Don't wanna be here? Send us removal request.

Text

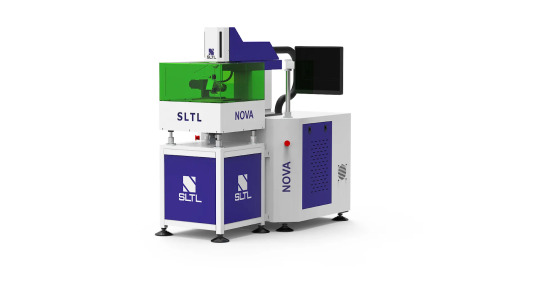

The Future of Laser Welding: Why SLTL Leads the Way in India and Beyond

Introduction

Laser welding technology has revolutionized modern manufacturing by providing unmatched precision, speed, and efficiency. As industries evolve, the demand for advanced welding solutions grows, and SLTL (Sahajanand Laser Technology Limited) stands at the forefront of this transformation in India and beyond. This article explores the world of laser welding, highlights SLTL's pioneering contributions, and examines the future of this innovative technology.

Overview of Laser Welding Technology

Definition and Brief History of Laser Welding

Laser welding involves using a high-intensity laser beam to join materials, offering precision and control that traditional welding methods cannot match. Developed in the 1960s, laser welding has advanced significantly, becoming an essential tool in various industries.

Evolution of Laser Welding Techniques

Over the decades, laser welding has evolved with improvements in laser sources, automation, and integration capabilities. These advancements have expanded its applications, making it a critical technology in modern manufacturing.

Importance of Laser Welding in Modern Manufacturing

Laser welding’s precision, speed, and ability to join dissimilar materials make it invaluable in today’s manufacturing landscape. It reduces production times, improves quality, and opens new possibilities for innovative product designs.

Advantages Over Traditional Welding Methods

Laser welding offers several advantages over traditional methods, including greater precision, faster processing times, and the ability to weld a wider range of materials. These benefits have made it a preferred choice for many industries.

SLTL: Pioneering Laser Welding Technology in India

Introduction to SLTL (Sahajanand Laser Technology Limited)

Company Background and History

SLTL was established with the goal of innovating and has developed into a world leader in laser technology.Their commitment to excellence and continuous improvement has made them a trusted name in laser welding.

Vision and Mission

SLTL aims to revolutionize manufacturing through cutting-edge laser solutions, enhancing efficiency, precision, and sustainability across industries.

Innovations by SLTL in Laser Welding

Breakthrough Technologies and Patents

SLTL has introduced numerous breakthrough technologies in laser welding, holding several patents that underscore their innovative prowess.

Unique Selling Points of SLTL’s Laser Welding Machines

SLTL's machines are renowned for their high precision, speed, and integration capabilities, setting them apart from competitors.

Manufacturing Excellence

State-of-the-Art Production Facilities

SLTL's production facilities are equipped with the latest technology, ensuring that every machine meets the highest standards of quality and precision.

Commitment to Quality and Precision

SLTL's dedication to quality is evident in their rigorous testing and quality control measures, ensuring that each machine performs flawlessly.

Advanced Features of SLTL’s Laser Welding Machines

High Precision and Accuracy

SLTL's machines utilize advanced laser sources and control systems to achieve unmatched precision in welding.

Examples of High-Precision Applications

From intricate medical devices to complex aerospace components, SLTL's machines excel in applications requiring the highest precision.

Speed and Efficiency

SLTL's laser welding machines are designed for speed, significantly reducing processing times and increasing productivity.

Case Studies Demonstrating Efficiency

Numerous case studies highlight SLTL's machines' ability to enhance efficiency in various manufacturing processes.

Automation and Integration

SLTL's machines are compatible with automated systems and robotics, allowing seamless integration into existing production lines.

Applications of SLTL Laser Welding Machines

Automotive Industry

SLTL's machines play a crucial role in automotive manufacturing, providing precise and reliable welding solutions. Numerous automotive manufacturers have benefited from SLTL's advanced welding technology, improving quality and efficiency.

Aerospace and Defense

The strict requirements needed in aircraft manufacturing are met by SLTL's machinery, guaranteeing the best quality and dependability. Their technology is also vital in producing defense equipment, where precision and durability are paramount.

Electronics and Electrical Industries

SLTL's laser welding machines offer the precision needed for electronics manufacturing, ensuring high-quality products. From circuit boards to battery components, SLTL’s machines provide reliable welding solutions for various electrical applications.

Medical Devices and Equipment

In the medical field, precision and safety are critical. The precision required for the production of medical devices is provided by SLTL's machinery. Notable projects include advancements in medical technology driven by SLTL’s innovations.

SLTL’s Global Impact and Market Reach

Expanding Beyond India

SLTL has established a strong presence in international markets, exporting their cutting-edge laser welding machines worldwide. Their strategies for global expansion include forming partnerships, participating in international exhibitions, and continuous innovation.

Partnerships and Collaborations

SLTL collaborates with leading global companies to develop advanced welding solutions tailored to various industries' needs. These collaborations often result in joint ventures and research partnerships, driving further advancements in laser welding technology.

The Future of Laser Welding Technology

Emerging Trends in Laser Welding

The future of laser welding looks promising, with emerging trends like increased automation, AI integration, and enhanced precision. Upcoming technological advancements will further elevate the capabilities of laser welding, making it even more integral to modern manufacturing.

SLTL’s Role in Shaping the Future

SLTL continues to innovate, with several upcoming projects that promise to push the boundaries of laser welding technology. Their long-term vision includes leading the way in sustainable and efficient manufacturing practices, setting new standards for the industry.

Sustainability and Environmental Impact

Conclusion

SLTL has firmly established itself as a leader in laser welding technology, driving industry advancements and setting new standards with their pioneering innovations and global reach. As we look to the future, the potential for laser welding continues to grow, with SLTL leading the charge in enhancing manufacturing efficiency, precision, and sustainability. Businesses eager to stay competitive in the evolving manufacturing landscape should consider exploring SLTL's advanced laser welding solutions. For more information or to get started, visit SLTL's website or contact their sales team today.

0 notes

Text

"SLTL Laser Welding Machines: The Global Benchmark for Quality and Precision"

Introduction

Overview of Laser Welding Technology

Definition and Basics of Laser Welding

Laser welding is a technique that utilizes a concentrated laser beam to join materials, typically metals or thermoplastics. The high-intensity laser melts the material at the weld point, creating a strong and precise bond.

Historical Development and Evolution of Laser Welding

The journey of laser welding began in the 1960s, evolving rapidly with advancements in laser technology. Over time, laser welding has become more and more popular because to its accuracy, speed, and versatility.

Introduction to SLTL

Brief History of SLTL

Since its founding in 1989, SLTL has led the way in the advancement of laser technology.With a commitment to excellence and continuous improvement, SLTL has grown to become a global benchmark in laser solutions.

SLTL’s Commitment to Innovation and Quality

SLTL’s dedication to research and development has resulted in state-of-the-art laser welding machines. Their focus on quality and innovation ensures that their products meet the highest industry standards.

SLTL Laser Welding Machines: Features and Benefits

Advanced Technology Integration

SLTL laser welding machines incorporate the latest technologies, such as fiber lasers and automated systems. These advancements enhance the precision and efficiency of the welding process.

High Precision and Accuracy

Precision is crucial in welding, especially for intricate applications. SLTL machines ensure high precision through advanced control systems and high-quality laser sources.

Efficiency and Speed

One of the significant advantages of SLTL laser welding machines is their speed. Laser welding is substantially faster than traditional welding techniques, which decreases production time and boosts throughput.

User-Friendly Interface

SLTL designs its machines with the user in mind. The interface is intuitive and easy to navigate, making it accessible for operators with varying levels of expertise.

Durability and Reliability

Constructed with robust materials, SLTL machines are built to last. Their dependability ensures constant performance by reducing maintenance expenses and downtime.

Applications of SLTL Laser Welding Machines

Automotive Industry

Laser welding machines plays a crucial role in automotive manufacturing, providing strong and precise welds. SLTL machines have been instrumental in enhancing the quality and efficiency of automotive production.

Aerospace Industry

In aerospace, precision is paramount. SLTL laser welding machines contribute significantly to the production of high-precision components, ensuring safety and reliability.

Medical Device Manufacturing

The medical field demands stringent standards. SLTL machines meet these requirements, providing precise and clean welds for medical devices.

Electronics and Microelectronics

SLTL’s technology is essential for welding tiny and delicate electronic components, ensuring high performance and reliability.

Jewelry and Artisanal Work

Beyond industrial applications, SLTL laser welding machines are also used in artistic fields, allowing for intricate and creative designs in jewelry and artisanal work.

The Global Impact of SLTL Laser Welding Equipment

Market Reach and Presence

SLTL has a significant global presence, with distribution networks across multiple countries. Their influence extends to various industries, making them a leader in laser welding technology.

Customer Testimonials and Reviews

Customers from diverse sectors praise SLTL machines for their precision, efficiency, and reliability. Success stories highlight the positive impact of SLTL technology on their operations.

SLTL’s Role in Advancing Industry Standards

SLTL collaborates with industry bodies to set and advance standards in laser welding. Their contributions ensure that the industry continually evolves and improves.

Future Trends and Innovations

Emerging Technologies in Laser Welding

The future of laser welding is bright, with emerging technologies promising further advancements. With its cutting-edge solutions, SLTL is at the forefront.

Sustainable and Eco-Friendly Practices

SLTL is committed to sustainability, incorporating green technologies and eco-friendly practices in their manufacturing processes.

R&D and Innovation at SLTL

Conclusion

SLTL has established itself as a global benchmark in laser welding technology, offering machines that excel in precision, efficiency, and reliability. By delivering cutting-edge technology and unwavering quality, SLTL continues to lead the way in laser welding, setting new standards for the industry. Explore the innovative range of SLTL laser welding machines and discover how they can revolutionize your production processes. For more information, visit SLTL’s website or contact their sales team today.

0 notes

Text

Why Sheet Metal Fabricators Should Visit EuroBlech 2024 Exhibition in Germany

Introduction

The EuroBlech 2024 Exhibition in Germany is more than just an event; it is a pivotal gathering for professionals in the sheet metal fabrication industry. Scheduled from October 22nd to 25th, 2024, this exhibition is set to showcase cutting-edge technologies, innovative machinery, and industry trends that are transforming the landscape of metalworking. One of the standout exhibitors this year is the SLTL Group, known for its revolutionary laser cutting machines. In this article, we will explore why attending EuroBlech 2024 is essential for sheet metal fabricators and how SLTL's innovative solutions are making a significant impact on the industry.

The Significance of EuroBlech 2024

1. Premier Global Exhibition for Sheet Metal Working

EuroBlech is recognized globally as the premier exhibition for sheet metal working. It attracts industry leaders, innovators, and professionals from around the world, making it an unparalleled platform for networking, knowledge exchange, and business development.

2. Access to Cutting-Edge Technologies

The exhibition is a hotspot for unveiling the latest technological advancements. From laser cutting to automation and robotics, EuroBlech 2024 promises to feature groundbreaking innovations that can enhance productivity, precision, and efficiency in sheet metal fabrication.

3. Networking Opportunities

EuroBlech offers an excellent opportunity to connect with industry peers, potential partners, and customers. The event fosters a collaborative environment where attendees can share insights, discuss challenges, and explore new business opportunities.

4. Insightful Seminars and Workshops

Attendees can benefit from a range of seminars and workshops conducted by industry experts. These sessions cover a variety of topics, including emerging trends, best practices, and future projections for the sheet metal industry.

Why Sheet Metal Fabricators Should Attend

5. Discover the Latest Innovations

For sheet metal fabricators, staying updated with the latest innovations is crucial for maintaining a competitive edge. EuroBlech 2024 will showcase advancements in machinery, software, and processes that can significantly improve operational efficiency and product quality.

6. Learn About Industry Trends

Understanding industry trends is essential for strategic planning and growth. EuroBlech 2024 will highlight current and future trends, helping fabricators adapt to changing market demands and technological advancements.

7. Meet Industry Leaders

The exhibition provides a unique opportunity to meet and interact with industry leaders. These interactions can lead to valuable insights, collaborations, and even partnerships that can drive business growth.

8. Evaluate New Suppliers and Products

EuroBlech 2024 is an ideal platform to evaluate new suppliers and products. Fabricators can explore a wide range of offerings, compare features, and make informed purchasing decisions that align with their operational needs and budget.

SLTL Group at EuroBlech 2024

9. Innovative Laser Cutting Machines

One of the highlights of EuroBlech 2024 will be the SLTL Group's exhibition of their innovative laser cutting machines. Located in Hall 12, Stand D86, SLTL Group is set to demonstrate how their technology is transforming the sheet metal fabrication industry.

10. Transforming the Industry with Laser Technology

SLTL Group's fiber laser cutting machines are renowned for their precision, speed, and versatility. These machines can handle a variety of materials and thicknesses, making them ideal for a wide range of applications. The integration of advanced software ensures optimal performance and efficiency.

youtube

11. Advantages of SLTL's Laser Cutting Machines

a. Precision and Accuracy

SLTL's machines are designed to deliver high precision and accuracy, reducing material wastage and ensuring high-quality outputs. This precision is crucial for fabricators aiming to meet strict tolerances and standards.

b. Speed and Efficiency

With the ability to cut through materials quickly and efficiently, SLTL's laser cutting machines enhance productivity and reduce lead times. This speed is a significant advantage in meeting customer demands and deadlines.

c. Versatility

SLTL's machines are versatile, capable of cutting various materials including steel, aluminum, and copper. This versatility allows fabricators to cater to diverse customer needs and expand their service offerings.

12. Live Demonstrations and Expert Consultations

At EuroBlech 2024, attendees will have the chance to see live demonstrations of SLTL's laser cutting machines. Additionally, experts from SLTL will be available for consultations, providing insights into how their technology can be integrated into existing operations to achieve better results.

Conclusion

EuroBlech 2024 in Germany is a must-attend event for sheet metal fabricators. It offers a unique opportunity to explore the latest innovations, network with industry leaders, and gain insights into future trends. The SLTL Group, with its groundbreaking laser cutting machines, stands out as a key exhibitor. Their advanced technology is poised to revolutionize the sheet metal fabrication industry, offering unmatched precision, speed, and versatility. Make sure to visit Hall 12, Stand D86 from October 22nd to 25th, 2024, to witness these innovations firsthand and discover how SLTL can transform your fabrication processes.

0 notes

Text

SLTL Exhibits at EuroBLECH 2024: Showcasing Ultra-High-Power Laser Cutting Machines in Germany

The metal fabrication industry is about to witness a significant event as Sahajanand Laser Technology Ltd. (SLTL) gears up to exhibit at EuroBLECH 2024. This premier exhibition, held in Germany, will spotlight SLTL's cutting- ultra-high-power laser cutting machines, setting a new benchmark in the field. This article will go into detail on SLTL's involvement, the advantages for the automotive and metal fabrication industries, and how this exhibition will influence future trends in the industry.

Understanding EuroBLECH: The Epicenter of Innovation

EuroBLECH is renowned globally as the leading exhibition for the sheet metal working industry. Held biennially in Hanover, Germany, it attracts thousands of professionals and exhibitors from around the world. This event serves as a platform for showcasing the latest innovations in machinery, tools, and services, providing unparalleled opportunities for networking and business development.

youtube

SLTL's Legacy in Laser Technology

SLTL has a rich history of pioneering innovations in laser technology. With a diverse portfolio ranging from laser cutting and welding to marking and engraving, SLTL has established itself as a global leader. Their participation in EuroBLECH 2024 is set to highlight their latest advancements and reinforce their position at the forefront of the industry.

The Spotlight: Ultra-High-Power Laser Cutting Machines

At EuroBLECH 2024, SLTL will unveil its ultra-high-power laser cutting machines, designed to deliver unprecedented precision and efficiency. These machines are engineered to handle the most demanding applications in metal fabrication and the automotive industry, offering superior performance, versatility, and reliability.

Key Features of SLTL's Laser Cutting Machines

High Precision Cutting: Utilizing advanced laser technology, these machines ensure immaculate precision, crucial for intricate designs and complex geometries.

Speed and Efficiency: Capable of cutting through thick materials swiftly, reducing production times and increasing throughput.

Versatility: Suitable for a wide range of materials including aluminum, steel, and other alloys, making them ideal for diverse industrial applications.

Cost-Effective Operation: Designed for minimal maintenance and maximum energy efficiency, leading to lower operational costs.

Automation and Integration: Equipped with the latest automation technologies, these machines can seamlessly integrate into existing production lines, enhancing overall productivity.

Benefits for the Metal Fabrication Industry

Enhancing Production Capabilities

The introduction of SLTL's ultra-high-power laser cutting machines will significantly enhance production capabilities in the metal fabrication industry. These machines enable manufacturers to produce high-quality components with greater speed and accuracy, meeting the growing demands for precision-engineered parts.

Reducing Production Costs

By streamlining the cutting process and minimizing material waste, SLTL's machines help reduce production costs. Their energy-efficient design further contributes to cost savings, making them an attractive investment for fabrication businesses.

Improving Quality and Consistency

Consistency is key in metal fabrication, and SLTL's laser cutting machines deliver consistent, high-quality cuts every time. This reliability ensures that manufacturers can meet stringent quality standards and deliver superior products to their customers.

Impact on the Automotive Industry

Advancing Automotive Manufacturing

The automotive industry stands to benefit immensely from SLTL's innovations. The precision and speed of their laser cutting machines are ideal for manufacturing complex automotive components, from chassis parts to intricate engine components.

Supporting Lightweight Construction

As the automotive industry shifts towards lightweight construction to improve fuel efficiency and reduce emissions, SLTL's machines provide the capability to work with advanced materials like aluminum and high-strength steel, essential for modern vehicle designs.

Enabling Customization and Prototyping

The ability to quickly and accurately cut custom parts is invaluable for prototyping and customization. SLTL's laser cutting technology supports rapid iteration and the development of bespoke components, helping automakers innovate and stay ahead of the competition.

EuroBLECH 2024: A Platform for Networking and Collaboration

Connecting Industry Leaders

EuroBLECH 2024 will bring together industry leaders, innovators, and professionals from across the globe. SLTL's presence at this event provides a unique opportunity to connect with potential partners, clients, and collaborators, fostering relationships that can drive future growth and innovation.

Showcasing Innovations

By showcasing their ultra-high-power laser cutting machines, SLTL will demonstrate their technological prowess and commitment to advancing the industry. This visibility can attract new business opportunities and cement SLTL's reputation as a trailblazer in laser technology.

Learning and Development

The exhibition also offers numerous seminars, workshops, and presentations on the latest trends and technologies in the metal fabrication industry. SLTL's team will have the chance to engage with these sessions, gaining insights that can inform future product development and strategy.

The Future of Metal Fabrication and Laser Technology

Emerging Trends

Trends like automation, digitization, and sustainability are propelling change in the metal fabrication business, which is changing quickly. SLTL's innovations align with these trends, positioning them to lead the industry into the future.

Sustainable Manufacturing

Sustainability is becoming increasingly important in manufacturing. SLTL's energy-efficient laser cutting machines support sustainable practices by reducing energy consumption and material waste, helping manufacturers meet environmental goals.

Digital Integration

The integration of digital technologies in manufacturing is transforming the industry. SLTL's machines are designed for compatibility with Industry 4.0 standards, enabling smart manufacturing practices and data-driven decision-making.

Conclusion

SLTL's participation in EuroBLECH 2024 marks a significant milestone for the metal fabrication and automotive industries. By showcasing their ultra-high-power laser cutting machines, SLTL is set to revolutionize manufacturing processes, enhancing precision, efficiency, and sustainability. This exhibition not only highlights SLTL's technological advancements but also provides a platform for networking, collaboration, and learning. As the industry continues to evolve, SLTL remains at the forefront, driving innovation and setting new standards for excellence in laser technology.

0 notes

Text

Revolutionizing USA Sheet Metal Fabrication: The Innovation of Ultra High Power Laser Cutting Machines

In the dynamic world of manufacturing, advancements in technology continually reshape industries, and sheet metal fabrication is no exception. One of the most groundbreaking innovations in recent years has been the advent of Ultra High Power laser cutting machines. These cutting-edge tools have ushered in a new era of precision, efficiency, and versatility in sheet metal fabrication across the United States.

The Evolution of Laser Cutting Technology

Laser cutting technology itself has been transformative since its inception. Initially introduced for industrial applications in the 1960s, lasers gradually evolved from CO2 and Nd

lasers to the more powerful fiber lasers used today. These advancements have significantly enhanced cutting speeds, accuracy, and the range of materials that can be processed.

Enter Ultra High Power Laser Cutting Machines

Ultra High Power (UHP) laser cutting machines represent the pinnacle of laser cutting technology. These machines typically utilize fiber lasers with power outputs exceeding 10 kW, and some can reach up to 40 kW or higher. This substantial increase in power provides several key advantages:

Increased Cutting Speeds

UHP lasers can cut through thick metal sheets at speeds far surpassing traditional methods. This acceleration not only reduces production time but also enhances overall efficiency.

Improved Cutting Quality

Higher power levels enable cleaner, smoother cuts with minimal burring or rough edges. This precision is crucial for industries where component quality is paramount.

Expanded Material Compatibility

UHP lasers can effortlessly cut through a wide range of materials, including stainless steel, aluminum, copper, and various alloys. This versatility makes them indispensable in diverse manufacturing environments.

Cost Efficiency

While initial investment costs may be higher, UHP laser cutting machines offer substantial long-term savings through reduced labor costs, faster production cycles, and lower maintenance requirements.

Applications in USA Sheet Metal Fabrication

In the United States, where manufacturing standards are stringent and demand for high-quality components is constant, UHP laser cutting machines have found numerous applications:

Automotive Industry

Precision parts and components for vehicles require exacting standards that UHP lasers can consistently meet. From chassis components to intricate engine parts, these machines deliver unmatched accuracy.

Aerospace Sector

Aircraft manufacturers benefit from the speed and precision of UHP laser cutting for everything from structural elements to interior fittings. The ability to handle diverse materials ensures compliance with aerospace-grade standards.

Electronics Manufacturing

The miniaturization trend in electronics demands precise cutting of thin metal sheets and delicate components, tasks that UHP lasers excel at without compromising integrity.

Architectural and Construction

From decorative metal panels to structural components, UHP laser cutting enables architects and construction engineers to realize complex designs efficiently and economically.

Future Prospects and Challenges

Looking ahead, the future of UHP laser cutting machines seems promising. Continuous advancements in laser technology, including enhanced automation and integration with AI-driven systems, will further streamline operations and expand capabilities. However, challenges such as regulatory compliance, workforce adaptation to new technologies, and environmental impacts remain focal points for industry leaders and policymakers.

SLTL is Excited to Connect with Florida's Growing Manufacturing Base

This year, we can't wait to bring SLTL’s Ultra High-Powered Laser Innovations to Orlando and provide the expanding Florida manufacturing sector with another opportunity to witness SLTL's cutting-edge laser technology up close. Manufacturers from all over the world will gather in Orlando for FABTECH 2024 to witness innovative solutions and remain ahead of the curve in manufacturing technology.

SLTL is going to offer attendees the opportunity to witness live equipment demonstrations, build strategic partnerships, identify solutions, and stay ahead of the curve in the ever-evolving manufacturing landscape.

Knowledge Hub at SLTL’s Booth

The 2024 SLTL booth will be a knowledge hub for attendees, featuring demonstrations and insights into laser cutting, laser marking, laser welding, automation, smart manufacturing, and much more. In addition, attendees will gain knowledge about IoT-integrated machinery and witness live demonstrations of them.

Prepare for the Groundbreaking Experience

Get ready because SLTL is prepared to have an amazing time with the attendees at this event, which promises to be an incredible experience in its own way. Come see us in Hall No – S31150 at Orange County Convention Center in Orlando, Florida, from October 15-17, 2024.

Conclusion

In summary, Ultra High Power laser cutting machines have revolutionized sheet metal fabrication in the USA by setting new benchmarks in speed, precision, and versatility. Their adoption across diverse industries underscores their pivotal role in modern manufacturing processes. As these technologies continue to evolve, they promise to redefine the possibilities of what can be achieved in sheet metal fabrication, paving the way for a more innovative and efficient future.

Whether you’re in automotive manufacturing, aerospace engineering, or electronics production, embracing UHP laser cutting machines is not just about staying competitive—it’s about leading the charge in shaping the future of American manufacturing excellence.

0 notes

Text

"The Future of Metal Fabrication: Leading Laser Cutting Machines in Ahmedabad"

Introduction to Laser Cutting Technology

Laser cutting has revolutionized metal fabrication. It's precise, efficient, and versatile. In Ahmedabad, the adoption of advanced laser cutting machines is on the rise. This trend is transforming the metal fabrication industry, setting new standards in quality and productivity.

Why Ahmedabad is a Hub for Laser Cutting Machines

Ahmedabad is emerging as a key player in metal fabrication. The city boasts a robust industrial infrastructure. Its strategic location and skilled workforce make it ideal for manufacturing. Companies here are investing in the latest laser cutting technology to stay competitive.

Benefits of Using Laser Cutting Machines

Precision and Accuracy

Laser cutting offers unmatched precision. The technology allows for intricate designs and detailed cuts. This precision is essential for high-quality metal products.

Efficiency and Speed

Laser cutting machines are fast and efficient. They can cut through various metals quickly. This speed reduces production time and increases output.

Versatility

Laser cutters can handle different types of metals. Whether it's aluminum, steel, or copper, these machines can cut them all. This versatility is a significant advantage for metal fabricators.

Leading Laser Cutting Machines in Ahmedabad

Machine A: High Precision and Speed

This machine is known for its high precision and speed. It's ideal for manufacturers looking to produce detailed and intricate designs quickly.

Machine B: Versatile and Reliable

Machine B stands out for its versatility. It can cut through various metals with ease. It's also known for its reliability and durability.

Machine C: Cost-Effective and Efficient

For those on a budget, Machine C offers cost-effective solutions. It balances efficiency and cost, making it a popular choice among smaller manufacturers.

The Future of Metal Fabrication in Ahmedabad

Innovation and Growth

The future of metal fabrication in Ahmedabad looks promising. With continuous innovation and investment in technology, the industry is set to grow. Laser cutting machines will play a pivotal role in this growth.

Sustainability

Sustainability is becoming a priority in manufacturing. Laser cutting machines are energy-efficient and produce less waste. This eco-friendly aspect will drive their adoption in the future.

Conclusion

Ahmedabad is at the forefront of the metal fabrication industry. The adoption of leading laser cutting machines is transforming the sector. With their precision, efficiency, and versatility, these machines are setting new benchmarks. The future of metal fabrication in Ahmedabad is bright, promising innovation and sustainable growth.

#LaserCutting#MetalFabrication#Manufacturing#AhmedabadIndustry#PrecisionEngineering#IndustrialInnovation#SustainableManufacturing#AdvancedTechnology#EfficientProduction#VersatileMachines#FutureOfFabrication#EcoFriendlyTech#MetalWorking#HighPrecision#CuttingEdgeTechnology

1 note

·

View note