Text

TYPES OF STEELS YOU SHOULD KNOW BEFORE CONSTRUCTION

Life in the era of modernization has grown to be simpler and swifter than it was years before. Time changed, and so the technology! With the introduction of steel, humans started building different structures, making it last for a more extended period. The discovery and use of steel led us to various developments and construction of infrastructures. There are different types of steels used for the construction purpose. Whether you are looking for structural steel or MS Flat, you can choose from the types.

Excellent and robust steel can last up to 50 years, whereas traditional methods and techniques give you a maximum of 17 years of support. We use steel to construct buildings, bridges, and many things, and that is why one should have minimal knowledge of what type of steels goes in making a lasting and robust building. Steel gives durability and longevity, which you keep your construction safe.

Types of Steel for construction:

Structural Steel: This is not just durable but also string, which can be transformed in any of the shapes and just not only I-Beam, L Shape, T, and Z shape. It is very commonly used and gets used in making high rise buildings, skyscrapers and garages, buildings, and bridges. It is fire-resistant, affordable, environment safer, and durable. Structural steel is the most important source in construction. Be it the bridges, buildings or any other large construction, the use of structural steel is essential. One of the reasons why structural steel is widely used for the construction purpose is because it helps in improving the strength of the structure.

Mild Steel: Also known as plain-carbon steel, it contains 2.1% of the carbon constitution by weight. The best example of this mild steel is the MS Flat steel or bars that are heavily used for various manufactures and constructions. It is durable, as well as reliable and flexible. It is made earthquake resistance and widely used in the earthquake-prone areas.

Stainless Steel: It is alloy but with improved corrosion resistance to standard allow steel. The mixture of the components got chromium, molybdenum, and nickel. It also contains 10% extra of chromium by weight, which gives it the perfect properties. Steel Saria is one of the best steels that can be given and used as an example of stainless steel. There are more than 60 of the different kinds and division of stainless steel.

Light Gauge Steel: This steel tends to provide a wide range of benefits such as faster construction, cost-effective, secure handling, energy-efficient, and much more. This type of steel gets used for modular structures; light framed building, walls, and more. There are also many other uses of light gauge steel, which can be readily available.

In recent years steel has started gaining much popularity with its numerous benefits that it tends to provide. In this world, there are so many wonders that are built-in support of steel, making it to stand tall for years and generations to come. Steel can be given any shape and size and are easy to work with and around, which makes it the best for any constructions.

It may be a mixture of iron and carbon, but with the 3,500 various types and grades of steel, the construction work becomes quite easy. It is important that you do the best research before you finalize the steel to use for the structure building.

Make your dream home or construction after choosing the right steel that will be value for money. This will help in keeping the structure strong for long.

0 notes

Photo

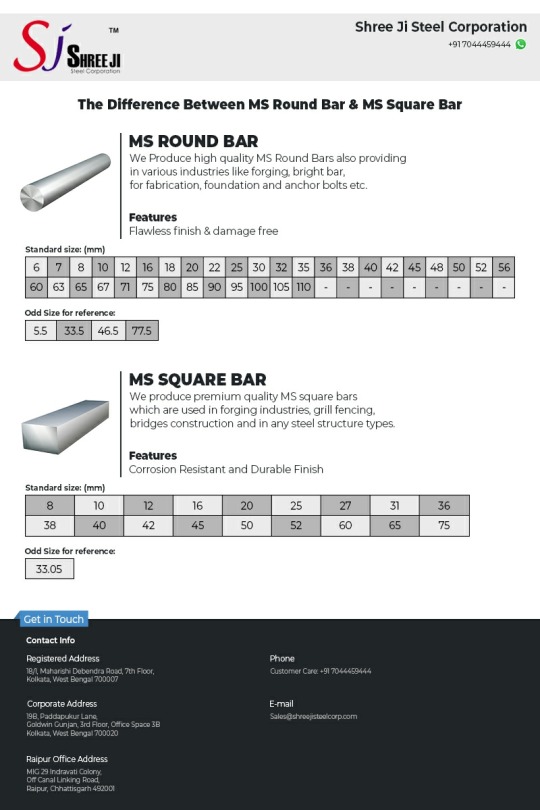

The Difference Between MS Round Bar & MS Square Bar

0 notes

Text

Top TMT Bars Manufacturers In The Construction Industry

TMT bars are one of the mostimportantmechanisms of any building constructionthereforeselecting the right TMT bar manufacturer is very critical for any construction development. The iron and steel industry play animportant role in developing countries like India and hence TMT bars and steel manufacturing places the groundwork of industrial growth and civil expansion in our country. The growth of Indian steel industry has been directed by the accessibility of raw materials such as iron ore and cost-effectivelabor, internally. According to the Economic Survey, the manufacturing of steel will touch 128.6 million tones by 2021. The iron and steel industry areobserving anincrease in the investment by objects from other segments and global players. All of these factors have fortified the development of a number of TMT bar constructers in India.

Why You Need TMT Bars?

TMT bars are one of them most vital construction resources that are broadly used for multistoried high rise, homes, bridges and other civil engineering structures. This is because TMT bars guarantees high strength to the constructions and develop their durability. TMT bars can efficientlyendure any kind of weight and load, consequently, procuring the structure from any further damages.

TMT Bars are Thermo Mechanically Preserved steel bars. These bars are subject to Thermo-Mechanical treatment. The procedurecomprises passing the steel wires through Tempo core water cooling system once they are rolled in the Rolling Stand Mill. It hardens the outer layer of the TMT bar while maintaining the inner core soft. While manufacturing homes and other structures. The TMT bars are continuallyopen to water. One of the majorbenefits of using TMT bars for building your home is that the TMT bars do not need the extraprocedure of cold rotation which makes the bars erosionresilient.

TMT bars are broadly used in the formation buildings and other distinct structures. These bars are used to strengthen the concrete. Concrete has good compressive strength but poor tensile strength. This is why TMT bars are essential for added reinforcement. TMT bars forms a sturdyconnection with the concrete. Also, it has thermal competence which makes the TMT bars resilient to fire accidents.

TMT bars are favored as a construction material for many reasons. Their exclusive properties have made them perfect for numerous types of construction work. The properties of TMT bars comprise superior strength, super ductility, and weldability. Furthermore, TMT bars are earthquake resilient. They have a ferrite-pearlite inner core which allows them to endure any seismic activity, therefore, offers permanency and sturdiness to any solid structure. Construction builders, workers and people typicallydesire TMT bars as they can fight high temperature and are supple in nature. They can be molded into any shape. This makes them suitable for any type of solid structure such as dams and bridges. The finest part of using TMT bars for construction is that they are very cost effective when related to other steel bars and gives 20% sturdier structure with the same amount of steel. This makes them a reasonable and valuable option for constructing homes and for other engineering projects.

Few main attributes of the TMT Bars are:Uniform and Parallel Rib Pattern, High UTS/YS, HYQST Technology, Superior Weldability: Low Levels Of Carbon, Corrosion Resistant

Here are few Best TMT Bars Manufacturers in India

There’s a huge competition in the Indian steel market because of the easy availability of raw materials and less expensive work force, in the country itself. Let us view at some of the best manufacturers of TMT bars in India:

· TATA Tiscon.

· Jindal Panther TMT bars(JSPL)

· Electrosteel Steels Limited

· Rathi Steel Group

· Shyam Steel

· Amba Shakti

· Shree Steel Corp.

0 notes

Text

The Difference Between ms round bar and ms square bar

MS Round bar looks like a cylindrical long metal bar stock having a lot of commercial and industrial applications. The most usual application is shafts. Average diameters start from 1/4″ all the way up to 24″. Other sizes may be available too. Round Bar is readily available in few metal types that include Cold-Rolled Steel, Hot-Rolled Steel, Stainless Steel, Aluminum and more. Round bar can be bought at any metal store location or online. It can be customized and made to any required specification.

Steel Round Bars

Steel round bars are available incold rolled and hot rolled.

Hot rolled round bar is normally used for areas like construction where complete and exact dimensions are not a priority. On the contrary, cold rolled round bar is used for areas where a superior surface complete and precise dimensions are necessary. Some usual applications of steel round bar include frameworks, supports, shafts, braces, and axles.

Stainless Steel Round Bars

Stainless steel round bars are extremelyerosionresilient. The stainless steelcan be used in chlorine bearing environments or alkaline solutions and will allow high levels of acidity.

Aluminum Round Bars

Aluminum round bars acquire light weight and durableerosion resistance, while being easy to use for machines and cut. Usual applications of aluminum round bar comprise supports, shaft,trim,dowels and pins.

Brass Round Bars

Brass round bars are used whenelectrical conductivity, strength, corrosion resistance and spark resistance are important. Brass is easy to machine and has an attractive sheen when is polished. Some examples of brass bar applications are marine hardware, instruments, fasteners and fittings.

Application of round bars-

Nursing home, college, institute, class, business center, University, housing society, corporate area, housing projects, school, project site, factory, companies, Work station, service center, back office, call center, commercial office. Security cabin, pane try, cafeteria, go down, work shop, Residential, Home, flat, office, commercial building, Bathroom, Showroom, Exhibition, Warehouse, Hotel , Kitchen, Bungalow, Hospital, Laboratory, Banks, Resorts, Restaurants, plaza’s, Salons, Stall, Beauty Parlors, Departmental Store, Nri Home, Computer Institutes, Health Club, Kids Room, Industrial building, lodge, resort, hostel, public utilities, shopping mall, etc.

Mild Steel Square bar and it’s uses

Mild Steel Square Bar is a mild steel solid bar, hot rolled, with radius corners that are ideal for all essential applications,manufacturing, repairs and general fabrication. Steel Squares are extensively used inagricultural implements, industrial maintenance,ornamental iron work, transportation equipment, fencing, artwork, etc. This steel shape is simple to cut, weld, and machine with the right knowledge and equipment. Metals Depot stocks lot of sizes of steel square at reasonable prices in ready to deliver pre-cut and mill lengths or can be ordered online just what you require custom made in small or large quantity.

MS square bars also called Mild Steel Bars, are mostly used in constructing and forming gates, frames, fences, trailers, etc.

It is also used to construct heavy-duty manufacturing units or to support the structure of the huge machines that are found in the factories. Mild steel bars are used when one requires firmness to a structure made of metal. They effortlesslyare placed under the machine and give the best firmness of all the materials. You can see these bars typically used in applications that are constructed to last for a long period of time. In layman’s language, these bars are used to fix semi-permanent projects.

0 notes

Text

Reasons Why Structural Steel Is Such a Popular Building

Every part of Buildings involves steel that helps in strengthening them, from houses to parking lots, from schools to skyscrapers. Steel is also used on roofs and as covering for exterior walls such as MS Flat, Steel Saria, TMS bars etc. Hence, one of the most important steel using industries is construction industry, that includes almost 50% of world steel demand.

Purpose of using structural steel in building constructions

Safe and Sturdy: Structural steel fabrication is a safe procedure that doesn’t cause any destruction to the environment when it is taken care by professional fabricators. Structural steel is aextremelyresilient material. Being an inorganic material, it is not affected by termites, insects, fungus, mold, etc. To a certain extent, structural steel structures are fire resistant too. Also, it is unaffectedby natural disasters like earthquake, flood, lightning, etc.

Highly Long-lasting:It is a strong material when it comes to housing construction. Its strength and potentials do not deteriorate with the years. Structural steel structures do not twist or break due to hefty load. Your house will stayrobust and attractive for years as structural steel doesn’t decay, deteriorate, or even crack.

Speedy Buildings:No one can patiently wait for a long time to move into their newly built homes. Due to the expectedness and correctness of its components, your structural steel residential property can be created quickly. Structural steel components are pre-built by the fabricators and then traded to the construction site. This fabrication procedure doesn’t take days or weeks, and hence, you can get your house prepared in a short period of time.

Extremely customizable and multipurpose: Structural steel has a great strength to weight ratio. It needs less support to build vast structures, thus giving you a large house. Also, it is very flexible and can be made-up according to your design requirements. Later, you will not have to think numerous times about your budget before striking down a wall or pillar. Plus, you also may not have to think before enhancingby adding a new segment in your house. The renovation procedure will be stress-free like never before if you pick structural steel over other materials.

Cost effective and Eco-friendly: The cost of structural steel has become economical in the last 15 years. Use of structural steel in residential construction can be extremely cost effective as compared to concrete and wood. These structures need low maintenance costs. Not only this, reparation and additional costs also decrease when you have a house made of structural steel. Also, structural steel can be recycled several times without adding to the pollution levels. Which is why structural steel is known as a green material.

This shows that structural steel fabrication procedure is saves time, is economical and accurate. Usage of structural steel will always be an efficient and a long-term investment for your house

0 notes

Photo

TMT Bar and Metal Angle | Shree Ji Steel Corporation, Kolkata

0 notes

Text

Importance of Steel Channels

MS channels are one of the most prevalent products for Stainless Structures. The use of stainless-steel channels is becoming very popular in numerous industries because of the obtainability of different sizes, grades, lengths, and finishes. The capabilities and product range of Stainless Structurals plays a very large part in this upsurge in the market. Stainless steel channels are the answer for any designs and structures needed for eroding or harsh environments.

Uses of MS channels include platforms, skids, tower supports, rails, stop-logs, guides and more. Some of the many industries that you can find our stainless-steel channels comprise building and construction, architecture, oil and gas, chemical plants, food processing.

We at Shree ji Steel Corporation deal in an extensive collection of MS Channels. We source them from some of the dependable vendors of the market. These MS channels are produced using first-class mild steel. Mild Steel channels are extensively utilised for structural support in construction works. We deliver these channels to our patron at most competitive prices in the market.

Steel Saria are one of the most widely used materials used in the construction industry. With an exclusive metallurgical procedure that binds work hardening along with heat-treatment to generate robust and high strength bars from low-carbon steel.

They can boast of high thermal stability and can resist temperatures ranging from 400 to 600 degrees Celsius. Thus, they are flawless for resisting fire and provide safety.

At Shree Ji Steel Corporation we are one of the renowned firms in the domain, involved in providing a broad spectrum of Steel Saria. TMT Rod/Saria find its wide usage in building construction. These high strength steel bars or concrete rebars, improve the safety and durability of the structures and prevent damages as they are precisely engineered under experts’ surveillance, using high-grade metal alloy at well-developed production unit.

0 notes

Text

Rising Demand OF TMT Steel & TMT Bars

TMT bars or Thermo-Mechanically Treated bars are high-strength reinforcement bars having a hard outer core and a soft inner core. The very first step of the manufacturing process involves passing the TMT steel wires through a rolling mill stand.

TMT bars are one of the most significant construction materials that are extensively used for building earthquake-resistant structures. Earthquake resistant TMT bars are provided with this ductility and elongation characteristics that defines their structure. TMT bars feature a composite metallurgical structure, with a sturdy exterior martensite surface and a soft ferrite-pearlite core. This distinguishing factor in them remains constant whichever way they are manufactured, either through the ‘Thermax’ or through the ‘Tempcore’ processes. Earthquake resistance is incorporated in any structure by the action of the core allowing mild tilting and the exterior surface bringing it back to its original position during seismic activity.

Global demands for steel ex-China are expected to rise by 1.8% this year. Apart from that, the implementation of GST (Goods and Service Tax) from April 2017 will further improve steel demands in the country. Implementation of GST is expected to ease processes and increase transparency along with increasing public participation in both urban and rural construction. This is resulting in a rapid growth for steel and TMT bars.

We at Shree ji Steel Corporation are a renowned firm in the domain, involved in providing a broad spectrum of TMT Bars. TMT Rod/Saria find its wide usage in building construction. These high strength steel bars or concrete rebars, improve the safety and durability of the structures and prevent damages as they are precisely engineered under experts’ surveillance, using high-grade metal alloy at well-developed production unit.

Shree Ji Steel Corporation is the leading manufacturer, supplier, trader, importer and exporter. Our array of products that are most well-known in the market comprise of Iron & Steel and Hardware Goods.

1 note

·

View note