Text

SAP: Customize and Improve

There are two great rules Metinvest used to apply while working with SAP: take the ready solution that is good for everybody and make it better for yourself by customizing it.

Metinvest Group took part in the annual exclusive event SAP select focused on senior management and owners of SAP clients. Unlike classic events, where SAP experts speak of platform capabilities, this event focuses on experience sharing between clients.

Up to 500 attendees from all over the world gather for the event. The head of Organizational Development Department Yuliya Ryakhovskaya spoke on the discussion panel titled "Connect Employees to Business Purpose", which was also attended by Belgian and German companies from different business sectors. Yuliya spoke about the implementation of SAP SuccessFactors for goal-setting and assessment at Ilyich Iron and Steel Works in Mariupol, Ukraine.

It's hardly an overstatement to say that this solution is unique in the post-Soviet countries. Our pilot project covered 15,000 people and 5 levels of management from shopfloor to the general director. SuccessFactors saves us time and effort and enables us to follow up on the achievement of goals. Thanks to SuccessFactors, employees can see and understand how their result affects the company's big picture.

We selected Success Factors due to its canned, one-size-fits-all solution, which could simplify the implementation at the enterprise. However, the "can" was too tight for us. We, therefore, took SAP basic solution and enhanced the relevant modules in-house.

We also had to tackle the issue of enabling employees to work with their goals directly in SAP SuccessFactors. To this end, we installed computer centers in shops, where employees can run the application using their individual accounts. There is also a special mobile application for smartphones.

Another rule we have for SAP: Scale. Replicate your successes. The company intends to implement SAP SuccessFactors at other enterprises and to apply other modules in the training field. They will help every employee gain the relevant knowledge and skills to achieve KPIs.

0 notes

Link

READ THE FULL RELEASE (PDF)

0 notes

Text

Metinvest joined the Association of Industrial Automation of Ukraine

Metinvest joined the Association of Industrial Automation of Ukraine (APPAU). For Metinvest, membership in the Association means additional opportunities for interaction and cooperation in the field of automated process control and IT with other members of the ecosystem of high-tech industrial companies.

Bringing technical policies in the field of industrial automation and IT integration in line with IEC/ISO international standards is among priority areas of cooperation. In particular, it is planned to consider initiatives to introduce standards for cybersecurity of control systems, as well as the integration of Automated Process Control Systems with MES/MOM.

Metinvest intends to develop innovations at its enterprises, as well as support national programs and initiatives of the Industry 4.0 movement. The center of industrial automation expertise will be formed at Metinvest Digital, a new IT company at Metinvest Group, which was established in September of this year.

“The driver for the development of industrial high-tech and Industry 4.0 in Ukraine today is precisely the major industrial brands,” said APPAU, commenting on the accession of Metinvest and other industrial companies to the association.

The Association of Industrial Automation of Ukraine was established in 2011. APPAU represents the interests of the Ukrainian community of industrial automation enterprises. The principles of cooperation and joint solution of common problems is the heart of its work. The association joins manufacturers and suppliers of industrial equipment, IT-developers, engineering companies, universities and industrial enterprises.

0 notes

Text

DMYTRO NIKOLAENKO: "THE STRATEGIC GOAL IS TO DEVELOP CLIENT SERVICE"

The current year is still not over, but there have already been several significant events at Metinvest Holding. Among these are the completion of deals for the acquisition of new production assets and the growth of sales of metallurgical products by 38% overall and by 14% on the domestic market. In addition, as recounted by Dmytro Nikolaenko, director of sales at the holding, thanks to the development of cooperation with Ukrainian producers, the company succeeded in improving its positions in the long products segment and stabilised the supply of rebar to customers on the “home market”. The Group’s future plans are linked to further strengthening of its positions on the Ukrainian and global markets, both through the improvement of production processes and through an integrated programme for the transformation of sales with the goal of developing client service.

Dmytro Volodymyrovych, how do you evaluate Metinvest’s interim results since the beginning of the year?

The first half of the year was successful for all market players: Global steel prices rose against a backdrop of stable demand in all regions. Metinvest’s sales in the metallurgical sector grew by 38%, primarily from pig iron, slabs and square billets.

Sales of iron ore grew insignificantly and this is linked to the re-orientation of volumes from Asian markets to higher-margin ones in Europe and Ukraine.

Turning to the domestic market, we succeeded in increasing product sales in Ukraine by 14% thanks to increased demand for flat and long products in key, steel-consuming industries, such as machine building and construction.

How have the Group’s positions changed on the market for long products and rolled plates in Ukraine, taking into account the increase in sales?

In comparison with last year, our positions are unchanged across all product groups, with the exception of rebar. We have a stable presence on the market with products from Azovstal. We supply rolled products and wire from our partner, Dnepr Steel Plant. These volumes allowed us to compensate for the lost capacity of Yenakiieve Steel. The sale of steel sections made at the Promet Steel plant in Bulgaria is covering the requirements of our key clients and partners in the regions.

This year we also succeeded in establishing stable supplies of square billets produced at ArcelorMittal Kryvyi Rih. We also plan to further develop the relationship with this producer and plan to increase the supply of square billets through our sales network.

Does the Group require importation of rebar to Ukraine for the development of market positions in this segment?

At present we are not considering the importation of rebar as a means to increase sales. We are satisfied with our cooperation with ArcelorMittal Kryvyi Rih and planned to expand it. Today the domestic production fully maintains the needs of our network and partners in the regions.

In what other product segments are the Group developing its business? What are you undertaking for this?

Capital expenditures have increased nearly two-fold compared with the same period in 2017, demonstrating that we are actively implementing projects within the framework of the company’s Technological Strategy. The goal of the strategy is to increase the quality of our high-quality products.

Another key project in the first half of 2018 was the completion of the first stage of the reconstruction of the hot-rolled coil mill at Ilyich Steel. A new heat-treatment furnace was launched and a new heavy-duty coiling machine was installed. The implementation of project allowed for an increase in the weight of hot-rolled coils from 9.5 to 16.5 tonnes. In 2019, we plan to begin the output of 27 tonne coils.

In 2017, we were limited by the casting capacity of Ilyich Steel. At the end of 2018, we anticipate the launch of continuous casting machine no. 4 with a capacity of 2.5 million tonnes of premium-segment cast slabs. With the launch of the unit, the plant will able to increase productivity to 4 million tonnes per year.

One of the promising segments for the company remains coated steel, which projects were implemented in this area?

In September of this year, we completed a deal for the acquisition of Unisteel (Kryvyi Rih), a producer of galvanised steel. The deal strengthened our profile of high-margin products and permits us to work on the development of sales with Ukrainian and European products. The Metinvest product line was supplemented with galvanised steel with a thickness of 0.4-2.0mm with zinc covering from 60 to 350g/m2. The capacity of the plant is up to 100,000 tonnes of galvanised steel per year. Among the additional advantages of this product is the environmental technology of production and compliance with requirements of the European market. This expands our ability to supply products to European partners.

Has the strengthening of global protectionism impacted sales volumes and the Group’s positions on the international market?

The introduction of tariffs on hot-rolled steel on the European market had a negative impact on our sales. In 2017, the volume of deliveries of hot-rolled steel to the EU from our Ukrainian enterprises contracted by nearly half, to 0.6 million tonnes, and in the first half of 2018, supplies fell to a minimum level of less than 40,000 tonnes. But we re-directed volumes to the markets of North Africa, the Middle East, Turkey and other countries.

At the same time, we have stable sales volumes to Europe of plates and cold-rolled steel.

A direct indication of the differentiated approach to duties in the EU was disproportionate strengthening of a range of other importers to the EU, in particular Turkish suppliers (the growth of imports to the EU since the beginning of 2018 was more than 35% compared with the same period last year) and selected Russian companies (import growth doubled over the same period).

Under these conditions, has the sales strategy of the Group on the European market changed?

If we are talking about sales strategy, we are actively developing the European distribution network and working on the opening of new metals service centres in key regions for us in the EU. Plans include the integration of a line for cutting coils in our supply chain on the markets of Eastern Europe and Italy, as well as cutting and the further treatment of the surface of the sheet.

The preferred development model of the metal service centres for us is strategic partnership with existing operators on the market. Today, we are conducting talks with a series of potential partners who are interested in long-term cooperation with Metinvest.

What key goals has the Group set for 2019?

As I already said, we are continuing to strengthen positions in Europe and grow the share of high value-added products, to modernise production and launch new products.

As regards the company as a whole, we have a strategic goal of developing client service, which will become our additional competitive advantage. This year, we started the MiClient customer support programme. This is an integrated programme for the transformation of sales where the client is the working centre of any service in the company.

We are concentrated on the project for improving customer experience. We are committed to making the buying experience at Metinvest the most comfortable for the client. In order to achieve this, we are increasing the efficiency of the sales process and developing the service structure within the organisation and making the whole process transparent through the use of modern IT tools.

This year we introduced several initiatives valued by customers. For example, we introduced the option of in-time delivery for key markets. This flexibility allows the client to reduce the time required for project implementation and provides the ability to efficiently manage working capital.

Another example is a new technical service for customers. It is designed to solve systemic problems for the customer in processing metal products. Our team of technical experts helps to adapt the product to the client’s needs and make products meeting the most complex requirements for chemical content, mechanical properties and set up the client’s equipment to work with our product.

What new services can the Group’s clients expect in the future?

Near-term plans include the introduction of several IT projects, such as electronic document management and a personal online account for the customer. The goal of the projects are to increase the transparency of joint work and optimise, to the maximum extent, operational processes for completing deals and provide prompt support in real time. For example, after the introduction of the “personal account” project, any client will able to look at their warehouse stock, independently configure their order and generate an invoice. There will also be options for tracking orders in process, logistical routes and delivery dates for goods. The electronic account will have saved in a convenient format all information about the client’s previous cooperation with Metinvest, including every order and a historical database of prices. We plan that clients will be able to use a portion of these services already by 2019.

0 notes

Text

All to SAP: Metinvest's development will save $20 mln annually

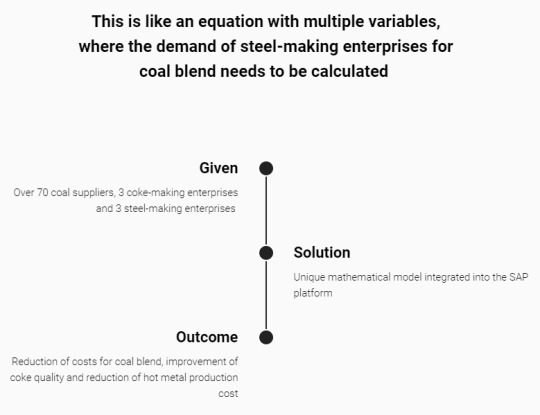

In summer of 2011, Metinvest launched its digital transformation and implementation of SAP. platform. The company did not stop at automating the processes through standard applications and proposed a customer solution for the planning of the process route from supply of coal to production of coke and and hot metal. The outcome helped the company save cash and gain recognition in Europe.

Start: scientists against mathematicians

The traditional process of coal blend planning could take up to several weeks. Process engineers from the enterprises and experts of the Ukrainian State Coal and Chemical Research Institute would come and manually decide which coal goes to which coke-making enterprise. They could discuss one enterprise the whole day. By the end of the day, it would turn out there was not enough coal. The process had to be started all over again.

The idea of using mathematical models in the process planning appeared in 2006. It was only in 2014 that the plans could become reality when the S&OP (Sales and Operations Planning) function was re-set in Metinvest Group to move away from time-consuming manual work with huge amount of data in Excel through the automation of planning procedures in SAP. The obvious cost effect and personal involvement of the new management of the function made it possible to calculate the annual business plan for all steel-making enterprises in SAP at the end of 2014 and include GOKs into the SAP planning perimeter by the end of 2015. The difficulties arose when integrating coke-making enterprises into the system. SAP has special solutions (modules) that were suitable to replace our developments for steel-making enterprises. SAP proved to be effective at GOKs. However, it could not handle the coal blend planning for coke-making enterprises. We had to go back to mathematics again.

"We had been working on blend optimization with Glushkov Institute of Cybernetics for six years and couldn't get any results because too many parameters had to considered. That's why I had little confidence it would work out", says Igor Drozdnik, the head of coal department of Coal and Chemical Research Institute, who explored coal and coke for more than 30 years and consulted the Metinvest team for 1.5 years.

Scientists and mathematicians would sit side by side for half a year, each fighting for their own calculations. The breaking point was when real savings became visible. The coal blend calculated using the mathematical model was several dollars cheaper. When translated into the company's volumes, that was over a million of dollars. It took several months of tests in real-life conditions, and by the end of 2013 the coal blend was already calculated using the new model.

The model would be one big pack of advantages if it were not for a small "but" - it could not be transferred into SAP and integrated with the global planning system. We had to find a solution to that. To achieve this, Metinvest had to take the issue to the international SAP forums. A council of experts in Waldorf, Moscow and Kiev were racking their brains for several months. As a result, Metinvest was able to complete SAP standard applications with customer mathematical models. Six months later, the model began to function as a part of the system.

Coal – Coke – Hot Metal project

When doing the planning we would sometimes ask ourselves if we were right in trying to reduce the cost of the coal blend. Maybe, we should be more expensive and better quality coal instead. This would improve the quality of coke, the cost of hot metal would be less and the volumes would be more. And the costs would pay back", says the head of Sales and Operations Planning Department Irina Lyamtseva.

Such logic brought an idea of continuing the logical sequence and plan the entire coal-coke-hot metal chain. S&OP initiated a project, whose main purpose was the end-to-end planning of coal-coke-hot metal chain.

The project was finished in 2017, and the system went live at the start of 2018. It undergoes adjustments from time to time, where theory is balanced with practical things. "This project first proved that we can! Second, it proved that SAP can produce real benefits," summarizes Kirill Makarov. This is not the end of the story - we have one more chain waiting and that is iron ore-sinter-hot metal.

Effect after project implementation

Queue of competitors

Economics and Business System Development Directorate that was started in April 2018 to secure stable development of the company in the long-term and continue the practices of S&O planning, nominated Coal-Coke-Hot Metal project for SAP Quality Awards, where the project was honoured with gold as the best innovative project in CEE in 2018. Metinvest became the first Ukrainian gold winner in the history of SAP Quality Awards. The prize was given on September, 11 in Sopot, Poland.

Kirill Makarov, Director of Business Process Transformation Department of Metinvest Group at the SAP Quality Awards ceremony

The victory in the regional European competition gives Metinvest a chance to participate in the global competition for Europe, Middle East and Africa. A short list of the regional winners will be created at the beginning of the next year, and the winners will be announced in April. "After we won the competition, we now have a queue of peers wanting to see how the systems works. We already had six meetings with foreign companies. SAP, peers and industry leaders know about us," says Kirill Makarov. Experts from Economics and Business System Development Directorate are now working on a new project for strategic planning that would allow to save not just dozens but rather hundreds of millions of dollars. We are talking about a 10-year planning tool that will help manage the company value.

0 notes

Photo

Azovstal is ranked among ukraine’s leading steel producers. Azovstal is a high performance steelmaking company with fully integrated production process – from coke and sinter production downstream to steelmaking and high quality long and flat rolled products manufacturing.

#azovstal#donbass#ukraine#steel#metinvest#GALLERY#photography#beauty#factory#Azovstal Iron and Steel Works

0 notes

Video

youtube

A picture is worth a thousand words. Video of #steel production is worth even more 👍

https://lnkd.in/gf9E6GD

0 notes

Text

New Europe bridge

Vidin, Bulgaria – Kalafat, Romania

Over seven thousand tonnes of rebar rolled by Promet Steel (Metinvest) were used for this project.

Some architecture is associated with light, hope and friendship. Bridges, for example. Especially if they connect two countries. There are concrete, brick and even wooden international bridges. Each one of them is unique. Some have difficult history, and other - funny.

According to a fable, the shortest international bridge is located in the Thousand Islands region. Local tour guides say the bridge connects two small islands of Canada and the USA. The border was shifted long ago, while the tourists are still there. 😊

The Oresund Bridge between Denmark and Sweden suddenly disappears under the water and turns into a tunnel. A Sino-Korean Friendship Bridge simply breaks off in the middle of the river. Next to it there is a bridge that is used, whereas the Broken Bridge was kept in place in memory of the Korean War.

One of the oldest bridges is a brick bridge between Georgia and Azerbaijan, which was built in the 17th century. New Europe Bridge over Danube was opened only three years ago. It connects Vidin (Bulgaria) and Kalafat (Romania). In 1909, citizens of Vidin called for a People's Gathering and approved a petition for the construction of a bridge.

The new bridge had to replace the railway bridge that had been in operation for several decades and a ferry. However, its construction began only 98 years later in 2007. It took another five years to build four highways, one railway, one bicycle and two pedestrian lanes between the cities and, therefore, the countries. It was designed a concrete-decked cable-stayed bridge. The bridge is 3,600 m long, extending for 1,791 m over the water with its pylons as high as 45 m. Over seven thousand tonnes of rebar rolled by Promet Steel (Metinvest)were used for this project.

The construction of the century is always magnificent and massive especially if takes over one hundred years from concept to implementation. 😊

0 notes

Video

youtube

Hleyevatsky mining pit in 360˚ 😮 📍 Central Iron Ore Enrichment Works Metinvest #Ukraine

https://lnkd.in/eRu9_6F

2 notes

·

View notes

Photo

They are amongst the largest vessels in their category. They were built from steel produced by Metinvest

Tankers is a very specialized group of vessels that transport liquid cargoes. Their names reflect their purpose. There are gas carriers, chemical carriers, product carriers, water carriers and other. For example, asphalt carriers. Why transport asphalt by sea for thousands of kilometers if it is produced everywhere? It's simple. The main component of the asphalt composition is bitumen, a by-product of crude oil processing. It is a binding agent for sand, granite powder and crushed stone mix. To keep bitumen from solidification during the transportation, asphalt tanker carriers are equipped with special tanks. The can expand or shrink depending on the temperature of the transported material. They are also fully insulated to minimize the heat loss. Standard asphalt tanker carriers are maximum 120 m. Being ones of the largest vessels in their category, T. ESRA and T. AILIN tankers are made of steel produced by Metinvest. They are 156.5 m long and 25 m wide.

1 note

·

View note

Text

Metinvest`s mine rescuers are the best in the USA 💪

The team of the Wellmore Coal Company, subsidiary of the United Coal Company (UCC), won the 2017 National Mine Rescue Competition in Beckley, West Virginia, USA, with the best result among more than 60 teams from 13 states. Metinvest United Coal Co. West’s Red Team was established in 2016 and has won a number of titles at the regional level. After that, the team decided to go into the prestigious national competitions. Representatives of Metinvest Group became the only team that showed the perfect performance in two days of contest. The victory had special significance for the management of United Coal Company - UCC Vice President J. P. Richardson was on the mine rescue team himself for nine years.

0 notes

Photo

Inside the blast furnace 😮 Metinvest Azovstal The revamp of #blastfurnace No. 3 at Azovstal Iron and Steel Works envisages its complete reconstruction, where the furnace shell will be replaced, and the furnace will be fit with state-of-the-art equipment, refractory materials and process control automation system. The installation of a new closed circuit cooling system will allow to stop using sea water. Similarly to blast furnaces No. 4 and 2, blast furnace No. 3 will be transferred to pulverized coal, which will allow to save up to 30 mln. m3 of natural gas per year. Dust emissions are expected to decrease by 80% 👍

0 notes

Text

National Olympic Stadium

Kyiv, Ukraine

Metinvest supplied hot-rolled plates for the manufacture of 7.5 К t of steel structures for the rennovation of the stadium for EURO-2012.

The National Olympic Stadium was built in 1923 to hold football games, athletic competitions, cultural, entertainment and other events. The stadium is the largest in Ukraine and the second in terms of its seating capacity in the CIS. Its total area covers 145,741 sq. m. The stadium seats 70,050 people.

The National Olympic Stadium hosted sporting and cultural events many times. Six group tournament games and one quarter final of Summer Olympic Games 1980 were held here. During EURO-2012 championship, which was held in Ukraine and Poland, three group tournament games, one quarter final and a final were held at the stadium. The stadium hosted the Tavria Games festival. Concerts of Madonna, George Michael, Shakira, Red Hot Chili Peppers, Kasabian, Depeche Mode and Elza's Ocean were held here. The Ukrainian football championship attendance record was set at the Olympic Stadium in 2011. Dinamo Kyiv - Shakhtar Donetsk game was attended by 73,950 people. This record cannot be beaten since the capacity of the Olympic Stadium after its last reconstruction was reduced to 70,050 people. The stadium underwent several reconstructions to change its layout and seating capacity. Metinvest supplied hot-rolled plates for the manufacture of 7.5 К t of steel structures for the reconstruction of the stadium for EURO-2012. The reconstruction lasted 38 months. After its commissioning, The Olympic Stadium was top-ranked by UEFA.

0 notes

Video

youtube

Watch and relax. 30 seconds. Water. Calm. It is not just a ship. This is a small story with a sequel. And it’s about the #steel which then becomes something new – a bridge, a building, a stadium or a new ship.

https://lnkd.in/e7y75ty

2 notes

·

View notes

Photo

The Shard

London, UK

Over 5,000 tonnes of Metinvest plate were used to manufacture steel structures of the supporting frame.

The Shard is a skyscraper in London. It stands 309 m high. with 72 floors of offices, apartments and service rooms. The last floor of the building hosts the highest viewing platform and a gallery in the UK. Before the skyscraper was built, the view of London that opens from the platform was available only for people who flew over the city in a helicopter. The Shard is the tallest building in London, the fourth tallest in Europe and the 45th tallest in the world. The skyscraper got its name from its irregular pyramidal shape and glazing made of 11,000 glass panels, which shine in the sun.

0 notes

Photo

WorldEmojiDay – we have our own emoji ;) Each describes one of Metinvest values:

✋ Life, Health and Environment

👍 Customer focus

👌 Professionalism

💪 Leadership

👐 Team work

https://lnkd.in/g5ESUBR

1 note

·

View note