Meba Electric Co., Ltd is a professional manufacturer and supplier of highly designed and premium quality electrical appliances.

Don't wanna be here? Send us removal request.

Text

Exploring Cam Switches: Versatile Components for Electrical Control

Cam switches are essential components in electrical control systems, known for their versatility and reliability. These switches play a crucial role in managing electrical circuits by controlling the flow of current through different positions. Whether used in industrial machinery, control panels, or various other applications, understanding cam switches can help optimize their use and ensure efficient operation.

What Is a Cam Switch?

A cam switch supplier is a type of rotary switch that operates through a rotating cam mechanism. This switch type allows the user to select multiple circuits or positions by turning a knob or handle. The cam mechanism inside the switch aligns with various contact points, enabling or interrupting the electrical flow to different circuits based on the switch position.

Key Features of Cam Switches

1. Multiple Positions: Cam switches can have multiple positions, typically ranging from 2 to 12 or more. Each position corresponds to a different circuit or function, providing flexibility in controlling various aspects of an electrical system.

2. Durable Construction: Designed for robustness, cam switches are built to withstand harsh environments and frequent use. They are commonly made from durable materials such as metal or high-grade plastics.

3. Clear Position Indication: Most cam switches offer clear position indicators, such as numbered or labeled positions, to ensure accurate and easy operation. This helps users select the correct setting without confusion.

Benefits of Cam Switches

1. Versatility: The ability to control multiple circuits with a single switch makes cam switches highly versatile. They are ideal for applications that require switching between different functions or settings.

2. Reliability: Cam Switch wholesale is known for its reliability and long service life. Their mechanical design ensures consistent performance even under heavy loads or in demanding conditions.

3. Ease of Use: The rotary action of cam switches allows for intuitive and straightforward operation. Users can quickly select the desired circuit or function by turning the switch to the appropriate position.

Considerations When Choosing a Cam Switch

1. Number of Positions: Determine the number of positions needed for your application. The switch should match the number of circuits or functions you need to control.

2. Current and Voltage Ratings: Ensure that the cam switch is rated for the voltage and current levels of your electrical system. Using a switch with appropriate ratings is crucial for safe and effective operation.

3. Environmental Conditions: Consider the operating environment, including factors like temperature, humidity, and exposure to chemicals. Choose a cam switch with suitable environmental protection features if needed.

Conclusion

Cam switch manufacturer are indispensable components in many electrical systems, offering versatile control and reliable performance. Their ability to manage multiple circuits and withstand various conditions makes them a valuable choice for both industrial and commercial applications. By understanding their features and selecting the right model, you can enhance the efficiency and functionality of your electrical systems.

Follow our Facebook and Twitter for more information about our product.

1 note

·

View note

Text

Motor Sirens: Powerful Tools for Alarming and Alerting

Motor sirens, robust and versatile devices, are integral to various applications where loud and clear alerts are crucial. From industrial settings to emergency services, these sirens are designed to deliver high-decibel warnings that can be heard over significant distances. Understanding their features, benefits, and ideal applications can help you choose the right siren for your needs.

What Is a Motor Siren?

A motor siren supplier is an electronic device that produces a loud, attention-grabbing sound using a rotating motor and a set of siren blades or horns. Unlike electronic sirens, which rely on speakers and amplification, motor sirens use mechanical rotation to generate sound. This mechanism typically involves a motor-driven rotor that spins rapidly, creating a siren effect as it passes air through an opening.

Key Features of Motor Sirens

1. High Sound Output: Motor Siren Wholesale is known for its powerful sound output, often exceeding 120 decibels. This makes them effective for use in noisy environments or for outdoor applications where the alert needs to carry over long distances.

2. Durability: Built to withstand harsh conditions, motor sirens are often made from rugged materials like metal and are designed to resist weather elements, making them suitable for both indoor and outdoor use.

3. Variety of Tones: Many motor sirens offer multiple tone settings, including wailing, whooping, or steady tones. This versatility allows users to customize the alert sound according to the situation.

Benefits of Motor Sirens

1. Effective Communication: The loud, distinctive sound of a motor siren ensures that alerts are heard clearly, even in noisy environments. This is crucial for emergencies where immediate attention is required.

2. Reliability: Motor sirens are highly reliable due to their simple mechanical operation. They are less susceptible to electrical failures compared to electronic sirens and can perform consistently over time.

3. Versatility: These sirens can be used in a variety of applications, from industrial alarms and fire warnings to security systems and emergency vehicle sirens.

Considerations When Choosing a Motor Siren

1. Sound Level and Range: Select a siren with the appropriate sound level and range for your specific needs. Consider factors like the size of the area to be covered and the typical ambient noise levels.

2. Power Source: Motor sirens generally require a robust power source. Ensure you have access to a compatible power supply and that the siren meets your operational requirements.

3. Installation and Maintenance: Proper installation is crucial for optimal performance. Regular maintenance, including checking the motor and blades, ensures the siren remains in good working condition.

In conclusion, Motor siren manufacturer are powerful and reliable devices that serve critical functions in alerting and alarming. Their high sound output, durability, and versatility make them ideal for a wide range of applications, ensuring effective communication in both emergency and routine situations.

1 note

·

View note

Text

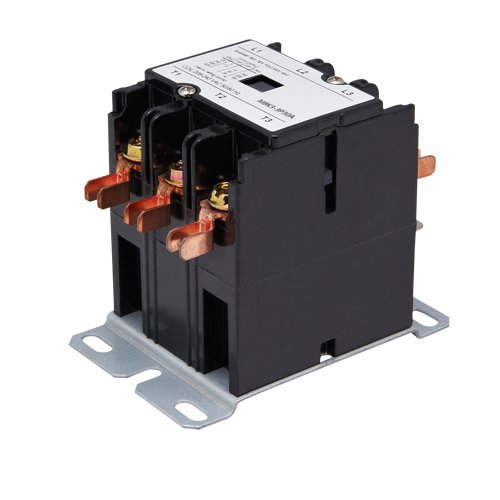

Understanding AC Magnetic Contactors: A Crucial Component in Electrical Systems

AC magnetic contactors play a pivotal role in electrical systems, serving as reliable switches that control the flow of electricity to various devices and equipment. These devices are essential in industrial, commercial, and residential applications where the switching of electrical loads is required.

What is an AC Magnetic Contactor?

An AC magnetic contactor is an electromechanical device designed to establish or interrupt an electric circuit by physically separating the contacts within the device. Unlike manual switches, contactors are typically controlled remotely through a control circuit, often using a lower voltage than the main power circuit they control. This feature allows them to handle much higher currents and voltages than a simple switch.

Structure and Functionality

Coil: The core component of an AC magnetic contactor is its coil, which, when energized, generates a magnetic field that pulls the contacts together, closing the circuit. This mechanism allows for the controlled activation or deactivation of electrical loads.

Contacts: AC contactors feature multiple sets of contacts, typically made of durable materials such as silver alloy. These contacts are designed to handle significant electrical currents without welding or sticking, ensuring reliable operation over extended periods.

Auxiliary Contacts: Many contactors also include auxiliary contacts that are mechanically linked to the main contacts. These auxiliary contacts provide additional control functions, such as signaling the status of the main contacts or facilitating interlocking between multiple contactors.

Applications

AC magnetic contactors find application in a wide range of scenarios:

Industrial Machinery: Used to control motors, pumps, compressors, and other heavy-duty equipment.

HVAC Systems: Essential for switching heating elements, fans, and other HVAC components.

Elevators and Escalators: Control systems that manage the operation of motors and safety features.

Lighting Control: Often used in large-scale lighting systems to manage circuits efficiently.

Advantages

Reliability: Contactors are designed for frequent operation and can withstand high electrical loads.

Remote Operation: This can be controlled from a distance via control circuits, enhancing safety and convenience.

Longevity: Built with durable materials to ensure a long operational life span in demanding environments.

Considerations

When selecting an AC magnetic contactor, factors such as current rating, voltage rating, and environmental conditions should be carefully evaluated to ensure compatibility and optimal performance. Additionally, proper maintenance and periodic inspection are crucial to prevent issues like contact wear or coil degradation.

In conclusion, AC magnetic contactors are indispensable components in electrical systems, providing efficient and reliable control over electrical loads across various industries. Their robust construction, remote operability, and versatility make them essential for ensuring the safe and effective operation of electrical equipment and machinery. Understanding their role and functionality is key to leveraging their benefits effectively in any electrical application.

Follow our Facebook and Twitter for more information about our product.

1 note

·

View note

Text

Exploring Essential Electrical Accessories: Enhancing Safety and Functionality

Electrical accessories supplier encompasses a diverse range of components crucial for the effective and safe operation of electrical systems in residential, commercial, and industrial settings. These accessories play a pivotal role in enhancing functionality, ensuring safety, and optimizing the performance of electrical installations.

Types of Electrical Accessories

Switches and Outlets: Switches control the flow of electricity to lights, appliances, and other devices, while outlets provide access to electrical power for plugging in appliances and equipment. Variants include traditional toggle switches, dimmer switches for adjusting lighting levels, and outlets with built-in USB ports for charging devices.

Circuit Breakers and Fuses: Circuit breakers and fuses protect electrical circuits from overloads and short circuits. They automatically disconnect the circuit when the current exceeds safe limits, preventing damage to wiring and appliances. Circuit breakers can be reset after tripping, whereas fuses must be replaced.

Junction Boxes: Junction boxes house electrical connections, providing a secure enclosure that protects wires from damage and prevents accidental contact with live wires. They are essential for organizing and safely routing electrical wiring in walls, ceilings, and floors.

Wire Management: Cable ties, conduits, and wire ducts are used to organize and protect electrical wiring, ensuring neatness and reducing the risk of damage or tripping hazards.

Grounding and Surge Protection: Grounding accessories include grounding rods, clamps, and conductors that channel electrical faults safely into the ground. Surge protectors safeguard electronic devices from voltage spikes caused by lightning or electrical surges.

Importance in Electrical Installations

Safety: Properly installed and maintained electrical accessories prevent electrical hazards such as shocks, fires, and equipment damage.

Functionality: Accessories like switches, outlets, and circuit breakers provide convenient control over electrical systems, ensuring reliable operation and ease of use.

Compliance: Meeting electrical codes and standards is essential for legal compliance and ensures installations are safe and reliable.

Choosing the Right Accessories

Selecting suitable electrical accessories involves considering factors such as load requirements, environmental conditions, and compatibility with existing infrastructure. Consulting with electrical professionals can ensure the correct selection and installation of accessories tailored to specific needs.

Conclusion

Electrical accessories manufacturer are fundamental components that enhance the safety, functionality, and efficiency of electrical systems in various applications. From basic switches and outlets to advanced surge protectors and grounding solutions, each accessory plays a crucial role in ensuring reliable and safe electrical operation. Understanding their importance and selecting the right accessories is key to maintaining a robust and compliant electrical installation.

#electrical accessories manufacturer#electrical accessories supplier#electrical products china#electrical accessories wholesale

1 note

·

View note

Text

The Significance of Isolator Switches China

The waterproof isolator switch is an often overlooked but essential component in electrical systems. This inconspicuous gadget is crucial to guarantee the safety and proper operation of any equipment, including air conditioners.

What is the main purpose and benefit of an isolator switch?

An isolator switch, also known as an isolation switch or disconnect switch, is designed to entirely isolate an electrical circuit or equipment from its power supply.

To protect safety during maintenance and repairs, isolator switches cut electricity to equipment or circuits. Isolating the power supply eliminates inadvertent contact with active electrical components, lowering the danger of electric shock or damage.

Emergency Shutdown

In the case of an electrical failure, fire, or other dangerous scenario, an isolator switch provides a quick and easy way to turn off the power supply to the afflicted circuit or equipment.

Isolator switches from waterproof isolator switch supplier prevent electrical equipment from harm during maintenance or while not in use. Disconnecting the power source eliminates power surges, electrical failures, and voltage spikes that might damage sensitive components.

Complying with electrical requirements

Electrical codes and regulations frequently demand the use of isolator switches in certain applications to guarantee that safety requirements are followed. Isolator switches allow electrical systems to comply with these rules.

Overall, the primary function of an isolator switch is to offer a safe and effective method of isolating electrical circuits or equipment from their power supply. It improves electrical safety, protects persons and equipment, and enables maintenance and emergency procedures to be completed without exposing people to electrical risks.

Does an air conditioner require an isolator?

Yes, most air conditioners require an isolator switch. An isolator switch is a critical component for the safe installation and operation of air conditioners. It enables the disconnection of electricity to the air conditioner, assuring the safety of anybody doing maintenance, repairs, or inspections on the device. With the current load shedding, electricity is sometimes quite unstable, thus a trained electrician should install a separate waterproof isolator switch china for all air conditioners. This is an important safety feature that enables the cutoff of power to the device during maintenance, repairs, or emergencies, assuring individual safety and compliance with electrical standards.

Follow our Facebook and Twitter for more information about our product.

#waterproof isolator switch china#waterproof isolator switch wholesale#waterproof isolator switch supplier#waterproof isolator switch manufacturer

1 note

·

View note

Text

Pros Offered By a Weatherproof Junction Box

Sometimes weatherproof electrical box is required on the exterior of your property, whether at home or business, to the point where a specific style of box and accompanying accessories can be acquired. If you want to make a waterproof connection outside, a weatherproof junction box is the best option.

Weatherproof junction boxes are an excellent choice for protecting parts from dangerous exterior components. These boxes are normally sealed enclosures designed for placement on roof overhangs, outside walls, decks, and other surfaces. These boxes are used to mount lighting fixtures and outside receptacles.

Weatherproof junction boxes must feature an exterior fixture or a cover suited for wet environments, however this varies by application. They are often IP (Ingress Protection) or NEMA-rated (National Electrical Manufacturers Association) to endure a wide range of environmental conditions such as extreme cold or heat, UV radiation, wetness, and strong winds.

Benefits of weatherproof junction boxes

Durable

As previously said, weatherproof electrical boxes and weatherproof gang box are constructed with durable materials that will function properly regardless of the weather conditions. Weatherproof junction boxes constructed of stainless steel are resistant to a variety of environmental issues, resulting in a long and reliable product life.

Shock resistant

Depending on the material chosen to construct a weatherproof electrical box, it can provide some degree of impact resistance. Polycarbonate enclosures, in particular, can provide shock resistance due to their great dimensional stability.

Protect against extreme weather fluctuations

When junction boxes are exposed to extreme cold and hot temperatures or UV radiation, they can degrade and lose their capacity to protect your electrical elements. Nonetheless, weatherproof junction boxes can successfully address this immediate weather issue since they are made of high-quality materials that can survive harsh weather conditions. These junction boxes come in a variety of durable materials, including polycarbonate, aluminum, FRP (fiber-reinforced polyester), and stainless steel.

Protect against accidental damage

Weatherproof junction boxes safeguard against unintentional damage to the elements caused by heat, loose connections, sparks, and short circuits. Furthermore, these enclosures protect the wires from dust, grime, and moisture. A reliable and robust weatherproof power junction box is essential, especially if you want to protect your electrical components from the multiple harsh elements encountered in outdoor environments.

1 note

·

View note

Text

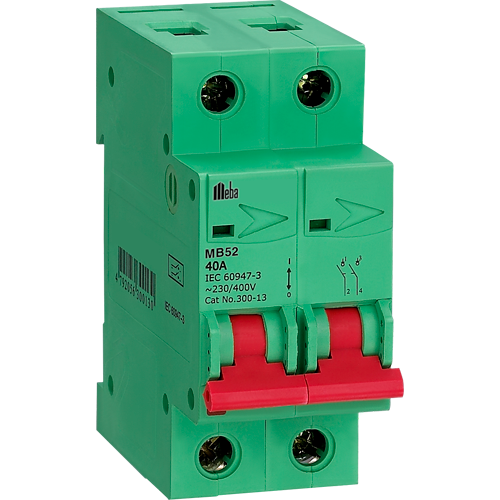

Reliable and Innovative Electric Breaker Manufacturers Ensure Electrical Safety

Circuit breakers are like unsung heroes in the vast fabric of modern technology. These essential components provide the smooth and safe operation of electrical systems, safeguarding infrastructure and people from the dangers of overcurrent and electrical failures. It is crucial to choose a competent circuit breaker manufacturer since the integrity of these parts is essential to the operational dependability of power systems all over the world.

The Manufacturers of Circuit Breakers' Role

The main responsibility of a circuit breaker maker is to create, manufacture, and guarantee the dependability of these devices, which are intended to automatically cut off electricity flow when safety thresholds are crossed. Manufacturers are partners in efficiency and safety as well as product providers. They need to continuously innovate in order to improve the technology and functionality of their products as well as to stay up to date with international standards.

Crucial Elements for Selecting a Manufacturer

Technology and Innovation: A top Electric Breaker Manufacturer makes research and development investments to improve their goods. Seek out businesses that include smart technology and provide services like energy management, predictive maintenance, and remote monitoring.

Quality and Reliability: Reputable producers use stringent testing procedures and quality control systems. Products frequently have approvals and certifications from reputable standards organizations, which attest to their adherence to performance and safety requirements.

Product Range: To serve a wide range of applications, from commercial and residential to industrial and high-voltage environments, a varied product range is necessary. A range of kinds, including air and vacuum circuit breakers, molded case circuit breakers (MCCB), and tiny circuit breaks (MCB), should be available from manufacturers.

Customer Service: Providing excellent after-sale service, training, and technical support service for customer is essential. By providing this assistance, items are made sure to be utilized appropriately and to keep performing at their best throughout the duration of their lives.

Selecting the best Miniature Circuit Breaker Manufacturer is more than just picking a product. It entails collaborating with a manufacturer who consistently aims to expand the realm of electrical circuit protection.

1 note

·

View note

Text

Get the best Metal Enclosures with best price in China

Metal enclosure supplier are protective housings made from various types of metal, typically steel, aluminum, or stainless steel, designed to enclose and safeguard electronic, electrical, or mechanical components. They provide protection against environmental hazards, electromagnetic interference (EMI), vandalism, and tampering. Here's an overview of metal enclosures, their features, and applications:

Materials:

Steel: Steel enclosures are robust and durable, offering excellent protection against physical impact and harsh environments. They are commonly used in industrial applications where ruggedness and reliability are essential.

Aluminum: Aluminum enclosures are lightweight yet sturdy, making them suitable for applications requiring corrosion resistance and electromagnetic shielding. They are often used in electronics, telecommunications, and aerospace industries.

Stainless Steel: Stainless steel enclosures provide superior corrosion resistance, making them ideal for outdoor or corrosive environments such as marine, chemical, or food processing industries. They offer long-term durability and protection against harsh weather conditions.

Features:

Enclosure Types: Metal enclosure manufacturer come in various types, including wall-mount, floor-mount, junction boxes, control cabinets, and rack-mount enclosures, to accommodate different installation requirements.

Accessories: Enclosures may include features such as doors, hinges, locks, gaskets, cable glands, ventilation panels, and mounting brackets to enhance functionality and ease of installation.

Customization: Many manufacturers offer customization options such as size, shape, cutouts, and paint finishes to meet specific customer requirements.

Metal enclosures China plays a critical role in protecting sensitive equipment and components from damage, ensuring reliable operation in demanding environments. Choosing the right enclosure based on application requirements is essential for maintaining the integrity and performance of the enclosed devices.

1 note

·

View note

Text

A Deep Insight about Moulded Case Circuit Breakers

There is a guardian in the complex world of electrical systems, where everything from the tiniest device to the biggest plant is powered by the unseen dance of electrons. The Moulded Case Circuit Breaker (MCCB) from Moulded Case Circuit Breaker Manufacturer, a staple of contemporary electrical engineering, is frequently disregarded yet vital to the security and effectiveness of electrical networks.

The Protector's Anatomy: Inside an MCCB

The Frame provides insulation and structural strength by housing all the components.

The movable and stationary contacts in the contact system control whether electricity flows through them or not.

The MCCB's brain, the Tripping Unit, is furnished with magnetic and thermal sensors to identify overloads and short circuits.

The Operating Mechanism responds to tripping signals automatically and allows manual control (to open or stop the circuit).

The Arc Chutes ensure a quick and safe separation by putting out electrical sparks that arise while cutting high current flows.

This well-planned assembly guarantees that, in the event of an electrical malfunction, the MCCB from Modular Device Supplier will act quickly to safeguard the circuit, acting as a real protector of the electrical domain.

The Changing Function of MCCBs

MCCBs have historically been primarily used to safeguard electrical circuits from overloads and short circuits, but as technology has advanced and electrical systems have become more complicated, so has their role. Modern MCCBs are essential to energy management plans because they maximize power usage and raise facility efficiency. The introduction of smart MCCBs, which include digital monitoring and communication features, has allowed them to provide previously unheard-of insight into the operation of electrical systems, allowing for predictive maintenance and reducing downtime.

Getting Around the Maze of Selection

Rating at the Moment: Compare the maximum current that the circuit can handle under typical circumstances with the MCCB's rating.

Features of Tripping: Depending on the requirements of your circuit, choose between thermal, magnetic, or electronic tripping mechanisms.

Breaking Capacity: Verify that the MCCB is capable of handling the system's maximum possible short-circuit current.

Guidelines and Accreditations: Check that the MCCB and Modular Device China are certified for quality and safety and comply with applicable standards.

1 note

·

View note

Text

RCBO Ensures Electrical Safety in Your Home

A sophisticated electrical safety device, RCBO Residual Circuit Breaker, guards against fault currents as well as overcurrents by keeping an eye on the current flowing through a circuit. It accomplishes this by spotting electrical current imbalances and quickly cutting the circuit when a problem is found, greatly lowering the possibility of electric shock and fire.

How Do RCBOs Operate?

Finding Residual Current: The live (phase) and neutral wire balance of a circuit is continually monitored by the RCBO. An appliance's input current and output current are equal in a healthy circuit. An imbalance results when a human unintentionally touches a live component because part of the current passes through it and down to the ground, lowering the returning current. This imbalance is frequently detected by the RCBO in milliseconds, at which point it trips, turning off the electrical supply and averting major harm or death.

Protection against Overcurrent: Short circuits and overloads can result in overcurrent. To reduce the risk of fire dangers and potential damage to appliances and wiring, the RCBO recognizes these situations and disconnects the circuit. The RCCB Circuit Breaker is also vital.

Why Do RCBOs Matter?

Safety: An RCBO's main function is to offer a high degree of protection against the possibility of fire and electric shock. It guarantees occupant safety by identifying fault currents and overloads.

Cost-effectiveness and Convenience: By combining the functions of an MCB with an RCD, RCBOs save installation costs and the requirement for separate devices, freeing up space in the consumer unit (fuse box).

Compliance: To fulfill electrical safety requirements, several areas have legislation requiring the installation of RCBOs in new construction and during significant modifications.

Establishment and Upkeep

Even though RCBOs are sturdy and dependable, a trained electrician should always perform their installation and maintenance. When an RCBO from RCBO Circuit Breaker Manufacturer is installed correctly, it is guaranteed to be appropriately rated for the circuit it guards, improving safety and adhering to regional electrical codes. As advised by the manufacturer, routine inspections and testing are essential to preserving their protective qualities over time.

1 note

·

View note

Text

Circuit Breaker Box Upgradation for More Efficiency and Safety

The circuit breaker box acts as a silent sentinel, protecting our houses from electrical threats in a world where our dependency on energy is expanding. However, as technology develops and our demands for electricity change, the standard breaker box could find it difficult to keep up. We'll talk about the value of replacing your circuit breaker box in this blog article so that your house is efficient and safe.

The Upgrade Requirement

Elevated Electrical Demand: Over time, the number of electronic gadgets, smart appliances, and home automation systems has led to a large increase in the electrical load in houses. Due to their increased demand, older breaker boxes might not be able to handle it, which might result in frequent tripping and possible safety risks.

Antiquated Technology: Older homes may have circuit breaker panels or fuse boxes that are devoid of contemporary comforts and safety measures. Changing to a newer model enables easier circuit management and improved protection against electrical failures.

Regulation Compliance: As new threats and technology arise, building codes and safety requirements change over time. To keep your house safe and insurable, you must upgrade your electric box to guarantee compliance with current requirements.

The advantages of upgrading

Improved Safety: More recent circuit breaker boxes come with cutting-edge safety features like ground fault circuit interrupters (GFCIs) and arc fault circuit interrupters (AFCIs). By offering further defense against electrical shocks, fires, and other risks, these gadgets reduce the possibility of mishaps occurring in your house.

Enhanced Capability: A higher-capacity circuit breaker box upgrade enables the installation of additional circuits and meets the rising electrical needs of contemporary homes. By doing this, you can make sure that you have enough power to run all of your appliances and gadgets without overtaxing the system.

Enhanced Convenience: More recent breaker boxes frequently have features like better labeling, simpler circuit identification, and even the ability to monitor remotely. This facilitates effective maintenance duties, problem-solving, and management of your electrical system.

Energy Efficiency: By making it easier to install energy-efficient appliances and systems, upgrading to a contemporary circuit breaker box can also help save energy. Furthermore, sophisticated features that optimize energy utilization and lower electricity costs include time-of-use metering and load shedding capabilities.

1 note

·

View note

Text

Ensuring Fairness in Consumption with Accurate Energy Meter

Accuracy is crucial in the utility industry since every kilowatt-hour matters. Energy meter is a small, inconspicuous device that are frequently hidden in utility closets or installed on building exteriors, yet they are essential for monitoring and metering energy use.

The Significance of Precision

An energy meter's primary purpose is to calculate how much power a home or company uses. Consumers pay for the energy they use, and this measurement serves as the foundation for billing. Consequently, the fairness of utility bills is directly impacted by the accuracy of these meters.

Overbilling causes consumers to pay more for power than they really use, which strains their finances and erodes their faith in the utility company. Conversely, underbilling might have short-term advantages but subsequently result in unanticipated large bills or even legal problems if found out. Inaccurate meters can cost energy companies money, cause arguments with consumers, and incur fines from the government.

Recognizing Accuracy

Energy meters' capacity to measure electricity within a given tolerance level in relation to actual usage is known as accuracy, and it is commonly stated as a percentage. A meter that has an accuracy of ±1%, for instance, might have readings that are up to 1% off from the actual amount of energy used.

The accuracy of energy and electric meter can be impacted by a number of factors, such as:

Age and Condition: The accuracy of energy meters can be affected over time by degradation, just like any other mechanical or electrical component. To guarantee that meters stay within reasonable accuracy bounds, regular calibration and maintenance are necessary.

Environmental Factors: Meter accuracy may be impacted by high or low humidity, temperatures, or other environmental conditions. In order to preserve accuracy, meters put in severe settings could need extra protection or unique designs.

Installation and Wiring: Inaccuracies in meter readings can be caused by improper installation or wiring. Accurate measurements can only be guaranteed by skilled professionals installing the system correctly.

Meter Type: The accuracy and sensitivity to outside influences of various power meter types varies. For example, smart meters provide sophisticated capabilities for controlling and monitoring energy use, but accuracy depends on appropriate calibration and upkeep.

Follow our Facebook and Twitter for more information about our product.

2 notes

·

View notes

Text

Voltage Regulator Is a Vital Component in Electronics

One unsung hero stands out in the complex world of electronics, where components pulse with energy and currents surge: the voltage regulator. The voltage regulator is a small but essential component that keeps many electrical devices operating smoothly and preserving stability.

Fundamentally, a voltage regulator is a circuit or device that, in the face of variations in input voltage, load current, or ambient temperature, maintains a constant output voltage. Put more simply, it guards against potential damage from fluctuations by ensuring that electrical devices receive the precise voltage they require to operate.

Voltage Regulator Types

Voltage Regulators in Line

To maintain a steady output voltage, linear regulators work by continually modifying a pass element, such as a transistor. They are less efficient despite being inexpensive and simple, particularly when the input voltage is significantly higher than the needed output voltage.

Voltage Regulators That Switch

To maintain the proper output voltage, switching regulators operate by quickly turning on and off a semiconductor device, often a transistor. Switching regulators are more expensive and complicated, but they have a better efficiency, which makes them perfect for applications that need precise voltage regulation or for battery-powered electronics.

Intelligent Voltage Regulators

Through external programming interfaces, users of programmable automatic voltage regulator can modify the output voltage, offering flexibility for a range of applications without requiring changes to the hardware.

The Use of Voltage Regulators

Energy Sources

Power supply units are replete with voltage regulators, which make sure that electrical equipment always receives steady, dependable power regardless of changes in the input voltage.

Processors and Microcontrollers

For optimal performance, microcontrollers and CPUs need exact voltage levels. By supplying the required voltage stability, voltage regulators protect these delicate parts from possible harm.

Systems of Communications

To provide continuous connectivity, voltage regulators are essential for supplying steady power to communication devices including radios, modems, and networking equipment.

Automobile Electronics

Voltage regulators are vital components of automobiles that improve overall performance and dependability by controlling electricity to a variety of electronic devices, including entertainment systems, engine control units, and safety features.

Transportable Electronics

Automatic voltage regulators are essential to battery-powered products like wearables, tablets, and smartphones because they maximize power efficiency and prolong battery life while maintaining reliable performance.

1 note

·

View note

Text

The Thermal Overload Relay Is Essential for Industrial Safety

An essential tool for guarding against overheating-related damage to electric motors is a thermal overload relay. Many industrial processes rely on motors as their power source, and any failure or overheating can have disastrous results. The thermal overload relay's main job is to keep an eye on the motor's current and temperature. If it notices any unusual activity, it will cut the power supply.

How It Operates

The idea behind how the thermal overload relay works is that too much current causes heat. The heating element or bimetallic strip that makes up the relay is incorporated into the motor circuit. The bimetallic strip warms up and triggers the relay, which disconnects the motor from the power supply when the current flows through the motor over the preset threshold.

Two metals with dissimilar coefficients of thermal expansion make up the bimetallic strip. Excessive current causes the strip to heat up and flex, which finally trips the relay and breaks the circuit. This straightforward yet efficient technology keeps the motor from overheating and guarantees system safety.

Relevance to Industrial Uses

Vehicle Safety

Thermal overload relay are an essential component of motor protection, shielding them from excessive current exposure that may cause them to burn out. This lowers maintenance expenses and downtime while also extending the motor's lifespan.

Preventing Fires

One major fire threat in electrical systems is overheating. As a first line of defense, thermal overload relays stop the motor before a catastrophic failure may happen, averting possible fires.

Efficiency in Energy Use

Thermal overload relays keep motors from operating when they are overloaded, which improves energy efficiency. This is especially crucial for sectors where motors run constantly since poor operations can result in wasted energy and higher expenses.

Respect for Regulations

Thermal overload relays are required by several industrial safety rules to protect electrical systems. Respecting these rules prevents legal issues in addition to guaranteeing a secure workplace.

Utilizations in All Sectors

Many different sectors, such as manufacturing, mining, oil & gas, and more, use overload thermal relays. The protective qualities of these relays might be advantageous to any company that depends on electric motors for its operations.

1 note

·

View note

Text

Guide to Applications and Types of Circuit Breakers

A circuit breaker is essential for protecting equipment and averting electrical fires in the complex world of electrical systems. When it comes to electrical defects such as short circuits and overcurrent, these devices serve as the first line of defense. It is crucial to comprehend the various kinds of circuit breakers to guarantee the dependability and safety of electrical installations. We'll explore the several kinds of circuit breakers, their traits, and their uses in this blog.

ACB ACBs, or air circuit breakers, are commonly utilized in low-voltage applications.

When a fault arises, they function by putting out the arc via the surrounding air.

Because of its versatility, ACBs may be used in both residential and commercial environments.

MCCB Molded Case Circuit Breakers, or MCCBs, are intended for use in medium- and low-voltage settings.

Compact in size and providing improved protection, these breakers are covered in a molded insulating substance.

Frequently utilized in commercial and industrial settings.

MCB Miniature circuit breakers, or MCBs, are frequently found in both residential and commercial structures. They are made for low-voltage applications.

MCBs are inexpensive, small devices that guard against overloads and short circuits.

Installing them and manually resetting them after tripping is simple.

Oil Circuit Breakers Designed primarily for high-voltage applications, oil circuit breakers put out an arc by filling them with insulating oil.

Ideal for uses requiring the absorption of substantial amounts of energy

Vacuum Circuit Breaker The arc quenching medium in vacuum circuit breakers is a vacuum.

They are small, low maintenance, and have no negative environmental effects.

Frequently employed in medium-voltage settings

It is essential for engineers, electricians, and everyone else engaged in the design and upkeep of electrical systems to understand the many kinds of circuit breakers. Concerning varying voltage levels and distinct protective needs, each variety has its special qualities and uses. It is possible to improve the safety and dependability of electrical installations and eventually contribute to the effective functioning of our linked world by choosing the appropriate type of circuit breaker like the SF6 circuit breaker for a certain application.

Next: Learn About the Working of Circuit Breaker

1 note

·

View note

Text

Get to Know About the Miniature Circuit Breaker

Fundamentally, an electric breaker is a safety mechanism that cuts off the flow of electricity when it reaches a preset limit. This essential feature guards against possible fire dangers, electrical overloads, and short circuits. Electric breakers prevent harm to your appliances, wiring, and entire electrical system by serving as a barrier.

Electric Breaker Types:

Circuit Breakers: Designed to safeguard specific circuits inside a distribution board, circuit breakers are the most widely used kind of electric breaker. When a problem is identified, it trips automatically, cutting off the current to that particular circuit.

Main Breakers: Located at the point where electrical power enters a building or facility, main breakers bear the enormous duty of completely cutting off the structure's electricity in the event of a serious malfunction or emergency.

GFCIs, or ground fault circuit Breaker

GFCIs are especially important in damp spaces like kitchens and bathrooms because they keep an eye on the current balance between the hot and neutral wires. A ground fault may be indicated by an imbalance, in which case the GFCI promptly switches off electricity to avoid shocks.

Arc fault breaker: These circuit breakers are made to recognize and react to electrical arcs that pose a risk of catching fire. They are crucial in residential situations because they provide an additional degree of security.

Electric breakers are essential for preventing fires: Electric breakers are essential for preventing fires because they react quickly to electrical problems that might produce heat and ignite a fire. Particularly important in identifying and reducing fire threats are AFCIs.

Safeguarding Appliances and Electronics: Electric breakers prevent potential harm to your expensive appliances and electronic equipment by stopping the passage of excessive electricity. This guarantees the longevity of your equipment and saves you money.

Increasing Safety: GFCIs and AFCIs have a major positive impact on occupant safety. While GFCIs guard against electrical shocks—particularly in locations with water—AFCIs identify and reduce the danger of fire, creating a safer atmosphere in homes and offices. The miniature circuit breaker is also quite useful.

2 notes

·

View notes