Don't wanna be here? Send us removal request.

Text

Why SINAMICS G120 is the Preferred Choice for Industrial Drives

In this day's competitive industrial scenario, everything has to run faster, smarter, and energy-efficiently. The kind of drive system you choose will determine if operations succeed in manufacturing, processing, or materials handling. That has somewhat forced many industries worldwide to consider the SINAMICS G120 Drive of Siemens: a drive system that needs to possess a high degree of versatility and performance to answer current automation needs.

Learn more, How SINAMICS G120 Supports Energy-Saving in Industrial Applications

What is SINAMICS G120?

The Drive SINAMICS G120 is a frequency inverter that is modular and is meant for securing the speed and torque of three-phase motors. With such freeway capabilities, it found applications in a vast array of industrial processes: pumps, fans, conveyors, compressors, mixers, and others.

What distinguishes Drive G120 from its competitors is the smart idea behind it: basically, this means it consists of two main components, the Control Unit (CU) and the Power Module (PM), which can be combined and replaced separately. This makes it an extremely flexible choice, easily integrated into existing systems.

Why Choose the SINAMICS G120 Drive?

Some reasons why various industries choose this drive system include:

Energy Efficiency: Regenerative feedback and ECO mode assist in keeping electricity expenses low.

Integrated Safety Functions: Safe Torque Off (STO) and other safety features protect the operator and ensure compliance with international standards.

Seamless Communication: Through communications such as PROFINET, PROFIBUS, and Modbus RTU, it can be interfaced into most automation networks.

Reliable Performance: Superior motor control is provided for constant and variable torque applications.

Drive G120 in Real-Life Application

User industries report increased system efficiency, with reductions in maintenance and performance, occurring with the installation of the Drive SINAMICS G120. Thus, in water treatment plants or automated warehouses, the drive keeps operations running smoothly and reliably.

For example, applications that require conveyors with constant speed change between different loads will benefit greatly from the Drive G120 torque controlling capability to minimize mechanical wear and maximize output.

Simple Setup and Maintenance

The simple web server and powerful diagnostics make for a very user-friendly interface for the SINAMICS G120. Parameterization, monitoring, and fault diagnostics can also easily be carried out by your maintenance crew within a very short time, with or without specialized training.

Another aspect of the modular design is that the components can be individually replaced, thereby reducing downtime in the maintenance process or when upgrading.

Final Thoughts

If the automation system demands enhanced drive solutions, then the SINAMICS G120 by Naksh Technology Solutions LLP can be regarded as the choice facing modern times. It has been crafted to meet contemporary industrial requirements-powerfully, modularly, and safely. Siemens engineered it to over-deliver: from Drive G120 flexible configuration to seamless integration with your existing PLC or HMI setup.

Want to upgrade or optimize your system? Then the SINAMICS G120 Drive is just what your operation needs.

0 notes

Text

Why SINAMICS G120 is a Game-Changer in Industrial Drive Systems

In this fast-moving world of industrial automation, a fast response is a must and so is flexibility. Be it packaging machines, conveyors, textile machines, or HVAC systems, the user will want a reliable solution that manages motion control accurately. That is where SINAMICS G120 comes in: one of the most versatile variable frequency drives aimed at being amongst the best in performance, safety, and convenience of integration.

Learn more, How SINAMICS G120 Supports Energy-Saving in Industrial Applications

What Makes SINAMICS G120 So Special?

There are so many VFDs around, but the G120 Drive is an intelligent power and adaptability system. With modularity at the heart of design, the Drive G120 allows the control unit and power module to be chosen independently so as to best meet the application requirements. This modularity brings minimal downtime and easier maintenance, rendering it extremely attractive to OEMs and system integrators.

Key Capabilities of the SINAMICS G120:

The very high energy efficiency is gained through regenerative feedback and eco-mode.

Safety Integrated Functions including Safe Torque Off (STO) and Safe Stop (SS1).

Modular design that is flexible and can be notified for configuration as well as upgrading.

Large power range from 0.55 kW to 250 kW.

Interfacing with full integrity with PROFINET, PROFIBUS, and other common field buses.

Whether retrofitting older systems or designing new ones from scratch, the SINAMICS G120 Drive assures that your application becomes more smooth, smarter, and efficient to run.

G120 Drive in Motion

Suppose a bottling plant requires speed and torque control across multiple conveyor belts. With Drive G120, operators optimize performance, limit energy consumption, and observe system health in real-time, meaning throughput is increased, downtime is reduced, and operations are rendered sustainable.

Easy Integration and Maintenance

The web server and diagnostic tools of the SINAMICS G120 allow for real-time observation and quick troubleshooting. Having one spatially on-site or remotely accessing the system would enable issues to be rectified smoothly, assuring operations with minimum intervention from the operator.

Final thoughts

For industrial requirements, if a drive system needs to be reliable, intelligent, and readily functional, the SINAMICS G120 by Naksh Technology Solutions LLP is a future-proof solution that grows as your systems progress. The SINAMICS G120 Drive can deliver energy efficiency, safety compliance, and integration.

Ready, then, to get your automation down with Drive G120? See for yourself how this could expedite your business operations and productivity.

0 notes

Text

Explore energy-efficient solutions with SINAMICS G120 – ideal for industries seeking lower power usage, better control, and sustainable operations.

0 notes

Text

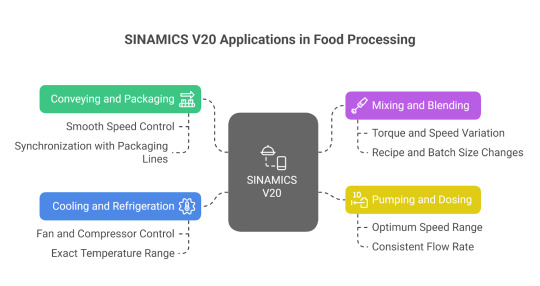

The Role of SINAMICS V20 in Smart Food Manufacturing

As Industry 4.0 evolves, food production is changing with new technologies. Companies are focusing on automation, efficiency, and sustainability. One of the main technology helping with this change is the SINAMICS V20, a Siemens drive that plays a big role in smart food manufacturing.

This blog explores the discussion on how the SINAMICS V20, a Siemens drive, is shaping food processing, packaging, and logistics, with Naksh Technology spearheading the implementation of these solutions.

SINAMICS V20: The Backbone of Basic Automation

The SINAMICS V20 is a small, cost-effective AC drive for the basic motion control application. Owing to its versatility and simplicity, it perfectly suits the food industry whose requirements vary from conveyor systems to mixers and pumps. With power ratings from 0.12 kW up to 30 kW, it helps execute tasks in the food processing line that demand smooth and energy-efficient operation.

Also learn more about How SINAMICS V20 Boosts Operational Flexibility In A Food Processing Plant.

Why Smart Food Manufacturing Needs Advanced Drives

Modern food manufacturing is all about precision and flexibility, apart from soaring speed. With consumer preference changes and ever-tightening regulations, manufacturers find themselves in a fast lane to quickly adapt to new recipes, packaging formats, and safety standards. Industrial automation powered by variable frequency drives (VFDs) such as the Siemens VFD V20 becomes essential.

Key Features of SINAMICS V20 in Food Manufacturing

Easy Installation and Commissioning: The SINAMICS V20 can be mounted either with push-through mounting or wall mounting, allowing for fast installation and side-by-side configuration to save on-floor space on crowded factory floors.

Energy Efficiency: It helps food manufacturers reduce their energy consumption by about 60%, a vital parameter for sustainable production, through automatic flux reduction and the ECO and hibernation modes.

Robustness and Reliability: With a unique cooling design, conformal-coated PCBs, and a vast voltage range, the drive is engineered to work within the rough environment of a food factory to minimize downtime and maintenance expenses.

Flexible Control Modes: The drive facilitates process enhancements through various control modes such as V/f, V2/f, FCC, and multi-point, according to differing machine requirements.

The Siemens Drive Advantage in Food Processing

Siemens drives are known for their integration and compatibility with automation systems. Siemens Sinamics family, including SINAMICS V20, is easily connected through PLCs, sensors, and cloud monitoring platforms. Such connectivity is important for smart food manufacturing, whereby it allows real-time process monitoring, predictive maintenance, and making decisions based on data.

Applications of SINAMICS V20 in Food Manufacturing

1. Conveying and Packaging

The movement of raw materials and finished goods must be smooth in food plants. SINAMICS V20 drives conveyors through smooth speed control to ensure the delicate products are gently handled and synchronized with packaging lines to reduce wastage and maximize throughput.

2. Mixing and Blending

Mixers and blenders require speed regulation with precision for the sake of consistent product quality. SINAMICS V20, therefore, supplies required torque and speed variation that is reactive to sudden recipe and batch size changes.

3. Pumping and Dosing

Dosing ingredients and fluids accurately forms the foundation of food production. The SINAMICS V20 ensures that the pumps are operating at speeds in the optimum range, thus saving energy and delivering a consistent flow rate for quality assurance.

4. Cooling and Refrigeration

Temperature maintenance is essential for food safety. The SINAMICS V20 controls the fans and compressors in a refrigeration system, ensuring minimum power consumption while maintaining an exact temperature range.

Naksh Technology: Your Partner in Smart Automation

Naksh Technology is leading provider of Siemens drive solutions with an area of expertise in the integration and support of SINAMICS V20 with food manufacturing plants. With the best knowledge in industrial automation, Naksh Technology guarantees trouble-free implementation together with design, up to after-sales service, enabling the food producers to realize the full power of Siemens VFD V20 and indeed of the entire Siemens Sinamics offering.

Benefits of SINAMICS V20 for Food Manufacturers

Cost Savings: The engineering, commissioning, and operational expenses are very low considering the drive's simplicity and efficiency.

Sustainability: Integrated energy-saving mechanisms support green manufacturing initiatives and set the path for global sustainability programs.

Scalability: SINAMICS V20 can be simply scaled onto any other production line whether small or big.

Future-Ready: With the digital connectivities, the drive is ready to integrate into the Industry 4.0 scenario for cloud-based analytics and remote monitoring.

Why Choose Siemens VFD V20 from Naksh Technology?

Naksh Technology, with its vast expertise in deploying SINAMICS V20, provides food manufacturers:

Tailored automation solutions for specific food industry challenges.

Reliable technical support and training for maintenance staff.

Access to the latest Siemens Sinamics innovations for continuous improvement.

Conclusion

The SINAMICS V20 acts as a green, smart, and efficient food manufacturer. As changes take place in the food industry, Naksh Technology and the Siemens drive solutions such as the Siemens VFD V20 stand for your operations, to keep them competitive, flexible, and future-ready. Go industrial in automation with Siemens Sinamics and change your food manufacturing journey. Contact us for more information!

0 notes

Text

Picture a food processing facility where every single machine responds to the demand, conserves energy and functions with ease. Designed with flexibility and rock-solid energy-saving Features, the SINAMICS V20 enables food plants to reconfigure faster and run more efficiently.

0 notes

Text

Learn how Siemens HMI improves airport baggage handling system through real-time control, better automation, and enhanced operational efficiency.

0 notes

Text

Siemens Drive: Powering Precision, Efficiency, and Innovation in Industry

In a fast-moving arena where industrial automation and motion control essentially control the producibility and manufacture of goods, the Siemens Drive family has become the microscopy for reliability and performance and flexibility. Be it to manage the manufacturing line or optimize energy usage in a facility or offer smooth motion control for robotics, Siemens solutions provide everything for drives, such as Siemens VFD Drive and Siemens Servo Drive.

Understanding Siemens Drive Technology

Siemens Drives are essentially very advanced electronic devices that control motor speed, torque, and direction. These are indispensable in modern industries for driving motors with precision and also prescribe energy efficiency and ease of integration with automation systems. A categorization of Siemens Drives will show them classified as:

Variable Frequency Drives (VFDs).

Servo Drives.

DC Drives.

All of them are tailor-made to suit specific applications so that industries can find their perfect match according to their operational convenience.

Siemens VFD Drive: Versatility and Energy-Efficient

A Siemens VFD Drive control a standard AC motor by changing the motor's speed and torque through varying its frequency and voltage. The flagship SINAMICS series comprises various models like the G120 and S120, all known for the vast degree of versatility and application of very advanced technologies.

Key Features of Siemens VFD Drives

Energy Savings: By varying motor speeds in tandem with process requirements, Siemens VFD Drives enable heavy industries to significantly curb their electricity consumption and operational cost.

Advanced Communication: The drives stand behind the new communication protocols such as Profinet, Modbus, and Ethernet/IP, ensuring real-time data exchange and integration with automation systems.

Robust Construction: Siemens VFD Drives are built to function in harsh industrial environments, and there are variants with IP65 protection for water and dust.

Simple to Operate: An operator is guided intuitively past all steps of configuration, commissioning, and diagnostics by means of SINAMICS Startdrive within the TIA Portal.

Safety: Features such as Safe Torque Off (STO) and advanced diagnostics enhance safety and reliability in operation.

Applications of Siemens VFD Drives

Siemens VFD Drives have found their application in:

Pumps, fans, and compressors

Conveyor systems and mixers

HVAC systems

Water/wastewater treatment

Renewable energy applications (wind turbines, solar trackers)

With their adaptability and energy-saving potential, they become a must-have for any industry striving to implement the best possible solutions for performance improvement and sustainability planning.

Siemens Servo Drive-Perfect and Dynamic Control

Where high levels of accuracy, speed of response, and complexity of motion are involved, the Siemens Servo Drive is the first choice. The SINAMICS S210 and S120 series are developed for the most demanding tasks in robotics, packaging, CNC machines, and multi-axis motion control.

Some Key Attributes of the Siemens Servo Drives

Precision: The drives shall have real-time feedback and adaptive control systems, thus ensuring that motors and machinery are perfectly synchronized.

Dynamic Performance: These Siemens drives perform well in application areas where speed of acceleration and deceleration as well as precision in positioning are of essence.

Multi-axis Capability: The drives also have the ability for the control of complicated coordinated movements across multiple axis, useful for robotics and automated assembly line operations.

Easy Integration: Made for integration with the Siemens automation platform, in this way ensuring easy engineering and commissioning.

Applications of Applications of Siemens Servo Drives

Robotics and pick-and-place systems

Packaging and labeling machines

CNC machining centers

Automated assembly lines

Siemens Servo Drives offer speed and responsiveness tailored for contemporary, high-speed manufacturing.

Why choose Siemens Drives?

All-Inclusive Portfolio: From simple motor control to the most sophisticated motion solutions, Siemens offers drives for every industry and every application.

Integrated Automation: Siemens Drives also integrate very smoothly with PLCs, HMIs, and SCADA, allowing one control and monitoring platform.

Warranty and Support: With the seal of global acceptance of Siemens, these drives are furnished with sturdy materials to ensure durability and long-lasting performance.

Scalability: Modular construction offers the possibility to upgrade and expand easily along with an increase in operational needs.

Selection of a Correct Siemens Drive

According to your application needs:

For energy savings and general motor control, a VFD Drive by Siemens should be the best choice, for example, the SINAMICS G120.

High-precision motion and multi-axis tasks require the application of a Siemens Servo Drive such as SINAMICS S120 or S210.

For legacy systems or heavy-torque DC applications, Siemens provides DC drives in ample varieties.

When selecting a drive system, consider aspects such as motor type, load, required precision, and integration needs.

Conclusion: Partner with Naksh Technology Solutions LLP

To harness the true capability of Siemens Drive technology, it comes almost as a necessity to have an informed and a reliable partner by your side. Naksh Technology Solutions LLP deals in Siemens automation products, providing expert assistance in genuine solutions and continuous support through the journey of your drive-related needs. Whether you require a Siemens VFD Drive for energy efficiency or a Siemens Servo Drive for precision motion, Naksh Technology Solutions LLP will ensure smooth integration and the best performance of your installation.

Make Naksh Technology Solutions LLP your preferred partner and let the innovation, reliability, and efficiency brought about by Siemens Drives become a reality in present-day industry.

0 notes

Text

How Siemens Drives Save Energy in HVAC and Chiller Plants

Discover how Siemens Drives enhance energy efficiency in HVAC and chiller plants. Learn about their advanced technology, cost-saving benefits, and why Siemens Drives are the smart choice for sustainable building management.

0 notes

Text

SINAMICS G120: The Modular Drive Revolutionizing Industrial Automation

The fast-paced development in industrial automation emphasizes the requirement for solutions that are stout-and-sturdy and flexible enough to accommodate various operational needs. SINAMICS G120 is a renowned workhorse of a modular drive system, designed to offer high performance, energy efficiency, and the greatest versatility for a wide range of industrial applications. This vast overview aims to cover the key elements, functionalities, advantages, and other components with emphasis on the drive G120 architecture and the core G120 power module.

What is SINAMICS G120?

In essence, the SINAMICS G120 is a VFD system designed as modular control of variable frequency speed. These VFDs allow motor speed adjustment according to the demanded application, thereby achieving energy savings. The modularity actually means that the users are able to pair different control units and power modules according to their application requirements.

The drive system finds widespread use in conveyor systems, compressors, pumps, fans, and the like, providing a versatile solution to industries such as automotive, textile, packaging, and general machinery building. Having power ratings high enough to cope from 0.55 kW to 250 kW, and voltage variants of 200V, 400V, and 690V, the SINNAMICS G120 stands to carry the load in practically all working conditions.

Also Read, Your Go-To Guide for SINAMICS G120 Drives

Features of the SINAMICS G120 Drive:

Modular Design: Thanks to modularity in the SINAMICS G120, the control unit and the power module can be selected and replaced independently for customization, scalability, and maintenance.

Wide Power Range: From small pumps and fans to heavy-duty machines, power modules from 0.55 kW to 250 kW are available.

Energy Saving: Integrated functions for energy saving, regenerative energy recovery, and low line harmonics help to cut down operational costs and minimize the environmental impact.

High-End Safety: Safety Integrated functions along with Safe Torque Off (STO), Safe Stop 1 (SS1), and Safe Brake Control (SBC) safeguard users, protect equipment, and ensure international safety requirements.

Easy-To-Use Operation: It has a removable control panel and intelligent parameterization software that allow easy configuration, monitoring, and fault tracing.

Flexible Communication: Can easily integrate with Siemens' Totally Integrated Automation (TIA) Portal as well as with a host of industrial communication protocols (PROFINET, PROFIBUS, CANopen, Modbus RTU, etc.).

Drive G120: Modular Architecture to Grant Maximum Flexibility

The drive G120 is designed with a modular setup and is composed of two major components:

Control Unit (CU): Takes care of the logic, control, and communication functions. Different types of CUs are offered to suit the varying level of complexities and connectivity.

G120 Power Module (PM): Provides the power required by the motor. Power modules come in different ratings and cooling choices, such as PM230 (for pumps/fans), PM240/PM240-2 (with integrated braking chopper), and PM250 (with regenerative ability).

The separation method allows quick adaptation to changing process requirements, simple replacement of faulty components, and thereby reduction in spare parts stock.

Also read, Top 5 VFD Drive Siemens for Industrial Applications

Advantages in the Use of SINAMICS G120 in Industrial Applications

Operational Efficiency: The modularity and energy-saving features of the SINAMICS G120 cause less downtime, reduced energy consumption, and maximized process operational efficiency.

Safety Enhancement: Several built-in functions grant safety to minimize any risk and maintain productivity even during hazardous scenarios that meet the standards of SIL2/3 and PL d certification.

Cost-Efficiency: Fewer spare parts and easy expansions, along with energy-efficient management, yield much more savings in the long run.

Versatility: It is an ideal solution for all types of applications, from very simple conveyor systems, through packaging, to multi-axis motion control systems.

Direct Coupling with Automation: Directly coupled to SIMATIC control systems, the SINAMICS G120 can be integrated into the TIA Portal to ease engineering and commissioning.

The Power Module G120: Core of Efficient Motor Control

This power module is one component that largely determines the drive's power output and its suitability for the application. Siemens offers the following variants:

- PM230: For use in pumps, fans, and compressors, with IP55/IP20 protection and limited braking behavior.

- PM240/PM240-2: General purpose product; carries an integrated brake chopper and permits a braking resistor to be connected externally; IP20 protection.

- PM250: Specially designed for conveyers; energy may be given back to the supply line, improving the energy efficiency of the system.

Perfect power module selection provides optimum performance, durability, and energy conservation for your application.

Industries and Applications

SINAMICS G120 is a well-trusted entity, amongst others, in the following industries:

Material Handling: Conveyor belts, roller conveyors, and chain conveyors.

Pumping and Ventilation: Centrifugal pumps, fans, and compressors.

Manufacturing: Mills, mixers, crushers, and agitators.

Automotive and Textile: Main drives for turning milling, drilling, and processing machinery.

Such versatility and ruggedness secure the drive as the contender for any kind of industry, be it basic or demanding.

Conclusion: Partner with Naksh Technology Solutions LLP for SINAMICS G120

While implementing cutting-edge automation solutions, making a correct choice of supplier becomes equally important as the technology itself. Naksh Technology Solutions LLP has evolved to become one of the leading suppliers of Siemens automation products, which also includes the entire range of SINAMICS G120 drives and power modules. Expertly experienced with a broad product range while focusing on customer satisfaction, Naksh Technology Solutions LLP assures you will acquire the product suited to your particular requirements.

Be it upgrading existing solutions or initiating new automation processes; let Naksh Technology Solutions LLP provide you with genuine Siemens products, professional guidance, and dependable support concerning your SINAMICS G120, drive G120, and G120 power module requirements. Realize unparalleled levels of efficiency, safety, and flexibility under modular power using SINAMICS G120.

0 notes

Text

How Siemens Programmable Logic Controllers Improve Industrial Efficiency

In the current fast-paced industrial setting, automation is a necessity to increase productivity, efficiency, and precision. The Siemens Programmable Logic Controller (PLC) stands at the forefront of modern automation; it brought a paradigm shift in control systems in industries. Due to its reliability, flexibility, and performance, the Siemens PLC is the most preferred choice by manufacturers, engineers, and system integrators in the world.

What then is a Siemens Programmable Logic Controller?

A Siemens Programmable Logic Controller is a capable digital computer that is used to control machinery, processes, and equipment in industrial applications. It would receive inputs from sensors or user devices, consider those inputs under programmed logic, and create outputs that would appropriately control the processes or operations of machines and systems.

Siemens supplies a wide range of PLCs to suit the needs of various industries, ranging from compact ones for small applications to powerful modular systems for maximum control of automation. Considered to be popular are the SIMATIC S7-1200, S7-1500, and S7-300 series. Offered by these controllers is high-speed processing, built-in communication features, and compatibility of seamless scaling.

Also read, The Impact of Siemens PLC on Mining and Heavy Equipment

Reasons for Choosing a Siemens PLC

Siemens PLC is preferred in automation control owing to several factors:

Reliability: For 24-hour uptime in demanding industrial conditions.

Flexibility: It is configured and adapted with ease according to industries and processes.

Advanced Communication: Interface without any hindrance with the field devices, HMIs, SCADA systems, and cloud platforms.

Scalability: One can start small and grow as much as needed, without having to change the essence of the platform.

Integrated Safety: There are models that have been integrated with safety functions for the safe operation of the machinery.

Such features give Siemens PLC a future-ready status that also creates possibilities in manufacturing, water treatment, power generation, automotive, packaging, and related industries.

Siemens Controller vs. Siemens PLC

Many people tend to use Siemens controller and Siemens PLC interchangeably and, therefore, it is important to know the difference. Siemens controller is a broad term that includes PLCs, PC-based controllers, and distributed controllers, whereas Siemens PLC is a Programmable Logic Controller widely used in automation processes.

If you are setting up small-scale plants or running the setup of a big industrial plant, optimum performance and long-term success will ensue from the right choice of Siemens controller-especially Siemens PLC.

Learn more, Siemens PLC: Benefits of Using it in Industrial Automation

Application of Siemens PLC in Industries

The versatility of Siemens programmable logic controllers allows them to be applied to many applications:

Automated Assembly Lines

Process Control Systems

HVAC Control

Material Handling

Packaging Automation

Building Management Systems

By having a Siemens PLC, one can automate a series of repetitive tasks that can lead to errors, thereby enhancing productivity.

Conclusion: Partner with Naksh Technology Solutions LLP

If one looks forward to implementing a Siemens Programmable Logic Controller for their automation needs, it is crucial to associate with a trusted and experienced supplier. Naksh Technology Solutions LLP is a foremost supplier of Siemens automation products providing expert consultation, product support, and on-time delivery from an array of industries.

With vast knowledge of Siemens controllers and an exhaustive range of Siemens PLCs, Naksh Technology Solutions LLP is the best fit to attain industrial automation excellence.

0 notes

Text

Industrial Ethernet SCALANCE Switches – Siemens Solutions by Naksh

Get high-quality Siemens Industrial Ethernet SCALANCE Switches from Naksh Solutions LLP. They are sturdy and built for tough industrial jobs. You will receive expert help and fast delivery.

0 notes

Text

SCALANCE Switch: The Core of Reliable Industrial Networking

Modern digital-based industries depend heavily on the seamless exchange of communication signals and other vital data for their functional safety and scalable growth. Whether you are working on retrofitting an old network or implementing an automated network from scratch, SCALANCE Switch by Siemens fits your most complex networking demand. By combining advanced technology and sturdy design, SCALANCE delivers high-performance connectivity in complex and mission-critical environments.

Differences Between SCALANCE Switches

Because of its heavy-duty industrial design, SCALANCE switches enable industrial automation and Industry 4.0. Designed for industrial environments, SCALANCE switches endure harsh conditions such as extreme temperatures, humidity, electrical interference, and mechanical shocks. They offer fast and reliable Ethernet communication required for real-time control and data acquisition.

From simple machine networks to expansive factory systems, SCALANCE offers unmanaged and managed switches to meet all kinds of industrial needs. So, whether one wants merely connectivity or some advanced features like diagnostics, VLAN, and redundancy, there is a SCALANCE for that.

Siemens SCALANCE: Trusted Performance for Every Industry

The Siemens SCALANCE series includes:

Unmanaged switches (SCALANCE X005/X108): These are plug-and-play devices that can be deployed quickly in simple network topologies.

Managed switches (SCALANCE X204/X300 series): These provide more control and allow for monitoring and configuration of more extensive and complex networks.

Modular and rack-mounted switches (SCALANCE X500 series): Scalable solutions for data-heavy environments and enterprise-level industrial systems.

All models are optimized for PROFINET communication, ensuring real-time communication as demanded by many automation processes.

Discover how the many capabilities of SCALANCE Switch can empower greater enhancement of your industry networks, ensuring smooth communication across all automation systems.

The Place of SCALANCE in Industrial Network Infrastructure

An Industrial Network Switch solution must provide reliability, speed, and security. SCALANCE switches achieve all three:

Redundant Ring Topologies: Offers network redundancy on link failure.

PROFINET Conformance: Works seamlessly with Siemens PLCs and automation systems.

Port Security and Firewall Features: Protect the network from unauthorized access and cyber intrusions.

Flexibility with Mounting Options: The options range from rail and wall mount configurations.

Whether implementing factory-wide automation or interconnecting smart field devices, SCALANCE PROFINET Switch capabilities will ensure timely and precise data exchange.

Conclusion

Choosing a switch is all important to the operations and through-put of industrial networks. With the SCALANCE Switch, Siemens offers a dependable product that supports digitalization and industrial automation in different industry fields. Robust and intelligent, with fully PROFINET compliant modules, this makes SCALANCE Switch an industrial Ethernet networker's best choice.

Naksh Technology Solutions LLP is a proud distributor of automation products, including the entire range of Siemens SCALANCE switches. Offering expertise and a genuine solution, Naksh Technology is dedicated to cementing all your industrial connectivity needs upon the right tools and technologies.

0 notes

Text

Boost Your Industrial Network with SCALANCE Switch Solutions

A reliable and secure communication infrastructure is the backbone of efficient operations in the era of smart manufacturing and industrial automation. SCALANCE Switch - a powerful industrial networking device developed by Siemens - is one of the core elements acting as a facilitator for this infrastructure. Designed for the harsh industrial environment, SCALANCE switches provide uninterrupted and forceful data transfer across your entire automation network.

What is a SCALANCE Switch?

A SCALANCE Switch is an industrial type of Ethernet switch manufactured by Siemens, specifically designed for rugged environments requiring critical operations in industries such as manufacturing, energy, transportation, and utilities. These switches can be both managed and unmanaged, providing deployment flexibility depending on the complexity of the network to control.

SCALANCE switches are highly capable of setting up secure and scalable industrial communication networks. Their special features such as being redundant, supporting VLAN, diagnostics, and real-time communication make them the perfect fit for automation systems that work on PROFINET or some other industrial protocol.

Types of SCALANCE Switches

Siemens designs a wide array of SCALANCE switches tailored for specific industrial application requirements:

SCALANCE X-000 / X-100 Unmanaged Switches: The only choice for simple application scenarios without configuration requirements.

SCALANCE X-200 / X-300 Managed Switches: These switches present an ideal solution for advanced industrial communication features, including port monitoring, redundancy protocols, and VLAN configuration.

SCALANCE X-500 Modular Switches: These switches are best for large, complex networks with high-speed requirements for modular expansion.

SCALANCE XC / XR Industrial Ethernet Switches: Rugged models that endure harsh industrial environments.

Discover how the many capabilities of SCALANCE Switch can empower greater enhancement of your industry networks, ensuring smooth communication across all automation systems.

Why Choose Siemens SCALANCE?

The Siemens SCALANCE family of switches has been designed for industrial environments considering long-term reliability and cybersecurity. Key features include:

Industrial-Grade Durability: Resistance to dust, vibration, temperature extremes, and humidity.

High Network Availability: Supports ring redundancy, RSTP, and MRP for fault-tolerant systems.

Easy Integration: Fully compatible with PROFINET Switch configurations for seamless communication within Siemens-based automation systems.

Network Diagnostics: Managed switches would provide diagnostic and monitoring tools in real time for proactive network detection and resolution of problems.

SCALANCE Switch in PROFINET Networks

The SCALANCE Switch, being a PROFINET Switch, is secure and optimized for deterministic data transmission and real-time control applications. These switches guarantee minimal latency and maximum uptime, which is the need for time-critical applications where robotics, machine control, or process automation are involved.

The SCALANCE switches provide a fast and accurate data exchange between PLCs, HMIs, and field devices to put up a responsive and scalable Industrial Network Switch infrastructure.

Conclusion

Whenever you want to improve industrial communication network with solid and high-performance switching technology, the SCALANCE Switch line from Siemens serves as the best-recommended solution. From a simple unmanaged solution to a full-blown managed switch for complicated systems, SCALANCE has the required flexibility and robustness for industrial usage.

Naksh Technology Solutions LLP is an eminent supplier of Siemens automation products, including the entire gamut of Siemens SCALANCE switches. With sincere support and genuine products, Naksh Technology stands as your best partner in building smarter and more efficient industrial networks.

0 notes

Text

The SIMATIC ET 200SP is a powerful, space-saving distributed I/O system designed for high efficiency in industrial automation. With its modular, flexible design, it ensures seamless scalability and fast integration. Offering high performance, reliability, and easy maintenance, it’s the ideal solution for modern automation needs. Upgrade your system today!

1 note

·

View note