#siemens programmable logic controller

Explore tagged Tumblr posts

Text

How Siemens Programmable Logic Controllers Improve Industrial Efficiency

In the current fast-paced industrial setting, automation is a necessity to increase productivity, efficiency, and precision. The Siemens Programmable Logic Controller (PLC) stands at the forefront of modern automation; it brought a paradigm shift in control systems in industries. Due to its reliability, flexibility, and performance, the Siemens PLC is the most preferred choice by manufacturers, engineers, and system integrators in the world.

What then is a Siemens Programmable Logic Controller?

A Siemens Programmable Logic Controller is a capable digital computer that is used to control machinery, processes, and equipment in industrial applications. It would receive inputs from sensors or user devices, consider those inputs under programmed logic, and create outputs that would appropriately control the processes or operations of machines and systems.

Siemens supplies a wide range of PLCs to suit the needs of various industries, ranging from compact ones for small applications to powerful modular systems for maximum control of automation. Considered to be popular are the SIMATIC S7-1200, S7-1500, and S7-300 series. Offered by these controllers is high-speed processing, built-in communication features, and compatibility of seamless scaling.

Also read, The Impact of Siemens PLC on Mining and Heavy Equipment

Reasons for Choosing a Siemens PLC

Siemens PLC is preferred in automation control owing to several factors:

Reliability: For 24-hour uptime in demanding industrial conditions.

Flexibility: It is configured and adapted with ease according to industries and processes.

Advanced Communication: Interface without any hindrance with the field devices, HMIs, SCADA systems, and cloud platforms.

Scalability: One can start small and grow as much as needed, without having to change the essence of the platform.

Integrated Safety: There are models that have been integrated with safety functions for the safe operation of the machinery.

Such features give Siemens PLC a future-ready status that also creates possibilities in manufacturing, water treatment, power generation, automotive, packaging, and related industries.

Siemens Controller vs. Siemens PLC

Many people tend to use Siemens controller and Siemens PLC interchangeably and, therefore, it is important to know the difference. Siemens controller is a broad term that includes PLCs, PC-based controllers, and distributed controllers, whereas Siemens PLC is a Programmable Logic Controller widely used in automation processes.

If you are setting up small-scale plants or running the setup of a big industrial plant, optimum performance and long-term success will ensue from the right choice of Siemens controller-especially Siemens PLC.

Learn more, Siemens PLC: Benefits of Using it in Industrial Automation

Application of Siemens PLC in Industries

The versatility of Siemens programmable logic controllers allows them to be applied to many applications:

Automated Assembly Lines

Process Control Systems

HVAC Control

Material Handling

Packaging Automation

Building Management Systems

By having a Siemens PLC, one can automate a series of repetitive tasks that can lead to errors, thereby enhancing productivity.

Conclusion: Partner with Naksh Technology Solutions LLP

If one looks forward to implementing a Siemens Programmable Logic Controller for their automation needs, it is crucial to associate with a trusted and experienced supplier. Naksh Technology Solutions LLP is a foremost supplier of Siemens automation products providing expert consultation, product support, and on-time delivery from an array of industries.

With vast knowledge of Siemens controllers and an exhaustive range of Siemens PLCs, Naksh Technology Solutions LLP is the best fit to attain industrial automation excellence.

0 notes

Text

The Power of Siemens Industrial Automation in Modern Manufacturing

Siemens Industrial Automation - Introduction

Rapid technological advancement made a great mark on the industrial environment, whereby automation is now an important part of modern production. Siemens Industrial Automation provides modern solutions for improving efficiency, productivity, and accuracy in industrial processes. From the wide variety of Siemens automation products, companies can create streamlined operations, minimized costs, and trouble-free production processes.

Siemens programmable logic controller (PLC) products, smart controllers, and many other types of automation solutions are for the manufacturing, energy, pharmaceutical, automotive, and diverse industries.

How Siemens Industrial Automation is Reshaping New Age Industries

Industrialization is propelled, and efficiency is realized with automation. Achieving operational excellence among many industries is possible by introducing automated practices that are designed in strategy with smart technologies that optimize performance. The automation solutions integrate less human interference and better accuracy and scalability.

1. Boost for Enhanced Productivity and Efficiency

The greatest benefit available through Siemens automation products is that it raises productivity. With modern systems operating at a higher level of precision, production rates are much faster as downtime is reduced to a minimum. Real-time monitoring and control of a process in a very efficient way is what seamless working of Siemens PLC and controllers promises.

2. Economical Solutions for Industrial Concern

All industries, in fact, look forward to cost-effective solutions, which will optimize operations. Cut in manual labor consumption, reduction of energy consumption, and reduced waste of raw materials are some aspects of lessening operational cost. Predictive maintenance is also facilitated by Siemens controllers, thus helping improve unplanned downtimes and repair costs.

3. Safety and Reliability enhancement

Increased safety: Industrial automation resulted in increased safety at workplaces as there will not be any hazardous tasks relying on human workers. Programmable logic controllers from Siemens will offer automation in a completely reliable and fail-safe manner preventing unwanted incidents and ensuring seamless operations

4. Scalability and Flexibility

Present automation solutions can be flexible and scalable, which are the requirements of modern industrialization to meet the various demands from time to time. Siemens automation products enable flexible integration of the current facility with such systems, which means that modernization can take place with minimal disruption in the processes.

Key Products of Siemens for Industrial Automation

1. Programmable Logic Controllers (PLCs) from Siemens

Siemens PLCs are one of the key elements in industrial automation. These controllers take charge of complex processes with a necessary degree of accuracy over machinery and equipment.

Siemens offers the following kinds of PLCs:

SIMATIC S7 Series- A powerful and flexible PLC family for a variety of industrial applications.

LOGO! Logic Modules- These are best suited for small automation projects with compact programming and easy, user-friendly programming.

ET 200SP- A modular PLC system that integrates with other automation components like a dream.

Also read, Siemens PLC: Benefits of Using it in Industrial Automation

2. Siemens Controllers

Siemens controllers accomplish their task of handling and controlling automated tasks effectively. Communication between these controllers and the different automation components is maintained so that real-time monitoring and controlling become possible.

Among the top Siemens controllers are:

SIMATIC S7-1500-A performance controller for complex automation tasks.

SINAMICS Drive Controllers- Precise speed and torque control in applications relating to motor control.

Distributed Controllers-A distributed automation system would do well with these controllers spread out in a large industrial set-up.

Also read, Top 5 Benefits of SIMATIC S7 1500 for Advanced Motion Control

3. Human-Machine-Interface Solutions of Siemens

Siemens produces various HMIs operated by these systems to enable operators to interact with the automation system. Such interface tools visualize data in real-time for easy monitoring and control of industrial processes.

Among the popular Siemens HMI products are:

HMI Panels-SIMATIC Panels with high-definition touchscreen for seamless industrial monitoring.

SCADA systems-Complete control and monitoring alternating solutions for large-scale automation systems.

Also read, Siemens HMI vs. Other HMI Solutions: Why Choose Siemens?

Applications of Siemens Industrial Automation

The various solutions provided by Siemens Industrial Automation find application in industries for ensuring operation efficiency and accuracy. Some of the industries benefitted from Siemens automation are:

1. Manufacturing Industry

In manufacturing, automation serves to ensure streamlined production lines. Siemens PLCs and controllers assist in process optimization, waste reduction, and overall efficiency enhancement.

2. Automotive Industry

Automated processes in the automotive industry are mainly used in assembly, painting, and quality control. Siemens' automation products make sure that factories doing automobile manufacturing operate to high standards, producing consistent quality.

3. Food & Beverage Industry

Automated processes in the food industry are used in packaging, inspecting quality, and monitoring production lines. Siemens controllers and HMI solutions assist in hygiene maintenance and operational efficiency.

4. Energy & Power Plants

Power generation and distribution need next-generation automation solutions to work seamlessly. In energy plants, the use of Siemens PLCs and SCADA systems guarantees an uninterrupted supply of power and efficiency.

Future of Siemens Industrial Automation:

The future of Siemens Industrial Automation is changing due to advancements in artificial intelligence, the Internet of Things, and digitalization. Smart factories-New-Norm Siemens Automation Products bring AI empowered analytics, therefore controlling operations for better performance. Meanwhile, with Siemens Controllers, Industries attain the efficiency to maintain themselves and their functionalities through real-time and predictive maintenance monitoring.

1. Industry 4.0 and Smart Manufacturing

Siemens has introduced this idea to develop Industry 4.0 -digital solutions through IoT, cloud-based computing-to make them automation-enabled. Likewise, Smart Siemens PLCs and controllers consider making industries access real-time data analysis for automation-driven decision making.

2. Sustainability and Energy Efficiency

Siemens constructs the idea of automation applied to sustainability by focusing on solutions that do not maximize energy consumption or carbon footprint. In essence, through such smart their-automation, resource utilization is optimized such that it becomes an environmentally friendly industrial practice.

Conclusion

Transforming industries, Siemens Industrial Automation promises groundbreaking, state-of-the-art, and trustworthy solutions for all industrial automation options, including Siemens programmable logic controllers and advanced Siemens controllers. These automation products guarantee seamless operations, cost savings, and enhanced productivity in all industries.

For industries interested in implementing Siemens automation solutions, Naksh Technology Solutions LLP serves as the trusted source for a premium range of all automation products and world-class consultancy services.

#siemens industrial automation#siemens automation products#siemens programmable logic controller#siemens controller

0 notes

Text

SR Ranade: Your Trusted Partner for Siemens PLC Automation Solutions in Mumbai

We make sure that from the entire stock of Siemens S7 programmable logic controllers, a wide range of product lines is available, characterized by their reliability, flexibility, and productivity offering bespoke automated solutions that can be easily integrated into your current operational systems to boost efficiency and productivity. https://www.quora.com/profile/Drive-PLC/SR-Ranade-Your-Trusted-Partner-for-Siemens-PLC-Automation-Solutions-in-Mumbai

0 notes

Text

Future Trends in Siemens PLC Technology

As technology evolves, so does the landscape of programmable logic Software Controllers. This article explores future trends in Siemens PLC technology, including advancements in artificial intelligence, machine learning, and edge computing.

We discuss how these innovations are expected to impact PLC capabilities, enabling more sophisticated automation solutions. Additionally, we consider the implications for industries, including enhanced productivity, safety, and energy efficiency. By looking ahead, this article aims to prepare businesses for the upcoming changes in automation technology and the continued relevance of Siemens PLCs.

Visit us for more information-

Ph.No- 1300 309 303

Email- [email protected]

Address- 5-7 Corporate Avenue,Rowville,Melbourne VIC,3178

Web- https://apsindustrial.com.au/

0 notes

Text

How Siemens Controllers Are Revolutionizing Music Production Studios

In the rapidly evolving world of music production, the quest for greater efficiency, precision, and creative control has led to significant advancements in technology. Among the innovations driving these changes are Siemens controllers, which are revolutionizing how music is produced, mixed, and mastered. By integrating Siemens' cutting-edge automation technology into music production studios, professionals are achieving new levels of productivity and sonic quality. Here's how Siemens controllers are making waves in the music industry.

Siemens Controllers: The Backbone of Modern Music Studios

Siemens controllers, including programmable logic controllers (PLCs) and motor controllers, are renowned for their reliability and precision in various industrial applications. However, their impact extends beyond traditional manufacturing environments. In modern music production studios, Siemens controllers are enhancing automation, improving control over studio equipment, and streamlining production processes.

One notable example is the use of Siemens’ SIMATIC PLCs in controlling and automating audio equipment. These advanced controllers manage everything from digital mixing consoles to automated fader adjustments, providing sound engineers and producers with a level of control that was previously unattainable.

Enhancing Efficiency with Siemens Automation Technology

Efficiency is paramount in a music production studio, where time is often as valuable as creativity. Siemens controllers play a crucial role in automating repetitive tasks and optimizing workflows. For instance, automated mixing and mastering processes are facilitated by Siemens controllers, which handle complex signal routing and processing tasks with precision.

By integrating Siemens’ automation technology, studios can reduce the time spent on manual adjustments and focus more on the creative aspects of music production. Automated systems controlled by Siemens controllers ensure that equipment settings are consistent and repeatable, which is essential for achieving high-quality results across multiple sessions and projects.

Precision Control with Siemens Motor and Motion Controllers

In a music studio, precise control over equipment is essential for achieving the desired sound quality. Siemens motor controllers and motion control systems provide unparalleled accuracy in adjusting audio equipment. Whether it’s controlling the movement of a motorized microphone stand or fine-tuning the position of speakers and monitors, Siemens controllers ensure that every adjustment is executed with pinpoint accuracy.

The ability to program and control these adjustments via Siemens’ programmable logic controllers allows sound engineers to create intricate setups and configurations that can be replicated with ease. This level of control enhances the overall quality of recordings and ensures that the production process is smooth and efficient.

Streamlining Production with Advanced Automation and Process Automation

Process automation is transforming music production studios by automating complex workflows and enhancing overall efficiency. Siemens controllers are at the heart of this transformation, offering solutions that streamline various aspects of the production process.

For example, Siemens controllers can automate the setup and calibration of audio equipment, reducing the time needed for manual adjustments. This automation extends to the management of recording sessions, where Siemens controllers handle tasks such as track switching, level adjustments, and signal routing with minimal human intervention.

Additionally, the integration of Siemens controllers into digital audio workstations (DAWs) allows for seamless control of software and hardware components. This integration ensures that all elements of the production process work in harmony, resulting in a more cohesive and efficient workflow.

The Impact of Siemens Controllers on Creative Processes

Beyond improving efficiency and precision, Siemens controllers also have a significant impact on the creative processes within music production studios. By automating routine tasks, these controllers free up time for producers and engineers to focus on creative experimentation and innovation.

The ability to program complex automation sequences and recall them with ease enables sound engineers to explore new creative possibilities. For instance, automated dynamic changes in a mix or the creation of intricate effects can be accomplished effortlessly using Siemens controllers, allowing for greater experimentation and artistic expression.

Implementing Siemens Controllers in Your Music Studio

Integrating Siemens controllers into a music production studio involves several key steps. First, assess your studio’s current setup and identify areas where automation and control improvements can be made. Siemens offers a range of controllers and automation solutions, including the SIMATIC PLCs and motor controllers, that can be customized to meet your specific needs.

Once the appropriate Siemens controllers are selected, the next step is to implement them into your studio’s infrastructure. This process may include configuring the controllers, integrating them with existing equipment, and training staff to utilize the new technology effectively.

Ongoing maintenance and support are essential to ensure that Siemens controllers continue to perform optimally. Siemens provides comprehensive support services, including technical assistance and software updates, to help you maximize the benefits of their controllers and maintain peak performance.

Conclusion

Siemens controllers are revolutionizing music production studios by enhancing efficiency, precision, and creativity. With their advanced automation technology, including programmable logic controllers (PLCs) and motor controllers, Siemens is setting new standards for control and automation in the music industry. By integrating Siemens controllers into your music production setup, you can streamline workflows, improve the quality of your productions, and unlock new creative possibilities. As the music industry continues to evolve, Siemens controllers will remain at the forefront of innovation, driving the future of music production.

#siemens#siemens controller#siemens controllers#industrial automation#programmable logic controllers#motor controllers#motion control#factory automation#automation technology#process automation#simatic#controllers#automation#controller#production#automated

0 notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Text

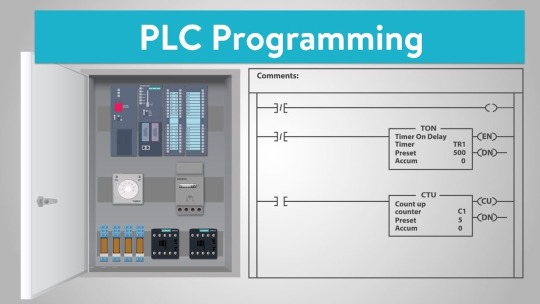

The Basics of PLC Programming: A Comprehensive Guide

If you're interested in the field of industrial automation or looking to enhance your skills in the industry, PLC programming is a crucial skill to possess. Programmable Logic Controllers (PLCs) are widely used in manufacturing and process control systems, and understanding how to program them is essential for ensuring efficient and reliable operation.

In this comprehensive guide, we will explore the basics of PLC programming, covering key concepts and providing valuable insights for beginners in the field.

1. What is PLC Programming?

PLC programming involves creating a set of instructions that control the behavior of a programmable logic controller. PLCs are used to monitor inputs from various sensors, process that data, and execute specific actions based on pre-defined logic. By programming a PLC, you can automate complex industrial processes, making them more efficient and reliable.

2. Why Learn PLC Programming?

PLC programming offers numerous benefits in the industrial automation realm. By acquiring this skill, you can:

Improve productivity: PLCs enable automation, reducing manual labor and increasing overall productivity.

Enhance efficiency: Automation minimizes human error and optimizes processes, resulting in higher efficiency levels.

Facilitate troubleshooting: Understanding PLC programming allows you to diagnose and fix issues efficiently, minimizing downtime.

Expand career opportunities: PLC programming expertise is in high demand, with many industries seeking professionals with these skills.

3. PLC Programming Training Courses:

To learn PLC programming effectively, it's essential to enroll in specialized training courses. These courses provide a structured curriculum, hands-on exercises, and expert guidance. Here are a few key aspects to consider when choosing a PLC programming training institute or center:

Comprehensive curriculum: Look for a training program that covers both theoretical concepts and practical implementation.

Experienced instructors: Ensure that the training institute has qualified instructors with industry experience to guide you effectively.

Hands-on practice: Practical exercises and projects are crucial for gaining proficiency in PLC programming.

Industry relevance: Verify that the training course aligns with current industry standards and practices.

Certification: Opt for courses that offer certifications upon completion, as they enhance your credibility in the job market.

4. Key Concepts in PLC Programming:

Ladder Logic: Ladder Logic is the most commonly used programming language for PLCs. It employs graphical symbols to represent logic functions and control sequences, making it easy to understand and implement.

Inputs and Outputs: PLCs interact with the physical world through inputs (sensors) and outputs (actuators). Understanding how to read inputs and control outputs is fundamental in PLC programming.

Programming Instructions: PLCs execute a set of instructions to perform desired operations. These instructions can include timers, counters, mathematical operations, logic gates, and more.

Program Execution: PLC programs are executed in a cyclical manner. The PLC scans inputs, processes logic, updates outputs, and repeats the cycle continuously.

5. Programming Tools and Software:

PLC programming software provides an interface to create, edit, and debug programs. Familiarize yourself with popular software tools such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider Electric Unity Pro, as they are widely used in the industry.

Conclusion:

PLC programming is an essential skill for individuals aspiring to succeed in the field of industrial automation. By learning the basics of PLC programming, you open up a world of opportunities to streamline processes, enhance productivity, and contribute to the advancement of various industries. Enroll in a reputable PLC programming training institute or center, explore the key concepts, and start your journey towards becoming a proficient PLC programmer.

#plc-programming#learn plc programming#plc programming training#plc programming courses#plc training course in india

3 notes

·

View notes

Text

Securing Automation with Reliable Spare Parts

The Critical Role of Automation Spares

In the fast-paced world of industrial automation, where precision and uptime are paramount, the availability of spare parts can mean the difference between seamless operations and costly downtime. Factories, refineries, and manufacturing plants rely on complex systems to maintain productivity, and when components fail, swift replacements are essential. The ability to Order Siemens Automation Spares Parts ensures that critical systems, from programmable logic controllers to servo drives, remain operational. These spares, designed for high compatibility and performance, support industries across the globe, keeping production lines moving without interruption.

Challenges of Maintaining Legacy Systems

Many industries operate with legacy automation systems, valued for their reliability but challenged by the obsolescence of their components. As manufacturers phase out older models, sourcing replacements becomes a hurdle. This is particularly true in regions like the UAE, where diverse industries demand both current and discontinued parts. Specialized stockists bridge this gap, maintaining inventories of hard-to-find components. These suppliers ensure that businesses can continue using trusted systems without forced upgrades, preserving investments while minimizing operational disruptions caused by unavailable parts.

The UAE’s Role as a Spare Parts Hub

The UAE, with its strategic location and thriving industrial sector, has emerged as a key hub for automation spare parts. Obsolete Automation Spare Parts Stockist UAE providers play a vital role in supporting the region’s oil and gas, manufacturing, and logistics industries. These stockists maintain extensive inventories, including discontinued components for older systems, ensuring rapid delivery to clients across the Middle East. Their expertise in sourcing and verifying parts guarantees compatibility and quality, reducing the risk of counterfeit or substandard replacements. This localized access strengthens the UAE’s position as a reliable partner for global industrial operations.

Streamlining the Ordering Process

Ordering automation spare parts requires precision to ensure the right components are sourced. Online platforms have simplified this process, allowing businesses to search for parts using model numbers or system specifications. These platforms often provide detailed catalogs, covering everything from motors to human-machine interfaces, with options for new, refurbished, or obsolete parts. Fast quote systems and same-day dispatch services, common among UAE suppliers, minimize lead times. This efficiency is critical for industries where even a few hours of downtime can result in significant financial losses, ensuring repairs are completed swiftly.

The Benefits of Refurbished and Obsolete Parts

Refurbished and obsolete parts offer a cost-effective alternative to new components, particularly for legacy systems. These parts undergo rigorous testing and reconditioning to meet original specifications, often backed by warranties of up to 12 months. In the UAE, stockists specializing in such parts cater to businesses seeking to extend the life of their equipment without costly system overhauls. By opting for refurbished spares, companies reduce waste and support sustainable practices, aligning with global trends toward circular economies. This approach balances affordability with reliability, maintaining system performance at a fraction of the cost.

Ensuring Quality and Authenticity

The risk of counterfeit parts in the automation industry underscores the importance of sourcing from reputable suppliers. In the UAE, trusted stockists verify the authenticity of every component, whether new or refurbished, ensuring they meet manufacturer standards. This diligence is crucial for automation systems, where incompatible or faulty parts can cause malfunctions or safety hazards. Suppliers often provide detailed documentation, including certificates of origin or testing reports, to reassure clients of quality. By partnering with reliable stockists, businesses protect their operations and maintain compliance with industry regulations.

Supporting Industries Across the UAE

The UAE’s diverse industrial landscape, from petrochemical plants to advanced manufacturing, relies on a steady supply of automation spares. Stockists in the region support these sectors by offering tailored solutions, such as consignment stock agreements or predictive maintenance programs. These services help businesses optimize inventory, reducing excess stock while ensuring critical parts are readily available. Emergency delivery options, often within 24 hours, cater to urgent needs, minimizing downtime during unexpected failures. This comprehensive support strengthens industrial resilience, enabling companies to focus on growth and innovation.

The Future of Automation Spare Parts

As automation technology evolves, the demand for spare parts will continue to grow, driven by the integration of smart systems and Industry 4.0 solutions. In the UAE, stockists are adapting by expanding their inventories to include parts for newer technologies while maintaining support for legacy systems. Digital tools, like AI-driven inventory management and online tracking, are enhancing efficiency, ensuring parts are available when and where needed. By staying ahead of industry trends, these suppliers position the UAE as a global leader in automation support, fostering a future where businesses thrive through reliable, accessible spare parts solutions.

0 notes

Text

Introduction to CODESYS PLC: A Comprehensive Overview

CODESYS (Controller Development System) is a leading software platform for industrial automation, widely used for programming and configuring Programmable Logic Controllers (PLCs). Developed by the German company 3S-Smart Software Solutions, CODESYS PLC is a versatile, hardware-independent development environment that supports a broad range of industrial applications, from factory automation to process control and motion control systems. This article explores the key features, benefits, programming capabilities, and applications of CODESYS PLC, highlighting its significance in modern industrial automation.

What is CODESYS?

CODESYS is an integrated development environment (IDE) that adheres to the international standard IEC 61131-3, which defines programming languages for PLCs. This standard ensures that CODESYS is compatible with a wide variety of hardware platforms from different manufacturers, making it a flexible and scalable solution. The platform supports all five IEC 61131-3 programming languages: Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). Additionally, CODESYS extends support for object-oriented programming (OOP) with languages like Structured Text, enabling advanced programming techniques.

The CODESYS ecosystem includes not only the core IDE but also additional tools for visualization, simulation, debugging, and communication with field devices. It is used in industries such as manufacturing, energy, automotive, and building automation, offering a unified platform for developing complex automation solutions.

Key Features of CODESYS

IEC 61131-3 Compliance: CODESYS supports all standard PLC programming languages, allowing developers to choose the most suitable language for their application. This compliance ensures portability of code across different PLC hardware, reducing development time and costs.

Hardware Independence: CODESYS is compatible with over 1,000 devices from various manufacturers, including Siemens, Beckhoff, WAGO, and others. This flexibility allows engineers to write code once and deploy it on multiple platforms without significant modifications.

Integrated Visualization: CODESYS provides built-in tools for creating Human-Machine Interfaces (HMIs). Developers can design graphical user interfaces for operator panels, web-based visualizations, or mobile applications, all within the same environment.

Fieldbus and Communication Support: The platform supports a wide range of industrial communication protocols, such as Modbus, CANopen, EtherCAT, PROFINET, and OPC UA. This ensures seamless integration with sensors, actuators, and other devices in an automation system.

Simulation and Debugging: CODESYS includes a powerful simulation mode that allows developers to test their programs without physical hardware. The debugging tools enable real-time monitoring, breakpoints, and variable tracing, streamlining the development process.

Scalability and Modularity: From small embedded systems to large distributed control systems, CODESYS is highly scalable. Its modular architecture allows developers to add libraries, function blocks, and extensions as needed.

Safety and Security: CODESYS supports safety programming according to standards like IEC 61508 (SIL 2/3), making it suitable for safety-critical applications. It also includes features for secure communication and user authentication to protect against cyber threats.

Programming with CODESYS

CODESYS offers a flexible programming environment that caters to both novice and experienced developers. The five IEC 61131-3 languages provide diverse options:

Ladder Diagram (LD): Ideal for electrical engineers familiar with relay logic, LD resembles electrical circuit diagrams and is widely used for simple control tasks.

Function Block Diagram (FBD): A graphical language that uses blocks to represent functions, making it intuitive for designing complex systems.

Structured Text (ST): A high-level, text-based language similar to Pascal or C, suitable for algorithmic and mathematical operations.

Instruction List (IL): A low-level, assembly-like language for precise control, though less commonly used today.

Sequential Function Chart (SFC): Used for sequential control processes, SFC is ideal for applications requiring step-by-step execution, such as batch processing.

In addition to these, CODESYS supports object-oriented programming, allowing developers to create reusable code through classes, methods, and inheritance. This is particularly useful for large-scale projects where modularity and maintainability are critical.

Benefits of Using CODESYS

Cost Efficiency: By supporting multiple hardware platforms, CODESYS eliminates the need for proprietary software tied to specific vendors, reducing licensing and development costs.

Flexibility: Developers can work in their preferred programming language and deploy code on various devices, enhancing project flexibility.

Community and Ecosystem: CODESYS has a large user base and an active community, with extensive documentation, libraries, and third-party tools available through the CODESYS Store.

Rapid Development: The integrated environment, combined with simulation and debugging tools, accelerates development and testing cycles.

Global Adoption: CODESYS is used worldwide, ensuring that skills learned in the platform are transferable across industries and regions.

Applications of CODESYS PLC

CODESYS is employed in a wide range of industries, including:

Manufacturing: Controlling assembly lines, robotic systems, and CNC machines.

Energy: Managing renewable energy systems, such as wind turbines and solar plants, as well as traditional power distribution networks.

Building Automation: Integrating HVAC, lighting, and security systems for smart buildings.

Automotive: Controlling production lines and testing equipment in automotive manufacturing.

Process Control: Managing chemical plants, water treatment facilities, and food processing systems.

Getting Started with CODESYS

To begin using CODESYS, developers can download the free CODESYS Development System from the official website. The software is compatible with Windows and supports a variety of PLC hardware. Beginners can start with the extensive documentation and tutorials available online, while advanced users can explore the CODESYS Store for additional libraries and add-ons.

A typical workflow involves:

Installing the CODESYS IDE.

Selecting a target PLC and configuring the hardware.

Writing the program using one or more IEC 61131-3 languages.

Simulating the program to test functionality.

Deploying the code to the PLC and monitoring its performance.

Challenges and Considerations

While CODESYS is a powerful platform, there are some considerations:

Learning Curve: For beginners, mastering all five programming languages and the IDE’s features can take time.

Hardware Dependency: Although CODESYS is hardware-independent, specific PLCs may require proprietary drivers or configurations.

Licensing: While the core IDE is free, certain add-ons, libraries, or runtime licenses may incur costs, depending on the application.

Conclusion

CODESYS PLC by Servotechinc is a cornerstone of modern industrial automation, offering a robust, flexible, and scalable platform for PLC programming. Its adherence to IEC 61131-3, support for multiple programming languages, and extensive feature set make it a preferred choice for engineers worldwide. Whether you’re developing a small control system or a complex, distributed automation solution, CODESYS provides the tools to streamline development and ensure reliable performance. As industries continue to embrace digital transformation, CODESYS remains at the forefront, empowering automation professionals to build the systems of the future.

0 notes

Text

Top Reliable Siemens PLCS Suppliers for Seamless Automation Solutions

When it comes to industrial automation, choosing the right Siemens PLCS suppliers can make all the difference in the success and efficiency of your projects. Siemens PLCs (Programmable Logic Controllers) are globally recognized for their robustness, versatility, and advanced features, making them a popular choice across various industries. However, sourcing genuine products from trustworthy vendors is essential for ensuring system reliability and long-term support.

Understanding the role of Siemens PLC distribution channels will also help you identify credible sources and avoid counterfeit or subpar components.

Why Siemens PLCs are the Preferred Choice?

Siemens PLCs are widely used for automating complex industrial processes, from manufacturing lines to infrastructure management. Their high processing power, scalability, and compatibility with various software make them suitable for diverse applications. Whether you need compact units for small automation tasks or advanced systems for large-scale operations, Siemens offers a wide product range to match your requirements.

By choosing verified Siemens PLCS suppliers, you can be confident in receiving devices that meet strict quality standards. These suppliers often provide additional benefits such as technical guidance, warranty services, and timely delivery, making your procurement hassle-free.

What to Look in Siemens PLCS Suppliers

Keep these key points in mind:

Authorized Distribution: Always choose suppliers officially recognized by Siemens to guarantee genuine products and manufacturer support.

Comprehensive Product Range: Suppliers with extensive Siemens PLC distribution capabilities offer access to the full lineup, from basic controllers to advanced models.

Technical Expertise: Reliable vendors provide expert assistance to help you select the right PLC based on your specific application and operational needs.

Competitive Pricing & Support: Look for suppliers offering fair pricing without compromising quality, along with post-purchase support such as installation help and troubleshooting.

Benefits of Partnering with Trusted Siemens PLCS Suppliers

Working with trustworthy Siemens PLCS suppliers ensures several advantages:

Reduced risk of equipment failure due to counterfeit or incompatible components.

Access to timely software updates and firmware upgrades from official channels.

Streamlined logistics with reliable Siemens PLC distribution networks providing fast delivery.

Professional advice for system integration, ensuring smooth project execution.

At Seamatic Surplus, we specialize in delivering high-quality industrial automation components at competitive prices. As trusted suppliers of Siemens PLCs, we ensure every product in our inventory is thoroughly inspected and sourced from reliable channels.

Conclusion

Selecting the right Siemens PLC suppliers is a crucial step for any business seeking to implement effective and reliable automation solutions. By purchasing from authorized vendors with proven distribution capabilities, you safeguard your operations against risks associated with low-quality components. For more detailed insights on choosing the best automation components and suppliers.

Name: Seamatic Surplus

Address: Dubai, United Arab Emirates

Phone No.: (+971) 55 836 7086

Email ID:[email protected]

Website: https://seamaticsurplus.com Frequently Asked Questions (FAQs)

Q1. Why are Siemens PLCs preferred for industrial automation? A: Siemens PLCs (Programmable Logic Controllers) are renowned for their reliability, scalability, and advanced functionality. They support real-time data processing, seamless integration with SCADA systems, and robust performance in harsh industrial environments.

Q2. What makes a supplier reliable for Siemens PLCs? A: A reliable Siemens PLC supplier should:

Be an authorized distributor

Provide genuine, warranty-backed products

Offer technical support and integration guidance

Maintain sufficient stock for timely delivery

Have a good reputation in the automation industry

Q3. Can I get Siemens PLCs customized for specific applications?

A: Yes, many reliable suppliers offer tailored automation solutions and customized PLC configurations based on industry-specific needs, whether for manufacturing, utilities, HVAC, or renewable energy systems.

#Siemens PLCS Suppliers#Siemens PLC distributors#Suppliers of Siemens PLCS#Suppliers of PLCS and Hmis

0 notes

Text

Programmable Logic Controller Market Set to Hit US$ 17.2 Bn with Strong Demand from Smart Industries

The global programmable logic controller (PLC) market, valued at US$ 11.6 Bn in 2022, is forecast to grow at a CAGR of 4.7% between 2023 and 2031, reaching a market value of US$ 17.2 Bn by the end of 2031, according to the latest industry insights. This growth is propelled by a surge in demand for industrial automation, smart manufacturing, and increased integration of the Industrial Internet of Things (IIoT).

Market Overview: A programmable logic controller (PLC) is a digital computer used to automate electromechanical processes, particularly in manufacturing environments. These devices are integral to the efficient operation of assembly lines, robotic devices, and any activity requiring high-reliability control and ease of programming. With increasing adoption across automotive, food & beverage, chemical, energy & utility, and construction industries, the global PLC market continues to expand in scope and application.

Market Drivers & Trends

The rising trend of smart factories and Industry 4.0 is among the most significant growth drivers. Manufacturers are increasingly adopting automation to reduce operational costs, improve productivity, and enhance precision. PLCs play a critical role in this transformation by allowing control over complex industrial processes with minimal human intervention.

Additionally, the growing need for data-driven decision-making, along with advancements in machine learning and artificial intelligence, is leading to deeper integration of PLCs in industrial settings. As automation becomes central to production and operational strategies, the demand for PLCs is expected to surge further.

Latest Market Trends

One of the most notable trends is the shift toward modular PLCs, which accounted for over 68.2% of the market share in 2022. These PLCs are gaining popularity due to their scalability and suitability for large-scale, complex automation tasks. Modular systems offer higher flexibility, can handle thousands of inputs/outputs, and support multitasking environments—making them ideal for high-volume manufacturing operations.

Another trend is the miniaturization of PLCs, which supports their deployment in compact systems and small machinery, especially in consumer electronics and smaller automated units.

Key Players and Industry Leaders

The competitive landscape is fragmented yet dominated by global industrial automation giants. Leading companies in the PLC market include:

Siemens

Rockwell Automation

Mitsubishi Electric Corporation

Schneider Electric

OMRON Corporation

ABB

Panasonic Corporation

Bosch Rexroth Corporation

Delta Electronics, Inc.

Honeywell International Inc.

These companies continue to drive innovation through strategic partnerships, R&D investments, and product expansions to enhance their market share and global footprint.

Recent Developments

Crouzet, in December 2022, launched Millennium Slim, the slimmest PLC in the world, tailored for compact industrial applications.

In July 2022, OMRON Corporation introduced the CP2E Micro PLC, designed for smaller devices and capable of data collection and machine-to-machine communication. This supports low-cost automation solutions for small- and mid-sized enterprises.

Electronics Corporation of India Limited (ECIL) released its own PLC and SCADA software in May 2022, targeting industrial control applications in Indian manufacturing ecosystems.

These product introductions underline the market’s commitment to technological advancement and responsiveness to evolving industrial demands.

Market Opportunities

The expansion of material handling systems, especially in e-commerce logistics, warehousing, and food processing industries, presents substantial growth potential for PLC integration. In material handling, PLCs streamline storage, movement, and tracking—drastically improving throughput and inventory management.

Additionally, the increasing popularity of energy-efficient manufacturing and sustainability initiatives provides ample opportunity for advanced PLC systems that help monitor and reduce energy consumption across production lines.

Gain a preview of important insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=32672

Future Outlook

The future of the programmable logic controller market lies in enhanced interoperability, cloud integration, and edge computing. With greater reliance on smart infrastructure and connected devices, PLCs are expected to evolve into more intelligent, connected controllers.

The incorporation of AI-powered PLCs is expected to revolutionize industrial automation by enabling predictive maintenance, self-diagnosis, and adaptive process control. As PLCs continue to advance, their use will extend beyond industrial sectors into smart cities, transportation systems, and building automation.

Market Segmentation

By Offering:

Hardware: CPU, I/O Modules, Power Supply, Memory System

Software

Services

By Type:

Compact PLC

Modular PLC

Nano, Micro, Small, Medium, and Large PLCs

By Application:

Material Handling

Packaging & Labeling

Process Control

Safety Monitoring

Energy Management

Home & Building Automation

Industrial Equipment Control

By End-use Industry:

Automotive

Energy & Utilities

Food & Beverage

Pharmaceuticals

Construction

Oil & Gas

Semiconductors & Electronics

Regional Insights

Asia Pacific held the largest market share of 36.3% in 2022, led by strong industrial growth in China, Japan, South Korea, and India. The increasing demand for smart manufacturing systems and compact automation solutions in the region is expected to maintain its dominance through 2031.

North America, with a market share of 26.4% in 2022, continues to grow due to early adoption of factory automation and significant investment in smart infrastructure in the U.S. and Canada.

Europe remains a hub for automation technology innovation, with countries like Germany, the U.K., and France focusing on Industry 4.0 implementation across automotive and manufacturing sectors.

Why Buy This Report?

This comprehensive report offers:

Detailed market size, forecast, and growth rate

In-depth competitive landscape and company profiling

Analysis of key market drivers, trends, and opportunities

Region-wise breakdown for strategic decision-making

Porter’s Five Forces, value chain, and trend analysis

Insights into technological developments and their impact

Market segmentation for customized investment strategies

With expert analysis and forward-looking insights, this report serves as a valuable resource for stakeholders, investors, industrial engineers, and policymakers seeking to navigate and capitalize on the fast-evolving programmable logic controller market.

Explore Latest Research Reports by Transparency Market Research: 5G Smart Antenna Market: https://www.transparencymarketresearch.com/5g-smart-antenna-market.html

Solid State Transformer Market: https://www.transparencymarketresearch.com/solid-State-transformer.html

Interactive Display Market: https://www.transparencymarketresearch.com/interactive-display-market.html

GaN Epitaxial Wafers Market: https://www.transparencymarketresearch.com/gan-epitaxial-wafers-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Powering Progress: A Look into Industrial Electrical Supplies in the UAE

The UAE has emerged as a global hub for industry, construction, and technology, fueled by rapid infrastructure development and industrial innovation. At the heart of this progress is a strong demand for Industrial Electrical Supplies UAE—critical components that power factories, buildings, refineries, and large-scale systems. From Dubai to Abu Dhabi and Sharjah, the growing need for reliable, high-performance electrical products continues to drive the sector’s expansion.

Essential Products and Their Applications Industrial electrical supplies include a broad range of products, such as circuit breakers, transformers, industrial cables, switchgear, control panels, connectors, relays, and industrial lighting. These components are essential in maintaining the safe and efficient operation of machinery and power systems. In sectors like oil and gas, manufacturing, water treatment, and renewable energy, these supplies form the backbone of day-to-day operations and long-term infrastructure.

Leading Suppliers and Brands in the UAE The UAE hosts a competitive market of Electrical Panel Supplier Ras Al Khaimah catering to domestic and international clients. Major companies like ABB, Schneider Electric, Legrand, Siemens, and Hager have a strong presence, often in partnership with local distributors. In addition, regional companies such as Al Fanar, Al Hathboor, and Powertech Group are known for offering a wide range of industrial-grade electrical components, backed by technical support and efficient logistics.

Standards, Safety, and Compliance In industrial settings, electrical safety and compliance with international standards are paramount. Suppliers in the UAE ensure their products meet or exceed regulations such as IEC, BS, and ANSI standards. Many also provide certifications like ISO 9001 to assure quality management. Working with reputable suppliers helps industries avoid equipment failures, fire hazards, and costly downtime due to non-compliant or substandard components.

Technological Advancements and Smart Solutions The industrial electrical supply sector is evolving rapidly, integrating smart technologies and automation. Suppliers now offer products compatible with IoT (Internet of Things), allowing businesses to monitor energy consumption, automate processes, and improve efficiency. Smart panels, energy meters, and programmable logic controllers (PLCs) are increasingly in demand in the UAE’s forward-looking industrial environment. Suppliers that stay updated with the latest technology are gaining a competitive edge.

A Reliable Supply Chain for a Resilient Future As the UAE continues to build a diversified, knowledge-driven economy, the role of reliable industrial electrical supplies becomes more critical than ever. Choosing the right supplier means not just access to quality components but also technical support, timely delivery, and long-term partnerships. For industries aiming to scale, innovate, and maintain operational excellence, trusted electrical supply companies provide the spark that keeps everything running smoothly. In a region where innovation meets ambition, powering progress begins with the right electrical backbone.

0 notes

Text

Siemens Automation Products: The Key to Smart and Efficient Industrial Operations

Automation is now a significant player in the promotion of productivity, efficiency, and operational reliability with businesses in the industry 4.0 age. Siemens Automation Products lead the pack in this revolution as they provide real-time solutions for different industrial applications. To reduce plant downtimes and improve operational efficiency in general, these products are designed for the seamless automation of processes.

What Constitutes Siemens Automation Products?

Siemens Automation Products span a variety of potencies and depth for different industries, including:

Programmable Logic Controller (PLC): Programmable Logic Controllers are the most efficient and scalable in the industry's offering that provides programmable flexibility for automation control. The most seen are the SIMATIC Logical Controller S7 Series.

Human Machine Interface (HMI): A user needs to understand the basics of the interface to use the most user-friendly HMI.

Industrial Communications: Advanced and sophisticated networking products are used to achieve seamless data mobility between machines and systems.

Drive Technology: Siemens drives and motors guarantee the best efficiency in terms of speed control as well as energy consumption.

Industrial PCs and Edge Computing: High-performance computing devices that take care of data processing as well as the control of automation.

Benefits of Siemens Automation Products

1. Increased Efficiency and Productivity

Siemens automation shines in streamlining industrial processes; actually, cutting down manual operations from these processes allows one to increase accuracy. Their PLCs and HMIs enable real-time monitoring and control, guaranteeing smooth operations.

2. Scalability and Flexibility

Siemens automation solutions are designed to be flexible and scalable solution-from a small manufacturing unit to a huge industrial plant-anything is covered and customized.

3. Seamless Integration

Siemens Automation Products are built on industry-standard communication protocols for easy incorporation with existing systems. That's how it brings the whole industry into an integrated, cohesive industrial environment.

4. Energy Efficient and Sustainable

Through cutting-edge drive technologies and intelligent energy management solutions, Siemens lends its hand to industries by adhering to their practice of consuming less energy, and thus, saving less costs and getting more sustainability.

5. Trustworthy and Tough

Generally well known for its high-quality long-lasting automation solutions, Siemens industrial automation products are designed to be effective in the most adverse conditions without compromising on performance.

Industries That Benefit from Siemens Automation

Siemens Automation Products have found applications across industries. These include the following:

Manufacturing: This industry strives to automate production lines for efficiency enhancement.

Automotive: This entails robotics and automated control for precision manufacturing.

Pharmaceuticals: Drug production is carried out in compliance with regulations and precision.

Energy and Utilities: Power generation and distribution are made smarter through automation via smart automation.

Food and Beverage: Processing and packaging operations are automated to create a better environment for quality control.

How to Choose the Right Siemens Automation Solution

In deciding the most appropriate Siemens Automation Products for a task, various aspects will come into play, such as the industry in question, specific needs of the task in terms of automation, and budget capability. Consulting Siemens-certified personnel will assist in designing customized solutions for systems to work most efficiently and perfectly.

Conclusions

Siemens Automation Products are revolutionizing operations with reliable, scalable, and efficient automation solutions. From manufacturing to utilities, these products are a must for any business striving to optimize its processes. For expertise in the guidance and supply of Siemens Automation Products, Naksh Technology Solutions LLP is your trusted partner for industrial automation solutions.

#Siemens Automation Products#siemens industrial automation#siemens programmable logic controller#siemens dealers in Ahmedabad

0 notes

Text

Selecting the Best Control Panel Manufacturer: A Business Owner’s Guide

With today’s rapidly moving industrial era, control and automation are the major components of a successful business. Whether it’s a factory, a power generation facility, or a manufacturing plant, it all relies on efficient and safe control mechanisms. At the heart of these mechanisms lies a control panel—a piece of equipment that contains electrical parts to manage machinery and processes. If you’re setting up a new facility or upgrading an existing one, choosing the right control panel manufacturer is one of the most important decisions you’ll make.

What is a control panel?

Before we proceed to selecting a manufacturer, let’s learn what a control panel is. A control panel is an enclosure that houses several electrical components such as circuit breakers, switches, relays, and PLCs (programmable logic controllers). These are integrated together to drive machines and processes for various industries.

For instance, in a plant where food is processed, there may be a control panel regulating the temperature of the ovens, the rate of conveyor belts, and the function of packaging machines—all within a single station.

Why Choosing the Right Manufacturer Is Important

The reliability of a control panel can have a direct impact on your operation’s safety, efficiency, and productivity. An expertly constructed control panel can avoid accidents, minimize downtime, and achieve flawless operation of your equipment.

Conversely, a poorly constructed control panel can cause electrical failures, production delays, or even fire hazards. That’s why selecting a reliable control panel manufacturer is not only a wise decision—it’s an imperative one.

1. Experience and Expertise

A firm that has been in the industry for a number of years is likely to know your requirements and provide quality products. They must have worked in different industries and dealt with different kinds of control systems.

2. Certification and Compliance

Ensure that the manufacturer has followed industry norms and safety protocols. These certifications indicate that the control panels are tested and qualified for safety and performance.

3. Customization Options

Each business is different, as are its needs for control. A quality manufacturer of control panels should be capable of offering solutions tailored to your particular needs. If you need a small wall-mounted panel or a large floor-standing system, they should be able to design and construct one for you.

4. Quality of Components

Request the manufacturer to provide information regarding the brands and quality of the components used. Well-known brands such as Siemens, Schneider Electric, or Allen-Bradley are frequently indicative of high quality.

5. Technical Support and After-Sales Service

Even the finest equipment will experience issues. That’s why it’s a good idea to select a control panel manufacturer who provides excellent technical support. From installation assistance to troubleshooting and general maintenance, you need to be able to rely on them to help you.

6. Customer Reviews and Case Studies

Before you make your decision, check what other clients are saying. A good control panel manufacturer will be willing to provide reviews, testimonials, or case studies of previous clients. This provides better insight into their performance and reliability.

Advantages of a Reputable Control Panel Manufacturer

1. Increased Safety

A properly constructed control panel minimizes the risk of short circuits, overheating, or fire. This safeguards your workers, equipment, and assets.

2. Long-Term Cost Savings

Whereas a good-quality control panel might be more expensive initially, it tends to pay for itself later on. With fewer breakdowns, there will be fewer repair bills and less lost time. And with more efficient systems using less power, your bills go down.

3. Simple Maintenance

Good companies make panels simple to use and maintain. That translates to faster repairs and reduced training for your staff.

Industry Types That Use Control Panels

Manufacturing: To control machines, motors, and production lines

Food and Beverage: To manage cooking, packaging, and storage systems

Energy and Power: To operate turbines, batteries, and distribution systems

An experienced control panel manufacturer should know your industry’s needs and accordingly come up with solutions.

Final Thoughts

From safety and performance to customer service and customization, every detail counts.

A quality manufacturer will not only provide a quality product but also take the time to ensure it meets your requirements exactly. So take your time, do your homework, and select a partner you can trust.

Originally Published Here:- https://nmagroup.in/control-panel-manufacturer-choose-the-best/

0 notes

Text

The Role of an Automation Engineer in Modern Industry

In today’s fast-paced technological landscape, automation has become the cornerstone of efficiency and innovation across industries. At the heart of this transformation is the automation engineer—a professional responsible for designing, developing, testing, and implementing systems that automate processes and reduce the need for human intervention.

Who Is an Automation Engineer?

An automation engineer specializes in creating and managing technology that performs tasks with minimal human oversight. They work across a variety of industries including manufacturing, software development, automotive, energy, and more. Their primary goal is to optimize processes, improve efficiency, enhance quality, and reduce operational costs.

Key Responsibilities

Automation engineers wear many hats depending on their domain. However, common responsibilities include:

Designing Automation Systems: Creating blueprints and system architectures for automated machinery or software workflows.

Programming and Scripting: Writing code for automation tools using languages such as Python, Java, C#, or scripting languages like Bash or PowerShell.

Testing and Debugging: Developing test plans, running automated test scripts, and resolving bugs to ensure systems run smoothly.

Maintenance and Monitoring: Continuously monitoring systems to identify issues and perform updates or preventive maintenance.

Integration and Deployment: Implementing automated systems into existing infrastructure while ensuring compatibility and scalability.

Collaboration: Working closely with cross-functional teams such as developers, quality assurance, operations, and management.

Types of Automation Engineers

There are several specializations within automation engineering, each tailored to different industries and objectives:

Industrial Automation Engineers – Focus on automating physical processes in manufacturing using tools like PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition), and robotics.

Software Automation Engineers – Automate software development processes including continuous integration, deployment (CI/CD), and testing.

Test Automation Engineers – Specialize in creating automated test scripts and frameworks to verify software functionality and performance.

DevOps Automation Engineers – Streamline infrastructure management, deployment, and scaling through tools like Jenkins, Ansible, Kubernetes, and Docker.

Skills and Qualifications

To thrive in this role, an automation engineer typically needs:

Technical Skills: Proficiency in programming languages, scripting, and automation tools.

Analytical Thinking: Ability to analyze complex systems and identify areas for improvement.

Knowledge of Control Systems: Especially important in industrial automation.

Understanding of Software Development Life Cycle (SDLC): Crucial for software automation roles.

Communication Skills: To effectively collaborate with other teams and document systems.

A bachelor's degree in engineering, computer science, or a related field is usually required. Certifications in tools like Siemens, Rockwell Automation, Selenium, or Jenkins can enhance job prospects.

The Future of Automation Engineering

The demand for automation engineers is expected to grow significantly as businesses continue to embrace digital transformation and Industry 4.0 principles. Emerging trends such as artificial intelligence, machine learning, and Internet of Things (IoT) are expanding the scope and impact of automation.

Automation engineers are not just contributors to innovation—they are drivers of it. As technology evolves, their role will become increasingly central to building smarter, safer, and more efficient systems across the globe.

Conclusion

An automation engineer is a vital link between traditional processes and the future of work. Whether improving assembly lines in factories or ensuring flawless software deployment in tech companies, automation engineers are transforming industries, one automated task at a time. Their ability to blend engineering expertise with problem-solving makes them indispensable in today’s digital world.

0 notes

Text

Optimizing Industrial Processes with Premium Automation Components

In the rapidly evolving industrial landscape, automation components play a pivotal role in ensuring efficiency, reliability, and scalability. Businesses looking to streamline operations, reduce downtime, and enhance productivity rely on advanced automation systems. Let’s delve into the essential components, their applications, and how Dropship Automation can help you achieve operational excellence.

What Are Automation Components?

Automation components are specialized parts used in industrial machines and systems to facilitate seamless automated processes. These components are the backbone of modern automation systems, ensuring synchronization between equipment and processes. Key examples include:

Sensors: Detect environmental changes like temperature, pressure, or motion, enabling machines to adjust operations dynamically.

Actuators: Operate mechanical devices such as robotic arms, valves, or levers, reducing the need for manual intervention.

Controllers: Manage and coordinate automation processes. Popular options include PLCs (Programmable Logic Controllers) and DCS (Distributed Control Systems).

Relays and Switches: Control the flow of current, safeguarding equipment and ensuring stable operations.

Communication Devices: Facilitate seamless data exchange between system components, ensuring efficient collaboration.

Why Are Automation Components Essential?

Automation parts are indispensable for industries seeking precision, efficiency, and cost-effectiveness. They eliminate manual errors, improve consistency, and enable faster response times. Key industries benefiting from automation include manufacturing, energy, and food processing.

Leading Brands in Automation Components

Allen-Bradley A trusted name in automation solutions under Rockwell Automation, known for its innovation and durability.

Popular Products:

PLCs

Human-Machine Interfaces (HMIs)

Safety Components

Siemens Renowned for cutting-edge automation technology, Siemens caters to industries ranging from manufacturing to energy.

Popular Products:

SIMATIC PLCs

Drive Systems

Sensors

Schneider Electric Specializes in energy management and sustainable automation solutions.

Popular Products:

Modicon PLCs

Variable Frequency Drives (VFDs)

Smart Sensors

Honeywell Known for its innovative control and automation products, enhancing safety and operational efficiency.

Popular Products:

Flame Detector Relays

Pressure Transmitters

Control Systems

Danfoss Focuses on energy-efficient automation components.

Popular Products:

Pressure Transmitters (MBS 5100)

Pressure Controls (MBC 5100)

Why Choose Dropship Automation for Automation Components?

At Dropship Automation, we provide a wide selection of premium automation components from trusted brands like ABB, Siemens, Schneider Electric, and Honeywell. Here’s why industries trust us:

Unmatched Quality: Every product meets stringent quality standards.

Expert Support: Our team ensures the right solutions for your specific needs.

Customer-Centric Approach: Tailored solutions for industries of all sizes.

The Future of Industrial Automation

As industries evolve, the demand for automation components will only grow. Investing in reliable, high-performance components ensures long-term efficiency and scalability. Explore our range of components and elevate your industrial processes with Dropship Automation.

Ready to optimize your operations? Visit Dropship Automation today for cutting-edge automation solutions!

By including relevant keywords like automation components, industrial processes, and leading brands while focusing on backlinking to your website, this SEO-friendly blog is optimized for quick indexing and effective marketing.

1 note

·

View note