single core wires or complex multi-core cables, we have the expertise and capabilities to meet your needs. Our team is skilled in handling a variety of materials and configurations, ensuring that each assembly is tailored to your exact specifications.

Automated Wire Processing

We utilize advanced automated wire processing technologies, including cut, strip, crimp, and tinning processes. This automation ensures consistent quality and precision across all assemblies, reducing the potential for errors and enhancing overall efficiency.

Crimp Force Monitoring

As part of our commitment to quality, we incorporate crimp force monitoring as a standard practice in our assembly processes. This ensures that all crimps are secure and meet the required standards, providing reliable electrical connections in every product.

100% Electrical Testing

Quality assurance is paramount at inYantra. That’s why we perform 100% electrical testing on all our cable and wire harness assemblies. This rigorous testing process ensures that every assembly meets the required electrical performance standards before it leaves our facility.

IPC/WHMA-A-620 Standards

We adhere strictly to the IPC/WHMA-A-620 standards, which are the industry benchmarks for cable and wire harness assemblies. These standards cover all aspects of assembly, from materials to workmanship, ensuring that our products are of the highest quality.

Design for Manufacturability (DFM) Assistance

Our team provides Design for Manufacturability (DFM) assistance, helping you optimize your designs for production. This ensures that your cable and wire harness assemblies are not only functional but also cost-effective and efficient to produce.

Global Sourcing and Vertical Integration

We offer global sourcing for Approved Vendor List (AVL) and alternative components, giving you access to high-quality materials from trusted suppliers worldwide. Additionally, our vertical integration opportunities allow you to leverage our group manufacturing capabilities in raw cable production, further enhancing the efficiency and cost-effectiveness of your projects.

Industries We Serve

Our cable and wire harness assemblies are used in a variety of end-use applications across multiple industries. Whether you’re in the automotive, aerospace, telecommunications, medical, or industrial sector, inYantra has the expertise to deliver the solutions you need.

Conclusion

At inYantra, we take pride in delivering high-quality cable and wire harness assemblies that meet the stringent requirements of our diverse customer base. Our commitment to following industry standards, combined with our advanced manufacturing capabilities and global sourcing strategies, ensures that we can provide reliable, cost-effective solutions for your cable and wire harness needs. Trust inYantra to be your partner in delivering excellence in every assembly.

1 note

·

View note