Microtec Measurement Systems is the leading precision dimensional measurement laboratory providing a wide range of quality measurement services to Automotive, Aerospace and various other manufacturing industries. We have over 20 years of experience in CMM, Metrology, GD&T and SPC.

Don't wanna be here? Send us removal request.

Text

Precision Matters: Exploring CMM Inspection Services Near You for Superior Quality Assurance

Welcome to our accredited Coordinate Measuring Machine (CMM) lab, where precision meets excellence. We take pride in offering cutting-edge metrology services with the assurance of accreditation, ensuring the highest standards of accuracy and reliability in dimensional measurements.

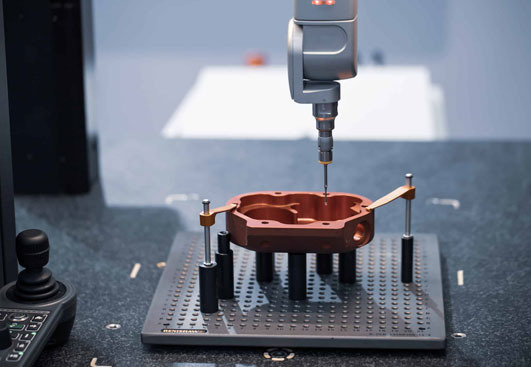

Our CMM lab is equipped with state-of-the-art Coordinate Measuring Machines, operated by skilled professionals trained in the latest metrology techniques. What sets us apart is our commitment to maintaining accreditation, a testament to our dedication to quality and precision in every measurement.

Key features of our accredited CMM lab:

Accreditation Assurance: Our lab holds accreditation from recognized bodies, attesting to our compliance with rigorous standards and best practices in dimensional metrology.

Cutting-Edge Technology: We employ advanced CMM technology to perform precise and repeatable measurements, ensuring the accuracy of your components and products.

Skilled Metrology Professionals: Our team consists of experienced metrologists who are experts in utilizing CMMs effectively, guaranteeing the reliability of your measurement data.

Comprehensive Dimensional Inspection: Whether you need first-article inspection, part validation, or ongoing quality control, our accredited CMM lab offers comprehensive dimensional inspection services tailored to your requirements.

Fast and Efficient Service: We understand the importance of timely results. Our efficient processes and skilled team ensure that you receive accurate measurement data promptly.

Customized Solutions: We work closely with our clients to understand their unique measurement needs. Our services are customizable to accommodate various industries and applications.

When precision matters, trust our accredited CMM lab to deliver accurate and reliable dimensional measurements. Whether you are in manufacturing, engineering, or quality control, our commitment to excellence ensures that your components meet the highest standards. Contact us for all your metrology needs, and experience the difference of working with a trusted and accredited CMM lab.

0 notes

Text

Exploring the World of Dimensional Measurement Laboratories

1. Introduction to Dimensional Measurement Laboratories

Dimensional Measurement Laboratories play a crucial role in ensuring accuracy and precision in various industries. From manufacturing and aerospace to automotive and beyond, dimensional measurements serve as a fundamental aspect of quality control and assurance. This article delves into the world of dimensional measurement laboratories, exploring their importance, technologies, applications, challenges, and future trends. By understanding the significance of accurate dimensional measurements and the advancements in measurement technology, we can better appreciate the vital role played by these laboratories in maintaining quality and driving innovation.

Exploring the World of Dimensional Measurement Laboratories

1. Introduction to Dimensional Measurement Laboratories

Overview of dimensional measurement

Dimensional measurement is a crucial aspect of various industries, ensuring that products meet specific requirements and adhere to precise specifications. It involves the assessment and quantification of physical dimensions, such as length, width, height, and shape. This process allows manufacturers to maintain quality control and ensure the functionality and performance of their products.

Introduction to dimensional measurement laboratories

Dimensional measurement laboratories serve as specialized facilities equipped with state-of-the-art tools and technologies to accurately measure and assess the dimensions of various objects. These laboratories play a vital role in maintaining quality standards and providing reliable data for research, development, and manufacturing processes. They utilize advanced techniques and instruments to ensure precise measurements, helping industries deliver products that meet customer expectations.

2. Importance of Accurate Dimensional Measurements

Role of accurate dimensional measurements in various industries

Accurate dimensional measurements are essential across a wide range of industries. In manufacturing, these measurements are crucial to ensure product quality, conformity, and consistency. They enable industries to detect any deviations from specifications, allowing for adjustments and improvements before mass production.

In fields like aerospace and automotive, accurate dimensional measurements are vital to guarantee safety and efficiency. From critical components to intricate assemblies, precise measurements ensure proper functionality and the integration of different parts. In the medical industry, dimensional measurements play a crucial role in the production of medical devices and implants, ensuring patient safety and optimal performance.

Implications of inaccurate dimensional measurements

Inaccurate dimensional measurements can have severe consequences for industries. Product defects, performance issues, and safety hazards may arise due to variations in dimensions. This can lead to costly recalls, customer dissatisfaction, and damage to a company's reputation. In critical industries like aerospace and medical, inaccurate dimensional measurements can compromise the integrity of entire systems, potentially leading to devastating consequences.

3. Key Technologies and Techniques in Dimensional Measurement

Overview of common dimensional measurement technologies

Dimensional measurement technologies have evolved significantly, providing precise and efficient measurement capabilities. Common technologies include coordinate measuring machines (CMMs), laser scanning systems, optical measurement systems, and 3D digitizers. These tools employ various principles, such as laser interferometry, optical triangulation, and touch probes, to capture and analyze dimensional data.

In-depth explanation of specific dimensional measurement techniques

One specific dimensional measurement technique is 3D scanning, which captures the geometry of an object using lasers or structured light. This technique creates a digital representation of the object, allowing for accurate measurements of its dimensions and surface features.

Another technique is tactile measurement, where contact probes are used to physically measure different points on an object. This technique is ideal for complex shapes and tight tolerances, ensuring precise measurements by directly assessing the object's surface.

4. Role of Dimensional Measurement Laboratories in Various Industries

Application of dimensional measurement laboratories in the manufacturing industry

Dimensional measurement laboratories are essential for the manufacturing industry as they act as quality control centers. They verify the dimensional accuracy of manufactured components, ensuring compliance with standards and specifications. These laboratories help identify any process variations or machinery issues early on, enabling manufacturers to rectify problems and maintain consistent product quality.

Role of dimensional measurement in the aerospace industry

In the aerospace industry, dimensional measurement plays a critical role in ensuring the precise assembly of aircraft components. These laboratories verify the accuracy of critical parts, such as engine components and airframe structures. By conducting detailed measurements, they ensure that aircraft meet stringent safety standards and performance requirements, contributing to the reliability and safety of air travel.

Dimensional measurement in the automotive industry

Dimensional measurement laboratories are crucial for the automotive industry, where precision and quality are paramount. These laboratories verify dimensional tolerances of various automotive components, such as engine parts, chassis, and body panels. Accurate measurements help ensure proper fit and function, contributing to vehicle performance, safety, and customer satisfaction.

In conclusion, dimensional measurement laboratories play a vital role in ensuring accurate measurements and maintaining quality across industries. By employing advanced technologies and techniques, they contribute to the development, manufacturing, and safety of products, ultimately enhancing customer experiences and industry standards.

5. Challenges and Solutions in Dimensional Measurement

Common challenges faced in dimensional measurement

Let's face it, dimensional measurement is not always a walk in the park. There are some common challenges that can make the lives of measurement experts a little less glamorous. From dealing with complex geometries to managing tight tolerances, there's never a dull moment in the world of dimensional measurement.

One of the most common challenges is the impact of environmental factors on measurements. Temperature, humidity, and even air pressure can have a significant influence on dimensional measurements. So, just when you thought you had everything under control, Mother Nature decides to throw a curveball.

Another challenge is the sheer complexity of the objects being measured. As technology advances, so does the intricacy of the components we encounter. Think of it this way: measuring a simple bolt is a piece of cake, but measuring a turbine blade with countless curves and angles can be a real brain teaser.

Strategies and solutions for overcoming dimensional measurement challenges

While dimensional measurement challenges can be daunting, they are not insurmountable. Here are some strategies and solutions to help you navigate through the maze of measurement woes.

First and foremost, it's essential to invest in state-of-the-art measurement equipment. Having the right tools for the job can make all the difference. Whether it's a coordinate measuring machine (CMM) or an optical scanner, upgrading your arsenal will give you a fighting chance against those challenging measurements.

Additionally, establishing clear measurement procedures and protocols is crucial. Consistency is key, so having standardized practices ensures accuracy and repeatability across different measurements and operators. It's like having a well-oiled machine that keeps cranking out reliable results.

Lastly, don't be afraid to tap into the power of automation. The latest advancements in dimensional measurement technology allow for more automated and streamlined processes. This means less room for human error and more time to sip your coffee while the machines do the heavy lifting.

6. Advancements in Dimensional Measurement Technology

Overview of recent technological advancements in dimensional measurement

Ah, technology, our ever-reliable partner in crime. In recent years, dimensional measurement technology has experienced quite the upgrade. From faster measurements to enhanced accuracy, the possibilities seem to be endless.

One notable advancement is the rise of 3D scanning technology. Instead of relying solely on touch-probe measurements, 3D scanners capture the geometry of the object using laser or structured light. It's like a speed date with precision, giving measurement laboratories the ability to measure complex shapes in a fraction of the time.

Impact of advancements on dimensional measurement laboratories

These technological advancements have had a profound impact on dimensional measurement laboratories. With faster and more accurate measurements, efficiency levels have skyrocketed. What used to take days can now be accomplished in hours, allowing for quicker turnaround times and increased productivity.

Moreover, the enhanced capabilities of these advanced measurement technologies have opened up new doors for dimensional measurement laboratories. They are now equipped to take on more complex projects and deliver precise results, making them a valuable asset in various industries like aerospace, automotive, and medical device manufacturing.

7. Best Practices for Dimensional Measurement Laboratories

Establishing standardized measurement procedures

No, we're not talking about measurements with a ruler that has a personality disorder. Standardized measurement procedures are the backbone of any dimensional measurement laboratory. They ensure consistency, accuracy, and traceability in all measurements, keeping chaos at bay.

By establishing clear and documented procedures, laboratories can have a reliable reference point for all measurements. This allows for easier replication of results, making it a breeze to identify any potential discrepancies or errors along the way.

Ensuring calibration and traceability

In the world of dimensional measurement, being a stickler for calibration is a must. Regular calibration of measurement equipment is essential to maintain accuracy and traceability. After all, you wouldn't want to measure a mile with a faulty ruler, would you?

Calibration ensures that measurement equipment is performing within acceptable limits, providing confidence in the accuracy of measurements. To take it a step further, establishing a traceability program allows for the calibration of instruments to be traced back to recognized national or international standards. This way, you can be sure that your measurements are on the right track.

Quality control and assurance in dimensional measurement

When it comes to dimensional measurement, quality is king. Implementing robust quality control and assurance measures ensures that the results obtained are reliable and meet the required specifications.

This involves performing regular checks, audits, and verifications to ensure that measurement procedures are followed correctly and consistently. It's like having Sherlock Holmes on the case, making sure that every measurement is accounted for and accurate.

8. Future Trends in Dimensional Measurement

Emerging technologies shaping the future of dimensional measurement

Hold on to your measuring tape because the future of dimensional measurement is looking quite exciting. Emerging technologies are shaping the way we measure things, making it faster, more accurate, and even more intelligent.

One such technology is the incorporation of artificial intelligence (AI) in dimensional measurement. AI-powered algorithms can analyze data, identify patterns, and make intelligent decisions, taking dimensional measurement to a whole new level. It's like having a measurement expert and a supercomputer rolled into one.

Anticipated advancements and trends in dimensional measurement laboratories

As we peer into the crystal ball, several advancements and trends are on the horizon for dimensional measurement laboratories. For instance, we can expect to see more portable and handheld measurement devices, allowing for measurements to be taken directly on the shop floor.

Additionally, the integration of dimensional measurement data with other systems, such as computer-aided design (CAD) software and manufacturing processes, will become more seamless. This means that measurement data can be used to optimize manufacturing processes and ensure the perfect fit every time.

So, buckle up and get ready for the ride because the world of dimensional measurement is only going to get more exciting from here.In conclusion, dimensional measurement laboratories play a pivotal role in today's industries, providing accurate and reliable measurements that impact product quality and performance. As technology continues to advance, these laboratories will continue to evolve, incorporating new techniques and equipment to meet the growing demands of various sectors. By embracing best practices and staying up to date with the latest trends, dimensional measurement laboratories can continue to drive innovation and ensure the highest level of quality in products and processes. As we move forward, these laboratories will remain an indispensable asset, contributing to the success and advancement of industries worldwide.

Frequently Asked Questions

1. What is the role of dimensional measurement laboratories?

Dimensional measurement laboratories are responsible for conducting accurate measurements of physical dimensions, ensuring the quality and precision of products. They play a vital role in industries by providing data for quality control, process improvement, and compliance with standards.

2. What technologies are used in dimensional measurement laboratories?

Dimensional measurement laboratories utilize various technologies, including coordinate measuring machines (CMMs), optical measurement systems, laser scanners, and 3D imaging techniques. These technologies enable precise and detailed measurements of geometrical features and dimensions.

3. How do dimensional measurement laboratories contribute to different industries?

Dimensional measurement laboratories have broad applications across industries. They contribute to manufacturing by ensuring the accuracy of machined parts and assemblies. In aerospace, dimensional measurements are crucial for safety and performance of aircraft components. Automotive industries rely on dimensional measurements for quality control and fitment of parts. Essentially, dimensional measurement laboratories support industries in achieving consistent quality and adherence to specifications.

4. What are the future trends in dimensional measurement?

The future of dimensional measurement is promising, with advancements in technology such as non-contact measurement methods, 3D printing, and artificial intelligence. These trends enable faster, more accurate measurements with improved automation and data analysis capabilities. Additionally, the integration of dimensional measurement with other technologies, such as robotics and Internet of Things (IoT), will further enhance efficiency and productivity in dimensional measurement laboratories.

0 notes

Text

Precision Unveiled: Exploring the World of Dimensional Measurement Laboratories

Introduction: Unraveling the Secrets of Dimensional Measurement Laboratories

Welcome to the intriguing realm of Dimensional Measurement Laboratories, where precision takes center stage, and the world of measurement is unveiled in all its glory. In this comprehensive exploration, we delve deep into the inner workings of these laboratories, shedding light on their pivotal role in industries ranging from aerospace to manufacturing. Prepare to embark on a journey where precision reigns supreme, and accuracy knows no bounds.

The Essence of Dimensional Measurement Laboratories

At the heart of every Dimensional Measurement Laboratory lies a commitment to precision. These specialized facilities serve as the nerve centers of dimensional analysis, employing state-of-the-art technology and highly skilled personnel to ensure accuracy in measurements that can often be imperceptible to the human eye. Let's break down the key aspects that define these laboratories:

1. Cutting-Edge Equipment: The Pillars of Precision

In the world of Dimensional Measurement Laboratories, equipment is everything. From coordinate measuring machines (CMMs) to laser scanners and optical comparators, these laboratories house an impressive arsenal of tools. These instruments are calibrated to perfection, enabling scientists and engineers to measure dimensions with astonishing accuracy.

2. Metrology Masters: The Art of Measurement

Behind every precise measurement is a metrology master, an expert skilled in the science of measurement. These professionals play a pivotal role in calibration, ensuring that instruments remain accurate and reliable. Their meticulous attention to detail is what sets Dimensional Measurement Laboratories apart.

3. Real-World Applications: Impact Across Industries

The applications of dimensional measurement are far-reaching, touching upon industries that shape our modern world. From ensuring the safety of aerospace components to guaranteeing the precision of medical devices, these laboratories have a hand in it all. In fact, they are indispensable in manufacturing, research, and development.

The Precision Paradox: Why It Matters

Precision may seem like a niche concern, but it has a profound impact on our daily lives. Let's uncover why precision matters, not just in Dimensional Measurement Laboratories but in our broader world:

1. Industry Advancements: Driving Innovation

Precision is the driving force behind innovation in various industries. Imagine the aerospace industry without accurate measurements; the consequences could be catastrophic. Dimensional Measurement Laboratories serve as the guardians of progress, ensuring that groundbreaking advancements can be made safely and reliably.

2. Quality Assurance: The Backbone of Production

In manufacturing, precision is synonymous with quality. A single measurement error can lead to a cascade of problems, resulting in defective products and financial losses. These laboratories act as quality assurance hubs, safeguarding the reputation and profitability of companies worldwide.

3. Scientific Discoveries: Expanding Our Horizons

In the world of scientific research, precision is the key to unlocking new discoveries. From understanding the properties of materials at the nanoscale to deciphering the mysteries of the universe through telescope calibration, Dimensional Measurement Laboratories enable scientists to push the boundaries of knowledge.

Navigating the Dimensions: How It's Done

So, how exactly do Dimensional Measurement Laboratories work their magic? Let's take a closer look at the intricate process of dimensional analysis:

1. Preparation: Setting the Stage

Before any measurement can take place, meticulous preparation is essential. This involves ensuring that the measuring instruments are calibrated to their highest precision and that the environment is controlled to minimize external factors that could affect measurements.

2. Data Acquisition: Capturing the Essence

Once the stage is set, it's time to collect data. This can involve a variety of methods, from contact measurements using CMMs to non-contact techniques like laser scanning. The goal is to capture the essence of the object being measured with utmost accuracy.

3. Analysis and Interpretation: Deciphering the Numbers

The data collected is then subjected to rigorous analysis. This stage involves complex mathematical algorithms and cutting-edge software to interpret the measurements accurately. Metrology masters play a pivotal role here, ensuring that the data is translated into meaningful insights.

4. Reporting: Precision in Documentation

The final step involves documenting the measurements with precision. Detailed reports are generated, providing clients with a clear understanding of the measurements and their implications. These reports are not just records but also tools for decision-making and quality control.

Beyond the Laboratory: Real-World Applications

Dimensional Measurement Laboratories extend their influence far beyond their physical confines. Let's explore some of the real-world applications where their precision makes a difference:

1. Aerospace Industry: Safeguarding Skies

In the aerospace industry, safety is paramount. Dimensional Measurement Laboratories play a critical role in ensuring the precision and reliability of aircraft components. From engine parts to structural elements, every component undergoes meticulous measurement and inspection.

2. Automotive Sector: Driving Efficiency

Precision in the automotive sector translates to fuel efficiency, safety, and performance. These laboratories are responsible for verifying the accuracy of engine components, ensuring that vehicles meet stringent emission standards, and enhancing overall vehicle quality.

3. Medical Devices: Saving Lives

The medical field relies on precision to save lives. Dimensional Measurement Laboratories verify the accuracy of medical devices, from surgical instruments to diagnostic equipment, guaranteeing that they meet regulatory standards and perform with utmost precision.

4. Research and Development: Innovating the Future

In research and development, every breakthrough begins with accurate measurements. These laboratories support scientific advancements by providing precise measurements for materials, prototypes, and experimental setups, enabling researchers to push the boundaries of knowledge.

Conclusion: The Precision Revolution

In conclusion, Dimensional Measurement Laboratories are the unsung heroes of our modern world. Their unwavering commitment to precision underpins innovation, ensures quality, and drives scientific discovery. From the aerospace industry to medical research, their influence is felt across a myriad of sectors. As we continue to push the boundaries of what's possible, we can rest assured that Dimensional Measurement Laboratories will remain at the forefront of precision, unveiling new dimensions in measurement and advancing our world in ways we can only imagine.

So, the next time you marvel at the precision of a spacecraft, the efficiency of your car, or the accuracy of a medical device, remember that behind it all lies the meticulous work of Dimensional Measurement Laboratories, where precision is not just a goal but a way of life.

2 notes

·

View notes

Text

First Article Inspection in Canada: Ensuring Quality and Compliance

Introduction

In today's rapidly evolving manufacturing landscape, ensuring the quality and compliance of products is paramount. The first article inspection (FAI) process plays a crucial role in achieving this goal, particularly in Canada. In this article, we will delve into the intricacies of FAI in Canada, its significance, and the steps involved in conducting a successful first article inspection.

Understanding First Article Inspection (FAI)

First, let's establish a clear understanding of what FAI entails.

What is FAI?

FAI is a comprehensive and systematic quality control process used by manufacturers to verify that a newly produced part or product meets all the required specifications, standards, and regulations before mass production begins.

The Significance of FAI in Canada

Now, let's explore why FAI holds such importance in the Canadian manufacturing industry.

Compliance with Regulations

In Canada, just like in many other countries, there are stringent regulations and standards that manufacturers must adhere to. FAI ensures compliance with these regulations from the outset.

Minimizing Costs and Errors

By conducting an FAI, manufacturers can identify and rectify any design or production flaws at an early stage, saving both time and resources in the long run.

Conducting a First Article Inspection

Having established the significance of FAI, let's outline the steps involved in conducting a successful first article inspection in Canada.

Step 1: Planning

The first step in any FAI process is meticulous planning. This involves defining the scope, selecting the appropriate inspection methods, and creating a detailed inspection plan.

Step 2: Documentation

Comprehensive documentation is essential throughout the FAI process. This includes capturing the design data, specifications, and any relevant standards or regulations.

Step 3: Verification

During this phase, the manufacturer verifies that the first article matches the design specifications and complies with all applicable regulations.

Step 4: Review and Approval

Once the inspection is complete, the results are reviewed and approved. Any non-conformances are addressed and resolved.

Step 5: Submission

The manufacturer submits all the documentation, including inspection records and approvals, to the customer or regulatory authority.

Benefits of a Well-Executed FAI

A successful FAI process offers numerous benefits to manufacturers in Canada.

Improved Product Quality

By identifying and rectifying issues early, FAI leads to improved product quality, reducing the likelihood of defects reaching customers.

Regulatory Compliance

FAI ensures that products adhere to Canadian regulations, preventing potential legal and financial consequences.

Cost Efficiency

Identifying and addressing issues at the outset minimizes costly rework and production delays.

Conclusion

In conclusion, conducting a first article inspection in Canada is a vital step in ensuring product quality, regulatory compliance, and cost efficiency for manufacturers. By following a systematic approach and paying attention to detail, manufacturers can reap the benefits of this essential process.

FAQs

What is the primary goal of a first article inspection in Canada? The primary goal of a first article inspection is to ensure that a newly produced part or product meets all required specifications, standards, and regulations before mass production begins.

How does FAI contribute to cost efficiency for manufacturers in Canada? FAI helps identify and rectify design or production flaws early, reducing costly rework and production delays.

Are there specific regulations that govern FAI in Canada? Yes, Canada has stringent regulations and standards that manufacturers must adhere to, and FAI helps ensure compliance with these regulations.

Is FAI a one-time process, or is it conducted regularly? FAI is typically conducted for the initial production run of a new part or product. However, it can be repeated if there are design changes or other significant modifications.

Can FAI be outsourced to third-party inspection services in Canada? Yes, many manufacturers choose to work with third-party inspection services that specialize in conducting FAIs to ensure impartiality and expertise.

0 notes

Text

First Article Inspection Services in Canada

Introduction

Welcome to our comprehensive guide on First Article Inspection (FAI) services in Canada. At Microtec System, we are committed to providing you with top-notch information and services to help you understand and navigate the world of FAI. In this article, we will cover everything you need to know about FAI, its importance, and how our services can benefit your business.

What is First Article Inspection?

First Article Inspection, often referred to as FAI, is a critical quality control process in manufacturing. It involves the meticulous examination and validation of the first production unit of a new part or product. The primary objective of FAI is to ensure that the manufacturing process is capable of consistently producing items that meet the required specifications.

The Significance of FAI

Quality Assurance

In today's competitive market, ensuring the quality of your products is paramount. FAI helps in identifying potential issues early in the production process, reducing the risk of defective products reaching your customers. This not only safeguards your reputation but also minimizes costly recalls and warranty claims.

Compliance

Many industries, especially aerospace and defense, have stringent regulations that require FAI as a mandatory step. Ensuring compliance with these regulations is essential to avoid legal consequences and maintain industry certifications.

Cost Reduction

By identifying and rectifying production issues early on, FAI can significantly reduce production costs. It prevents the need for costly rework or scrap materials, ultimately saving your company time and resources.

The FAI Process

Planning

The FAI process begins with meticulous planning. This involves defining the scope of the inspection, selecting appropriate sampling methods, and establishing inspection criteria. Our experienced team at [Your Company Name] excels in creating tailored FAI plans that meet your specific needs.

Inspection

Once the planning phase is complete, the actual inspection takes place. This involves measuring and inspecting the first production unit against the predefined criteria. Our team utilizes state-of-the-art equipment and methodologies to ensure accurate results.

Documentation

Comprehensive documentation is a crucial aspect of FAI. Our experts maintain detailed records of the inspection process, including measurements, photographs, and any non-conformance issues. This documentation is essential for compliance and traceability.

Why Choose [Microtec system] for FAI Services?

Expertise

With years of experience in the industry, our team of highly skilled professionals possesses the expertise needed to conduct FAI efficiently and accurately. We stay updated with the latest industry standards and regulations to ensure compliance.

Cutting-Edge Technology

We invest in the latest inspection equipment and technology to provide you with the most precise and reliable results. Our commitment to innovation allows us to stay ahead in the field of FAI.

Customized Solutions

We understand that every project is unique. That's why we offer customized FAI solutions tailored to your specific requirements. Whether you're in the aerospace, automotive, or any other industry, we have the expertise to assist you.

Conclusion

In conclusion, First Article Inspection is a critical process that should not be overlooked in your manufacturing operations. At [Your Company Name], we take pride in offering top-tier FAI services in Canada. Our commitment to quality, compliance, and cost-effectiveness sets us apart from the competition. Contact us today to learn more about how we can help you ensure the quality and reliability of your products through First Article Inspection. Let us be your trusted partner in achieving manufacturing excellence.

0 notes

Text

0 notes

Text

Nearby CMM Inspection Experts - Ensuring Your Components Meet the Highest Standards

1. Introduction to CMM Inspection and its Importance in Component Manufacturing

CMM (Coordinate Measuring Machine) inspection plays a critical role in ensuring the quality and precision of components in various industries. The accuracy and reliability of components are vital for the performance and safety of products. This article explores the significance of CMM inspection in component manufacturing and highlights the importance of nearby experts in this field. By understanding the role of nearby CMM inspection experts, considering key factors in their selection, and examining the benefits they bring, manufacturers can ensure that their components meet the highest standards of quality and reliability.

1. Introduction to CMM Inspection and its Importance in Component Manufacturing

1.1 What is CMM Inspection?

CMM, or Coordinate Measuring Machine, inspection is a critical process in component manufacturing that ensures the accuracy and quality of the produced parts. It involves using specialized equipment to measure the dimensions and geometrical features of a component to ensure it meets design specifications.

1.2 Why is CMM Inspection Essential for Component Manufacturing?

CMM inspection plays a vital role in component manufacturing by ensuring that the final products meet the highest standards of quality and precision. By thoroughly examining components, manufacturers can identify any deviations from the intended specifications, allowing for necessary adjustments to be made. This process helps prevent defects, reduces rejections, and minimizes the risk of costly errors during production.

2. Understanding the Role of Nearby CMM Inspection Experts

2.1 Who are CMM Inspection Experts?

CMM inspection experts are professionals with extensive knowledge and experience in operating and interpreting data from coordinate measuring machines. These experts are proficient in dimensioning, geometric tolerancing, and inspection techniques, allowing them to accurately assess the quality of components and provide valuable insights for improvements.

2.2 The Importance of Local Expertise

Having nearby CMM inspection experts is advantageous for component manufacturers. Local experts offer convenience and accessibility, allowing for seamless communication and collaboration. They understand the local manufacturing landscape and are familiar with industry standards, enhancing their ability to address specific challenges and provide tailored solutions.

3. Key Factors to Consider When Choosing CMM Inspection Experts

3.1 Technical Expertise and Industry Experience

When selecting CMM inspection experts, it is crucial to consider their technical expertise and industry experience. Look for professionals who have a deep understanding of your specific industry and have worked with similar components. Their knowledge and experience will ensure accurate and reliable inspection results.

3.2 Available Equipment and Technology

The quality and capabilities of the equipment and technology used by CMM inspection experts are paramount. Ensure that the experts are equipped with modern, high-quality CMM machines and software that can handle the complexity of your components. Advanced equipment allows for precise measurements and detailed analysis, leading to more accurate inspection results.

3.3 Quality Management Systems and Certifications

Choose CMM inspection experts who have robust quality management systems in place. Look for certifications such as ISO 9001, which demonstrate their commitment to quality and adherence to stringent standards. A reliable quality management system ensures consistent and reliable inspection processes, giving you confidence in the results.

4. Benefits of Utilizing Nearby CMM Inspection Experts for Component Quality Assurance

4.1 Faster Turnaround Times

By utilizing nearby CMM inspection experts, you can significantly reduce the time spent on quality assurance processes. The proximity allows for faster transportation of components, quicker communication, and expedited inspection turnaround times. This ensures that your manufacturing processes remain efficient and on schedule.

4.2 Cost-Effectiveness

Choosing local CMM inspection experts also brings cost-effectiveness to your component manufacturing process. By eliminating the need for long-distance shipping and reducing transportation costs, you can allocate your budget more efficiently. Additionally, local experts can provide cost-saving recommendations and insights to improve overall production efficiency.

4.3 Enhanced Accuracy and Precision

Nearby CMM inspection experts offer the advantage of on-site inspections, which minimizes the risk of measurement deviations due to transportation. The ability to collaborate closely with experts during the inspection process allows for prompt adjustments and immediate feedback. This leads to enhanced accuracy and precision, ensuring your components meet the highest standards of quality.

With local CMM inspection experts by your side, you can confidently manufacture components that meet the highest standards, benefiting from their expertise, speedy turnaround times, cost-effectiveness, and enhanced accuracy. So, don't compromise on quality and partner with nearby professionals to ensure your components shine!

5. How Nearby CMM Inspection Experts Ensure Components Meet the Highest Standards

5.1 Inspection Process and Methodologies

When it comes to ensuring your components meet the highest standards, nearby CMM inspection experts have got you covered. They follow a rigorous inspection process that involves using state-of-the-art Coordinate Measuring Machines (CMM) and advanced methodologies. These experts leave no stone unturned in their quest to measure every nook and cranny of your components to guarantee their quality.

5.2 Dimensional Analysis and Metrology Techniques

Nearby CMM inspection experts are well-versed in dimensional analysis and metrology techniques. They know the ins and outs of measuring dimensions, tolerances, and geometries with precision using the latest technology. These experts are like the Sherlock Holmes of the manufacturing world, sniffing out any deviations from the desired specifications and ensuring your components are in tip-top shape.

5.3 Identification and Resolution of Defects

No component is perfect, and defects can creep in during the manufacturing process. That's where nearby CMM inspection experts swoop in to save the day. With their keen eyes and sophisticated tools, they identify defects, such as surface imperfections, cracks, or misalignments, that can compromise the functionality of your components. They then work tirelessly to resolve these issues, leaving you with components that meet even the pickiest quality standards.

6. Case Studies: Successful Implementation of CMM Inspection by Nearby Experts

6.1 Case Study 1: Improving Component Quality in the Automotive Industry

In this inspiring case study, a nearby CMM inspection expert collaborated with a major automotive manufacturer to enhance the quality of their components. By implementing thorough inspection processes and using cutting-edge metrology techniques, they were able to detect and rectify defects early on, resulting in a significant reduction in faulty components. The partnership between the automotive manufacturer and the nearby CMM inspection expert not only improved the overall quality of their products but also boosted customer satisfaction.

6.2 Case Study 2: Ensuring Precision in Aerospace Component Manufacturing

In another incredible case study, a nearby CMM inspection expert joined forces with an aerospace component manufacturer. By applying their expertise in dimensional analysis and metrology techniques, they ensured that the components met the stringent standards required in the aerospace industry. Their accurate measurements and defect identification processes helped the manufacturer achieve precise and reliable components, ultimately contributing to the safety and performance of aircraft.

7. Overcoming Challenges in Implementing CMM Inspection with Nearby Experts

7.1 Communication and Collaboration

Implementing CMM inspection with nearby experts may present some challenges, such as effective communication and collaboration. However, by fostering open lines of communication, maintaining clear objectives, and establishing a strong partnership, these challenges can be overcome. The key is to establish a collaborative environment where everyone is on the same page and working together towards ensuring the highest standards for your components.

7.2 Adapting to Unique Component Requirements

Components come in all shapes and sizes, and each may have its own unique set of requirements. One challenge nearby CMM inspection experts face is adapting their inspection methodologies to meet these specific needs. However, these experts are adaptable and resourceful. They bring their expertise and creativity to the table, tailoring their inspection processes to fit the individual requirements of your components. With their flexibility, they ensure that your components meet the highest standards, no matter how unique they may be.

8. Conclusion: Leveraging Nearby CMM Inspection Experts for Superior Component Quality Assurance

When it comes to component quality assurance, nearby CMM inspection experts are your go-to partners. Their meticulous inspection processes, dimensional analysis techniques, and defect resolution capabilities ensure that your components meet the highest standards. Through successful case studies and the ability to overcome challenges, these experts have proven their worth in improving component quality in various industries. So, leverage their expertise and take your component quality to new heights. With nearby CMM inspection experts by your side, you can rest easy knowing that your components are in safe hands.

8. Conclusion: Leveraging Nearby CMM Inspection Experts for Superior Component Quality Assurance

In conclusion, partnering with nearby CMM inspection experts is a strategic choice for manufacturers seeking superior component quality assurance. Through their technical expertise, local knowledge, and advanced equipment, these experts ensure that components meet the highest standards of accuracy and precision. The benefits of utilizing nearby CMM inspection experts include faster turnaround times, cost-effectiveness, and enhanced quality control. By overcoming challenges and implementing CMM inspection processes, manufacturers can optimize their component manufacturing and deliver products that consistently meet and exceed customer expectations. Embracing the expertise of nearby CMM inspection professionals is a valuable investment in ensuring the reliability and excellence of components in today's competitive market.

FAQ

1. What is CMM inspection and why is it important in component manufacturing?

CMM inspection, or Coordinate Measuring Machine inspection, is a process that uses specialized equipment to measure the geometric features of components with high accuracy. It is crucial in component manufacturing because it ensures that components meet the required specifications and quality standards. By validating dimensions, tolerances, and surface characteristics, CMM inspection helps to identify and rectify any defects or deviations, ensuring the overall performance and reliability of the final product.

2. Why should I consider nearby CMM inspection experts for my component quality assurance?

Choosing nearby CMM inspection experts brings several advantages. Firstly, their proximity allows for faster turnaround times, reducing delays in the manufacturing process. Secondly, local experts have a better understanding of regional industry requirements, regulations, and standards, ensuring compliance and avoiding potential issues. Additionally, nearby experts can offer cost-effective solutions, as they eliminate shipping costs and logistical complexities associated with outsourcing inspection services to distant locations.

3. How do nearby CMM inspection experts ensure that components meet the highest standards?

Nearby CMM inspection experts employ advanced inspection techniques, such as dimensional analysis and metrology, to ensure that components meet the highest standards. They utilize state-of-the-art equipment, such as high-precision CMM machines, laser scanners, and optical measurement devices, to accurately measure and analyze component features. These experts also follow established inspection processes, identify and resolve defects, and provide detailed reports on component quality, allowing manufacturers to address any issues and maintain superior standards throughout the production process.

4. How can manufacturers overcome challenges in implementing CMM inspection with nearby experts?

Efficient communication and collaboration are crucial in overcoming challenges when implementing CMM inspection with nearby experts. Manufacturers need to establish clear lines of communication, provide comprehensive component specifications, and maintain an open dialogue with the inspection experts. Additionally, manufacturers should work closely with nearby experts to adapt the inspection process to the unique requirements of their components, considering factors such as materials, tolerances, and manufacturing methods. By fostering a collaborative relationship, manufacturers and nearby CMM inspection experts can overcome challenges and achieve optimal results in component quality assurance.

0 notes

Text

Exploring Nearby CMM Inspection Services: Precision Measurement at Your Doorstep

In today's fast-paced manufacturing landscape, precision is paramount. To ensure products meet exacting standards and tolerances, Coordinate Measuring Machine (CMM) inspection services have become a critical component of the quality control process. This article delves into the world of CMM inspection services, highlighting their significance, benefits, and how they bring precision measurement right to your doorstep.

Table of Contents

Introduction

What are CMM Inspection Services?

The Importance of Precise Measurements

Benefits of Nearby CMM Inspection Services

How CMM Inspection Services Work

Advanced Technology in CMM Inspection

Industries That Rely on CMM Inspection

Choosing the Right CMM Inspection Provider

Ensuring Accuracy in Manufacturing

Increasing Efficiency Through CMM Inspection

Future Trends in CMM Technology

Common Misconceptions about CMM Inspection

The Cost-Effectiveness of CMM Inspection

Frequently Asked Questions (FAQs)

Introduction

In the world of manufacturing, where tolerances are often measured in micrometers, even the slightest deviation can lead to costly defects and recalls. This is where CMM inspection services step in to save the day.

What are CMM Inspection Services?

Coordinate Measuring Machine (CMM) inspection services involve the use of advanced measuring instruments to assess the dimensions and geometric attributes of various objects. These services utilize precision tools to ensure that components meet design specifications with utmost accuracy.

The Importance of Precise Measurements

Precise measurements are the cornerstone of quality manufacturing. Even a minuscule error can compromise the functionality and safety of a product. CMM inspection services play a pivotal role in verifying the dimensional accuracy of intricate parts, guaranteeing that they adhere to required specifications.

Benefits of Nearby CMM Inspection Services

Time Efficiency: Having CMM inspection services nearby accelerates the production process, as measurements can be taken promptly, minimizing downtime.

Cost Savings: Local services translate to reduced shipping costs and shorter lead times, contributing to overall cost savings.

Real-time Analysis: Nearby services allow for real-time analysis of measurements, enabling quicker decision-making.

How CMM Inspection Services Work

CMM inspection involves the use of specialized machines equipped with touch probes and optical systems. These machines scan the object's surface, collecting data points that are then analyzed to determine dimensional accuracy.

Advanced Technology in CMM Inspection

Modern CMM inspection services incorporate cutting-edge technology, such as laser scanning and non-contact measurement techniques. These advancements enhance measurement speed and accuracy.

Industries That Rely on CMM Inspection

CMM inspection services cater to a wide array of industries, including aerospace, automotive, medical devices, and electronics. Any sector that requires precision components benefits from CMM technology.

Choosing the Right CMM Inspection Provider

When selecting a CMM inspection provider, consider factors like their experience, range of services, technology used, and reputation within the industry.

Ensuring Accuracy in Manufacturing

CMM inspection significantly reduces the likelihood of defective products reaching consumers, maintaining brand reputation and customer trust.

Increasing Efficiency Through CMM Inspection

By identifying discrepancies early in the manufacturing process, CMM inspection helps streamline production, reduces waste, and minimizes rework.

Future Trends in CMM Technology

The future of CMM inspection points toward even faster, more accurate measurements through artificial intelligence integration and automation.

Common Misconceptions about CMM Inspection

Contrary to misconceptions, CMM inspection is not only for large-scale production but is also relevant for small-batch and custom manufacturing.

The Cost-Effectiveness of CMM Inspection

Despite initial investment costs, CMM inspection services ultimately lead to significant cost savings by preventing defects and reducing rework expenses.

Frequently Asked Questions (FAQs)

What is the role of CMM technology in aerospace manufacturing? CMM technology ensures precise measurements of aerospace components, vital for flight safety.

Can CMM inspection be performed on-site? Yes, many CMM inspection providers offer on-site services for added convenience.

Is CMM inspection suitable for complex, non-standard parts? Absolutely, CMM technology excels at inspecting intricate and custom parts.

How does CMM inspection contribute to quality control? CMM inspection identifies deviations from design specifications, maintaining high-quality standards.

Are CMM inspection services only for large corporations? No, businesses of all sizes benefit from CMM inspection, given its role in precision manufacturing.

In conclusion, CMM inspection services play a pivotal role in maintaining the integrity and precision of modern manufacturing processes. With advanced technology and local accessibility, businesses can ensure their products meet the highest quality standards. By embracing CMM inspection, industries pave the way for innovation, efficiency, and a future marked by accurate measurements and impeccable products.

#CMM Inspection services near me#Accredited CMM Lab#Third Party CMM Inspection#Dimensional Measurement#First article Inspection Canada

0 notes

Text

Unveiling the Power of Reverse Engineering Services

Introduction: In today's fast-paced technological landscape, reverse engineering has emerged as a valuable tool for innovation, product enhancement, and troubleshooting. By dissecting and analyzing existing products or software, reverse engineering enables companies to gain deeper insights into their competitors' offerings, optimize their own products, and uncover new possibilities for improvement. In this blog post, we will explore the world of reverse engineering services and how they can benefit businesses across various industries.

What is Reverse Engineering? Reverse engineering is the process of dismantling and studying a product, software, or system to understand its design, functionality, and operation principles. It involves deconstructing the object of interest, analyzing its components, and reconstructing a detailed model or documentation of the original product. This process allows businesses to comprehend the inner workings of a product without relying on the original manufacturer's information.

The Applications of Reverse Engineering: a. Product Improvement and Innovation: Reverse engineering enables companies to gain a comprehensive understanding of their competitors' products. By evaluating their features, materials, and manufacturing techniques, businesses can identify areas for improvement or innovation in their own products.

b. Obsolescence Management: In industries where original equipment manufacturers (OEMs) discontinue products or no longer provide support, reverse engineering helps companies extend the lifecycle of their existing assets. By reverse engineering obsolete parts or systems, businesses can recreate and maintain them, reducing dependency on the OEM and ensuring operational continuity.

c. Interoperability and Compatibility: Reverse engineering plays a crucial role in achieving compatibility between different systems, especially in the software industry. By reverse engineering proprietary file formats or protocols, companies can develop solutions that seamlessly integrate with existing platforms or products.

d. Counterfeit Detection: Reverse engineering is instrumental in identifying counterfeit products. By examining and comparing genuine products with suspected counterfeit ones, businesses can uncover discrepancies in design, materials, or manufacturing processes, helping protect their brand reputation.

The Process of Reverse Engineering: a. Scanning and Digitization: Reverse engineering often begins with 3D scanning, where the object is meticulously captured in digital form. This process generates a detailed point cloud or polygon mesh that serves as the foundation for further analysis.

b. Analysis and Reconstruction: Engineers then dissect the scanned data to understand the object's structure, dimensions, and functionalities. This step involves employing various tools and techniques to reconstruct a virtual model, such as CAD (Computer-Aided Design) software or finite element analysis.

c. Documentation and Optimization: Once the virtual model is created, engineers document the findings and produce detailed technical specifications, assembly instructions, or performance analyses. This information can be utilized to optimize the existing product, design variations, or develop entirely new solutions.

Choosing a Reverse Engineering Service Provider: When selecting a reverse engineering service provider, businesses should consider the following factors:

Expertise and experience in the specific industry or technology.

Access to advanced scanning and analysis tools.

Intellectual property protection measures and confidentiality agreements.

Ability to deliver accurate and comprehensive documentation.

Track record of successful reverse engineering projects.

Conclusion: Reverse engineering services have become indispensable for companies seeking to stay competitive in a rapidly evolving marketplace. By harnessing the power of reverse engineering, businesses can enhance their products, improve interoperability, manage obsolescence, and safeguard their intellectual property. By partnering with a reliable and experienced reverse engineering service provider, organizations can unlock new opportunities for innovation, growth, and market differentiation.

0 notes

Text

0 notes

Text

Achieving Precision in Dimensional Measurement: The Microtec System Advantage

Introduction:

Accurate and precise dimensional measurement plays a critical role in various industries, from manufacturing and engineering to quality control and research. The demand for reliable measurement systems that provide precise and repeatable results has led to the emergence of leading companies specializing in precision dimensional measurement. Among these industry leaders is Microtec Measurement Systems, a renowned laboratory offering state-of-the-art solutions for dimensional measurement. In this article, we will delve into the importance of precision measurement, explore the capabilities of Microtec Systems, and highlight why they are the go-to choice for companies seeking accurate and reliable dimensional measurement.

The Significance of Precision Dimensional Measurement: 1.1. Quality Assurance: Precision dimensional measurement is essential for ensuring the quality and conformity of manufactured parts and components. Accurate measurements enable manufacturers to detect any deviations from specifications, identify potential defects, and maintain consistent product quality.

1.2. Process Optimization: Precise measurements provide valuable insights into manufacturing processes, allowing companies to identify areas for improvement, reduce waste, and enhance efficiency. By monitoring dimensional variations, companies can optimize their processes and achieve tighter tolerances, resulting in improved product performance and customer satisfaction.

1.3. Research and Development: In research and development, precise dimensional measurement is vital for validating prototypes, evaluating design modifications, and conducting accurate analyses. Accurate measurements enable researchers to make informed decisions, ensure product reliability, and drive innovation.

Introducing Microtec Measurement Systems: 2.1. Company Overview: Microtec Measurement Systems is a leading laboratory specializing in precision dimensional measurement. With a rich history and extensive expertise, they offer cutting-edge solutions to meet the measurement needs of various industries.

2.2. Advanced Measurement Technologies: Microtec Systems employs the latest advancements in measurement technology to provide accurate and reliable results. They utilize high-precision instruments, such as coordinate measuring machines (CMMs), optical measurement systems, laser scanners, and vision systems, to capture precise measurements of complex geometries.

2.3. Customized Measurement Solutions: Microtec Systems understands that each industry and application has unique measurement requirements. They offer tailored measurement solutions, collaborating closely with clients to understand their specific needs and provide customized approaches that ensure accurate and meaningful data.

2.4. Expertise and Accreditation: Microtec Measurement Systems boasts a team of highly skilled and experienced metrology professionals. Their experts possess in-depth knowledge of measurement techniques, data analysis, and industry standards. The laboratory is ISO 17025 accredited, ensuring the highest level of quality and adherence to international metrology standards.

Why Choose Microtec Measurement Systems: 3.1. Unparalleled Accuracy and Precision: Microtec Systems’ commitment to accuracy and precision sets them apart. With their advanced measurement technologies and expertise, they can achieve high levels of measurement accuracy, meeting even the most stringent requirements of industries with critical tolerances.

3.2. Comprehensive Measurement Capabilities: Microtec Systems offers a wide range of dimensional measurement services. From 3D scanning and digitization to dimensional analysis and reverse engineering, they possess the capabilities to address diverse measurement needs across various industries.

3.3. Timely and Reliable Results: Microtec Measurement Systems understands the importance of timely results in today’s fast-paced industries. They strive to deliver efficient measurement services without compromising accuracy, enabling clients to make informed decisions promptly.

3.4. Commitment to Customer Satisfaction: Microtec Systems is dedicated to ensuring customer satisfaction. They prioritize open communication, collaborate closely with clients throughout the measurement process, and provide comprehensive reports that are easy to understand, enabling clients to leverage the measurement data effectively.

3.5. Industry Recognition and Partnerships: Microtec Systems’ commitment to excellence has earned them recognition and trust within the industry. They have established partnerships with leading. In the realm of precision dimensional measurement, Microtec Measurement Systems stands out as a trusted and reliable laboratory. Their advanced measurement technologies, customized solutions, and expert team ensure unparalleled accuracy and precision in their measurements. By choosing Microtec Systems, companies can benefit from comprehensive measurement capabilities, timely results, and a commitment to customer satisfaction.

Microtec Systems’ utilization of cutting-edge instruments, such as CMMs, optical measurement systems, laser scanners, and vision systems, allows them to capture precise measurements of complex geometries. Their expertise in various industries and adherence to international metrology standards make them a go-to choice for companies seeking accurate and reliable dimensional measurement.

Furthermore, Microtec Systems’ commitment to customer satisfaction is evident in their open communication, collaboration with clients, and delivery of comprehensive reports. They understand the importance of timely results and ensure that clients receive efficient measurement services without compromising accuracy.

The industry recognition and partnerships established by Microtec Systems further attest to their excellence in the field of dimensional measurement. By choosing Microtec Measurement Systems, companies can have confidence in the accuracy, precision, and reliability of their dimensional measurements.

In conclusion, Microtec Measurement Systems provides a superior solution for companies in need of precision dimensional measurement. Their advanced technologies, customized approaches, and commitment to customer satisfaction make them a trusted partner in ensuring the quality, optimization, and innovation of products across various industries. When it comes to achieving precise and repeatable dimensional measurements, Microtec Systems sets the standard for excellence.

0 notes

Text

CNC Machining Inspection: Ensuring Quality and Accuracy with Microtec Measurement Systems

CNC (Computer Numeric Control) machining has revolutionized the manufacturing industry, providing greater precision and accuracy than traditional methods. However, the success of any CNC machining operation depends on proper inspection and measurement. That’s where Microtec Measurement Systems comes in, offering top-notch inspection solutions for the CNC machining industry.

Microtec’s expertise in CNC machining inspection is based on a deep understanding of the challenges faced by manufacturers. The company offers a range of inspection solutions, including manual and automated measurement systems, to meet the needs of customers in various industries. With its advanced technology and innovative approach, Microtec ensures that CNC machined parts meet the highest quality standards, saving manufacturers time and money by reducing the need for rework.

One of Microtec’s key offerings is its CMMs (Coordinate Measuring Machines), which provide accurate and reliable measurement data for CNC machined parts. These machines are equipped with state-of-the-art sensors and software, allowing for quick and easy measurement of complex geometries. Microtec’s CMMs are also highly customizable, making them suitable for a wide range of applications, from simple dimensional checks to complex form and surface inspections.

Another important aspect of CNC machining inspection is process control, and Microtec offers a range of solutions to help manufacturers achieve it. The company’s inspection solutions provide real-time data on part quality, enabling manufacturers to identify and rectify problems quickly. This leads to greater efficiency, improved quality, and reduced waste, making Microtec’s solutions a valuable investment for any CNC machining operation.

In conclusion, Microtec Measurement Systems is a trusted partner for the CNC machining industry, offering advanced inspection solutions that ensure quality and accuracy. With its commitment to innovation and customer satisfaction, Microtec is poised to continue helping manufacturers achieve their goals for years to come.

0 notes

Text

https://www.microtecsystem.com/about-us/

Microtec Systems is an ISO 17025:2017 accredited dimensional testing company, offering CMM inspections services to various industries. We are a professionally managed company, having over 20yrs of experience in CMM inspection, Metrology, GD&T and SPC.

0 notes