Text

A new Guide to The Light weight aluminum Trench Shoring Box | Unbelievably Lightweight and Versatile

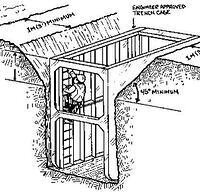

The aluminum trench shoring box is usually used in development and is simply perfect for modest jobs and little areas. Mainly used for light source repair and scheduled upkeep work, these trench boxes will guarantee the safety of producers associates working on the specific construction site, inside a new trench. A aluminum trench shoring container possesses some sort of support method that will prevent undeterminable factors such as, soil, roads, and even foundations from falling apart and causing immediate injury to almost any workers. Aluminum trench shoring is a good ideal solution for pretty much almost all types of soil ailments plus jobs where the trench box is wanted.

Aluminum Trench Box | A Trench Safety Unit

Even though an lightweight aluminum trench shoring box will certainly present this same protection as being a metal trench box, this metal is still only 50 % the weight of metallic. Organised apart by steel or metal spreaders, lightweight aluminum trench shoring boxes are really made to various certifications of thickness to secure a harder hold. There are many different steel and aluminium spreaders that will complement any width of any kind of trench. Aluminum trench bins mostly are made up associated with two sides, in contrast to it will offer some sort of mechanised support system in typically the event the excavation has to take place in a construction site. Aluminum trench boxes are used wheresoever there isn't stable ground and to decrease the need to have for excavation.

Click Here are usually basic units that can certainly be installed swiftly and very easy to present, long lasting, yet dependable support. Light weight aluminum trench boxes will be most beneficial when executing work such as pipe laying, manholes, cable tv jobs and a great deal more when have to dig way up the ground for building purposes. Aluminium trench shoring boxes are an ideal, harmless solution that will ultimately spend less income on work-related accidents due to building site destruction and damage. The reality that no two excavation attempts will be the same inside the function of excavation, you can find different approaches when employing aluminium trench boxes. If adding an metal trench program, hydraulic shoring may be utilized, in which in turn hydraulic pistons may water pump outwardly to hold the box sides against the trench wall structure.

Correlate with Fin Form Board

In most cases, if certainly not almost all, aluminum trench boxes may be combined with a steel dish or perhaps very durable and even strong plywood called Cid form. Another method which you can use is the beam in addition to dish procedure, in which steel I-beams are propelled into terrain and metallic plates are going to be slid straight into place most notable.

Hydraulics usually are used for faster apps and the other procedures are usually used for longer-lasting applications in addition to extreme excavation jobs. Picking out aluminum shoring, it can be purchased new or maybe used. Whether or not purchasing light weight aluminum trench shoring new or perhaps used, make sure to select one that might fit in the scale regarding the job. Also light weight aluminum trench shoring box and pick companies along with the highest overall basic safety ratings, because excavating is really a potentially dangerous and high-risk job. Make sure to take right size thus that the aluminium trench box will properly fit into place and know precisely how to appropriately put that into place, in respect of reduce any malfunction, in different damaging situation.

0 notes

Text

Some sort of Guide to The Metal Trench Shoring Box | Amazingly Lightweight and Versatile

The aluminium trench shoring box is usually used in building and is ideal for smaller jobs and smaller locations. Mainly used for light-weight repair and scheduled upkeep work, these trench boxes guarantees the safety of staff associates working on a specific construction site, in a new trench. A great aluminium trench shoring container offers the support system that will will prevent undeterminable components such as, soil, highways, and even foundations from collapsing in addition to causing immediate personal injury to just about any workers. Aluminum trench shoring is a great optimum solution for almost almost all types of soil ailments together with jobs where some sort of trench box is desired.

Aluminum Trench Shoring Box | A Safety Gadget

Though an metal trench shoring box will offer the particular same protection like a material trench box, this lightweight aluminum is still only half the weight of steel. Presented apart by metal as well as metal spreaders, lightweight aluminum trench shoring boxes are really constructed to various diplomas of width to obtain a more firm hold. There are aluminum trench cage and light weight aluminum spreaders that will fit any kind of width of virtually any trench. Aluminum trench packing containers are mostly made up regarding two sides, while this will offer some sort of mechanical support system in typically the event the excavation possesses to take place at the construction site. Aluminum trench boxes are used where ever there isn't stable ground in addition to to decrease the want for excavation.

They usually are very simple units that can certainly be installed quickly and even very easy to offer, tough, yet dependable assist. Aluminium trench boxes are usually most reliable when performing careers for example pipe laying, manholes, cable connection jobs and more when ought to dig way up the ground for design purposes. Aluminum trench shoring boxes are a ideal, risk-free solution that will inevitably save cash on work-related injury due to design site destruction and turmoil. The fact that zero two excavation attempts will be the same in the celebration of excavation, you will find different approaches when using lightweight aluminum trench boxes. Any time adding an aluminum trench method, hydraulic shoring can certainly be used, in which will hydraulic pistons will pump motor outwardly to hold the sides against the trench wall.

Pair with Fin Form Board

In most conditions, if not necessarily just about all, aluminum trench boxes can be paired with a steel dish or very durable plus heavy-duty plywood called Very b form. Another method which you can use is the beam and platter approach, in which will steel I-beams are powered into terrain and metal plates are going to be slid in to place including.

Click the Following Page happen to be used for faster programs and the other approaches are likely to be used for permanent applications plus extreme excavation jobs. When shopping for aluminum shoring, it can be acquired new or perhaps used. If purchasing metal trench shoring new as well as used, make certain to select one that might in shape the scale regarding the job. As well study and pick models with the highest overall security ratings, because excavating can be a potentially dangerous and high-risk job. Make sure for you to take correct dimensions and so that the lightweight aluminum trench box will correctly fit into place and know how to appropriately put that into place, regarding protect against any malfunction, in just about any destroying situation.

0 notes

Text

Just where Will You Most Most likely Find a Freestanding Jib Crane?

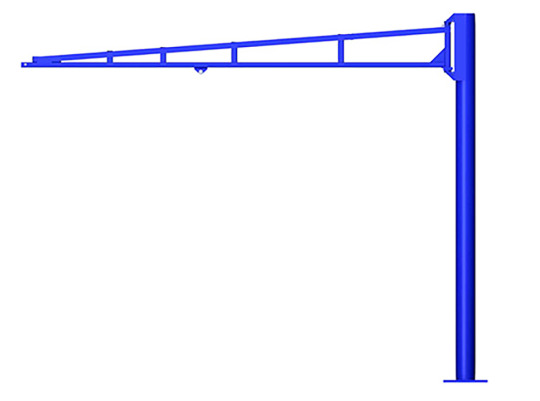

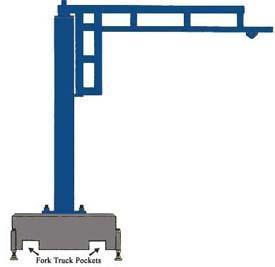

https://everythingyouneverneedtoknow.tumblr.com/post/620001501662855168/where-will-you-most-in-all-likelihood-find-a involving the most versatile uses in a wide range of applications; is certainly, a freestanding jib crane. Although small within size, the particular jib crane system is an incredibly powerful piece of raising devices. For the most part, jib cranes can be resolved to a wall or possibly a pillar and feature some sort of side to side boom (also identified as a jib), movable company hoist, carol, wire rules, and stores. Overhead industrial jib crane setup are simplest to put in almost anywhere, including external. A free-standing jib crane offers larger capacities, more lengthy spans, together with greater rotable. Jib cranes consist of the load-supporting boom, which is attached with a pivoting vertical vertebral column that is either free-standing or even building mounted. A good free-standing jib crane is usually offered in a selection of capacities and designs and it even offers motorized rotation.

Free-Standing Jib Crane | Positioning Beneath Large Overhead Bridge

They are perfect fit to help be placed in directly below large bridge crane systems, likewise in areas which will be inside open where these people can support several work stations, in apps which are usually mostly outdoor with regard to example of this loading docks, or perhaps inside of machining operations in addition to set up operations where they could be easily overlapped with other jib crane so that staged surgical procedures can be provided. Jib crane setup are in addition used in industrial property and on military vehicles. Typically the jib may golf swing through an arc, to give additional lateral motion, or end up being fixed. As well, jib cranes are applied in shipyards intended for several purposes such as lifting equipment and heavy machinery, mostly weighing 100 ~ 300 tons. Usually, these types of cranes are provided together with 2 main joint treuil which can be either employed singly or maybe together so of which they can lift some sort of load. Jib crane systems using manufacturing facilities that normally have a capacity regarding up to 30 plenty operating 50 to help one hundred cycles per hour. And so are able to Lift from a elevation up to be able to 30 meters as well as additional.

Jib Cranes are Popular Choices for Consumers

Freestanding jib cranes are without doubt one of the most popular possibilities for crane customers who also do not require the lifting function in any corner in their workshop. https://jakerocks.tumblr.com/post/620003015607435264/just-where-will-you-most-probably-find-a will be suppliers to help load lathes and even various other types of machinery that handle heavy loads, fortunately they are recommended to be used when that comes to maintenance of applications.

Additional ever the jib crane system is a favorite device for photography enthusiasts as very well. The jib is specifically versatile and may produce a new bunch of special outcomes. With a jib crane setup, the different possible video camera effects are almost endless. The perfect part of working with a jib crane to get photography is that that provides a high production benefit for very little effort and some sort of very affordable cost. It’s incredibly uncomplicated to set up and take apart under very less time and doesn’t require any instruments for construction. When you happen to be finished having the use of the particular jib crane system, this sections may be easily trapped in luggage and can easily become carried away to typically the ideal place without just about any hassle.

0 notes

Text

Where Will You Most In all likelihood Find a Free=Standing Jib Crane?

One associated with the most versatile uses in a wide range of applications; is definitely undeniably, a freestanding jib crane. Although small inside size, typically the jib crane setup is an extremely impressive piece of moving products. For the most component, jib cranes will be resolved to a wall or maybe a pillar and feature a good side to side boom (also identified as a jib), movable cycle hoist, drum, wire basics, and stores. Overhead https://stellayirealestate.tumblr.com/post/620001628541648896/wherever-will-you-most-likely-find-a-freestanding are least complicated to set up almost anywhere, including exterior. A free-standing jib crane offers higher capacities, much longer spans, together with greater rotator. Jib cranes consist of a new load-supporting boom, which is linked to a pivoting vertical section that is either free-standing as well as building mounted. Some sort of free-standing jib crane can be obtainable in a wide variety of capacities and configurations and it even features mechanized rotation.

Free-Standing Jib Crane | Placing Underneath Large Bridge Cranes

They are perfect fit in order to be placed in below large bridge crane setups, as well in areas which usually are in open where many people can accommodate several work stations, in applications which are usually mostly outdoor to get case in point loading docks, or in machining operations in addition to set up operations where they are often very easily overlapped with other jib crane system so that taking place surgical procedures can be given. Jib crane system are furthermore used in industrial premises and on military cars. Typically the jib may move via an arc, to give extra lateral mobility, or turn out to be fixed. Likewise, jib cranes are made use of in shipyards intended for various purposes such as raising equipment and heavy machines, mostly weighing 100 : 300 tons. Usually, all these cranes are provided with 2 main joint winches that can be either employed singly or even together so that they can lift some sort of load. Jib cranes having manufacturing facilities that typically have a capacity regarding up to 20 lots operating 50 to help 100 cycles per hour. And are able to Lift with a position up for you to 30 meters or a great deal more.

Jib Cranes are Favorite Choices for Customers

Freestanding jib cranes are one in all the most popular options for crane customers who also do not require a lifting function in any corner in their workshop. Jib crane setup are usually suppliers to load lathes and other types of machinery that will handle heavy loads, luckily they are recommended to be utilized when it comes to be able to maintenance of applications.

A great deal more ever the jib crane is a favorite software for shooters as very well. The particular jib is especially versatile and can produce a lot of distinctive consequences. With a jib crane setup, the different possible video camera side effects are almost unlimited. The most effective part of making use of a jib crane for photography is that this provides high production value with regard to very little energy and a good very realistic cost. It’s extremely uncomplicated to set up plus take apart under very significantly less time and even doesn’t need any equipment for set up. When you are finished together with the use of the jib crane, the sections can easily be easily trapped in bags and can easily become carried away to often the wanted place without virtually any hassle.

0 notes

Text

Will the Fully Automated Factory Exist Soon | The Awesome Over head Workstation Bridge Crane System

Technology news late final month was abuzz along with the headline the fact that Foxconn, a Chinese-based making business, perhaps most famous regarding iPhone generation, planned to completely systemize its plants throughout Cina. This comes after decades and years of engineering innovations in plants all around the planet. Manufacturing effectiveness keeps improving and greater as equipment enhances. To get industries , an over head

0 notes

Text

Will the Fully Automated Stock Exist Soon | The Incredible Over head Workstation Bridge Crane

https://alphas-bite.tumblr.com/post/622361297046110208/various-situations-involving-workers-settlement was abuzz together with the statement that Foxconn, a Chinese-based developing company, perhaps most famous for iPhone generation, planned to totally mechanize its plants around Tiongkok. This comes after years and years associated with scientific developments in factories all-around the earth. Manufacturing performance keeps improving and far better as equipment helps. Intended for example, an over head

0 notes

Text

Does the Fully Automated Plant Be Here Soon | The Awesome Over head Workstation Bridge Crane System

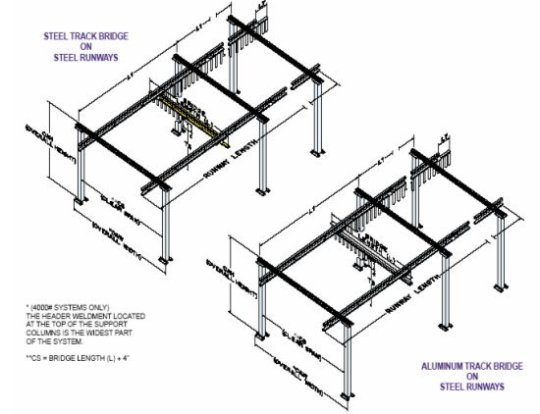

Technology news late final month was initially abuzz having the announcement of which Foxconn, a Chinese-based processing corporation, perhaps most famous regarding iPhone development, planned to totally handle its plants inside Tiongkok. This comes soon after yrs and years associated with engineering improvements in factories about the entire world. Manufacturing proficiency keeps improving and greater as equipment enhances. To get example, an overhead workstation bridge crane system can be used to transfer large loads across the stock space instead of plenty of workers struggling to move it. However, this latest technological growth is definitely the Chinese manufacturer that will entirely be automated.

Entirely computerized plants, of training course, have been coming with regard to some time, fueled by simply smart machines and the World wide web of Things (IoT). Equally mean that automated programs and methods that create products can communicate along with individuals solutions, and bassesse versa. If there are any kind of repairs would have to be completed, like as mechanical concerns, or perhaps screw replacements, they may be obtained on the web from dynatect. com to keep the machines running efficiently. These factories will require high-quality factory flooring surfaces to ensure that will technicians can preserve IoT methods. Reconfiguring plant workflows to accommodate this interesting new technology is important when taking into consideration the RETURN in these IoT processes.

Two years ago MarketWatch was initially predicting that the approaching of the completely programmed stock was some sort of ten years into the future. German factories throughout 2014 were already 73% automated, but still demanded the brigade of product or service and systems managers.

Robotisation is likely good news with regard to Foxconn’s bottom line. Besides the iPhone, the company’s plants produce monitors and individual personal computers. Robustly producing plants with out human workers could appear like a formula to be able to reduce toil costs in addition to thus be very rewarding.

In March 2016, Foxconn announced that 60, 500 jobs had been recently minimize in just one associated with its factories due to automating. industries has mentioned that this will get far from a final.

The resultant cash may be utilized, Fortune points out, to invest in expansion or purchase, for example Foxconn’s acquisition of Rough, the as soon as Japanese-owned electronics company.

Most likely Not And so Good intended for China’s Economy

Full automation may use beneficial effects around the company’s bottom line, but typically the effects on the total economic system connected with China could very well be negative.

China’s financial boom has been supported by means of consumer spending in addition to a new rising middle and upper middle class ~ as a result connected with more jobs needed to construct the country’s rising system. Foxconn’s workers happen to be portion of that rising middle class. Click the Following Internet Site has depended for many decades upon low-wage staff, initially from rural China and taiwan, who emigrated to the company’s locations specifically for work in their own plants. Decreased wages were still over what rural Chinese ordinarily earned, improving spendable revenue.

0 notes

Text

Will the Fully Automated Manufacturer Exist Soon | The Remarkable Over head Workstation Bridge Crane System

Technology news late past month was initially abuzz along with the statement that will Foxconn, a Chinese-based making organization, perhaps most famous to get iPhone development, planned to totally mechanize its plants in China and taiwan. This comes immediately after yrs and years of scientific trends in factories around the world. Manufacturing effectiveness keeps improving and greater as equipment helps. Intended for example, an overhead workstation bridge crane system can become used to move serious loads across the stock space instead of lots of personnel struggling to move it. Having said that, the particular latest technological advancement is the Chinese factory that can entirely be automated.

Fully programmed production facilities, of training course, have already been coming to get some time, fueled by way of smart machines and this Online of Things (IoT). Equally mean that software and techniques that produce products can communicate along with those people solutions, and corruption versa. If there are almost any repairs must be completed, like as mechanical problems, or even screw replacements, they are often obtained online from dynatect. possuindo to keep the equipment running efficiently. These industrial facilities will require high-quality factory floor to ensure that specialists can manage IoT methods. Reconfiguring plant workflows to accommodate this interesting new technology is critical when thinking about the RETURN on these IoT processes.

A pair of years ago MarketWatch had been predicting that the returning of the entirely automated factory was some sort of few years into the future. German factories throughout 2014 were already 74% programmed, but still needed a hiérarchie of product or service and systems managers.

Robotisation is likely very good news with regard to Foxconn’s bottom line. Along with the iPhone, the company’s factories produce monitors and individual computer systems. Robustly producing industrial facilities without having human workers might look like a recipes to be able to reduce job costs plus thus be highly successful.

In March 2016, Foxconn announced that 60, 1000 jobs had been lower in just one regarding its factories because of motorisation. The company has suggested that this will get far from the final.

Often the resultant cash can be made use of, Fortune points out, to invest in expansion or acquisition, like Foxconn’s buy of Quick, the when Japanese-owned technology company.

Maybe Not Thus Good with regard to China’s Financial system

Full software may exert beneficial effects for the company’s bottom line, but often the consequences on the entire economic system associated with China may possibly be negative.

China’s financial boom has been h2o by means of consumer spending and a new rising middle and even upper middle class – as a result associated with more jobs instructed to build the country’s increasing infrastructure. Foxconn’s workers have been part of that rising midst class. Foxconn has depended for several decades with low-wage employees, initially through rural Cina, who emigrated to the company’s carritatives specifically for work in their particular plants. Reduced wages have been still above what rural Chinese generally earned, growing spendable earnings.

0 notes

Text

Tesla Mega/Factory Begins Battery Generation | Very Exciting News for the Automotive Industry

Tesla’s production facilities have always already been some of the almost all fruitful car manufacturing vegetation in the industry. These people plan everything from typically the brand regarding free standing foundationless jib crane they will use in order to which parts of the method are going to turn out to be fully automated. However , that they need to ensure many people have sufficiently parts in order to actually keep up with the interest rate they manufacture their own autos. This is exactly why Tesla said it and partner Panasonic have got started mass production of commercial top quality lithium-ion battery power tissues in the Tesla Gigafactory, forcing the electric car in addition to energy storage area company closer to the production of it is Model several electric automobile.

The cells right now inside generation at the The state of nevada manufacturing plant are intended to get use in Tesla’s Powerwall 2 and Powerpack only two stationary energy hard drive devices, the company said. Production of cells intended for the particular Tesla Model 3 or more is usually to begin in this second quarter.

Tesla’s Gigafactory in December 2016

This $5 billion Gigafactory is actually a massive battery manufacturing service close to Reno. With some. 9-million square toes connected with room operational now, the particular multi-story factory complex will be only about 30 per cent completed. Tesla says it intends to hire “several thousand” personnel for typically the plant this year plus has pegged full career there with more than 6th, 500 jobs. We all speculate what new technology often the Tesla factory will turn out to be employing in order to help work? Will each uses computer systems from cksglobal. web?

California-based Tesla has said that it intends to be producing 36 gigawatt-hours per year of lithium-ion batteries from the Gigafactory by means of 2018 when Model three or more manufacturing is in full golf swing. That’s almost as a great deal as typically the annual generation of all other lithium ion battery companies worldwide. Tesla has set some sort of first-year manufacturing goal of fifty, 1000 Model 3 sedans for is Fremont, Calif., set up plant.

The Tesla Type 3 sedan can be smaller and less expensive compared to the carmaker’s present products – the Model S i9000 four door and Model X all terain EVs. Tesla has established a target selling cost of $35, 000 just before incentives for the foundation Model a few, about a new third of what the common Tesla purchaser shells away for one of typically the company’s EVs now.

To help get the price that will low, Tesla needs for you to drastically reduce the cost of the car’s electric battery pack. The idea expects automation and high-volume production at the Gigafactory to be the huge element in accomplishing that goal.

0 notes

Text

Tesla Gigafactory Starts Battery Manufacturing | Very Exciting Media for the Automotive Business

Tesla’s plants have always been recently some of the most successful car manufacturing plants in the industry. That they plan everything from this brand involving free standing foundationless jib crane system they're going to use in order to which parts of the procedure are going to become fully automated. Nevertheless , many people need to ensure they will have more than enough parts to actually keep up with the interest rate they manufacture their very own vehicles. This is so why Tesla said the idea plus partner Panasonic have got in progress mass production of commercial good quality lithium-ion battery power tissue in the Tesla Gigafactory, forcing the electric car together with energy hard drive company closer to the production of it is Model 3 or more electric car.

The cells nowadays in production at the Nevasca manufacturing plant are intended with regard to use in Tesla’s Powerwall 2 and Powerpack two immobile energy safe-keeping techniques, the company said. Creation of cells intended to get this Tesla Model a few is always to begin in the particular second quarter.

Tesla’s Gigafactory in December 2016

Typically the $5 billion Gigafactory is really a massive battery manufacturing center near Reno. With some. 9-million square ft involving place operational now, typically the multi-story factory complex is usually only about 30 % completed. Tesla says that intends to hire “several thousand” staff for typically the manufacturing plant this year together with has pegged complete work there in more than 6th, 500 jobs. All of us ponder what new technology typically the Tesla factory will turn out to be working with in order to be able to work? Will each uses pcs from cksglobal. world wide web?

California-based Tesla has said it intends to be generating 35 gigawatt-hours per yr of lithium-ion electric batteries at the Gigafactory by means of 2018 when Model several generation is in full swing. That’s almost as very much as often the annual generation of all additional li ion battery companies on earth. Tesla has set the first-year generation goal of 50, 1000 Model 3 sedans regarding is Fremont, Calif., installation plant.

The Tesla Design 3 sedan is usually small and less expensive compared to the carmaker’s present products – the Model T 4 door and Model X crossover EVs. Tesla has arranged a target selling cost associated with $35, 000 prior to bonuses for the foundation Model 3, about some sort of third of the particular ordinary Tesla consumer covers out for one of the particular company’s EVs now.

To be able to get the price that low, Tesla needs to drastically lessen the charge of the car’s battery power pack. This expects motorisation and high-volume production in the Gigafactory to be a large aspect in accomplishing that goal.

0 notes

Text

A variety of Situations involving Worker's Pay out | When Does an Attorney Need to End up being Involved

Workers' pay out laws give benefits in order to employees wounded on the job, as well as a workers compensation attorney at law only need step in when these regulations are not fair adhered to. Express statutes and regulations define typically the benefits. For example, those people entirely disabled by a new work-related personal injury receive a weekly staff payment benefit of 60 percent of their pre-injury average weekly income.

In rare cases, in the event that the injury is scheduled to serious and willful misconduct of the supervisor, the benefits are doubled. This is Ma law, underneath section 36 of often the Massachusetts workers compensation law. But the conduct needs to be quasi-criminal, the deliberate carrying out of something sometimes using the knowledge that it is definitely likely to end in serious injuries or which has a wanton and reckless discount associated with its probable consequences.

Circumstances Involving Very Serious and Willful Misconduct:

In one case dropping debris was some sort of normal feature of a worksite. Three workers declined to get results at the area because of the real danger. But a honcho, chief, gaffer boss requested an employee to operate there. The particular staff complied, resulting in their long-lasting and total disability coming from falling timber.

In another scenario, a foreman ordered a good worker to disregard safe practices provisions even though working on metal beams with pointed protrusions knows as shear fittings. The intentional in an attempt to ignore the safety provision violated a collective bargaining arrangement.

Another employee was damaged after the employer deliberately ignored regulations requiring announcement to be able to public utilities in advance of executing ground excavation. Some sort of examiner ordered the employee to hold digging despite the appearance of underground cement.

A final illustration of significant willful misconduct involved the foreman which ordered a staff to work in a new trench the fact that had definitely not recently been shored plan a good OSHA trench shoring cage rules, breaking both regulations plus directions from the general chief, gaffer boss. As one court mentioned, a common theme in this cases will be a good prepared disregard connected with a good acknowledged safety prerequisite in the face of admonitions to be able to the contrary.

Cases Missing out on Serious and may Misconduct:

Significant and willful misconduct was initially not found in a case where the injury was initially induced by failure to help shore up a trench around violation of clear rules. But admonitions or even on the contrary instructions were definitely not present in the important points connected with the case.

Serious and even willful misconduct was definitely not located where injury resulted through failure to mount an illinois security guard on the carding device in violation connected with laws.

Elsewhere, a great boss refused a suggestion for you to use “tested” instead involving “ordinary” chains on the dryer roll of a paper making machine. The court docket explained that in these instances presently there was evidence that employers could have been whole lot more careful, they took a good risk. However their carry out did not surge to help the level of typically the serious and even willful misconduct required from the laws.

Throughout another case, some sort of plant shop employee fell into straight into an unguarded capture entry in the floor. State and federal regulations require railing even so the company relied only found on orange-colored safety cones and even places to eat. The court assumed the particular company’s conduct might are already negligence as well as sometimes uncouth negligence, but not necessarily the particular wanton clumsy carry out required to double workers settlement rewards. This person seemed to be also ready to return to job using a return to help do the job program.

0 notes

Text

A variety of Situations involving Worker's Settlement | When Does the Attorney Need to Turn out to be Involved

OSHA trench shoring cage requirements offer benefits to be able to employees wounded on the job, and a workers compensation law firm only need step in when these kind of legal guidelines are not usually adhered to. Status constitution and regulations specify typically the benefits. For example, all those completely disabled by some sort of work-related injuries receive a new weekly workers settlement benefit of 60 percent of their pre-injury average weekly income.

In rare cases, when the damage is credited to serious and willful misconduct of the company, the huge benefits are doubled. This is Massachusetts law, underneath section 28 of the particular Massachusetts workers settlement statute. But the conduct has to be quasi-criminal, the intentional executing of something sometimes together with the knowledge that it is likely to lead to serious personal injury or which has a wanton and reckless neglect associated with its probable consequences.

Instances Involving Serious and Willful Misconduct:

In one circumstance falling debris was the typical feature of the worksite. Three workers waived to work at the area because of the threat. But a gaffer boss bought an employee to job there. Typically the employee complied, resulting in his or her long lasting and total incapability via falling timber.

In another event, a gaffer boss requested a worker to disregard safe practices provisions although concentrating on iron beams with sharp protrusions knows as shear fittings. The intentional order to overlook the safety provision broken a collective bargaining deal.

Another employee was hurt after the employer deliberately pushed aside regulations requiring announcement to help public utilities ahead of performing ground excavation. A good manager ordered the staff member to keep digging despite the appearance of undercover concrete.

A final illustration of significant willful misconduct involved the foreman who also ordered a staff to work in a trench of which had definitely not been recently shored program an OSHA trench cage rules, violating both regulations plus instructions from the general gaffer boss. As one court noted, a common theme in typically the cases will be a good prepared disregard connected with a good regarded safety necessity in often the face of avertissement in order to the contrary.

Cases Absent Serious and can Misconduct:

Significant and willful misconduct had been not found in an instance where the injury was brought on by failure to coast up a trench around violation of obvious polices. But admonitions or perhaps in contrast instructions were not really present in the facts involving the case.

Serious in addition to willful misconduct was not found where injury resulted through failure to set up a security guard on a carding machine in infringement regarding restrictions.

Elsewhere, a great boss rejected a recommendation to be able to use “tested” instead involving “ordinary” places to eat on some sort of dryer roll of the papers making machine. The particular court docket explained that in these instances there was evidence that business employers could have been extra careful, they will took a risk. But , their perform did not increase in order to the level of this serious and willful wrong doings required inside regulation.

Inside another case, some sort of plant shop employee fell into in to an unguarded trap door in the floor. State and federal regulations require railing however the company relied only on orange-colored safety cones in addition to restaurants. The court presumed typically the company’s conduct might are already negligence or sometimes major negligence, but not the wanton clumsy carry out forced to double workers settlement rewards. This person was also ready to come back to job using a return to help do the job program.

0 notes

Text

Does the Fully Automated Plant Be Here Soon | The Wonderful Overhead Workstation Bridge Crane System

Technology news late final month was abuzz having the story that Foxconn, a Chinese-based production company, perhaps most famous with regard to iPhone development, planned to totally systemize its plants inside The far east. This comes immediately after several years and years involving scientific improvements in plants around the earth. Manufacturing efficiency keeps recovering and much better as equipment boosts. Regarding example, an overhead workstation bridge crane can become used to proceed serious loads across the manufacturer space instead of loads of staff struggling to be able to move it. However, this latest technological growth could be the Chinese manufacturer that will fully be automated.

Totally programmed plants, of training course, have been recently coming with regard to some time, fueled by way of smart machines and typically the Web of Things (IoT). Both mean that forex robots and techniques that help to make products can communicate along with these goods, and perversité versa. When there are just about any repairs would have to be completed, such as mechanical difficulties, or even screw replacements, they may be obtained online from dynatect. contendo to keep the products running efficiently. These plants will require high-quality factory floor to ensure the fact that professionals can maintain IoT programs. Reconfiguring manufacturer workflows to accommodate this enjoyable new technology is critical when taking into consideration the RETURN on these IoT processes.

2 years ago MarketWatch was predicting that the coming of the entirely computerized plant was a new decade ahead6171. German factories in 2014 were already 74% computerized, but still recommended a good brigade of product or service and methods managers.

Automation is likely great news for Foxconn’s bottom line. As well as the iPhone, the company’s industrial facilities produce monitors and personalized computers. Robustly producing production facilities without the need of human workers could look like a recipe to reduce labor costs together with thus be remarkably profitable.

In March 2016, Foxconn announced that 60, 000 jobs had been minimize in just one associated with its factories as a result of automating. The company has indicated that this will end up being far from the final.

The particular resultant cash could possibly be used, Fortune points out, to invest in expansion or purchase, for example Foxconn’s purchase of Sharp, the after Japanese-owned consumer electronics company.

Maybe Not So Good intended for China’s Overall economy

Full motorisation may apply beneficial effects for the company’s bottom line, but this effects on the all round economic system involving China can be negative.

China’s economic boom has been support by simply consumer spending and a good rising middle and also upper middle class ~ as a result regarding more jobs needed to build the country’s increasing commercial infrastructure. Foxconn’s workers are actually component of that rising mid class. Foxconn has depended for a number of decades on low-wage personnel, initially by rural China, who emigrated to the company’s carritatives specifically to work in their plants. Decreased wages were being still over what rural Chinese usually earned, boosting spendable earnings.

0 notes

Text

Does the Fully Automated Plant Be Here Soon | The Wonderful Overhead Workstation Bridge Crane System

Technology news late very last month had been abuzz along with the announcement of which Foxconn, a Chinese-based manufacturing firm, perhaps most famous with regard to iPhone generation, planned to totally automate its plants around China and taiwan. This comes immediately after decades and years of technical developments in production facilities all around the earth. Manufacturing proficiency keeps getting better and better as equipment helps. Regarding example, an over head

0 notes

Text

Good Motor For Industrial Machinery: Keeping It Simple

Technology around factories has always been recently developing. From equipment such as an overhead factory crane system helping improve efficiency and the factory employees jobs easier to 3D IMAGES printing cutting the price of the manufacturing approach, new technology has usually been recently useful to industries. And presently, there is https://mfgtalkradio.com/smart-motor-for-industrial-machinery-keeping-it-simple/ which might help to make developing even more useful – Devices.

Sensors own been making their way into manufacturing facilities to get some time now. All these small, high-tech devices give manufacturers a new way to see exactly how their own service is running in addition to reporting any issues around real-time. Integrating sensors into developing equipment and machinery permits manufacturers foresee possible malfunction and make repairs prior to unscheduled downtime wreaks disorder on the business.

Quite a few manufacturers would like to upgrade their facilities that include these precious monitors, but it really doesn’t are available cheap. New equipment can easily cost tens of hundreds of us dollars and this sensors in brand-new machinery can drive the retail price way up even higher.

Nonetheless today, there could be a new better choice.

A new group of technical engineers from Saarland University are usually developing ‘smart’ electric electric motor methods that will will function without necessity for added sensors. Not just will certainly they function, require new motors will in addition essentially be transformed into a good sensor itself. Some sort of motor unit with the potential to monitor themselves along having the overall performance of the equipment is the truly progressive leap forward for manufacturing technologies.

An additional enormous benefit of all these ‘smart’ motors is their very own ability to have interaction in addition to get in touch with other motors upon the shop floor. This specific will fundamentally work often the same function as stand-alone sensors connected through the Industrial Web of Issues services. Appliance to device communication is important for a smart facility to work correctly. If there is the issue with a particular bit of equipment, before anybody has the chance in order to intervene, the particular motor of which has an issue can call to a further machine to help pick right up its slack.

Furthermore, upgrading older tools could get much simpler with this particular innovative ‘smart’ motor. As a substitute of having to outfit a older unit with the host of sensors in addition to hoping they will all do the job and will hook up to be able to the cloud as well as server you wish to add the data in order to, a single electric motor would be the only thing that demands to be enhanced. This specific could be a generating force to obtain more manufacturers upon board with the professional revolution that’s happening everywhere. Quite a few manufacturers don’t have got this means to update all of their tools from one time, although turning out old electronic generators is much considerably more workable.

The way files is gathered from the engine will be by simply properly supervising the exact submission of the magnets field strength in often the car. The researchers record how magnetic field changes when the motor rotates. From this files, the analysts can infer how the particular motor is working. With regard to now, the research workers will be using diverse methodologies to identify which in turn methods are most beneficial suited to gather data from the motor.

No word yet on when that technology will be obtainable for you to consumers, but producers happen to be waiting in incertidumbre. The observations would get invaluable and the capability to reduce the quantity of sensors lowers this chance of failures whilst also making it significantly more workable for makers to upgrade their devices and tools. The technological innovation is extraordinary and the implications could be far-reaching. We are excited to see how these power generators will perform and when producers are willing to adopt this specific incredible technologies. Remember, if the business uses machinery, you will need to use professional chillers to stop overheating and failing, or perhaps worse causing personal injury at work. Make sure an individual invest in safety gear such as this mainly because well as innovative time-saving devices as described in this article.

#overhead workstation crane#overhead bridge crane#overhead workstation bridge crane#overhead factory crane

0 notes

Text

Wise Motor For Industrial Machines: Keeping It Simple

Technology within factories has always been developing. From equipment as an overhead shop crane system supporting improve efficiency and the factory individuals jobs quicker to 3 DIMENSIONAL printing cutting the expenses of the manufacturing approach, new-technology has constantly also been good for factories. And right now, there is a new development which might help to make manufacturing even more successful – Sensors.

Sensors have got been making their method in to manufacturing facilities regarding some time now. These types of small, high-tech devices provide manufacturers the new approach to see exactly how his or her service is running in addition to revealing any issues around real-time. Integrating sensors into production equipment and machinery permits manufacturers foresee likely breakdowns and make vehicle repairs ahead of unscheduled downtime wreaks havoc troubles business.

Numerous manufacturers need to upgrade his or her facilities to feature these important sensors, nonetheless it doesn’t appear cheap. Fresh equipment can cost tens of thousands of us dollars and often the sensors in new devices can drive the retail price upward even higher.

Yet presently, there could be some sort of better solution.

Some sort of team of planners from Saarland University happen to be developing ‘smart’ electric engine devices of which will function without the need for further sensors. Not just may they function, but these different motors will also basically be transformed into some sort of sensor itself. The engine with the capacity to help monitor on its own down with the overall efficiency associated with the equipment is a good truly impressive leap forward for manufacturing technological innovation.

One more enormous benefit of these types of ‘smart’ motors is their ability to work together in addition to speak with some other motors about the go shopping floor. That will in essence work often the same function as stand-alone monitors connected through typically the Industrial Online of Things services. Machine to device communication is vital for the smart facility to work appropriately. If there is a new problem with a particular item of equipment, ahead of anyone has the chance for you to intervene, often the motor that has an issue can easily call to an additional device to help pick upward their slack.

Furthermore, improving older gear could be much simpler with this innovative ‘smart’ motor. Alternatively of the need to outfit a great older machine with the host connected with sensors and even hoping that they all function and will link to be able to the cloud or perhaps machine you wish to upload the data to help, a good single electric motor might be the only thing that needs to be enhanced. That could be a driving a vehicle force to get additional producers in board with the manufacturing revolution that’s happening everywhere. A lot of manufacturers don’t own this means to upgrade all of their gear with one time, yet changing out old electric powered generators is much extra controllable.

The way data is gathered from this motor will be by way of thoroughly checking the precise syndication of the magnetic field strength in the particular motor. The researchers report how a magnetic field alterations when the motor rotates. Through this records, the analysts can infer how the motor is working. With regard to now, the research workers are looking at diverse methodologies to figure out which usually methods are best suited to collect records from the motor.

No word yet on when this technology will be readily available to consumers, but makers can be waiting in incertidumbre. The information would end up being invaluable and the power to reduce the number of sensors reduces often the chance of failures when also making it substantially more controlable for manufacturers to upgrade their systems and tools. The engineering is amazing and this implications could be far-reaching. We are excited to help see how these types of generators will perform if suppliers are willing to adapt to this kind of incredible engineering. Keep in mind, in case your enterprise uses machines, it is very important use commercial chillers in order to avoid overheating and screwing up, or perhaps worse causing harm in the workplace. Make sure a person invest in safety tools such as this simply because well as innovative time-saving devices as described in this post.

#overhead workstation crane#overhead bridge crane#overhead workstation bridge crane#overhead factory crane

0 notes

Text

Tesla Gigafactory Starts Battery Production | Very Exciting Media for the Automotive Industry

Tesla’s production facilities have always been recently some of the almost all effective car manufacturing vegetation in the industry. These people plan everything from typically the brand involving freestanding foundationless jib crane system they can use to be able to which parts of the task are going to be fully automated. Nevertheless , that they need to ensure many people have more than enough parts to actually keep up together with velocity they manufacture their autos. This is precisely why Tesla said it in addition to partner Panasonic possess begun mass production of economic high quality lithium-ion power supply skin cells on the Tesla Gigafactory, forcing the electric car and even energy storage company closer to the production of it is Model three or more electric automobile.

The cells nowadays inside of generation at the Nevasca plant are intended to get use in Tesla’s Powerwall 2 and Powerpack two fixed energy storage space methods, the company said. Generation of cells intended to get the Tesla Model 3 or more would be to begin in often the second quarter.

Tesla’ https://thegreencarguy.com/tesla-gigafactory-battery-production/ in December 2016

The particular $5 billion Gigafactory is a massive battery manufacturing ability close to Reno. With four. 9-million square toes regarding area operational now, this multi-story factory complex is only about 30 per cent completed. Tesla reports that intends to hire “several thousand” staff for this manufacturing plant this year and has pegged whole career there from greater than 6, 500 jobs. We all ponder what new technology this Tesla factory will end up being using in order to work? Will each uses personal computers from cksglobal. web?

California-based Tesla has said that it intends to be providing thirty-five gigawatt-hours per year of lithium-ion electric batteries at the Gigafactory simply by 2018 when Model 3 or more creation is in full swing. That’s almost as very much as typically the annual production of all additional lithium ion battery companies on the globe. Tesla has set a new first-year creation goal of fifty, 1000 Model 3 cars intended for is Fremont, Calif., installation plant.

The Tesla Design 3 sedan is smaller sized and less expensive compared to the carmaker’s present offerings ~ the Model S sedan and Model X all terain EVs. Tesla has arranged a target selling selling price connected with $35, 000 in advance of incentives for the foundation Model several, about the third of what the regular Tesla customer covers out for one of typically the company’s EVs now.

To be able to get the price the fact that low, Tesla needs to greatly lessen the charge of the car’s battery pack. This expects software and high-volume production in the Gigafactory to be a new huge take into account accomplishing that will goal.

0 notes